Clutch is necessary to disconnect the engine from the rest of the transmission elements for a short time and smoothly connect them during gear shifting and the car begins to move. In addition, the clutch protects the transmission parts from shock loads.

On cars, electromagnetic, hydraulic, but most often friction clutches are used.

Electromagnetic clutch

When an electromagnetic field occurs, the leading and driven parts of the electromagnetic clutch are connected to each other directly or through a ferromagnetic powder, which loses mobility under the influence of an electromagnetic field.

Similar clutches were used on cars designed for the disabled. Now electromagnetic clutches are often used in automotive climate systems.

Hydraulic clutch

In hydraulic clutch between the master and slave disks having blades, fluid circulates. The speed of the driven wheel depends on the amount of fluid. If it is completely removed, the driven wheel stops. Such a clutch significantly increases the smoothness of the car, but complicates its design.

Friction clutch

In a conventional friction clutch, the torque is transmitted by frictional forces arising between the clutch leading and driven parts pressed against each other.

In cars, you can find one, two and multi-plate friction clutch discs which can work both in liquid (wet clutch), and without it (dry clutch).

Dry single plate clutch

Most often, modern cars use a dry single-plate clutch. It consists of the following details:

On some vehicles, instead of a diaphragm spring, cylindrical springs located around the circumference of the pressure disk and levers located radially are used.

The clutch basket assembly with a diaphragm spring and a pressure plate is attached to the engine flywheel and rotates with it, playing the role of the clutch leading part. Between the flywheel and the pressure plate is a clutch disc mounted on the splines of the input shaft of the gearbox.

The principle of operation of the clutch

If the clutch is engaged (the clutch pedal is not depressed), the pressure disk presses the driven disk against the flywheel by the action of the diaphragm spring and through this “sandwich” the torque is transmitted from the engine to the gearbox.

When the clutch pedal is depressed, the clutch actuator parts move the clutch fork. It moves the release bearing, which in turn acts on the central part of the diaphragm spring. She bends away from the pressure disk from the follower, freeing him. As a result, the engine is disconnected from the gearbox.

On the driven disk on its peripheral part, two rings of special friction material are fixed (glued or riveted) on both sides. The central part of the disk has an opening with slots. With their help, the driven disk is connected to the input shaft of the gearbox. The peripheral part is connected to the central part through damper springs located around the circumference. Springs are necessary to ensure smooth operation of the clutch and damping torsional vibrations.

The pressure plate is connected to the clutch basket by means of elastic plates located tangentially to the outer circumference of the disk.

The diaphragm spring is attached with its outer circumference to the pressure plate, and the release bearing is pressed on its central part (more precisely, on the ends of the radial lobes).

Engine flywheel

The flywheel is traditionally a flat disk mounted on the end of the crankshaft. A gear ring is pressed on its outer circumference to connect the engine starter to the crankshaft when starting the engine.

But modern cars have a slightly different flywheel design. The fact is that there is always vibration in the engine, no matter how it is balanced. They become more noticeable at low engine speeds. Vibration is added by the transmission.

The massive flywheel helps smooth out vibrations. Part of the work to ensure rotation without jerks is taken over by the damper springs of the clutch disc. But the large weight of the flywheel increases the weight of the engine and prevents it from gaining speed quickly, reducing the throttle response of the car.

Two-mass flywheel

Therefore, the so-called two-mass flywheels, consisting of two parts interconnected via elastic elements, are now used. In one design, these are two parallel disks connected through springs located around the circumference.

Another option is two concentric discs interconnected by spring-loaded rods.

The weight of the flywheel is reduced, it cools better, the design and weight of the clutch plate is simplified (no damper springs). In addition, shock loads on gearbox parts are reduced, which reduces their strength and, consequently, their weight.

Double disc clutch

On cars with powerful engines, double-disc clutches can be used to transmit large torque with a small size of the device. The clutch uses two driven discs mounted in series through an intermediate disc. The number of friction surfaces in this case increases to four.

Video: How Clutch Works In A Gas Trimmer

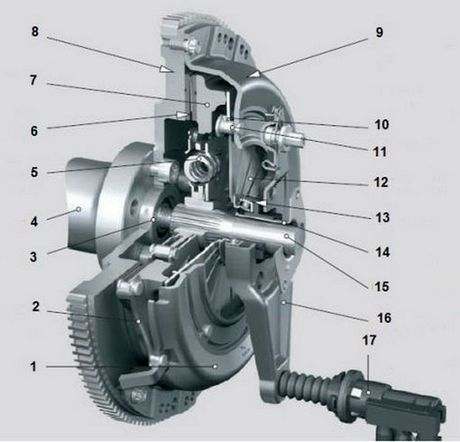

Double disc clutch diagram:

1. housing cover; 2. two-mass flywheel; 3. drive plate; 4. a driven disk 2 with damper springs; 5. a spacer; 6. a conducted disk 1; 7. pressure plate; 8. sensor spring; 9. an adjusting ring; 10. diaphragm spring.

Video. car clutch:

The video perfectly complemented the article. Good luck on the road!

A few words about the principle of the clutch. The operation of any engine in a car ends with the rotational movement of a heavy flywheel. By controlling the accelerator, you can only increase or decrease the speed of rotation of the flywheel. In order for the car to start, it is necessary to transfer this movement to a mechanical gearbox. gearbox. It is necessary to transmit this rotational movement very smoothly, otherwise the motor will simply stall. The same operation. the smooth shutdown of the transmission. is also necessary when the car is stopped. Clutch is such a “soft” switch.

The operating principle of this device is easy to understand. Imagine two spinning wheels the size of a small steering wheel. One of them is the flywheel of the motor, and the second is the clutch disc. If during rotation of the flywheel the disk from the gearbox is pressed firmly against it, then the rotational movement will be transmitted and the car will begin to move. Everything seems to be very simple. This all works, only the disks are compressed using special mechanisms, and special gaskets are installed between them.

The main problems can be poor compression of the disks or their untimely separation. It is said that the clutch “leads” or “slips”.

How the clutch slips

If during the movement of the car there is a burning smell, acceleration of the car has become worse, a decrease in speed when overcoming the rise is noticeable, then this is a clear symptom of a malfunction. slip. To clarify this diagnosis, when the engine is running and the hand brake is applied, the transmission can be engaged. Then, gently depressing the throttle control pedal, gently release the clutch pedal. If the engine stops, there is no slipping, and if it continues to operate, the clutch slips.

The reasons for this unpleasant phenomenon may be: violation of the pedal free play, wear or greasing of the friction linings, wear of the pressure springs or a malfunction of the clutch release hydraulic drive.

How does the clutch

The movement of the car is broken in jerks, there is a difficulty in shifting gears. Shocks in the transmission when starting the car, a sharp engagement of the clutch when the pedal is smoothly released, unpleasant noise are all signs of a malfunction, which is said to be “clutch”, that is, when you press the pedal, the discs do not diverge completely, and the drive shaft of the box gear keeps spinning.

The degree of disengagement of the clutch can be checked as follows. At low revs of the engine crankshaft, the clutch pedal should be squeezed to failure, and if the first gear engages silently, the clutch disengages completely. If, when you turn on the first gear, a strong noise of gears is heard and the gear does not turn on or does not turn on easily, then the clutch “leads”.

The reasons may be: a large free pedal travel, air entering the hydraulic drive of the system, leakage of brake fluid

It is possible that the engine mounting screws with the gearbox simply loosened or the bearings were completely lubricated. There are quite a few reasons for the malfunction, but there is only one conclusion. they must be eliminated, and the sooner the better and much cheaper.

It is rather difficult to set out methods for clarifying the diagnosis, adjustment and repair methods on a newspaper page. Further work to eliminate unpleasant phenomena should be entrusted to specialists.

Read about the principle of clutch operation on VAZ 2110, 2111, 2112 cars, as well as what is the difference in clutch between the tenth and twelfth models.

Clutch Design: Parts

15. a primary shaft of a transmission;

The principle of operation of automotive clutch

In an aluminum housing (17), there is a single-plate clutch with a diaphragm-type compression spring. The aluminum crankcase is attached to the engine block with three bolts and a 1st stud, and this integrates with the gearbox. The clutch cover (10) is connected by six bolts to the flywheel (number 13). The casing has three holes, which include the flywheel pins during installation. The casing (10) is connected by a drive disk (12) using three elastic steel plates. It is recommended to replace this assembly in its entirety, as it is balanced on the stand.

This replacement is required when the pedal effort decreases when the clutch is disengaged (this indicates a spring drawdown or a large wear on the surface of the drive plate), as well as when more than 0.8 mm of the pressure spring petals wear (18). On the splines of the input shaft (15) of the gearbox, a driven disk (14) is assembled with a spring-friction torsional vibration damper. Replacement is required if: from rivets to linings less than 0.2 mm, scoring, cracking, uneven wear, runout of the disc in the area of the linings more than 0.5 mm. Read more about clutch repair and how to remove the flywheel.

The difference between the clutch VAZ 2110 from 2112

The clutch on the VAZ 2112 engine, is available with other characteristics of the pressure spring and damper spring, this can be distinguished by the following signs: by the slot of the pressure spring petals (see Fig. 1) and the damper springs of the driven disk (see Fig. 2)

-

Petals of the engine clutch compression spring VAZ 2112.

The pressure spring disk on the VAZ 2112 engine in size (200 x 140) is exactly the same as on the VAZ 2110 model, but the torque is 12% more due to the reinforced pressure spring. On the VAZ 2110, you can put the pressure spring disk from the VAZ 2112. When installing the pressure disk from twelve on the VAZ 2110 model, the force increases when you press the clutch pedal. Pressure spring discs from 2110 to 2112 cannot be set.

The clutch drive on the car is cable-free and without gaps (there is no pedal free play with the clutch constantly on). In a special bracket (25), the clutch pedal (27) is installed on the axis, its upper end is connected to the cable tip (24), the cable sheath is fixed to the clutch pedal bracket, and in the engine compartment on the bracket (3) of the power unit. The steel cable (8) is connected to the clutch release fork (number on the diagram 9). The rubberized cover (4) covers the end of the steel cable, the nuts (6 and 7) located nearby are used to adjust the drive. After adjustment, the nuts are tightened together. counter.

After replacing the clutch, it is necessary to adjust the stroke of the clutch pedal (see “Replacing the clutch cable”). Over time, the lining of the driven disk is erased and because of this the pedal travel increases. The maximum allowable clutch pedal stroke is not more than 160 mm.