Maintaining Your HRX Mower

The Honda HRX is arguably the best residential walk behind mower on the market, but like any outdoor equipment, it won’t last if it isn’t cared for. Here’s what you need to do to keep your mower working for years to come.

Maintenance Schedule

Honda also recommends having the engine professionally serviced every year or 100 hours. The mechanic will check the valve clearance, idle speed and general condition of the mower.

Blades

The blades on these mowers can be handled like any other mower blade. They should be as sharp as a butter knife, and they should be replaced if the edges are worn, bent or cracked.

To access the blades, disconnect the spark plug cap and turn the fuel valve to “OFF,” then tilt the mower on its right side. Make sure the fuel cap is near the top of the mower.

When installing the blades, the curved ends of the lower blade should match up with the angled edges of the upper blade. When installing the blade bolts, the outer edge of the curved washers should face the blades. Torque the bolts to 36-43 ft-lbs.

Oil

Honda recommends 5W-30 or 10W-30 for normal operating temperatures, while SAE 30 can be used at temperatures above 50°F. The engine holds 12-13.5 oz of oil, or about a third of a quart.

The engine does not have a drain plug. To drain the oil, either use a siphon pump, or tilt the mower on its side so that the oil flows out of the filler neck into a container for recycling.

Air Filter

To access the filter, push down on the tabs on the air filter cover, then swing the cover downward.

To clean the filter, tap it against a hard surface or blow it out with compresses air. Limit the air pressure to 30 psi.

Spark Plug

The electrode gap should be between 0.028 and 0.031 inches, or 0.7 to 0.8 mm. It can be removed and installed with a 13/16 inch spark plug wrench.

When reinstalling a plug, thread it in by hand before using the wrench. Once the plug seats, turn it 1/8 to ¼ turn if it’s a used plug, or ½ turn if you’re installing a new plug. The plug should be torqued to 14 ft-lbs.

Spark Arrester

To access the arrester, remove the three flange bolts on the muffler cover, then remove the set screw holding the arrester inside the exhaust outlet.

Clean the arrester with a wire brush. If it has holes or other damage, it should be replaced. If you don’t have a spark arrester, one can be added to comply with local fire regulations.

Charging the Battery on Electric Start Models

The battery is normally charged by the engine electrical system, but it may need to be recharged after the mower has been in storage. This battery should only be charged with a Honda battery charger. Using an automotive charger will damage the battery.

Remove the three screws on the battery cover, located on the side of the box that houses the starter switch. 2. Slide the battery out of the box, then disconnect the wires on the battery terminals. 3. Connect the charger to the terminals, then plug the charger into a 120 volt outlet. 4. Let the battery charge for 8-24 hours. Charging for longer will damage the battery. 5. Disconnect the charger. 6. Connect the wires to the battery terminals. 7. Place the battery into the case with the terminals facing the handle. Route the wires so that they go across the top of the battery. 8. Reinstall the battery cover.

Get the Parts You Need for Your Honda Straight From Your Browser

Hondalawnparts.com is a certified Honda Engines and Power Equipment dealer, which means we can ship the OEM parts you need to maintain your HRX mower straight to your door. Select your model and serial number, and our site will show you parts that will fit your specific mower, complete with factory descriptions and exploded parts diagrams. We ship to both the U.S. and Canada.

How to adjust snowblower engine valve lash

This illustrated repair guide and DIY YouTube video give step-by-step instructions for adjusting the valve lash on a common snowblower engine.

What is engine valve lash?

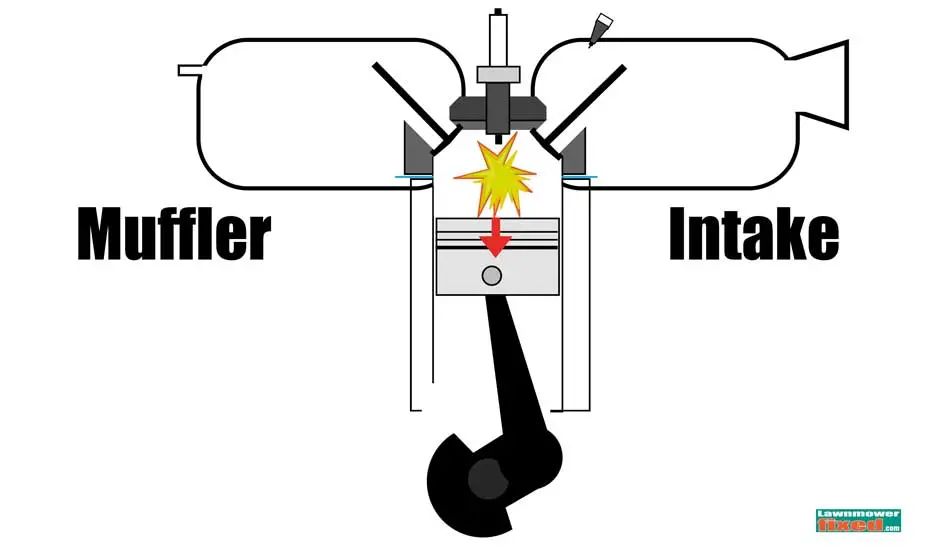

Valve lash is the space between the top of the valve stem and the rocker arm when the piston is at the top of its travel (top dead center) inside the engine cylinder. At this point, a valve should be fully closed. When the piston is at top dead center of the compression stroke, both the intake and exhaust valves should both be fully shut.

Incorrect valve lash prevents the valve from opening or closing properly.

Bad valve lash adjustment can make the engine:

Check and adjust engine valve lash when the engine exhibits these symptoms and basic troubleshooting doesn’t fix the problem.

Engine manufacturers also recommend that you check valve lash after the first 25 hours of use and then after every 100 hours of engine use.

What is top dead center (TDC)?

Top dead center is the position of the piston when it’s at the very top of its travel inside the engine cylinder. When the cylinder is at TDC, a valve will be fully shut so you can accurately measure valve lash. When you position the piston at TDC for the compression stroke, both the intake and exhaust valves should be fully shut so you can check valve lash for both valves on many types of snowblower engines. Valve lash should only be measured and adjusted when the piston is at TDC.

What types of snowblower engines need valve lash adjustment?

MTD, Briggs Stratton and other brands of engines on snowblowers typically need valve lash adjustments to start and run smoothly. Check the engine owner’s manual for valve lash guidelines for the engine on your snowblower or snow thrower.

This video shows how to adjust valve lash on a typical MTD engine that is commonly used on these brands of snowblowers:

Follow the procedure for checking and adjusting valve lash listed in the owner’s manual for your snowblower or your snowblower’s engine. (Many snowblowers and snow throwers have a separate owner’s manual for the engine.)

Biggest Mistake You Will Make When Adjusting The Valves On A Generator

Lawn Mower Valve Adjustment Symptoms And The Solutions

You need to keep a sharp eye on some common lawn mower valve adjustment symptoms. Because poor valve adjustment may result in a damaged lawnmower.

To be precise, the precise gap between the rocker and the valve head needs to be checked which is also known as valve lash.

In this guide, you will find the complete guide on noticing such symptoms, their impacts on your mower, and basic maintenance tips to deal with them. Keep reading!

Common Symptoms of Lawn Mower Valve Adjustment

Later in this article, I will mention some consequences of bad valve adjustment and some highly effective tips to fix your mower. But it’s important to identify the above-mentioned signs of such adjustments as soon as possible.

Irrespective of brands and models, those signs are common. And just to let you know, some lawnmower brands should be avoided in the first place to avoid such problems.

So, each one of you should take action upon noticing such signs. But first, let’s talk about these signs in detail:

An increase in the valve gap will result in increased tapping noise. It’s not a surefire but it’s definitely a good sign and hopefully, you may notice it before your neighbor does.

You should not ignore such tapping noise because it indicates the exhaust valve the inlet is no longer supporting the engine to perform smoothly. Before the engine becomes off-balance pretty soon, you should fix the problem ASAP.

Such behavior of your mower also indicates increased/decreased tappets that will result in decreased efficiency and power of the mower.

Not only it’s just harmful to your mower, it will consume more fuel without providing any extra performance. To keep it running for a long time and to have increased performance, you need to fix that.

Another common sign of valve gap (not aligned properly) is the hard starting of the mower. It simply indicates there is an increased valve gap that is affecting the whole mechanism of the mower valve movement.

Excessive valve lash may not be the only reason for hard starting but you should check the issue once in every season.

And the valve train timing will be out when the valve clearance is out of spec which in turn will result in hard starting.

Without fixing the problem, if you continue to hard start, it will harm the head gasket and you may notice oil leaking problem too.

A stuck valve results in a lack of compression and you can provide such compression to the spring easily. You don’t need a complex lawn mower valve adjustment tool for that. A simple screwdriver is enough!

But for that, you should run a compression test every now and then to check the engine life.

It’s important to have enough compression on the spring because due to the damaged, stuck, or misaligned valve, the mower will have a starting issue.

Almost every lawnmower has a compression release mechanism. To release the cylinder pressure, it opens the valve a little early. Under normal circumstances, that’s the reason you don’t need much power pulling the cord.

But it becomes hard due to the excessive valve lash.

One of the most common riding lawn mower valve adjustment symptoms is the harder case of pulling the starting cord.

The reason the cord becomes too hard to pull is due to the increased valve gap and excessive cylinder pressure.

Again, let me be very clear about it. The excessive valve lash is NOT the only reason why the cord becomes too hard to pull like faulty flywheel brake and key.

Some other reasons like the bent crankshaft, a faulty carburetor needle, blade obstruction from dry grass broken branches may lead to the same problem.

Importance of Valve Adjustment of Any Lawn Mower

The reason why you should keep the valve adjustment smooth and functioning have many answers.

But in general, the overall performance of your mower largely depends on the steering alignment adjustments and exhaust valve maintenance.

Here are some of their importance and why you need to fix any problems related to it:

- Ensuring the right opening and closing times of the valves is important. When your mower has the precise valve adjustment, it is perfectly ensured!

- You get improved performance and engine mileage.

- It provides much-needed space for thermal expansion.

- Proper valve adjustment also results in lower fuel consumption.

The Solution

Before you start doing it yourself, I need to remind you something. The valve clearance differs from model to model. There are plenty of reasons why the lawn mower won’t start. So, read the manual first and learn the exact and ideal gap.

The lawn mower valve adjustment cost is high if done by a professional which you should pay if you don’t know what you are doing. It may make the situation worse!

But if you are cool with tools and engines and if you have the right tool and guide, it can be a fun DIY! Watch the very short but highly-effective instructional video to make yourself comfortable first.

Timely fixing the valve gap will prolong the life of your mower. Follow the steps to fix the valve adjustment problem:

- Without removing the pushrods, keep the engine rotating and the blades turning. That way you can keep the intake valves compressed and open.

- With the suitable lawn mower valve adjustment tool, remove the valve covering bolts spark plug wire.

- Turn the blades to rotate the engine clockwise.

- To unload the valve springs, turn the object into the cylinder.

- Before you increase/decrease the valve gap, find the exhaust valve located at the muffler. Then you will find the rocker arm fixed right above the exhaust valve.

- Use a screwdriver to increase/decrease the gap between the valve and the setscrew. Get a feeler gauge to test the gap after you tighten the jam nut.

- Once you get the right valve adjustments, tighten the nut, and keep a record for future adjustments.

Frequently Asked Questions (FAQ)

How does a Briggs compression release work?

Answer: Almost every mower’s overhead-valve engine has a compression release feature so that you don’t have to pull it hard to start the engine. To bleed off the excess compression, it opens the valve a little early.

How do I know if I need my valves adjusted?

Answer: If the engine is making any tapping or clicking sound, it’s a surefire sign. However, do not wait for the engine to cry and let you know. Inspect the valve lash at the regular interval recommended by the manufacturer.

What happens when valves are out of adjustment?

Answer: The engine will have a breathing problem because of too little or too much valve clearance. That will result in poor performance of your mower.

What are the symptoms of bad valves?

Answer: Higher level of oil consumption, hard pulling the starting cord, not starting, a higher level of smoke, oil leaks, and so on.

What should compression be on a Briggs and Stratton?

Answer: Around 100-140PS.

You can’t tell for sure whether the valves need readjustment or not without examining them. But the engine will show some signs to guess the problems.

So, look at the engines and carefully observe the lawn mower valve adjustment symptoms. And take action ASAP!

Den Hicks

Traveler, food lover, interior designer, and blogger. I love gardening a lot! I designed my home myself with the help of my beloved wife. You are welcome!

What is Tappet Clearance. How to Measure Adjust Properly

What is tappet clearance and how should you properly adjust it based on the engine’s needs? When talking about ship engines, this is one of the few issues that will come up sooner or later. Hence, it is an important skill for any engineer that will eventually troubleshoot engine problems.

In this article we delve into the basics of measuring, and adjusting tappet clearance to solve common engine issues on ships. After reading this post you should have a better idea of what tappet clearance is and why it’s important.

What is tappet clearance and when is it needed?

Tappet clearance, also known as valve clearance, is the small gap between the rocker arm and the top of the valve stem (Yoke).

HOW TO ADJUST THE VALVES ON HONDA LAWNMOWER HRC216

Engineers can observe and adjust tappet clearance only when the valves are in a closed position and the engine is cooled at the compression stroke.

As for when you need to check tappet clearance, there are generally two indicators you need to keep in mind:

- First, as shown in the engine’s manual, the process should be taken after a certain number of running hours. These differ based on the engine model.

- Second, if you notice irregularities coming from misaligned tappet clearance, like noise coming from the rocket arm. We discuss all issues resulting from incorrect tappet clearance in the following chapters.

Purpose of tappet clearance

The main purpose of tappet clearance is to allow a small expansion gap of the valve stem and pushrods to accommodate the effects of a heated engine.

Note that, if this isn’t done, the valve will not sit correctly as the engine heats up. As mentioned above, this could eventually result in power loss, irregularities in the engine, and other issues.

Why tappet clearance is necessary

The clearance between the valve stem and rocker arm is very important mainly for two reasons:

- It accommodates the thermal expansion of the valve’s axis (spindle) that is caused by the heat of the ship’s engine when in operation.

- It ensures the closing of the ship’s valve regardless of temperatures and working conditions.

In short, knowing what is tapper clearance and why it’s necessary will help you maintain the right timing through the delayed or early opening of the inlet. To do this, however, you need to know how to measure and adjust the open/close of the valves. So let’s briefly talk about this as well.

Tappet clearance measurement

To measure tappet clearance (a.k.a. perform a tappet clearance procedure) you will need to measure the increase or decrease of the clearance. Depending on that, you will notice changes in the timing of the opening and closing of the valve.

- If the tappet clearance decreases, the valve will open sooner and close later. This is because the locker arm stays connected to the valve for a longer period of time. With less clearance, we get a bigger contact area between the valve stem and rocker arm. In turn, this keeps the valve open for longer as the rocker arm pushes the valve down for a longer period of time.

- If the tappet clearance increases, the valve will have a delayed opening and an early close. Since there is more clearance there is a smaller contact area between the valve stem and rocker arm. As such the valve remains open for a shorter period of time but remains closed for longer (which explains the delayed opening).

Symptoms of valve clearance problems

To understand whether the tappet clearance is wider or tighter than it should be, you can observe how the engine responds to it. Based on this, you will know if adjustments are needed.

When tapper clearance decreases:

- The valve will open sooner and close later

- You may observe air leaks in the combustion chamber, leading to less available air for proper combustion.

- The power and performance of the engine will decrease

- Fuel consumption of the engine will increase

- The temperature of the exhaust will increase

- In some scenarios, the valve could stay open for an extending period of time, causing decrease in the engine’s compression pressure. If this happens you may notice exhaust valve gets burn, and a spike in turbocharger fouling.

When tappet clearance increases:

- The valve will open later and close sooner

- The max lift of the valve will decrease

- Reduction in scavenge air (power decrease) due to less heat energy being delivered to the engine’s turbocharger

- Problematic removal of exhaust gas (not proper function)

- Repeated collision with the rocker arm can cause damage to the valve stem

- (Common tell) You may observe noise that, if left unchecked, can lead to damage on the working surface.

How to check tappet clearance. Practical applications

Let’s get to work now. How exactly can you check valve clearance? Before you start, make sure you review the manufacturer’s manual, as the explanation below is rather generic. Combining the two will usually lead to the best result.

To start, make sure that you take all the necessary safety precautions, make sure the engine is cooled, and check if the valves are closed.

Ensure that the piston is set in Top Dead Centre (TDC) by checking the following:

- The marking of the flywheel

- The marking on the fuel pump ( camshaft fuel)

- Position of the valve cam

- If the pushrods are not obstructed (as mentioned above, with both valves closed at this point, so the pushrod should be free)

If any of the above are not in TDC, don’t proceed to the next step. Instead, use the necessary turning gear when the indicator cock is open, to set them at TDC.

Four-stroke engines usually contain six to eight units. Therefore, the flywheel should now indicate two units set at TDC.

If you want to check whether a unit is on the compression stroke instead of the power stroke, you can manually turn the pushrods of the TDC-indicated units.

- If the pushrod is free it’s at the compressions stroke

- If the pushrod is tight it’s at the power stroke (avoid this one!)

At this point, you will have to find filler gauges, of multiple thickness sizes. Try to place them one by one between the valve clearance and rocker arm to find the ideal size. Usually, the manual of the manufacturers should speed up this process by indicating a range of sizes. Once you find the filler gauge that fits perfectly you will know if the distance between the valve stem and rocker arm is larger or smaller than it should be.

Valve tappet clearance adjustment

Once you have performed the check as demonstrated above, you can now proceed to a valve tappet adjustment. To do this, you will need once again need to use a filler gauge. In this case, the ideal size depends on the valve:

- For the inlet valve choose a gauge with 0,4mm thickness

- For the exhaust valve, choose a gauge with 0,5mm thickness (for this one review the manufacturer’s manual as well, as the size, often depends on the engine)

Similar to the course of action you took previously, ensure that all safety precautions are taking, the piston is set of TDC, and the engine is cooled down.

Then, loosen up the lock nut of the rocker arm to place the gauges. Based on the manufacturer’s manual, place the recommended gauge between the valve stem and rocker arm, and then adjust the tappet clearance by tightening or loosening the nut under the lock nut. The filler gauge should not feel very tight in the clearance; instead, it should be able to slide through the gap.

To effectively measure tappet clearance during this stage, you can use one of the following:

- Vernier caliper. Learn how to use it here

- Screw pitch gauge. Learn how to use it here

- Feeler gauge. Learn how to use it here

- You can also use a typical engineer’s scale

Summing up

You should now know what is tappet clearance and what role it plays in the engine’s environment. The small gap between the rocker arm and valve stem is primarily focused on providing space for heat expansion, and can easily be adjusted based on the symptoms you might notice.

When measuring tappet clearance remember:

- If the tappet clearance decreases, the valve will open sooner and close later.

- If the tappet clearance increases, the valve will open later and close sooner.

When adjusting tappet clearance try to always use the manufacturer’s manual in conjunction to your knowledge, as every engine requires different attention and details.

The Plan M8 Yacht maintenance app has recently been launched to the public. We are constantly adding new features. Sign up for a free trial and get in touch with us for an intro and an individual offer.