Before starting, I want to warn that I am a beginner, I have no answers to all questions, but I can tell you how to turn the process of making a knife into a pleasure. If you are burning with the desire to make a knife with your own hands, and you do not have expensive equipment, then here is a small list of materials that may come in handy. I understand that these are not the best materials, but it works, although it can cause a smile.

How to make a knife with your own hands, making a knife from improvised materials, at home.

Buy a piece of 5160 spring steel, about 1.80 pounds in weight, or so. Measure out 7-8 inches of length from a piece, or how much you decide. Take a new plate, not an old car spring. For reference. 1 inch. 2.54 cm, 1 foot. 30.5 cm, 1 pound. 0.454 kg.

Total, you spent 19.

Features of the choice of material and design for his first homemade knife.

If this is your first time making a knife with your own hands, then choose a simpler design. 3. 3 1/2 inches will be a suitable length for the blade, because you will have to use files when processing the blade. A straight blade without frills is easier to handle, and it is easier to work with a file in a straight plane. Choose a handle for the knife is simple, without a lot of fancy recesses for the fingers, and without a guard.

I forgot to add a couple more things to the list of necessary items: a cheap chisel, and a sufficiently large clamp, with which you will press the knife to the table or bench. However, if there is no clamp or bench, you can do without them. These purchases will add about 10 more to the total, but I bet you already have some of the tools.

You will also need a manual electric drill. Take it from someone for a while, as nothing will happen to her. You will only drill a few holes. Next, I will use pictures to explain my actions.

DIY knife, manufacturing process.

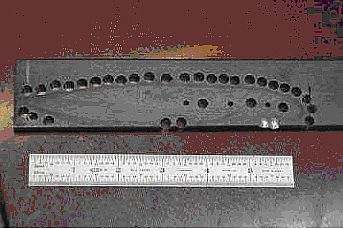

The silhouette of the knife is drawn with a marker, then I drilled a bunch of holes around the drawing with a 1/4 inch drill. You’ll have to work a lot with a hacksaw for all this.

Screw the knife to the bench, stump, or whatever you have there, and use a hacksaw to remove some of the metal around the handle. Do this so that you can then give the handle the desired shape with a file. This should be done first, because if you remove the metal around the blade, then you will not be able to attach it to the bench. The handle is processed first! As soon as it takes shape, remove unnecessary material, attach the knife through the holes in the handle, and take up the blade.

Ok, I forgot to add a 1/4 inch drill to the tool list. add it too. So, I drilled the entire silhouette of the knife. this will greatly facilitate the work of the hacksaw blade when sawing it. Then I unscrewed the workpiece from the bench, and re-attached it so as to remove excess metal from the handle. Drill 1/8 made holes in the handle for copper rods, and drill 1/4. so that it can be fixed to the bench when some part of the blade is processed.

Then I sawed the pen, and added a couple of recesses under the fingers, so that it held tight in my hand. After that, I processed the rest of the silhouette with a file, and sawed off the bevel. be patient, since working with a file takes time.

The formation of descents in the future homemade knife.

Well, now I have a knife blank, sawn with a hacksaw for metal and filed. It starts to take shape.

I marked the incisal edge with my 1/4 inch drill. He blackened the blade with a marker, and then began to move the end of the drill along the cutting edge so that a thin fishing line appeared. Turn the knife over, and repeat the same thing on the other side, getting two mowing lines, at a distance of about 025 to 030 from each other.

If these two mowing lines are too close to each other, then again mark the desired location with a marker. Then take the drill and move it up or down accordingly, repeating everything again. mowing line will be separated from each other by about 1/2 the thickness of a penny coin.

Then, using suitable wood screws, screw the knife to the top of the bench. Begin to file the plane of the blade.

The goal is to connect the scratched mowing line and the top of the knife edge. This will require a lot of hard work and patience. And maybe a few breaks.

Based on the article “How to make a knife with your own hands” (translation).

Scott Jones

Reading time: 3 minutes No time?

Ceramic dishes, like any other, have the property of deteriorating. To prevent this, you have to carry out regular maintenance. It is in today’s publication that the editors of HouseChief will consider how to sharpen a ceramic knife at home in order to restore its former sharpness. The listed methods will help to save and avoid buying a new product for cutting products.

Video: How to Attach a Knife To a Forza F340 Trimmer

Read the article

What are the special and different ceramic knife blades from metal

By the appearance of the cutting kitchen tool, it can be determined that the metal and ceramic specimens have significant differences. As for the second type of knives, they have an aesthetic design, are easy to operate, less dull (of course, if it is a quality tool).

However, the way to care for such knives is more serious. They must be stored in a specially designed stand or niche, used for sharpening only special accessories, do not cut hard objects, etc.

Speaking of knives with a metal cutting edge, we can distinguish that they are no less sharp, but they have an ultra-thin sharpened edge. These models will be cheaper, but dull faster than their ceramic counterparts. There are many cases when the handles of steel tools break off, which makes their use inconvenient.

What is sharpening ceramic knives at home: possible ways

Poor knife in contact with abrasive

Before you start updating the cutting edge of a ceramic knife, you need to take care of special grinding tools. After all, those that we used to use for steel blades are not suitable for this treatment. Consider the possible options for sharpening ceramics with your own hands.

How to sharpen a knife with a ceramic blade at home on one side

Some products can paint the surface of ceramics, which impairs its properties.

Single-sided knives are one of the most convenient and unique devices. They are sharpened only on one side and have incredible sharpness. Therefore, the approach to improving the properties of the blade is individual.

- First, clean the knife well and dry it. It is advisable to do all this with a soft cloth.

- Then, so that the edge remains perfectly sharp without chipping, sharpen one side with a slope, which corresponds to the factory blade wedge.

- Stitch the wedge-shaped face in smooth movements in one direction until burrs are formed.

- To remove the defect that has appeared, you should sharpen the opposite side slightly, but only until the notch completely disappears.

It remains only to bring the knife in proper form and it can be used. It is worth noting that single-sided ceramic knives are more suitable for cutting products of exact thickness. This is often practiced in professional activities, for example, in restaurants.

How to sharpen a ceramic knife from two sides at home

Do not use a ceramic dishwasher to clean ceramic knives

For bilateral edges two types of whetstone are used: coarse and fine-grained. First of all, the blade on both sides is grinded with a coarse stone, after which the final sharpening is done exclusively with fine emery.

How to sharpen a ceramic knife at home using various tools

When wondering how to sharpen a ceramic knife at home, you need to understand what tools are suitable for this. Indeed, if you use analogues for steel cutting tools, this can quickly spoil the working surface of the knife.

Special musat for ceramic

If you sharpen the knife slowly, the probability of missing the smallest millimeter is minimized

This type of garbage is easy to use, but requires special care and storage, as it has a similar ceramic surface for sharpening. Usually it has different abrasiveness on each side. Using this sharpener, it is necessary to correctly update the cutting edge. on this below:

- the knife should always be in the right hand, and the musat in the left;

- maintain the angle at 20 degrees when sharpening;

- you need to lead towards the handle of the grinding tool;

- these steps should be repeated 6-8 times.

Far it remains only to polish the knife with the help of special musat with a smooth ceramic surface. As a rule, with this method of sharpening, barbs appear rarely, so you can bring the tool to working condition in just a few minutes.

Use of bar and grindstone for ceramic knives

The whetstone should be stored separately from cutlery and in a designated place so that nothing will damage it.

A whetstone is a prepared product specifically for processing ceramic blades. It has two working surfaces: one with small crumbs, the other with a large one. The whole process begins with the processing of edges with coarse grain. At the end, the opposite side of the stone is used. Let’s consider in more detail the entire instruction.

- We place the knife blade perpendicular to the surface of the sharpener, while do not forget about the angle that the manufacturer provided.

- All movements are performed by lightly pressing the blade.

- If double-sided sharpening is necessary, all movements in the opposite direction should be performed.

- Do not forget to moisten the bar 30 minutes before processing the knife.

- Move along the entire length of the grinding surface.

Eliminate all physical effort and sharp turns of the cutting edge. Otherwise, you risk damaging the working side of the ceramic knife.

Manual sharpener for ceramic knives and the basics of its use

This type of sharpener works according to the elementary principle: only movement forward and backward is needed from a person. Everything else will be done by disks installed inside the working mechanism. Manual grinding tools are absolutely safe for ceramics, since they provide for placing the knife in grooves at a strict angle.

It is necessary to sharpen a ceramic edge repeatedly, thus without hurry. Then the sharpening result will be perfect.

Ceramic knife sharpener

The electrical appliance can be powered by mains or batteries. It updates the cutting surface in a few minutes, completely harming the knives. The working mechanism has two built-in wheels with diamond spraying. They begin to move when the engine starts. Grinding angle can be adjusted. All that is needed from the owner is just to insert the knife into the connector and wait for the end of the sharpening process. Therefore, the owner should no longer have a question than to sharpen a ceramic knife at home.

Using Diamond Paste

Chemical detergents should be used only if the knife is greasy, otherwise, it is enough to rinse it in running water

How to sharpen ceramic knives at home, except as a grinding device? An excellent alternative is considered to be diamond paste. The tool is quite effective and safe. However, it is recommended to use it only for the final sharpening, first you will have to use one of the above options. The product is sold in tubes, the composition includes diamond particles up to 5 microns in size.

The use of a special machine

The knife can be used right after sharpening

The sharpening machine is equipped with two diamond blades, which perform perfect grinding actions with respect to ceramic blades. During initial processing, a disk with an abrasiveness of 80 microns is used, and to complete the procedure, it should be changed to a less aggressive one, for example, 40 microns. For a more detailed acquaintance with this sharpening procedure, we recommend watching this video on how to sharpen a knife at home.