In the spring we bring the equipment to the personal plot. Unfortunately, a situation often arises. the tiller does not start. The reasons may be different.

For example, improper storage of equipment in the winter: a cold and damp garage, exposure to atmospheric precipitation, vapors of aggressive liquids, gases and particles of bulk materials.

It is also worth paying attention to the floor of the room where the tiller is stored: floor slabs should be without slopes.

The owner must quickly determine the cause of the failure and troubleshoot the tiller.

Start gasoline and diesel units

tiller is a multifunctional tool. It is indispensable for farming. Attached equipment allows you to perform land cultivation, grass mowing, snow removal, cargo transportation, planting and harvesting.

The equipment is equipped with gasoline or diesel engines. Running a diesel tiller and a gasoline unit has differences. Therefore, it is necessary to analyze the reasons for which the tiller does not start for each specific type of engine.

Before you start a tiller, prepare the equipment. It is necessary to verify the availability of all parts, to verify the reliability of the fastening mechanisms.

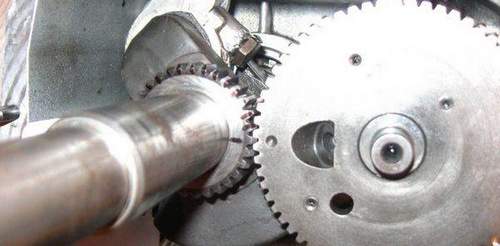

Gears often refuse to work after winter. A long break causes malfunction of the tiller systems. Storage in a cold and damp room leads to the following breakdowns:

- Oxidation of contacts.

- Violation of wire insulation.

- Watering fuel and oil.

- Clogged carburetor jets.

Before starting a new tiller, all joints, clutch cable, reverse and gas are checked. The course of the cables should be smooth, effortless. Do not start the unit if there are clamps and twisting of the strands of the tow.

During the first start-up, the oil level in the crankcase must be checked. Lack of lubrication will damage the piston group. The crankshaft rotates up to 1,400 rpm at idle. A couple of seconds is enough to form a scuff on the surface of the cylinder.

Old oil can cause engine failure. At the same time, the tiller smokes white exhaust fumes. A complete oil change begs.

It should be borne in mind that the tiller starts up poorly with insufficient oil. Observe this parameter before starting a carburetor and diesel tiller. Some models have low protection. The sensor blocks the start and the unit stalls.

Video: For What Reason Tiller Doesn’t Start?

It should be remembered that each type of engine requires gasoline of a certain brand. For a two-stroke engine, fuel is prepared separately. The fuel mixture consists of gasoline and oil. The amount of ingredients is maintained in a strict ratio.

Get gas for tiller at gas stations. The service life of the machines directly depends on the quality of the fuel. Do not start a tiller with bad gasoline.

Repair of knots and mechanisms

Starting a diesel tiller after a purchase can be difficult. The fact is that air enters the fuel supply system. If a long scrolling (starter) fails to start, then air plugs should be released. To do this, open the diesel supply valve and untwist all the connections along the fuel channels. The final purge point is the nozzle.

In order for the internal combustion engine to start, a number of requirements must be met. We list them in order:

- Fuel mixture preparation.

- Fuel supply to the cylinder.

- Ignition mixture.

- Exhaust gas.

The fulfillment of the above conditions guarantees the start of any motor.

Start-up difficulties indicate a malfunction of components and mechanisms. The success of the repair depends on the correctness of the diagnosis. If defects are found, they repair the diesel tiller. Maintenance and minor repairs can be done on their own. You will need a set of keys, metalwork tools and skillful hands.

At the stage of preparing the fuel mixture, the following incidents are possible:

- the air filter does not let air through;

- the hole in the tank cap is clogged;

- clogged fuel path;

- the carburetor broke.

After a series of failed starts, it is useful to unscrew the candle. The working part can be filled with fuel. Dry the item. Next, pump the cylinder through the hole. We twist the candle and start it again.

If the candle is dry, then fuel does not enter the combustion chamber. We perform a series of steps to restore the feed system:

- drain old gasoline;

- flush the tank;

- clean the filter from dirt;

- blow through the fuel supply hose;

- blow carburetor jets;

- fill the tank with clean gasoline;

- open the faucet;

- clean the airway in the cap.

Malfunction of the ignition system

The engine will not start if there is a malfunction in the ignition system. Why it happens? The sources of failure can be magneto, high-voltage wire, cap and spark plug. External inspection check the cleanliness of the parts of the ignition system. Dirt and moisture cause breakdown of high voltage on the housing. The absence of sparks occurs when the cap is in poor contact with the central electrode of the spark plug.

A weak spark indicates poor spark plug performance. Check the clearance and condition of the electrodes. The clearance is checked with a dipstick. Usually it is 0.8 mm. If necessary, remove the cinder from the metal parts and the insulator. A candle replacement is recommended.

The condition of the piston group parts affects the availability of the engine as a whole. They work in difficult conditions. Under load, the friction surfaces heat up. The cylinder, piston and rings are responsible for an important indicator. compression. A low compression ratio in the cylinder will indicate replacement parts.

Also check the intake and exhaust valves. They should fit snugly against the saddles. Silencer. the last item on the route of exhaust gases. On the walls of the muffler, combustion products are gradually deposited, and the engine stalls. For normal exhaust passage, the walls should be periodically cleaned of carbon deposits.

Experts advise to adhere to all manufacturer’s recommendations. Do not overload the unit.

Fulfillment of all requirements will extend the life of the mechanisms.

Before starting work, the owner should read the operating instructions.