Do.it.yourself trenches chain

For digging trenches for private or for industrial purposes, special equipment is used. A traffic controller for a walk.behind tractor is a replacement mechanism that allows you to dig a trench of any size for laying underground highways, electric networks, communication communications, pipes, and can also be used for other purposes.The trenches (bar) can be attached to the walk.behind tractor and intended for:

- digging ditches and pits;

- removal of an already unsuitable road surface;

- soil cutting;

- preparation of land for landing;

- loosening work;

- reclamation;

- work with the filling of the foundation;

- drainage.

Information about the trenches

Although trenches can be manually digging, nevertheless, the use of specialized technology is more profitable.

Here are a few reasons for this:

- In the process of working the trench, it turns out narrow, deep and with steep edges. With this digging method, the risk of sprinkling the walls decreases.

- The quality and efficiency of the unit does not suffer if the earth is more dense than usual.

- When working this mechanism, the need to export dug soil is significantly reduced.

- When compared with an excavator, it should be noted that dug soil can be used at any time to fill up the pit. In this case, the excavator can dig out blocks, which before use must be broken down.

- This mechanism has high performance.

- The gangster effectively works in winter conditions when the trenches are digging in the frozen earth.

DIY trenches for a walk.behind tractor

For construction work in the personal plot, the development of the territory near the house, when laying sewer, water pipes and cable networks, summer residents and small landowners need a groove.digger. Whole and hinged units that are offered in domestic markets are not cheap and are suitable only for certain motor blocks. Therefore, many owners decide to make a trenches for a walk.behind tractor with their own hands.

A homemade unit should satisfy the following requirements:

- Aggregation with a motor unit with a capacity of 8-13 liters.With. With VOM;

- power plant: hydraulic pump NSh-10, engine cutter GMSh-32;

- Cutting system: 2 road cutters EC-1800;

- Danger depth-up to 0.35 m, and width-0.10-0.15 m;

- Estimated weight. 80 kg.

In order to make a gangster yourself, such materials and equipment are needed:

The main working knot of the machine is a hinged body consisting of elements:

The process of manufacturing a range of a canoper is not difficult for the master and is as follows:

- A bar with primer cutting cutters is installed on the front suspension.

- Dumped shovel for removal from the trench of the soil is attached on the rear suspension.

- Cutting system and chain gear are equipped with a protective casing.

When the engine is turned on, the hydraulic system of the mounting mechanism is launched. The transfer of torque to the chassis should be disconnected. The cutter of the cutter is launched, the rotation of the disks begins, the cutting of the trench is formed. The drive of the chassis encourages one.time tractor to the movement. At this time, the dump shovel selects the destroyed soil with milling cutters and throws it to the upper part of the trench. The operator practically does not use much effort.

Homemade trenches will save money, facilitate manual labor and will be an excellent assistant in the implementation of many work in personal plots.

What homemade homemade chainsaws can be done?

Chainsaw is a very convenient tool for making homemade. Having adapted it to a special platform with wheels, and connecting the circuit with the shaft on which the knives will be installed, you can get a powerful lawn mower. By the way, in order not to bother for a long time, you can install an asterisk from the rear wheel of a bicycle on the shaft.

In addition, an excellent sawmill can be made from a chainsaw, since the removal of this tool, in this case, is also minimized.

In general, all the home.made homemade ones can be divided into two large groups:

- The first group includes those homemade products, in the manufacture of which there is practically no need to disassemble and modernize the chainsaw;

- The second group of homesproofs, all kinds of technology belongs: snowplowing machines, mopeds, aerosany, ATVs, etc. D. In other words, complex mechanical devices, for the manufacture of which you will have to radically disassemble the chainsaw, make a water or air cooling system, in general, completely change this gasoline tool.

Consider what can be done from the chainsaw, which will definitely come in handy in the household.

So, for example, on the basis of the Friendship chainsaw, the following homemade can do:

If it comes to automobile self.proceeds, then from almost any chainsaw, you can make:

Of course, the second group of homesproofs from a chainsaw requires a thorough approach and a complete study of the structure.

Also, you will need to buy all the necessary materials, and in some cases, you can not do without a welding machine.

Pylorama from a chainsaw

The easiest to manufacture is a home.made pillar of the Urals, taiga or friendship chainsaw. The essence of the work of home.made sawmill is that there is one large guide, according to which on moving sleds, back and forth, chainsaws are moving.

As a guide, you can use a rail or several long, but even metal corners. The platform on which the chainsaws will subsequently be fixed are made from a piece of thick steel, the thickness of which should be at least 5 mm.

The mobile part of the sawmill deserves special attention, the one by which the platform carries out its movement along the guide. As rollers, here you can use a metal pipe with a rubberized surface

It is very important that the width of the mobile part would coincide with the width of the guide

As you can see in the photo, a log located next to the sawmill, is quite easily cut into several parts, through moving along the guide chainsaw. Thus, you can decently save on the purchase of sawmills, while, as you can see, the chainsaws practically do not need to be redone, disassembled, etc. D.

uniform chainsaw tractor

As mentioned above, various home.made home.mades and cottages can be made from a chainsaw. One of these self.proceeds, are a mower and a one.axle tractor. With a mower from a chainsaw, things are not as difficult as with a walk.behind tractor, for the manufacture of which you will have to cook a metal frame, and then adapt two wheels to it on the side.

The principle of manufacturing a motorblock from a chainsaw is to use several stars that could convey a spinning effort to knives. For these purposes, the stars are located on the sides of the metal shaft, on which several knives are welded.

Homemade uno.ears of the Ural chainsaw or friendship will become a real assistant for those who have a fairly large garden area. Maybe such a single tractor will not differ in high power, but it will be enough to solve the main task of cultivating land.

How to work with a flat cutter for a walk.behind tractor?

In principle, each owner is free to adapt the existing unit to individual requirements, as well as experience its capabilities, therefore, in this case, experiments are welcome.

The history of the creation of a plane cutter

As can be seen from the name, the idea of creating and using a plane cutter belongs to Vladimir Vasilievich Fokin. He was not a scientist and did not sit days or night in the laboratory, inventing, testing and improving his brainchild. Vladimir Vasilievich did not devote his life to the idea of creating an instrument combining a shovel, a rake and a hoe that allows you to easily loosen and reassure the beds. Having served in the army, he went to work as a designer for a machine.building plant, then he worked for the benefit of a collective farm. Throughout Fokin, Fokin was not: a fire safety engineer, the chairman of the comradely and the assessor of the district court, the deputy, the lecturer, the chief of staff of the civil defense, the journalist of the newspaper Leninets. only 18 public burden. But it was the work of the journalist that gave him the opportunity to come into contact with the issues of agriculture, to learn from ordinary peasants about urgent problems in this area.

Read also: Key cartridge for the penetrator

Hard work does not pass without a trace. In 1987, Vladimir Vasilievich receives the most difficult heart attack and disability. On active physical work, I had to put a cross. But a person like Fokin, accustomed to work and not thinking himself without him, could not give up just like that. “Twice (three months) was nursed in the hospital: an extensive, as they said later, transmural heart attack. Disability. Pension. “Straw at the door Home. at work and in school. Silence. at least a wolf howl. Hit read about spies. not that “. The awakened love of agriculture prompted the idea that it is necessary to come up with something that would allow, without unnecessary load, to work at least in her garden. Elena Nikolaevna. Fokina’s wife. recalls in her memoirs: “Volodya worked for a long time for a plane cutter. On his table were often lying various drawings, schemes. At first he did this just for the sake of interest, but then the usual curiosity grew into a serious business “. And the author of the invention describes this process in his notes as follows: “The searches of a manual plane cutter were long. Made dozens of structures starting with a plow all the wrong. I invented years. Made. in 3 days “. Patent for the invention of Ploskorez and its author Vladimir Vasilievich Fokin. Photos from sites: www.Offokin.ru, Blagodatmir.ru, but one way or another, the plane cutter became the work of the whole family of the Fokins, and his first test can rightly be called a birthday: “I will never forget that day. We joked a lot, laughed. We really liked the plane cutter, he was our brainchild “. Vladimir Vasilievich decided to issue a patent for the invention only after he gave him “to test” to all friends. They really liked the plane cutter. Well, his further path was predictable. A positive assessment of strangers and wide popularity among lovers of gardening made it possible to open production and even supply flat cutters to other countries: Lithuania, Estonia, Belarus, etc.D. The invention survived its creator, unfortunately, who left in 2002.

Cool devices. Dig the foundation of a chainsaw and trimmer

The hardest work during the construction of the house is the development of soil for the foundation and digging trenches.

Undoubtedly, you can dig up with an excavator, and drink a trench with a bar, but all this will result in very expensive.

There are some ways to facilitate such types of work and even without the use of special. technology.

Sprinkle the virgin lands using the Urals or Friendship chain with the old bus and chain.

The soil is sawed with cubes, it is easier to remove it so.

The speed of digging increases every five. That’s for sure, I did this more than once.

Make a chipper for a saw for the earth and forward.

This is what type of nozzle, just put a tire with a chain, but not hook, but a straight line.

The soil should be dry and dense, the other is easier to dump with a shovel.

Look at the video taken by me from the Pro channel, as they saw a trench, very interesting

This is not an innovation, we have such chips on the Urals twenty years ago. Conveniently, the earth does not fly or get dirty.

Swim holes on the marked foundation using a trimmer for grass or manual drill. (link to an article about trimmers for grass) This will also accelerate the process several times, no less effective than the first.

These methods are applicable with shallow foundations, up to 2 meters depth.

It is much more difficult to work with manual drill, but it is also possible if there is strength and desire.

10 useful tips for you:

- Do not throw out the old TV

- Do not throw away the old trimmer for grass

- Cool adaptations for construction, all to facilitate labor

- Revolutionary innovation in construction

- Do not throw out the old chainsaw

- What can be done with a compressor from an old refrigerator

- Warm floor in a bathhouse from a simple stove

- Unrealistically cool countertop with your own hands

- Cool homemans from saw disks for the garden and not only

- How economically to make a well yourself

- Do not throw away the old tape recorder

- How modern plumbing saves water and expenses for it

Features of trenches

Dances of ditches and trenches, digging holes are common types of earthwork. A trench is a recess in the ground, performed in a section in the form of a rectangle or trapezoid with a length of several to a thousand meters.

The methods of digging trenches differ depending on the purpose. Sometimes you need to dig a ditch or trench in a place where you cannot fit special equipment, in such cases you have to use a manual method. working with a shovel. It happens that the place of digging the trench is tightly occupied by communications in the territory. Then the help of a motor block with a trenches will be required.

Motoblocks with a trench digging device can perform the following work:

- dig a pit for arranging the foundation;

- Dig a drainage trench;

- help in arranging the design of garden plots, for example, in laying borders and planting trees;

- dismantle asphalt coating;

- dig channels for reclamation.

All types of work require attracting a certain amount of labor, and mini-technology will cope with the minimum number of people.

Industry produces two types of trenches:

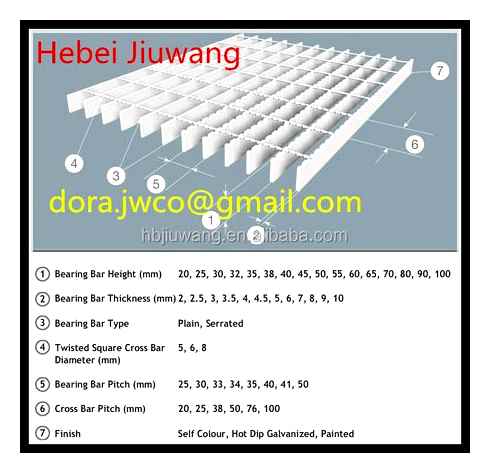

The working parts of the hinged trenches consist of:

- steel frame;

- cutting chain (bar);

- drive (mechanical or pneumatic and t.D.);

- stretch device for the circuit;

- dumped screw;

- protective coupling.

Depending on the type of working mechanisms, such types of trench diggers are distinguished:

Advantages and disadvantages of independent digging trenches

In order to choose the method of digging a trench, you need to analyze the advantages and disadvantages of each of them. The use of shovels for digging the trenches has several significant advantages. The cost of a shovel is much lower than the rental of a tractor.

Manual inventory for crap of drainage trenches in drained areas

The trench, dug by hand, is even and neat, while the tractor pulls out a lot of excess soil, which is why the width and depth of the trench can increase. In the future, this leads to an unplanned consumption of building materials (sand, cement, etc. D.). And also the tractor is not able to dig out trenches with straight angles, which again forces to spend additional building materials.

Manual digging allows you to monitor the straightness of the trench. The tractor can dig a crooked hole, which then still will have to be aligned manually.

Installation. US Trench Drain

But the shovel is seriously inferior to the tractor in such an aspect as the time spent. To dig a trench under the foundation of a medium.sized house, the tractor will take about five hours. Not to mention the fact that the use of a shovel will require the cost of significant physical efforts.

- Digging using a shovel allows you to dig a flat trench of the same depth and width, while the tractor dugs a curve hole;

- The use of a shovel will save a lot of money (according to the coarse estimates. from 20 to 25 thousand), since the rental of a tractor is not cheap;

- When using the tractor, you will have to spend on additional building materials, since excess soil is removed during work;

- When using special equipment to digging trenches, it will take much less time and effort than during work by hand.

Purpose and principle of work

The same.based tractor with a trenches is able to perform the following work:

- dig a trench under the foundation;

- Dig a drainage ditch;

- help in planting trees and laying borders;

- design work;

- removal of asphalt coating;

- digging reclamation channels and t. D.

DIY French Drain & Landscaping | River Rock | Yard Drainage Solution

A hinged trenches for a walk.behind tractor to cope with any type of soil, while the cut remains neat and does not crumble into the resulting cavity.

The bar cuts out the soil and, as it deepens into the soil, drops to its optimal depth (for motor-block nozzles it is 25-90 cm., Whereas a specialized technique will wipe the soil to a depth of 1200 cm.). The soil is captured by the cutting edges (shoulder blades) and is supplied to the dumpy screw, which takes it at a distance of 15 cm. From the trench.

The choice of the right model

It is difficult for the user to choose the necessary brand among the variety of ganguers. The performance of the unit depends on the power of the walk.behind tractor, mass, depth and width of digging trenches with hinged equipment. The same factors dictate the price.

Two types of grooms are practiced:

- Trenches that are created as a single, whole mechanism with the unit. In practice, brands are most often found: Laski TR 50/TR 60, TKG-1200, Barreto 912 HM. This technique is very expensive and designed for professional use.

- Hinged gangens. Produced by factories for certain types of power units. Choosing a groove for a walk.behind tractor is very difficult.

In the countries of the former union, Trench IT hinged equipment, developed by Quick Attach, which is compiled by specially designed connecting couplings, with the John Deere, Case, Yanmar, Daewoo, Yanmar units.

Buy or rent?

If production activities requires the regular use of many units of such special equipment, it is more advisable to buy or take it. Small-sized hand-bacon can cost around 150-500 thousand. If a trenches is needed to solve one specific problems, it is advisable to rent it. Such a machine is selected individually. The rental cost, as a rule, includes the operator’s wages, the cost of fuel and lubricants. When renting above the performance of the equipment, the tenant has no problem with its breakdown. The cost of its transportation to the object usually does not include.

Payment of rent can be made from the calculation of costs per meter of the length of the trench or for the shift. per shift. The exact figures for rental fees are calculated when concluding a lease agreement. At the same time, the volume of work, the cost of the machine and other indicators are taken into account. It is important that often companies that provide a hand tile for temporary use make discounts depending on the terms of lease.

Advantages of trenches

The trenches for the walk.behind tractor is characterized by the following advantages:

- High performance and labor mechanization.

- Small extraction and backfill.

- Mobility, are able to deliver equipment to any place.

- Maneuverability can work in places limited area.

- The edges and walls of the trench are even, the convenience is created for laying communications.

- The ability to increase depth, you can get the trenches of the necessary depth.

- The duration of the service life.

- Simplicity of design.

- Safety during operation. mobile units are protected from accidental contact with workers.

- Universality.

The device grinds the ground, so the breakdown of large Комментарии и мнения владельцев is not required.

A homemade trenches adapted to the walk.behind tractor cope with any type of soil, leaves the sections with neat. Destroyed soil does not crumble into the formed recess.

The choice of the right model

It is difficult for the user to choose the necessary brand among the variety of ganguers. The performance of the unit depends on the power of the walk.behind tractor, mass, depth and width of digging trenches with attaching equipment. The same factors dictate the price.Two types of grooms are practiced:

- Trenches that are created as a single, whole mechanism with the unit. In practice, brands are most often found: Laski TR 50/TR 60, TKG-1200, Barreto 912 HM. This technique is very expensive and designed for professional use.

- Hinged gangens. Produced by factories for certain types of power units. Choosing a groove for a walk.behind tractor is very difficult.

In the countries of the former union, Trench IT hinged equipment, developed by Quick Attach, which is compiled by specially designed connecting couplings, with the John Deere, Case, Yanmar, Daewoo, Yanmar units.

DIY trenches for a walk.behind tractor

Digging a trench with a motor block much faster and easier, however, many are stopped not only by the high price of a primer, but also the infrequent use of this nozzle (unit) in the farm. Therefore, the owners of summer cottages often prefer a home.made trenches for the walk.behind engineer to the factory.

A homemade device for digging a trench with a walk.behind tract can be made from improvised materials, using a welding machine, an angular grinder and imagination. Craftsmen exhibit detailed descriptions and diagrams of home.made primers on the Internet, we offer one of the schemes:

Attachment executive: 1. cutting disk; 2, 3, 7. chain gear: 4. hydraulic motor; 5. shaft of a hinged device; 6. disk bar.

The sequence of the process of creating this attachment equipment is as follows:

- The manufacture of a suspension on which an earth arrow with a baroque chain will be fixed;

- The rear suspension should be equipped with a special shovel that will allow the ground to capture the ground from the bottom of the moat and raise it out;

- Do not forget about protection, which should cover both the chain itself and the cutting elements;

- When the hinged is ready, it is necessary to construct a special hitch, with which homemade soil toss will aggregate with a walk.behind tractor.

Ivan, 36 years:

I want to say a few words in favor of a trenches. I bought a cottage three years ago, decided to be built, I left an old house as a barn, took up the construction of new housing for the family. Construction would drag on for a long time.If not for the advice of good people. Basically, all digging work was carried out by cars (hired appropriate equipment), including trenches for the foundation (a tractor with a primer came and did everything in a couple of hours). Later, when the box was ready and the turn came to pull the communications, I remembered the primer and found compact analogues for motoblocks on the Internet. I decided not to spend money in vain, but to make a tool with your own hands. The trenches acquitted the efforts spent, later I began to use it in the garden. Now the construction is completed and my family lives in a cozy cottage, garden, a small garden. everything is like people.

Sergey, 54 years old:

I also had construction on the site, so the trenches was very necessary. I could not choose the right one, so I decided to make a hitch itself. The experiment was a success, but the depth of soil cutting is not enough. 25 cm. I handed the electricity throughout the site, then I decided to use the primer in the aesthetic direction. I cut out the trenches for the curbs, built a small grotto in the garden. also not without the participation of a cerebral cutter.

Alexey, 31 years old:

Hello! My father has the same.based Tractor Neva, I want to use it to the maximum, there is a construction of construction, I would like to facilitate the work by adapting one.time tractor. Advise which manufacturer to choose, which particular model? I even agree to homemade, I can do it myself, but there are no specifics on the Internet, I would have a step.by.step instructions for making a primer. Thank you in advance!