Modern chainsaws have a complex system and consist of several main components, which periodically require maintenance and adjustment. In this article, we’ll talk about how to adjust the carburetor on a Husqvarna chainsaw.

When is carburetor adjustment necessary?

The reasons that will require adjustment of this unit can be listed for a very long time.

Among the main malfunctions, the following can be distinguished:

- The increase in idle speed;

- The appearance of a large amount of smoke during operation;

- Deterioration of starting properties;

- Insufficient tool power when cutting.

Here is a far from complete list of all known faults. Sometimes a procedure such as adjusting the carburetor on a Husqvarna chainsaw needs to be performed after a major overhaul of the power plant or after maintenance.

The developers of Husqvarna 137 write in the passport that carburetor adjustment must be carried out before and after the tool break-in.

Carburetor for Husqvarna 142-136 chainsaw

Chainsaw carburetor GOOD LUK GL45

120 UAH

Carburetor for Rebir 1.4 chainsaw

200 UAH

The device and principle of operation of the Husqvarna carburetor

To successfully set up a Husqvarna chainsaw carburetor, you need to know its device and understand how it works. In fact, everything is not as complicated as it seems at first glance.

The saw carburetor has a built-in fuel pump, which is responsible for transporting a mixture of gasoline with oil, as well as a diaphragm, a needle valve with a rocker. Their joint work allows metering the fuel supply to the main chamber and two shutters.

One of the dampers is designed to adjust the fuel supply to the cylinder when pressing the gas, it is called the throttle, the second is responsible for restricting the air supply from the air filter to facilitate the start of the Husqvarna cold chainsaw. At that moment, when the operator shuts off the air supply to the carburetor with the help of an air damper, the fuel mixture is depleted and its supply to the cylinder is increased, due to which the chainsaw starts up much easier than when the cold start is carried out in normal mode.

An injector valve is involved in the operation of the Husqvarna carburetor, which atomizes the fuel and prevents air from entering the main chamber. Often problems when working with a saw can be caused by defects in this particular element. For example, a valve, if the chainsaw is not stored properly, can stick, fuel supply will stop, which will make the engine impossible. Also, malfunctions of the nozzle can cause air to leak into the main fuel chamber of the carburetor. In such cases, adjusting the position of the adjusting screws will not correct the situation; repairs or replacement of the assembly will be required.

For adjusting the quality and quantity of the mixture, as well as the number of revolutions of the crankshaft in idle mode, there are three adjusting screws installed in the carburetor body:

- screw (L). adjusts the amount of fuel in low and medium speed mode;

- (H). responsible for traction at high speeds and their number;

- (T). changes the position of the throttle valve, thereby regulating the amount of fuel mixture entering the cylinder and the engine’s engine idling.

Screws (L) and (H) cannot be adjusted without specific knowledge and experience. Incorrect adjustment of the quality and quantity of the fuel mixture can cause the engine to stop working or malfunction, which will lead to its rapid deterioration or even jamming.

Custom carburetor Chinese chainsaw

Husqvarna Chainsaw Carb Adjustment

Like all other saws, husqvarna has the same carb adjustment algorithm. Therefore, the instruction will be relevant for other tools and models of chainsaws such as Husqvarna 142, 236.

Before starting work, make sure the air filter is clean and that all other components are working properly. The fuel supply to the float chamber should work without interruptions, and the ignition system is configured correctly and has a fresh candle.

- Set the carburetor to factory settings. Do this with the engine stopped.

- Now you can start the engine and be sure to warm it up for several minutes. Adjustment of the XX carburetor Husqvarna 137 is carried out only on a warm engine.

- Turning the screw L clockwise, you need to set the highest revolutions of the crankshaft, then turn back a quarter of a turn. Use screw T to adjust the crankshaft speed so that the chain does not rotate. It should not be set in motion without pressing the accelerator.

- Now you need to set the maximum speed and their power. It is enough to connect the tachometer to the ignition system and set the maximum possible speed using the accelerator. Compare them with the passport data. If they differ, then unscrew or tighten the screw H. By changing the range, you can create restrictions in order to make the saw work efficiently and save the motor resource.

What you should pay attention to?

As soon as the adjustment of the Husqvarna carburetor is completed, you need to make sure that the engine is stable and that the saw easily picks up and slows down. The rotation of the circuit at idle speed is considered an abnormal phenomenon, therefore, it is necessary to adjust its connection with the clutch again using screw H.

Do not forget that the unit is not configured immediately: you need to wait a while, since the Husqvarna chainsaw does not immediately respond to the change in the position of the screws. This time can vary from 5 to 15 seconds. The table does not prescribe this time, so you can only find out experimentally.

If after adjustment a huge amount of smoke appears during operation, then the flow of the fuel and oil mixture must be adjusted. For these purposes, rotate screw L.

What is the factory setting for the Husqvarna chainsaw carburetor?

In order for the chainsaw to start anyway even with the wrong setting, the factory settings of the H and L screws are applied. Most Husqvarna chainsaws can be started by unscrewing both screws exactly one and a half turns. Only then can the position of the screws be changed in order to achieve the required fuel consumption and maximum work efficiency. XX is also regulated after these manipulations.

If you still have questions about adjusting the carburetor on the Husqvarna 137 chainsaw and other models in this line. I recommend watching this video:

Husqvarna Chainsaw Carb Adjustment

Like all other saws, husqvarna has the same carb adjustment algorithm. Therefore, the instruction will be relevant for other tools and models of chainsaws such as Husqvarna 142, 236.

Before starting work, make sure the air filter is clean and that all other components are working properly. The fuel supply to the float chamber should work without interruptions, and the ignition system is configured correctly and has a fresh candle.

- Set the carburetor to factory settings. Do this with the engine stopped.

- Now you can start the engine and be sure to warm it up for several minutes. Adjustment of the XX carburetor Husqvarna 137 is carried out only on a warm engine.

- Turning the screw L clockwise, you need to set the highest revolutions of the crankshaft, then turn back a quarter of a turn. Use screw T to adjust the crankshaft speed so that the chain does not rotate. It should not be set in motion without pressing the accelerator.

- Now you need to set the maximum speed and their power. It is enough to connect the tachometer to the ignition system and set the maximum possible speed using the accelerator. Compare them with the passport data. If they differ, then unscrew or tighten the screw H. By changing the range, you can create restrictions in order to make the saw work efficiently and save the motor resource.

What you should pay attention to?

As soon as the adjustment of the Husqvarna carburetor is completed, you need to make sure that the engine is stable and that the saw easily picks up and slows down. The rotation of the circuit at idle speed is considered an abnormal phenomenon, therefore, it is necessary to adjust its connection with the clutch again using screw H.

Do not forget that the unit is not configured immediately: you need to wait a while, since the Husqvarna chainsaw does not immediately respond to the change in the position of the screws. This time can vary from 5 to 15 seconds. The table does not prescribe this time, so you can only find out experimentally.

If after adjustment a huge amount of smoke appears during operation, then the flow of the fuel and oil mixture must be adjusted. For these purposes, rotate screw L.

What is the factory setting for the Husqvarna chainsaw carburetor?

In order for the chainsaw to start anyway even with the wrong setting, the factory settings of the H and L screws are applied. Most Husqvarna chainsaws can be started by unscrewing both screws exactly one and a half turns. Only then can the position of the screws be changed in order to achieve the required fuel consumption and maximum work efficiency. XX is also regulated after these manipulations.

If you still have questions about adjusting the carburetor on the Husqvarna 137 chainsaw and other models in this line. I recommend watching this video:

DIY carburetor adjustment on a chainsaw

Adjusting the carburetor of the chainsaw ensures efficient operation of the tool at full power with economical fuel consumption. Adjustment should be made with a clean fuel and air filter. For a larger number of carburetors, the adjustment is carried out by three screws: for maximum and minimum speed and idle adjustment.

Screws H and L adjust the ratio of the gasoline-air mixture determined by opening the carburetor throttle. When the screws are loosened, the mixture is enriched, and the revolutions accordingly fall; when the screws are twisted, the mixture becomes leaner. the revolutions increase.

The designation H refers to the maximum speed screw that controls the main jet, L to the minimum speed screw that controls the idle jet. Screw S provides precise idle speed control. Sometimes, to simplify the adjustment, the number of carburetor adjusting screws available is reduced.

Setting the carburetor of the chainsaw is divided into two stages. basic (factory settings), carried out with the engine turned off. and final, produced on a running warm engine. The exact angle of rotation should be taken from the operating instructions for the particular chainsaw. Failure to follow the manufacturer’s instructions could result in engine damage.

Basic carb adjustment.

The adjusting screws for the maximum H and minimum L revolutions are slowly turned clockwise until they stop, after which they are turned back 2 turns, other settings are also possible

Check and adjustment of idling.

We find the highest idle speed, for this, slowly turn the screw L in different directions. After finding the position of the highest engine speed, turn screw L 1/4 turn counterclockwise. If the chain rotates at idle, screw T or (S) should be turned by turning it clockwise until it stops.

Checking and adjusting the maximum speed.

Changing the maximum number of revolutions is carried out by screw H. When it is screwed in (clockwise rotation), the speed increases, when turned out, it decreases. Chainsaw engines have the highest rotation speed of 11,500 rpm. up to 15000 rpm Ignition does not provide a higher speed, in addition, it becomes dangerous for the engine. The maximum speed can be determined by interruptions in the ignition. If they come, screw H is slightly turned counterclockwise.

If the engine is not tested for acceleration and maximum speed, then the adjustment of the chainsaw cannot be considered complete.

With a smooth pull of the gas trigger, the engine must confidently and quickly gain speed from idle to maximum (from 2800 rpm to 11500-15000 rpm depending on the unit). If the speed is slow, delayed, screw L must be slowly turned out counterclockwise, but no more than 1/8 turn.

After adjusting the acceleration and maximum revolutions, you should again check the operation of the saw at idle. the engine should work stably, the chain should not move. Chainsaw setting should be repeated if this condition is not met but with the exception of the basic adjustment step.

How to adjust the carburetor on a chainsaw yourself

"A carburetor is a device responsible for the mixture and supply of fuel to the combustion engine of an internal combustion engine."

I am glad to welcome all lovers of "interesting and suitable men’s toys."

Correct carburetor adjustment ensures reliable operation of the chainsaw in all modes, and with economical fuel consumption. In general, if you remove the word "chainsaws", then this applies to all internal combustion engines.

Now let’s talk about how to adjust the carburetor on a chainsaw. Setting up a Husqvarna 137 carburetor usually does not cause any problems. In general, such a procedure is carried out from time to time. Factory setting is the best and highest quality option. But, as needed, it is made a means of adjusting special screws. Let’s figure out how to rebuild with our own hands:

how to adjust, adjust, remove, correctly

A chainsaw is an indispensable tool for people living in private households. It is a mechanism consisting of carefully fitted parts and assemblies.

Video: How to Adjust a Husqvarna 142 Chainsaw Carburetor

Like any mechanism, it requires periodic care and adjustment. Especially because of low-quality fuel. Consider the principles and procedure for adjusting the carburetor of a Husqvarna chainsaw.

The device and the principle of operation of the carburetor

The carburetor is used to prepare the combustible mixture in the proportion determined by the operator from gasoline and air.

Overly enriched, as well as overly poor, the mixture will lead to unstable engine operation, can cause overheating and accelerate piston system wear.

The proper functioning of the device depends on the proper settings and adjustments.

And for this, you need to know the principles of the carburetor of the Husqvarna chainsaw.

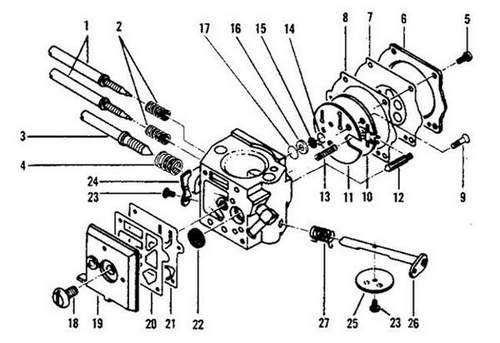

Its design consists of the following elements:

- case with clamping bolts and a set of gaskets;

- fuel pump. a device that injects a gasoline-oil mixture into a carburetor;

- diaphragm. designed to limit the flow of the combustible mixture into the engine;

- float chamber. fuel is collected in it, the level is regulated by the float, as necessary, the mixture is fed into the main chamber for mixing with air;

- the main chamber. air passes through it, and fuel is injected there, the amount of the mixture supplied to the engine is regulated by the throttle located here;

- diffuser. a section of the narrowing of the tube supplying air at the fuel injection site;

- needle valve. a device that regulates the supply of fuel;

- jet. screws that control the flow of the mixture at high and low speeds, as well as the idle screw.

Also in the carburetor device, in addition to the throttle, there is a damper located at the inlet of the air filter. It artificially reduces air flow, making the mixture more saturated to facilitate starting a cold engine.

The injector valve is responsible for injecting fuel into the main chamber, it also prevents air from entering. When setting up a carburetor on a Husqvarna chainsaw, special attention should be paid to this valve, since its condition has a direct effect on engine operation. After prolonged storage, the nozzle may stick. This will limit the flow of fuel and prevent the engine from starting.

Also, from prolonged use or due to factory defects, the valve can let air into the main chamber. In this case, only a replacement will help to fix the problem.

The carburetor operates as follows: the air flow entering the diffuser is mixed with the injected fuel, the resulting mixture is fed into the engine. The amount of mixture is regulated by a butterfly valve. The larger the mixture, the higher the engine speed.

When adjustment is needed

The need to adjust the carburetor of the chainsaw is rare. Often there are problems with the flow of fuel, air or wear parts. But sometimes adjustment is still required:

- A started engine stalls after a few seconds, or does not start. the reason for this is too rich a mixture;

- excess exhaust, high revs, increased consumption. in this case, on the contrary, the mixture is too lean, that is, there is not enough air;

- revolutions are kept at the same level after they are reduced or increased by the operator. the cause may be a sticky needle valve.

Factors leading to such changes may be as follows:

- Strong vibration damages the protective cover, and the adjusting jets get out, changing the setting. In this case, it is possible to adjust the carburetor on the chainsaw.

- Deterioration of piston system components. Setting the carburetor in such a situation may provide temporary assistance. Replacing worn components is recommended.

- Poor fuel, a defective filter, or long-term storage can cause blockages. In this situation, the carburetor must be removed, rinsed with a special liquid or clean gasoline, collected and re-adjusted.

It is best to start setting up the saw by checking the nozzles, the fuel and air supply. After that, proceed to dismantling the carburetor, and then to checking the piston system.

What tool will be needed

First of all, you need to prepare a tool for adjusting the carburetor of the chainsaw. You will need a set of screwdrivers and open-end wrenches, a special cleaning compound that dissolves soot and debris.

Disassembly is best done on a table or workbench. On a part of the table, lay a flap of clean, preferably light and plain fabric, on which the removed parts and the washing container will be laid out. Optimal if it is an ultrasonic bath.

How to remove the carburetor and whether it should be done before tuning

In the event that the chainsaw does not develop revolutions or, on the contrary, works at excessively high, the carburetor can be adjusted without removing.

But if the chainsaw does not start, the speed hangs at the same level or it works unstably. Setting the chainsaw carburetor will not change the situation. It must be removed to clean or replace parts. In this case, it is necessary to act in the following order:

- Unscrewing the holding fasteners, remove the upper casing of the saw.

- We remove the gasket and part of the air filter by unscrewing the bolts or by clicking off the fasteners.

- To the right of the carburetor is the fuel hose. Remove it with the throttle control rod.

- We remove the carburetor from its fastenings.

Dismantling the carburetor is carried out in accordance with the supplied instructions. When disassembling with extreme caution, it is necessary to fold the parts on a pre-prepared fabric. Due to the small size, there is a risk of losing components during disassembly and flushing.

All parts thus obtained are washed in a special liquid, dried and wiped with a lint-free cloth.

The channels, tubes and jets are purged with compressed air, if possible, pre-washing them in an ultrasonic bath.

How to adjust

For this, 3 adjustment jets are provided in the design of the device. The idle adjustment screw (T) is located at the top of the carburetor. Below is a pair of nozzles for adjusting the fuel supply at minimum (L) and maximum (H) rpm, left and right, respectively.

The procedure for adjusting the carburetor on a Husqvarna chainsaw is as follows:

- Warm up for 5 minutes.

- Turning the screw L, we bring the engine to the highest speed in the unloaded state and return it a quarter of a turn.

- Hold the throttle button with one hand for 15 seconds. At this time, turn the jet H to the right until it stops and reaches maximum speed. Then we turn it back one and a half turns or until the “squeal” of the engine disappears.

- After releasing the gas, turn the idle screw (T) clockwise until the chain starts to move. After that, we rotate it in the opposite direction until the chain stops moving.

During the adjustment process, a situation may arise in which the chainsaw stalls. This may be due to excessively twisted jets, too rich or poor mixture.

If this happens, it is necessary to tighten the jets of minimum and maximum revolutions to the stop. Then turn them back one and a half turns and try to start a saw.

Ignition adjustment after carburetor adjustment

If cleaning and tuning the carburetor did not fix the existing problem, you need to check the spark plug and adjust the engine. You should act in the following order:

- A candle is twisted and a visual inspection is carried out. If it is dry with a light brown deposit, it can be considered healthy.

- If traces of gasoline are detected on the spark plug, the carburetor must be readjusted. This is because it delivers excess fuel to the engine, filling it.

- If the candle looks normal, check the operation of the electrical equipment. First of all, the cable that supplies current to the candle. The end is brought to a short distance to the radiator grill of the cylinder and the starter is scrolled with a cord. A spark should slip through. If not, check the cable with a tester and replace if necessary.

- If the cable is working, the ignition coil is tested. If the inspection does not reveal scorched or dangling wires, the coil is called a tester, comparing the data with the accompanying documentation. If deviations are found, the unit must be replaced with a similar one.

After replacing the coil unit, set the gap in the magneto. The gap between the ignition coil and the flywheel should be between 0.2 and 0.4 mm. To set the gap, you need a set of probes or you can use a foil of suitable thickness. The probe is clamped between the coil and the flywheel at the time of installation, and then pulled out.

How to understand that everything is done correctly

After setting, you need to start the chainsaw. Check stability at idle. In this case, the chain should not move. When you press the accelerator, the chainsaw should steadily accelerate and stop without delay.

At minimum and maximum speed levels, the Husqvarna 350 should work stably, without extraneous noise. At the time of operation there should not be a sharp loss of power or shutdown.

Model benefits

- The relatively small weight of the Husqvarna 142 chainsaw and ergonomic design, combined with a curved front handle make operation of the equipment very comfortable.

- Anti-vibration system allows you to not feel lethargy for a long time.

- The presence of a shield and a chain brake is foreseen to ensure the safety of users.

- The power of the Husqvarna 142 chainsaw is increased by means of a forged crankshaft, consisting of 3 sections.

Chainsaw Carb Adjustment

The carburetors of most chainsaws have three adjustment screws:

- L. jet screw for low speed adjustment

- H. jet screw for adjusting high revs

- Screw. T at the Partner and Husqvarna (at Calm LA ). chainsaw idle speed adjustment

Screws H and L adjust the ratio of the gasoline-air mixture determined by opening the carburetor throttle. When the screws are loosened, the mixture is enriched, and the revolutions increase accordingly; when the screws are twisted, the mixture becomes leaner. the revolutions fall.

Screw T (LA) is used to adjust idle speed. The main setting of the chainsaw is made at the factory during the final test. The carburetor, as a rule, is adjusted to supply a richer (than optimal) fuel mixture. Factory adjustment is necessary to keep the first hours of operation of the saw. Then (optionally) a more accurate carburetor adjustment is made.

We begin the adjustment by setting the idle speed, for this we turn the T (LA) screw counterclockwise, achieving a complete stop of the circuit at stable engine speeds.

For further fine adjustment, you need a tachometer and it is better to entrust it to specialists. especially since in most cases it may not be needed.

We begin the tool setting with screw L, then use screw H and finally screw T (LA).

We find the highest idle speed, for this, slowly turn the screw L in different directions. After finding the position of the highest engine speed, turn screw L 1/4 turn counterclockwise. If the chain rotates at idle, screw T should be turned by turning it clockwise until it stops.

Screw N adjusts the power and speed. Adjusting the carburetor to lean mixture leads to excess revolutions, overheating of the engine and failure of the piston chainsaw.

We warm up the engine of the chainsaw at idle for at least 10 seconds and turn the screw N 1/4 turn counterclockwise. Let the engine run for about 10 seconds. then check the maximum engine speed with a tachometer. If the maximum speed does not match the passport, the operation should be repeated. If the mixture is too rich, the muffler starts to smoke, when the saw is too poor, the saw squeals and overheats.

We finish the adjustment by setting the idle speed, as already described above. The idle speed is set correctly if the engine runs smoothly at minimum speed and the chain does not rotate.

A carburetor can be considered adjusted if the engine accelerates quickly and resembles a four-stroke full-throttle sound.

Technical and technological features

To increase productivity, operational reliability and durability, higher-quality materials are involved in the production of the chainsaw assortment. Also experience in the successful implementation of past developments, own design solutions.

Only by purchasing the original, you can get full confidence that the power and other properties of the chainsaw Husqvarna models 142 can be controlled with transverse, diagonal or longitudinal sawing of all types of wood with a diameter of up to 30 cm.

- These characteristics determine the suitability of the tool for the preparation of wood fuel, cutting the structure of timber, the formation of crowns of decorative and garden trees.

- The possibility of operating a saw with smaller and more comfortable tires for working in inaccessible places determines the suitability of the tool for the construction of wooden structures for special and general purposes.

- Working with a saw does not require professional qualifications; the necessary abilities are rapidly being developed in the process of the work itself.

Engine

Motor failure is one of the most common and time-consuming. This problem is manifested by such factors:

- Unbalanced idle.

- Does not start.

- There is not enough power, or the Husqvarna 142 chainsaw starts up and stalls as it starts to gain momentum.

Before proceeding with the repair of the Husqvarna 142 chainsaw, it is recommended that a complete diagnosis of the equipment be made to clearly identify the circumstances of the problems.

Structural advantages

Constant traction properties contribute to low-cost operation powertrain, economical fuel and consumables consumption. Comfort and safety of the instrument are ensured by the design of the case, comfortable configuration of the handles and balancing.

The list of additional amenities:

- easy start system;

- effective vibration damper;

- access to tuning points of units and assemblies;

- convenient placement of controls;

- the ability to work with alternative working headsets.

The reason why the Husqvarna 142 chainsaw does not start

If the Husqvarna 142 chainsaw does not start, there may be several circumstances. Of the more common, the following can be distinguished:

- Damage to candles. in order to realize whether a candle is working, it is necessary to turn it out and perform an inspection. In this case, if the porcelain insulator gave a crack, you see a burned or warped electrode, you should immediately change the candle. In addition, after working for several seasons, the Husqvarna 142 chainsaw asks for inspection of spare parts. Candles also produce their own resource, and to protect the work of the saw, change them to new ones.

- Carburetor clogging. during operation, evenly, fuel vapor settles on the internal walls, forming a sticky consistency that can clog the carburetor, preventing the engine from starting. You will need to clean it with a special detergent. When repairing a Husqvarna 142 chainsaw, carburetor adjustment is always carried out with a warm engine and cleaned systems.

- Malfunction of the ignition coil. before you decide to replace this part, make sure that the candles correspond to the required technical condition.

Guaranteed operational safety and easy start

The risks of injuries in the event of an emergency are minimized due to the high-precision operation of the brake device, which is activated when the upper shield is slightly moved in the front direction.

Easy-start manual starter, booster pump and advanced electronic ignition guarantee a successful start powertrain in conditions of extremely low and high ambient temperatures.

Experts saw Husqvarna 142 is characterized as quite comfortable in work, productive, reliable and durable household tool that meets the requirements of modern technical and operational standards.

Information support

A detailed instruction manual contains information about the features of preparing the saw for work, maintenance, troubleshooting.

Read the same

The description of the most typical malfunctions will help to quickly eliminate the cause of the failure when the engine does not start or starts and stalls, and also does not develop full power.

The tool is characterized by established service. Spare parts and consumables are presented in a wide range. If necessary, the owner of the saw can perform a simple ongoing repair with his own hands.

Specifications

Model Husqvarna 142 features a tight layout, combined with convenient access to adjusting assemblies and filling necks. The 4.6 kg instrument is perfectly balanced, so it fits comfortably in the hands.

The ergonomic shape of the handles provides a secure grip for complex work. The built-in vibration protection system and low noise level contribute to high labor productivity and preservation of the operator’s working capacity when performing bulk work.

The principle of operation of the carburetor saw (summarized):

This unit prepares an air-gas mixture in a certain ratio. If this balance is not respected, then the operation of the internal combustion engine (gasoline engine) will fail. An improper mixture can be either oversaturated (when the amount of fuel in relation to air increases) or depleted (when there is more than enough air and less fuel).

- The air flow moves through a special channel, and the damper controls its speed;

- Opening the damper controls the amount of fuel and air;

- Gasoline and air flying through a diffuser are mixed and sprayed;

- The mixture formed as a result of this enters through the intake manifold into the combustion chamber (cylinder).

Powertrain

The saw is equipped with a 40.2 cm3 two-stroke carbureted air-cooled engine and 2.6 hp. The power unit is characterized by flexible traction parameters, optimal fuel consumption, easy start, simple maintenance and a long overhaul life.

The fuel is a mixture of gasoline and two-stroke ICE oil, which enters carburetor from an internal gas tank with a volume of 410 ml.

In the design features of the power unit:

- a crankshaft made of forged steel;

- wear-resistant chrome coating of the cylinder liner;

- piston group with two compression rings and a working resource increased up to 5 years;

- simplified access to the air filter;

- reliable and durable ignition system;

- best in class japanese carburetor Walbro

Built-in primer. the pump provides a quick start of the engine, regardless of the ambient temperature.

Headset

This assembly consists of a 15 inch removable guide rail, a cutting chain in 0.325 inch increments. The kit also has a drive sprocket and tensioner. It is possible to install alternative kits of a smaller size, which more closely meet the requirements of the task.

Chain lubrication eliminates overheating and accelerated wear. The system includes an oil pump with adjustable capacity, into which the working fluid is supplied from an integrated tank with a capacity of 200 ml.