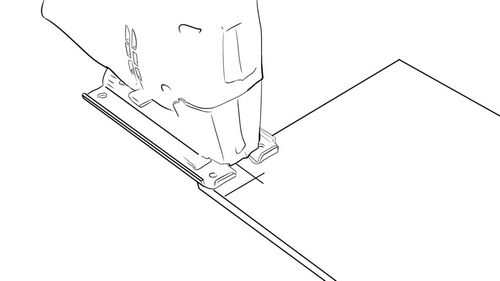

Open with a jigsaw

The jigsaw is used for small amounts of work and when it is necessary to create curved cuts. An abrasive saw is required to cut the tile. Here are recommendations for cutting tiles with a jigsaw.

- The tool should be able to adjust the speed, not worth setting the maximum parameter. A neat result can be achieved by operating at low or medium speeds.

- The sole can leave scratches on the face of the tile; when sawing, the tile must be turned upside down. It is also recommended to glue the soles of the tool with masking tape to reduce damage to the tile.

- Indoors, it is advisable to use a tool with a pipe. The branch pipe allows you to connect a construction vacuum cleaner, which eliminates a large amount of dust.

- When cutting tiles, do not put pressure on the tool or force the process in any other way. Move the jigsaw smoothly and effortlessly along the mowing line.

The jigsaw handles medium thick wall tiles. Sawing floor tiles or porcelain stoneware with this device is quite difficult. If it is necessary to dust thick tiles, then it is better to give preference to the second tool.

Glass cutter for tiles

Any glass cutter is suitable for cutting ceramic tiles. The principle of operation is NOT different from glass. Markings are applied to the tile, then in one motion you need to draw a straight line. The incision must be made with one press throughout the entire area and the first time, because then it will be very difficult to get into the first furrow.

When the fishing line is drawn, the tiles are broken against the edge of the table or against a cylindrical object (nail, screwdriver tip). For the first option, to break the tile, hang from the edge of the table and press on the hanging part. If you break into a cylinder, then the object fits under the cutting line, then you need to press on two edges of the tile.

If a small cut of 2.3 cm is made, then part of the tile can be broken off with pliers.

This cutting method is only suitable for straight cuts, making a glass cutter a round hole is almost impossible. Also, the tool is not well suited for textured surfaces, as it will get stuck all the time.

Before introducing a glass cutter, you need to take a damaged tile and practice it, puts the mowing line first on it.

Tile cutting methods

The cutting method depends on the material and the complexity of the cut, we will consider the most common methods.

Manual tile cutter (mechanical)

In most sources, this device for cutting tiles is called manual, although in fact it would be more correct to call this device mechanical. The manual tile cutter works like a glass cutter and is specially designed for easy and error-free cutting of tiles. The cutting element is a diamond roller, which is fixed on a movable element, a carriage. The carriage moves along two guide rails. Compared to the introduction of a glass cutter, making a straight cut is much easier.

The manual tile cutter has a special stop for breaking off the cut part of the tile. Lever design relieves pressure on the press. Depending on the model, tile cutters differ in the presence of various design features in them.

- Dry running, grease sliding or roller bearing.

- The presence of a device for figured cutting.

- Resizing for different types of tiles.

When working with a manual tile cutter, it is important to follow a certain sequence of actions.

- At the first stage, you need to make a markup, on the front side you need to apply a cutting line.

- The tile is laid on a tile cutter so that the line coincides with the protrusion on the bed.

- The cutting element is installed at the beginning of the marking line, then, with a slight pressure on the lever, we stretch the carriage.

- After that, by pressing in the middle of the cut line, we break the tile.

Varieties of facing material and features of its various types

Here are the types of facing material, the cutting method depends. The most important thing in this matter is not only the material, but also the role that each tile in the composition plays. Tiles are usually produced in collections. These are thoughtful sets in terms of color and pattern. Most of the collections have a few required elements.

- Background tiles usually have no patterns. Collections may contain several tiles of different colors. It is better to cut the tiles in those places where the background is uniform, so the cut cladding will not be so striking.

- Curbs. Small elements that separate large color arrays of tiles are often rectangular in format. Whenever possible, cutting curbs can be avoided if these elements do not fit the walls.

- Decorated tiles. This type of tile with a pattern or embossed image. It’s better to refuse cutting tiles with decor right away. To do this, at the stage of layout, tiles with decor must be taken out to the central places of the room. Also, tiles with decor are not recommended to be placed under the ceiling or in the floor.

Laying tiles without prior layout increases the number of cut pieces. If you plan the location on paper, you can avoid a lot of scraps and rejects. Read more about the error when laying tiles in the article “https://www.Sdvor.com/articles/new/581/”

- Floor tiles are usually thicker than wall tiles and therefore more difficult to cut. In addition, large-format tiles are often used on the floor, irregularities during cutting are also noticeable on it.

Floor tiles have to be cut more often if the corners in the room deviate from 90 degrees. For this reason, for laying tile flooring on the floor, the walls in the room must be leveled. Read about leveling walls with plaster in the article “https://www.Sdvor.com/articles/new/588/”

Jigsaw

Some complex cuts are best done with hand tools. An ordinary jigsaw copes well with this task. Its principle of operation is similar to that of an electric one, but it will work much longer, but you will not need to worry about the quality of the result.

Saws for wood or metal will NOT work, dusting the tile should be done with tungsten carbide strings or diamond saws. Work also requires accuracy and skill.

To soften the material, it is recommended to wet the ceramic with water.

Electric drill

The drill is used to drill circles into the tile, such cutouts are necessary for sockets or pipes. To do this, you need to use diamond-coated nozzles: a ballerina or a crown.

To avoid slipping the drill on the surface, masking tape must be glued to the tiles. To reduce friction and heat, the tiles should be periodically moistened with water. Also, moisture will get rid of a lot of dust.

Tool types

Currently, modern technology offers many devices for pruning. They are subdivided into specialized and amateur ones, however, this division is rather arbitrary. Each of the selected tools has high functionality, suitable for better cutting porcelain stoneware at home. Some are small, while others are very bulky. Most often, the choice falls on:

- Glass cutter and pliers;

- Jigsaw;

- Angle Grinder;

- Tile cutter;

- Diamond wire;

- Sharp forceps.

Tile cutting tools

These options are suitable for tiles with a soft surface. It is worth knowing that a large amount of work performed with such tools will still become too exhausting. Although adjusting with them will be a great finishing touch.

Water saw. Fast, accurate and dust-free

A water saw is sometimes called an electric tile cutter, which resembles a circular in design and belongs to professional tools with appropriate capabilities and cost. The device is equipped with a work table, in the longitudinal hole of which a diamond-coated cutting disc rotates. The peculiarity of the electric tile cutter is that the tiles are cut in the presence of water, which wets the disc abundantly. It enters the place of the cut made through a special branch pipe (in more expensive models) or the disc is wetted, being partially submerged in a pan with water.

Water saw. The professional tool for cutting any tile

A wet cut at high blade speeds allows you to form an ideal cutting edge that does not differ from the factory one (a chamfer is formed at an angle of 45%). Due to constant wetting, dust is NOT generated during cutting, as well as chips on the cut tile edges. It is possible not only straight, but also figured cutting, the formation of holes of various configurations and sizes. The quality and type of tile affects only the cutting speed, and then. Slightly. The water saw will cut a strip of any width from any tile. Wall, floor and even porcelain stoneware. Electric tile cutter. The best option to cut floor tiles. What is inside, what is outside, as well as tiles with a relief surface. In this case, it is not necessary to use plastic corners when laying the facing material, covering the cut edge. It is enough to fill the fillet joint with tile grout.

If you have such equipment at hand (which is not surprising), but at the same time you need to cut different types of tiles, cut holes of various shapes and sizes, you can use a universal power tool, one of the models of which will certainly be found in the arsenal of any home craftsman.

Working with a jigsaw

It turns out that you can cut with a jigsaw Not only wood and materials based on it, but also successfully cut ceramic tiles correctly at home. It is only necessary to purchase a special abrasive file. Cutting with a jigsaw allows you to make curly cuts on tiles designed for mounting sockets and switches, bypassing sewer and water pipes. Also, Applying cutting tiles with a jigsaw, you can make a fairly accurate cut.

The electric jigsaw is used for sawing, sawing, cutting shapes from various materials

And if you decide to work with a jigsaw for cutting, we will give advice on how to do it correctly:

- Mark the cutting line with a pencil or marker.

- Check the setting with a jigsaw with a diamond file.

- Without much pressure, we smoothly start cutting the tile.

- To prevent breakage of the cutter, rather than push the tool forward until it has completely cut through the tile.

- Make sure the jigsaw is always upright.

Jigsaw cutting is best for medium-sized wall tiles.

In order to properly cut the floor tiles, it is better to use an angle grinder. This very popular tool is available in many households, which is a big plus eliminating the need to purchase a tool for cutting tiles at home. You only need to purchase a diamond-coated cutting disc.

Working with an angle grinder

- Install the cutting disc on the tool.

- Marking the cutting strip.

- Securely restrains material on a flat surface.

- We begin the cutting process smoothly and without strong pressure, you need to move away from yourself.

- At the first stage, a shallow incision is made, then the furrow gradually deepens.

- The division of the tiles into parts is carried out in a way already known to us, laying on the edge of the table, carefully breaking off the required part.

When cutting tiles, an angle grinder must be extremely careful.

When working with an angle grinder, it is also necessary to comply with all safety requirements, during the process of cutting ceramics, a lot of dust and sparks are generated, therefore, it is better to use protective glasses or a shield, and it will also be useful to use a respirator.

You can use an Electric Drill to make holes in the tiles.

Working with an electric tile cutter

- Placing the tool on a level table or workbench.

- We carry out the required markings on the front surface of the tile.

- Place the tiles on the tool by aligning the marked line of the future cut with the pointer to the tile cutter.

- Turn on the tool.

- With little effort we feed the material towards the cutting element.

- The moment of contact of the tile with the disc should be slow and accurate to prevent the tile from chipping.

When working with an electric tile cutter, you must follow safety rules and use protective equipment correctly. These are earplugs to protect hearing organs from excessive noise levels generated by the operation of an electric tool, and safety glasses to protect against sparks and small particles of ceramics.

Types of tile cutting tools

The tools available for this action can be conditionally divided into two types:

- Electric tools.

- Hand tools and fixtures.

Electrical include:

- Electric tile cutter;

- Angle Grinder;

- Jigsaw;

- Drill with attachments.

Basic types of tile cutting tools

Manual include:

- Manual tile cutter;

- Glass cutter;

- Hacksaw for ceramic tiles;

- Nippers.

And even with the help of a banal large nail and a fairly sharp end, you can cut the tile at home. The cutting process is actually the same as when using a glass cutter. Consider the selection of a tile cutting tool in more detail.

Advice: in order to make the ceramic tile easier to cut, it must be soaked in water for a couple of hours.

First of all, the choice of tools will depend on the amount of work planned. If this is a small fit, without complicated cuts, then you can do with a diamond glass cutter, in the case of a large number of Undercuts (diagonal laying pattern), it is already better to use a tile cutter.

Tile cutting hand tools

Glass cutter

This is the simplest and cheapest ceramic tile cutting tool. It has a different design:

- Cutting element. Small diameter wheel;

- Diamond stylus;

- Roller glass cutter with oil reservoir in the handle. Grease flows down a narrow groove and makes it easier to carry out notching.

Glass cutter cutting elements can be replaced as you seam. How to cut ceramic tiles with a glass cutter? On the front side, a cut line is drawn with a pencil or marker. Holding the ruler on the mowing line, slide the glass cutter towards you from the far edge of the tile. Purpose. Draws a uniform depression that reduces the strength of the tile.

Then place the tiles on the edge of a table or other flat surface. The line should be cut to match the edge. Holding the edge of the tile on the table with one hand, the other gently press on the edge that is suspended. The tile should crack along the notch. Its edges are sanded with a file for ceramic products.

It is advisable to use a glass cutter for small amounts of work. It allows you to make straight cuts vertically and diagonally. Not suitable for cutting floor tiles, porcelain stoneware tiles and tiles over 5 mm thick. Glass cutter is problematic to cut a strip less than 20 mm wide.

Other ceramic tile trimmers

What is the best way to cut ceramic tiles if you need non-standard edge shapes? There are various devices for this.

- Nippers. Used for biting off small parts, corners and semicircular. They leave behind an uneven edge, which must be trimmed with an emery wheel.

- Diamond string. It is fixed in a conventional hacksaw for metal, used for curly cutting. Cuts only wall tiles and requires a certain skill, since during a jerk, chips are formed on the surface.

- Crowns are used to make round holes in ceramic tiles for sockets and switches.

- Ballerina. With the help of such a drill, holes of various diameters are made. The size is adjusted manually by changing the distance to the cutter. Up to 20 cuts can be made with one nozzle.

How To Cut Ceramic Tile Angle Grinder

New wheels are used for dry cutting, diamond dusting or for work on concrete. An angle grinder is best used with variable speed. At a rotation speed above 3.5 thousand rpm, the tile cracks, and the dust content increases significantly.

Floor tiles, porcelain stoneware and wall tiles can be cut with the angle grinder. With a certain skill, you can cut circles 70 mm in diameter and make curly cuts.

The cut is made from the back of the tile, as small chips may remain on the surface. The canvas is laid on a solid and even surface, mark the line with a marker, draw an angle grinder around it and break off the part that is longer. The cut surface can be trimmed with the same angle grinder.

How to cut ceramic tiles

When working with tiles, the question arises: what is the best way to cut ceramic tiles? The choice of tool is determined by the amount of work and the properties of the tile itself. There are several ways to cut ceramic tiles.

How to cut ceramic tiles with a manual tile cutter

The tool allows you to cut strips from 5 mm wide, straight or diagonally.

It can be used to cut durable floor tiles and porcelain stoneware up to 15 mm thick. By design, it is a base, on it are fixed carriage runners with a cutting wheel. It is slightly larger in diameter than in a glass cutter, which allows a greater notch depth to be achieved. The minimum size of the wheel is 1.5 cm.It is also removable, it can be replaced after a cycle of work.

On the base of the manual tile cutter there is a strip of solid material, with the help of which, after the incision, the tile is broken. There is a T-shaped piece in front of the roller on the carriage, which exerts pressure on the two halves of the tile.

The tile is placed on the base of the tool, after marking the break line, tightly clamped., The clamping corners must be metal in order to cut the floor tiles; plastic is enough for the wall. Pull the handle of the carriage, making an incision on the front surface of the tile.

The incision is made once. After the end of the cut, press the handle and the tile breaks. Edges will also have to be processed if they fall on a corner. If grout is used, then it will hide all defects.

How to cut ceramic tiles

In any case, special tools will be needed for the work. The simplest one. A glass cutter, a manual tile cutter has a greater productivity, for professionals it is recommended to opt for an electric tile cutter. Upon gaining a certain skill, the tile can be cut with an angle grinder, and a diamond string is used to make art products.

How to cut tiles with a mechanical (machine) tile cutter

The machine tile cutter easily “takes” even floor products of medium thickness (6 mm). Due to the large diameter of the cutting wheel, the groove is deeper and the cut breaks more easily. You can quickly cut pieces of the desired size with a minimum of scrap.

Advantage of a machine cut: the harder the tile structure, the easier it is to cut a narrow strip.

How to work with the machine tool:

- Mark a segment on the front surface and place it on the plane of the tool so that the cutting wheel coincides with the marking;

- Walk along the mowing line, controls the lever;

- Fix the tiles on both sides of the cut border;

- Opposite edge of tile (ceramics) Lift and push the cutter handle;

- She will split.

Life hack. How to cut porcelain stoneware or tiles that are constantly chipping. Insert into the machine, make a cut;. Mark the boundaries of the cut and line the back side (level or ruler. Help);. Along the marked boundary, we will cut an angle grinder, making a recess. From the INSIDE it will become thinner, and from the outside it is marked with a tile cutter;. Cut on the machine. There will be no chips or chipping on the cut. Even thin sections are NOT necessary.

See an overview of the advantages of Makita GA9010 and Makita GA9020 grinders

The best way to cut tiles: 4 proven ways

We will buy expensive tiles. We are happy! We start working as a tile cutter. We get problems: it cuts poorly and gives chips. One of two things: either the is dull, or you are doing something wrong.

How to cut tiles with a manual tile cutter or glass cutter

The hand cutter for thin to medium hard ceramics and tiles is very easy to use:

- Mark out the tiled surface and cut with force towards you. Keep the glass or tile cutter strictly at right angles. The front side should have a visible continuous strip;

- Take your time, hit and break along that mowing line like chocolate.

Soak a hot (hard) tile in water for half an hour or an hour. It will be cut exactly along the intended cut and will adhere well to the wall when laying.

There are two ways to break tiles.

- Align the cut with the edge of the table and click on the Overhang. Will break along the cut line.

- Place the already cut tiles on a glazing bead or a nail. Press down on both sides of the cut edge. Will break where it’s supposed to.

Life hack. How to cut a tile that “not included ”in the machineUnstandard long tiles (more than 60 cm) cut with a hand cutter or glass cutter. The same tile cut will serve as a ruler. Align and mark the edges of the cut. Cut off this section (you get a barely noticeable track). Place the tile vertically on your knee, grab the top edges and break. There will be perfectly smooth edges of the halves.

How to cut tiles to get a perfect cut without chips. How to cut a tile without chipping with an electric tile cutter

The chip of the electric cutter with water cooling. Powerful diamond blade and water supply to the cutting site. Without dust and much effort on your part, the tool makes cuts with smooth edges, even in porcelain stoneware with a thickness of up to 60 mm. In a matter of minutes, you can cut a lot and the desired size, and not spoil a single one. Just remember to wear safety glasses to protect your eyes from flying crumbs.