How Does an Electric Lawn Mower Clutch Work?

An electric lawnmower clutch, commonly called a power takeoff clutch (PTO), is the part of a lawnmower or riding tractor responsible for engaging the blade. The electric clutch helps to transfer engine power to the drive train. The clutch connects two drive shafts and is controlled by a toggle switch. PTO clutches work in conjunction with the PTO drive shaft and must be compatible with the transmission of the lawnmower.

An electric lawnmower clutch gets energy from the mower’s engine and transfers it to the mower blade. An electric clutch also performs the function of a brake to stop the blades when the PTO gets turned off. Some lawn mower manufacturers suggest the purchase of a PTO over running clutch. This type of clutch prevents the mower from moving after the driver disengages the mower clutch.

An electric clutch is technically an electromagnetic apparatus. Inside the disc shaped clutch is a magnetic coil. When the clutch receives power from the starter, the magnetic coil forces an armature into contact with the rotor. The rotor is attached to the crankshaft, and as the armature begins to spin it will turn a pulley that spins the mower’s blades. For larger mowers or small tractors that have more than one blade set, electric clutches can work in conjunction with the drive assembly to operate the blade sets at different speeds.

When the power to the electric clutch turns off, the magnetic energy releases control of the armature. At that point, the springs that control the armature’s movements force it back against the brake. The brake then stops the pulley, which turns off the mower’s blade. The electric mowing clutch can turn off the rotation of the blades without affecting the running of the engine. This is how drivers can ride a mower a long distance without having to worry about hitting spinning blades on protruding rocks or other objects in the grass.

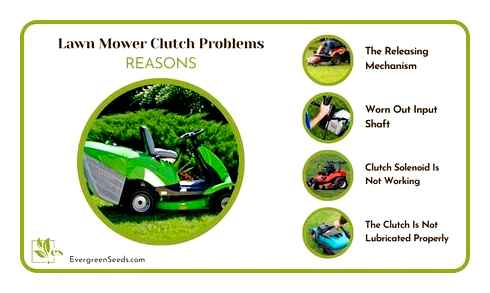

Lawn Mower Clutch Problems: Their Quick And Easy Fixes

Lawn mower clutch problems can be a nuisance when using a riding-style mower for lawn maintenance. A clutch is a particularly sensitive part of the mower equipment that is easily prone to get damaged.

This article lists all the probable reasons your clutch might not work properly. You will also learn practical methods for checking for problems and solving them yourself.

What Are Some Common Lawn Mower Clutch Problems?

Some common lawn mower clutch problems would be the releasing mechanism, the worming out of the input. On the other hand, it can also be due to the solenoid not working, and the clutch not being properly lubricated.

On the other hand, the clutch of gas-fueled and electric lawn mowers might have problems because of a defective releasing mechanism or a worn-out input shaft. A faulty or fused solenoid is one of the most common reasons, and it provides a variety of symptoms.

– The Releasing Mechanism

The releasing mechanism of an electric PTO clutch gets damaged quite easily. This would be the result especially when the machine is used improperly on a bumpy surface. The latter is because the machine is made to work on smooth surfaces, with no uphills or crusted bumps on the edges.

When these are present, the machine will become weaker, because it is not made for these reasons. The dysfunctionality will be represented by the mower’s weird noises when the clutch engages or disengages. This would indicate that the mechanism has been messed up, and the clutch is not in the right position as it should be.

What you must do in this case is to turf off the engine and then press and release the clutch. If the release mechanism has been affected, the peculiar noises will continue even with the engine being turned off.

The mechanism is the one that is responsible to adjust the proper functionality of the machine and how it would be running throughout the time. Remember that if this is damaged, then the whole thing will have a major issue when it is aiming to do the work.

– Worn Out Input Shaft

A clutch input shaft connects the engine to the clutch and transfers rotational forces to it. Naturally, the bearings around this shaft might wear off after years and years of mower use. The shaft is what will be gripping well the clutch, and as a shaft gets worn out, or weakened, the clutch would start seeing different problems. This is an aspect that you wouldn’t think of, because this issue is not an obvious one.

However, it might also occur due to bad PTO clutch use when you overexert your riding lawn mower and its clutch, which would get damaged as the years would pass by. As a result to the latter, you can very obviously, tell that the problem lies in the input shaft when the mower makes whirring or chirping noises in a neutral position, but the sounds go away when the clutch is depressed.

– Clutch Solenoid Is Not Working

A PTO solenoid, in layperson’s terms, is simply a switch activated when the engine engages with the clutch. Once the clutch, in turn, connects with the external shafts of mower tires, this solenoid gets deactivated.

The clutch will stop working whenever there is something wrong with this solenoid; on the other hand, it may also be due to the wrong calibration of the solenoid, which is not properly adjusted, as a result you will feel like the machine is not doing its job right.

A lot of mower clutch problems arise because of a dysfunctional clutch. Sometimes, this solenoid turns into a bad fuse and must be taken care of, or else the machine would get tired so quickly.

At other times, the solenoid might be working all right but is not getting the right voltage from the battery, so the battery needs to be fixed, and this is a matter of reverse standardization, where one would effect the other.

When the mower is not stored properly, someplace dry, the solenoid rusts. Dust can get stuck in the mower engine, affecting the sensitive electromagnet from which the solenoid is made. When the solenoid gets fused, damaged, or corroded, you have no other option but to replace it.

– The Clutch Is Not Lubricated Properly

When the electric clutches are not lubricated properly as part of regular mower maintenance, problems would begin to arise. As a result of lacking of oil, the machine may start showing you signs such as a squeak of noise coming out, or a challenge when trying to work through the task.

To elaborate further, the friction in the clutch parts might cause it to become stuck while working or not turn properly. You will feel resistance in the mower movement even with the engine at full throttle and the clutch fully engaged, as a result the problem would be relevant and obvious.

A lack of power is not the only thing that happens when lubrication of riding mower clutches needs to be taken care of. When friction starts to occur, then it will cause the clutch components to wear down quickly, and this might end up damaging the mechanism of this machine on a permanent scale. In addition to this, sometimes, fluids might start leaking into the clutch from lack of lubrication.

Lastly, the resistance and friction between these parts will increase the heat production in the clutch. The temperature of the whole engine will be raised, which is a dangerous thing to happen in any machine.

How To Solve Lawn Mower Clutch Problems?

To solve the lawn mower problems with the clutch, you must first test the clutch well, and make sure you would replace the electromagnetic solenoid. In addition, you should also replace the battery, and invest in better lubricating oil, and remove the defected clutch and replace it.

To fix your problematic PTO clutch, you need to see what is wrong with it and then fix it accordingly. In case the clutch is completely damaged, take it out and then replace it with a new one.

– Test The Clutch First

The first step is to carry out extensive clutch troubleshooting for the pto switch clutch. after which it can be fixed. This will help you pin the issue right from the start, it will tell you and signify what is really going on.

First and foremost, you must make sure that the mower’s engine has been turned off and cooled before working. This is when you must push a mower jack underneath it and lift it using two rear jacks and two front ones.

Then, make sure you try to lift the hood to expose the battery and disconnect its terminals. Use a millimeter to read the volts on the battery. If the voltage falls below 12.4 volts, the inadequate voltage is why the clutch is not engaging, and this is the way you would start to tackle the problem.

Next, check the fuse in-line and see if it has blown or is black with soot. It will have to be replaced if it is damaged. See that nothing is jamming the belt and the pulley system of the mower, like broken twigs or tree branches.

Put in the ignition key and turn the engine off to check the working of the clutch. Before turning the engine, engage the lever and disengage it after turning it on. If the pulley is slowing down during this, then this means that the clutch has fused with the plates.

Which means that you should take the matter into a closer look, and fix this situation by replacing it, or adjust it properly.

– Replace the Electromagnetic Solenoid

Many problems can go wrong with a mower clutch, and each needs to be addressed individually. However, if you check that the clutch is not sitting right, then you should try to work with fixing the solenoid.

If the problem lies with a faulty solenoid, this electromagnet will have to be replaced by a new one. This is something other than what we recommend doing yourself, and it’s best to ask for professional help instead.

When it sits right, after you have replaced it, you won’t go through so much difficulty, because after adjusting, it won’t show you any issues. Sometimes, it is just the switch that is defective and in need of a replacement, this would be upon the situation, of course.

Your local hardware store will give you a brand new one that must be bolted in place of the old one.

– Replace The Battery

When the problem lies with the battery voltage, there is no need to mess with the clutch anymore, don’t go any further and try to put yourself in a chaos of a situation. The battery only needs to be cleaned and get IRS electrolyte refilled, and it will be fair to get it done.

When the machine has been set with a really old and worn-out battery will have to be replaced by a new one, and as you try to turn it on after you have replaced it, you shouldn’t face any clutch problems.

– Invest in Lubricating Oil

Lack of lubrication will produce undue friction and generate heat from the clutch plates getting stuck together. Invest in a premium-quality lubricating oil and use it on the engine. If the problem persists, the clutch has been damaged already and requires a replacement.

When you invest in a quality lubrication oil for your lawn mower, and spread it to the right amount that is given, it will run in a smooth way, with no further complications, and no noise. This would show that the clutch is functioning very properly.

– Removing and Replacing the Defective Clutch Effectively

Put on your best rubber gloves and take a screwdriver and a socket wrench set. You do not need any other additional tools for this.

Once the engine has been switched off, and the ignition key is taken out, wait for the mower to cool down. Then remove the protecting covering of the spark plug and use its wrench to remove it as a precautionary measure.

Then you must place a jack under the mower and pull it upwards to access the deck and the pulleys. Remember that it is important to have a plastic coating is usually protecting the mower belt that must be removed.

Loosen the belt using the screws holding it in place on both sides to gain access to the clutch underneath. Once the belt has been loosened and removed, you can see the clutch connected to two wires. These wires connect the clutch to the engine and the blade, make sure this step is done neatly.

Ask someone to help you remove the bolt that connects the clutch to the top of the mower. Once this screw is loose, remove the flywheel cover and screw it back on. Remove the clutch as the final step and replace it with a new one.

Put everything back as you did before and restart the engine to see if it works, and adjust the grip, and make sure you turn it on and now see the way that it would be running.

Conclusion

Now that we have discussed the problems and the solutions associated with faulty mower clutches, here is a brief recap before we go.

Clutch Scag

Welcome to scagmowerparts.com! We offer the right clutch for your Scag mower. As a full-line Scag dealer, we carry only original equipment manufactured clutches for your Scag. Scagmowerparts.com is your #1 Source for your Scag clutches.

We recommend you verify which part is correct for your particular Scag unit. First, enter your model number by using our convenient Parts Lookup and Part Diagrams. Secondly, select the appropriate diagram. Third, select the appropriate part and quantity, then add it to your cart. However, should you be unable to find what you are looking for, please contact us via email or 800-866-5473.

After your order is placed, we will keep you informed of its status including notification when it ships. importantly, our growing partnership with UPS allows us to offer reasonable shipping rates throughout the U.S. We proudly offer free shipping on orders of 75 or more however, over sized packages will have a small additional charge.

Sign up now to receive our newsletter filled with informative lawn care tips and lawn mower maintenance tips. Additionally, you will receive special offers reserved for our most valued customers. Most importantly, it is completely hassle free and without strings attached. However, you may unsubscribe to our emails at anytime. If you sign up now, you will receive a 5% discount on your first order.

Who Are We?

Thank you for your patronage, Happy Shopping!

Unusual Noise

In addition to leaking fluid, another symptom of a bad PTO clutch in a lawn mower is an unusual noise when engaging the blades. If you hear any strange sounds coming from the engine or transmission when you pull the PTO lever, it’s likely that the PTO clutch needs to be replaced.

There could also be certain vibrations when the blades are engaged, indicating a faulty PTO clutch. If the blades don’t turn as quickly or easily as they normally do, it’s also likely that the PTO clutch has become worn out and needs to be replaced.

In order to avoid any major damage to the lawn mower, it’s important to address these symptoms as soon as possible. Replacing the PTO clutch can save you from costly repairs down the road and help ensure that your lawn mower runs smoothly for years to come.

Failure to Engage the Blades

One of the main symptoms of a bad PTO clutch in a lawn mower is failure to engage the blades. If you’re having trouble engaging your mower’s blades, it could be due to a faulty PTO clutch.

Other signs that could indicate a problem with the PTO clutch include grinding noises or clunking sounds when trying to engage the blades, a humming sound coming from the clutch, and difficulty restarting the mower after engaging the blades.

The best solution to this problem is to replace the PTO clutch as soon as possible. If you’re looking to replace the PTO clutch yourself, make sure to get the right part for your particular model of lawn mower.

The next step would be to disconnect the spark plug before beginning work so that you don’t accidentally start up the mower.

After disconnecting the spark plug, locate and remove the PTO clutch bolts to take off the old clutch. Depending on your lawn mower model, you may need a wrench or socket set for this step.

Finally, put in and secure the new PTO clutch with the appropriate bolts, reconnect the spark plug, and test out your new PTO clutch to ensure it’s working properly.

If you’re uncomfortable taking on this repair yourself, it’s best to take your lawn mower to a professional for assistance.

Overheating

A bad PTO clutch in a lawn mower can cause more than just overheating. It can also cause the blades to stop working and the mower’s engine to stall out.

Additionally, when you attempt to engage the blade, it may not turn at all or have an inconsistent turning speed. A loud grinding noise may be heard from the mower when the PTO clutch is malfunctioning.

If any of these signs are present, it’s important to have your PTO clutch checked out and replaced if necessary.

Failing to do so can result in further damage to the lawn mower or even bodily harm. To avoid overheating, stalling, and other issues with the PTO clutch, it is crucial to keep up with regular maintenance.

Ensure that the mower’s oil levels are correct, and check for any loose parts or worn belts. It is also a good idea to inspect your blades regularly and sharpen them as needed.

How to solve bad PTO clutch symptoms?

There aren’t a single solution to solve the PTO clutch problems. For example, If your PTO clutch solenoid is defective, then you need to replace the clutch. But, If the problem occurs on a switch, the problem will solve by replacing the switch.

Also, Adjusting the PTO clutch, especially electric clutches, are mandatory for getting the highest performance. Otherwise,You will notice the gap between contact plates that reduces magnet power and complexity to hold them together. For this, with a heavy load, the contact plates may slip, which will cause heat from the friction of lowering.

Sometimes, Adjusting the PTO clutch from time to time can solve some common issues and provide optimal performance.

Here are some common issues and solutions you may apply to solve the PTO clutch problem:

| Problem | Solution |

| Hard to start | Check the air filter and clean it or replace it.Check all wiring.Check the spark plug.Adjust carburetor. |

| Engine will not turn over | First, Depress the brake pedal, If it isn’t depressed. Clean battery terminals. Replace or check starter or solenoid. Contact qualified service center. |

| Engine clicks but wil not start | That may cause of dead battery; replace the battery and clean battery terminals. Check the whole wiring. |

How do I Test A PTO clutch?

Follow this quick guide to test a PTO clutch:

How Do You Remove A PTO clutch?

Fortunately, We don’t need any type of special tools and equipment to remove a PTO clutch. Just a screwdriver, a socket wrench set, and a pair of good-quality gloves are enough. After you collect those tools, let’s jump into the removing part:

Final Words

The power takeoff clutch is a piece of important equipment used on small tractors that activate mower tillers or blades. It’s used electricity to produce a magnetic armature to rotate the blade. But, to get the optimum performance, you need to keep it in regular maintenance.

So, Knowing some common Syndrom of bad PTO clutch helps you do the maintenance process easily and find out any problem quickly. In the above guide, You find some common syndrome and how to solve those, which might help you identify the problem and solve it.