Adjusting the carburetor of a brushcutter

Adjusting the carburetor of a brushcutter is a process that must be mastered for the full operation of the grass trimmer. Grass trimmer is a completely uncomplicated device, which can break down only in a few places and require mechanical repair or replacement of the part. Adjusting the float-type brushcutter carburetor may require some fine tuning. Nuances due to the model and the specifics of its functioning will allow to ensure a clear mode of mixing and feeding the fuel mixture.

Champion lawnmower carburetor, how to adjust? It is just a float-type grass trimmer. a common option, designed to mix in the prescribed proportions of air and fuel. The main problems encountered with the motor are roughly similar to the malfunctions that plague the carburetor in a car:

- The engine can shut down as soon as you start it. The reason is that not enough gasoline is being supplied. This is called “poor” fuel;

- Excessive gasoline leads to incomplete combustion, excessive mixture density and uneconomical fuel consumption.

Important! Adjust the carburetor has different circumstances: a change in temperature, fuel octane number or type of oil, after winter or the end of the running-in period, load or spontaneous turning of the screws due to strong vibrations of the housing. Some owners prefer to tune the module before each use to make sure it works correctly.

How to adjust the carburetor on a chain saw

How to adjust the carburetor on a Husqvarna 137 chain saw? STIHL FS 38 grass trimmer is probably familiar to all fans of quality garden equipment. I do not know where there is a grid and where it is not for all companies, but Oleo-Mac does not have one, and Husqvarna has one. Flush. blow out and adjust carburetor, wash air filter. my first channel: free consultation preferably by Skype ork.or.

Lawn mower design and common malfunctions

It is easiest to give the lawnmower in repair, allocating a certain amount of money from the family budget, prompt and high-quality repair with their own hands is no less simple and convenient if you want to understand the design of the lawnmower and fix all the problems.

The mass and piece production of trimmers is based on the use of common technology, the typical design scheme consists of certain elements and parts, it is important to know them when carrying out independent repair work:

- the upper part. The basis of the entire construction, where all the important elements are assembled, such as the starter, carburetor and lawnmower engine;

- middle part. Hollow rod, inside it there is a rope that connects the motor and the gearbox, which drives the cutting line for the trimmer. In this part, there are mounts for weight distribution of the entire structure and a belt for fixing the grass trimmer on the belt of the person who uses the grass trimmer for its intended purpose;

- lower part. It contains the gearbox and cutting elements, which are hidden under a practical cover that protects the user. The cover provides an increased level of safety by preventing coarse debris, stones, and glass from getting into the person while working with the lawn trimmer.

The most common and common self-repairable problems with the machine are

- engine malfunction, due to which the lawnmower does not start and does not work;

- increased vibration of the brushcutter boom, making it difficult to use it for its intended purpose;

- increased overheating of the gearbox, its accelerated heating during operation;

- slow and weak functioning of the cutting line at insufficient RPM;

- Blockage of the starter grid, causing the engine to overheat and stop working;

- rapid and frequent clogging of the carburetor due to the use of low-quality fuel;

- clogging of the air filter if you do not take care of the unit.

All of these problems can lead to the fact that the device will lose its ability to work, before ordering the necessary spare parts for the snowplow, you should conduct a visual inspection and diagnosis of the device.

Particular attention should be paid to individual parts and units of the device, to check them you do not need to go to a professional wizard, a set of diagnostic measures will help your own hands to identify the cause of the loss of performance.

When adjustment is necessary

Adjustment of the carburetor is necessary in the following cases:

- new engine has been run-in (4-5 liters of fuel mixture was used);

- The fuel composition (oil and gasoline brand) has changed;

- the weather has changed (it is hot, cold);

- air rarefaction has changed (concerns mountainous areas);

- after long storage;

- The load on the engine has increased (after changing tools, etc.).д.);

- The adjustment screws have unintentionally come loose due to vibration;

- fuel consumption increases, carburetor overflows fuel;

- the spark plug electrodes quickly become soiled (if the fuel mixture is prepared correctly);

- The engine starts and immediately stops or revs up poorly;

- there is no petrol in the cylinder;

- large amount of exhaust gases.

Problem with inlet adjusting lever

This problem can occur if the regulating lever is installed incorrectly or if it is bent before installation. As a result, the contact surface becomes misaligned, which disturbs the auxiliary fuel supply.

Fuel pump problems

A frequent malfunction that “haunts” a fuel pump is a deformation of the pump membrane. the diaphragm does not seat properly and the pump passages are not sealed.

Causes of membrane deformation may be the following:

As a result, damage to the diaphragm reduces pump performance, and as a consequence:

- the mixture is depleted;

- the engine can no longer be started;

- there are interruptions in the work of the motor;

- the piston is damaged.

to remove the blockage, you must disassemble the carburettor and clean the diaphragm.

Operating principle

Carburetor. a module of the power system, in which liquid fuel and air are mixed before being fed into the engine cylinders. Depending on the tool and its mode of operation, mixing and feeding is adjusted accordingly.

Brush Cutter Repair | How To Set Carburetor Tuning

The design of the lawnmower carburetor is the same in almost all cases. It belongs to the category of float devices. The latter provide stable parameters of ready mixes.

- The air enters the body of the tube with an air damper. The latter increases or decreases the air flow depending on its position.

- At the section where the gasoline orifice is formed, the tube has a constriction. a diffuser. Here the flow velocity increases.

- Fuel from the float chamber flows through the nozzle into the tube. Lawn mower carburetor setup. Adjusting the carburetor of a Kraftec lawnmower. The level of the float determines the quantity of fuel. Since the pressure in the chamber is normal, and in the tube is low because of the greater rarefaction of air, the gasoline is sucked through the nozzle.

- Accelerated air flow picks up fuel and atomizes it, forming air-fuel mixture of required density.

- The mixture is drawn into the cylinder through the tube.

The more the air damper in the tube is open, the higher the airflow density is, which means more fuel is getting into the cylinder. Tuning the lawnmower carburetor comes down to setting such a ratio of the flaps, at which the density of the fuel mixture becomes optimal.

Lawn trimmer carburetor for grass

The carburetor for grass trimmer is one of the most important units of the unit, which is responsible for the fuel mixture. If the machine is used incorrectly, the element can be damaged so that the brushcutter can no longer be operated without repair. To repair a garden tool, you need to know about its construction, how it works, and how to adjust it.

Peculiarities of design and principle of operation of the lawnmower carburetor

Structurally, carburetors from well-known brands and Chinese manufacturers do not practically differ.

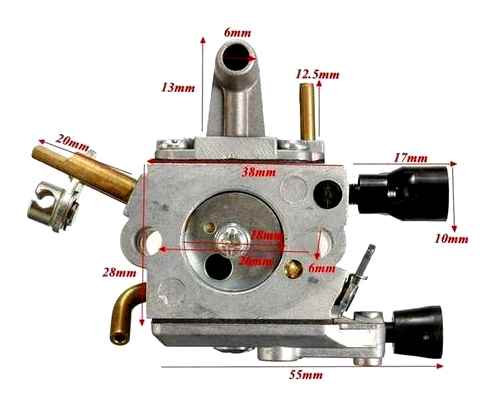

The structure of the brushcutter carburetor consists of the following elements:

- priming pump;

- Atmospheric diaphragm tuning systems;

- Primer, which facilitates the start of the motor;

- Cold stroke system;

- Elastic double-valve plate;

- Dosing system with a rotating rotor;

- Throttle valve.

The model functions as follows:

- From the air damper air goes to the tube, which increases or decreases its flow;

- In the area with the fuel mixture opening, a narrowed area. the diffuser. Air moves faster in this area;

- The fuel mixture flows from the float chamber through the nozzle into the tube. The float determines the amount of fuel;

- The intensified airflow picks up the fuel and atomizes it. Creates an air-fuel mixture with sufficient density;

- Draws the mixture into the cylinder through a piping.

The concentration of air flow depends on how ajar the air damper is open, respectively, more fuel is fed into the cylinder. Adjusting the carburetor of brushcutter is to set the correct ratio of the flaps to achieve the optimum consistency of fuel mixture.

Read also from

How much is the brushcutter binding?

Landlord: grass trimmer trimmer fishing line for grass trimmer Garden trimmer today. It’s a very common tool. But without a line for the trimmer for grass, it is impossible to work with it. There are quite a few lines. Experts consider the most reliable of them nylon. Types of trim tabs trimmer fishing line for grass trimmer differs in its cross section. But not everyone knows which section is needed for the tool. The most universal cord. is a line for a trimmer with a round

Read also: Instant Food in a Multicooker

How to Properly Install the Cover on the Grass Trimmer

With the advent of summer, many owners of homestead plots are concerned about the question, with the knitted then, how to put a knife on the trimmer for grass. pressing are the questions of why and when it is purposeful to substitute the line for the trimmer on the brushcutter with a stronger cutting element. In our article, we will try to break down all of the above and give useful tips for dacha owners. A grass trimmer with a blade installed is best used for

How to Properly Wind a Line for the Trimmer on a Gas Trimmer

Despite the fact that the garden equipment is used for quite some time, for some owners of private houses, it is still a novelty. For this reason, there are often questions that, how to correctly wind the line for a trimmer electronic or gasoline trimmer for grass. It’s really an easy operation, but our customer still needs to perform it well in order to achieve a proper result.

Increased fuel consumption and quick formation of carbon deposits on the lawnmower plug with a properly prepared fuel mixture suggest that the carburetor needs to be adjusted. Here’s how to adjust trimmers with carburetors that have a single screw for adjusting the fuel supply.

Main problems and malfunctions of the carburetor.

Strainer. There are most often two problems with this element:

To find out what is causing the problem unscrew the fuel filter cap to remove the strainer. If it is just a dirty element, it can be washed in petrol or flushed out.

If there is visible damage to the strainer, it is necessary to put a new one. There may also be damage to the fuel supply pipe (when repairing it, it is a good practice to check this element).

The carburetor starter mechanism does not work in most cases due to blockages. You should use acetone or the same gasoline for flushing.

Blowing out parts of a clogged carburetor with compressed air is an acceptable and convenient repair practice.

Throttle body, carburetor component bundling places, inlet or outlet piping. all of these parts are subject to depressurization. You can check for sure in a primitive way. smear soapy foam on the problem area.

How to adjust the carburetor on a chain saw

Before adjusting, the filters must be thoroughly cleaned according to the maintenance in the manual.

Further adjustment of the lawnmower carburetor with your own hands is performed by adjusting screws. There are three of them in total:

Right (L). adjustment of the fuel mixture for low rpm.

Need to find the maximum idle RPM. To do so, turn screw (L) slowly to the right and left.

To adjust the blade, turn the screw a quarter of a turn anti-clockwise.

Lower screw (T) is responsible for adjustment of the engine at idle speed.

For the correct adjustment exactly the idle speed is characteristic:

- steady operation of the cold engine;

- not overdrive revolutions of the hot engine;

- for the trimmer head a large RPM margin;

- stable operation of the engine during changes of position (sudden raising or lowering of the blade).

Left (H). adjustment of the mixture at high revolutions. (The screw is adjusted last).

The left screw (H) is responsible for general regulation of maximal revolutions, engine power, temperature and petrol consumption.

Adjustment of the lawnmower carburetor with the last screw is as follows:

- Open the throttle to the full, at the same time give out full throttle. Turn the screw clockwise until the speed drops (in this case, guided by hearing).

- Turn the screw as slowly as possible counterclockwise until the engine is uneven.

- Then turn it back just a little bit, barely hearing a steady, even operation.

- It is more convenient to consider the work of an experienced user for a more clear application of skills:

It is interesting that from the point of view of the author of the video, the setting (its correctness) is determined by the color of the candle, and not only by the revs and stability of the engine.

The correct adjustment of the carburetor with their own hands in this case. combustion of the fuel mixture without residue, the color of the candle should be light brown.

Adjusting the brushcutter carburetor in practice. video

NOTE. If you have a question, you can ask it in the Комментарии и мнения владельцев to the article below! Our experts will answer your question in the near future (1-2 days), sign up for a comment to be notified in time for an answer!

You can also ask a question on this page, then we will prepare a detailed answer (5-7 days), which will be located here!

Carburetor Adjustment Brush Cutter || Not Starting Brush Cutter Starting Problem

Hi! You have an excellent article, in general, the site is very interesting and informative. I wish you good luck and prosperity in your business. I have spent a lot of time researching automotive issues. Good luck)))