How to work with a power drill?

The main task when cutting baseboards is to cut the corners correctly. In rooms with right-angled corners, it is easier to saw baseboards: you just need to maintain a 45° angle when cutting. Before you cut the corners of the ceiling plinth, you need to apply an angle to the corresponding sections of the ceiling, and if its sides are close enough to the walls, then you can safely apply the plier. This device allows you to cut blanks of wood and other materials at a precisely defined angle. Nevertheless, before starting work, it is better to practice on rough blanks, to gain some experience.

And the process of cutting the ceiling plinth in the jigsaw looks like this.

- The skirting board is inserted into the mould.

- Its edge, which will touch the ceiling, should be pressed against the edge of the jigsaw.

- A wood hacksaw (for wooden strips), metal hacksaw or a construction knife (for foam strips) are inserted into the slots of the device.

- The corner is cut.

After processing 2 slats adjacent to each other to put them to the place of installation and check whether there are gaps between them. Small gaps (up to 2 mm) can be corrected. The EPS skirting board ends are adjusted with a knife, and the wooden product edges are sanded with sandpaper, wrapped around a joist.

The composition and characteristics of the material

To understand how to properly cut a baseboard, you should understand its composition. It will help us choose the right tool and cutting technique.

- Styrofoam. The price and durability of this material is the lowest. But since we create a decorative ceiling decoration, the strength is not particularly required than the usual foam. To cut this material the most common knife is used.

Tip: Sharpen your knife well before use. This will avoid the presence of jagged edges in the cut areas.

Tip: The shallower and more frequent the saw tooth, the more even the edges will be. You can even use a metal blade.

Using an ordinary hacksaw blade

How to cut and install wall baseboard trim 45° cuts

- If the plank reaches both corners, then first trim the inner corner, and then the outer. It may turn out that after cutting the corner, the strip is not enough.

- As in the first case, apply to the ceiling, to mark the dimensions.

- The bar must be positioned so that it is pressed against the near wall.

- We hold it with the left hand and put the hacksaw in 45 degree position. the handle is close to the left hand.

- Cut at.

- Let’s put the second slat in the same way, but hold it with the right hand.

- The hacksaw becomes a mirror to the first option of trimming the baseboard.

- Cut it.

It is worth noting that the plane is useful to you only if all the angles in your apartment are equal to 90 degrees. When the corners are not straight, you have to use other trimming methods.

As we can see, it’s not at all difficult to cut a skirting board properly with a wire cutter.

How to cut a skirting board properly. A diagonal plane for cutting corners

Advice how to cut a skirting board at 45 degrees on the network now more than enough, the only bad thing is that most of them are given by people who have never done it. Next, from the point of view of practice, I will tell you how to trim the baseboards on the corners with your own hands in 3 variants, and you will learn about both traditional ways, and folk universal recipes.

The science of how to properly trim ceiling baseboards in the corners is not as complicated as it may seem.

How to properly cut the corners of wooden baseboards

The most difficult and responsible process in the installation of floor and ceiling baseboards is the joint of the corners. Accurately and neatly performed work makes the interior beautiful, complete and coherent. To create a beautiful and correct joint, you need to know the trimming technique and installation methods.

So different skirting boards for your home

Currently, the construction market presents baseboards made of different materials. wood, fiberboard, plastic.

Wooden skirting boards are considered traditional. They have long been used for plank, parquet and laminate flooring. They differ in relief or smooth outer surface, many models have special cable channels. Mounting is done with self-tapping screws, nails or glue for fixing to the floor.

When installing with self-tapping screws, it is important to choose the right screw design, the tip of the screw must have a cutter, otherwise you will have to do pre-drilling, which is your time.

Products are durable, environmentally friendly and safe. Can even be used repeatedly, dismantled and reinstalled with new floors.

Baseboards always need to be painted with oils, varnishes or enamels. This is a prerequisite for their flawless appearance, long service life and variety of shades and colors to suit your interior.

Wood of valuable species. this is not a cheap material, which affects the cost of the final product. You will need special tools to trim the corners here.

Wooden skirting board

Plastic skirting boards stand out for their simplicity and convenience. They have an elaborate design with cable troughs. To form corners, hide joints, masking places of attachment there are corners and plugs. They are quick to install and are available in a variety of shades. No need for painting or puttying, harmonizes well with any finish.

Plastic skirting board

Skirting boards made of fiberboard have an attractive appearance, protected from dust and dirt, do not fade. They do not require any special maintenance, they are easy to install. When trimming the edges of such a skirting board, remember its fragility, and work carefully.

Wood-fibre board skirting boards

Skirting boards made of any material are available in many color variations. So it will not cause any difficulties to pick it up to your interior. Often the color of the profile is matched to the color of the floor or the trim.

Trimming the edges of skirting boards made of different materials is not particularly different. The only difference is the density. That’s why wood is quite easy to work with.

Tools required for work

- Chisel. a special tray, consisting of three surfaces. Its sides contain special slots, located at certain angles to the axis. They guide the blade of the hacksaw at the desired inclination when cutting.

- A pencil, a erasable marker, a tape measure.

- Knife, fine-toothed hacksaw, or a good mitre saw. Plastic skirting boards can be cut with an ordinary sharp knife or metal hacksaw.

- A sandpaper, sanding of a wooden skirting board for painting is necessary.

- Fixing elements, self-tapping screws, nails, dowels.

- Hammer, electric screwdriver.

Chisel

Before starting work, you must first calculate the required number of skirting boards. For this purpose, the standard length of the product (2.5 or 3 meters) is multiplied by the perimeter of the room and a 10% reserve for trimming is taken. You also need fasteners and plugs for installation.

How to properly cut the corners of the ceiling plinth

The ceiling plinth can be made of wood, plastic, foam plastic. The last option is the most common. It has an affordable price, many varieties and easy to work. To cut it a sharp knife is usually used.

Before you begin, you need to cut the material according to the perimeter of the room. You can pre-draw a diagram on paper, noting all the corner joints.

Technology for trimming baseboard corners

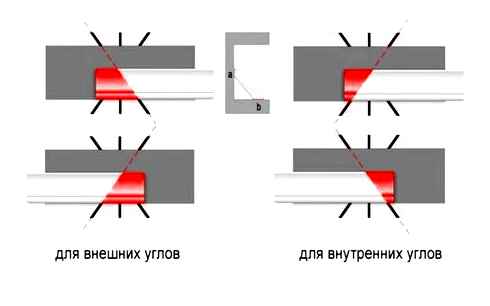

Trimming baseboards in the mortiser. Trimming technology

- The right side strip is inserted into the notch from left to right. The back part, which will be attached to the ceiling, lies on the bottom.

- The profile is pressed firmly to the tray and cut at a 45º angle.

- From right to left another strip is put and cut in the same way.

- Corners of cuts are docked in a place of fastening and corrected with the knife (for foam plastic and plastic).

Cutting out the “inside” corners

The standard room has a rectangular shape with 90º corners. In fact, such perfect corners are quite rare and are only a dream of the installer. If you are lucky, the procedure of cutting the corner of the edge of the skirting is as described above, it is very easy to do it with a facing.

Remember which side the skirting board will be located when trimming. You can use putty to create a perfect corner for wooden surfaces or a joint, but a good carpenter will never do this, but will simply file evenly.

Cutting an inside corner

What is necessary to form an internal angle that is not equal to 90º

- It is necessary to make a preliminary marking on the floor with a pencil. On both sides the profiles are attached in turn and their borders are marked. Thus a rhombus is formed in the corner. Its diagonal will be the cutting line.

- We enclose the bar to the obtained figure and we put a diagonal mark.

- Connect the mark and the corner of the baseboard. This angle will be the cutting line.

- The received side edge needs to be painted in the color of the skirting board.

If the inner corner is cut with a small exaggeration, it will allow you to make the most accurate fit. Sometimes a plug is inserted into the plastic or foam in the final stage of the joint and a nice, neat corner is obtained. In the wooden products, the joints are simply trimmed carefully, puttying is the destiny of the incompetent.

Cutting out the “outer” corners

If the outer corner is standard and equals 90º, then the stages of installation are similar to the internal one. When carrying out works it is necessary to remember the location of the trimmed strip. But if it is not standard, we will have to sweat.

Outer corners

A non-standard external corner is done as follows:

- We put a profile to a wall and draw all its inner and outer edges with a pencil.

- Similar manipulation is carried out with the other molding.

- By analogy with the inside corner we get a rhombus. Only in this case it is on the outside. The diagonal of the resulting figure is the sawing line.

- In the jigsaw, we cut corners with a saw.

- Grinding the edges and assembling.

At the final stage, it is necessary to finally fix the skirting board along the perimeter with self-tapping screws or liquid nails.

Atypical configurations of rooms and corners

Some rooms have original, atypical configurations. In such situations, it is quite difficult to beautifully install the baseboard. Because corners are often exterior and interior at the same time. There are also rounded options. All of the above techniques do not work here.

If there is a round corner, the skirting board is cut into several (usually 4-5) pieces. A neat corner is made of parts with the use of plugs. The plinth is fixed with liquid nails or self-tapping screws, with or without plugs

Custom inner corner

Cutting corners for a ceiling or a floor requires preparation of necessary tools (depending on material). The work requires attention and diligence.

Custom external corner

All necessary materials for such works can be bought in our online store LesoBirch. We can also arrange delivery within Moscow and St. Petersburg.

The photo shows the junction of baseboards in the inner corner of the room.

The floor plinth is represented by a very wide range of products:

- PVC foam, plastic, available with and without cable channels for wiring.

- Wooden, made of different types of wood, solid or laminated; Installation of wooden skirting is no different from the installation of plastic trim.

- Metal, steel and aluminium, with cable channels and flat.

Plastic or metal products come with various joints and endings, with which it is easy to install. So almost never a question of how to cut plastic skirting boards at the joints. Wooden ones do not have such connecting elements. They must be trimmed for a beautiful connection.

Important. Wooden fillets prior to installation should be kept in the room for which they were designed at least one day. As with any wood product, it must adapt to the temperature and humidity of the air.

Let’s consider how the trimming process is carried out.

To connect the slats when bypassing the corners, the question arises how to cut the baseboard at 45 degrees? It is very simple to do, but it is desirable to have a special device called a plier.

No matter whether a professional tool made of metal or simpler versions of plastic or wooden devices you buy, they will all help to perform this work with your own hands without too many problems.

In this case, the price of a professional device is justified, if you often have to do this work. For small amounts of work, you can be limited to simpler and cheaper options.

Important. The height of the walls at the machine should overlap the height of the trimmed slat to get an even cut.

Fixture for sawing moldings, arrows show the technological slots for work in accordance with the instructions.

Internal

- prepare two pieces of the river for the joint;

- take the first piece, insert it into the unit from right to left so that it lies on the base as on the floor and leans against the far wall of the fixture, as against the wall;

- sawing the product from the left end, passing the saw through the holes number 1;

- the second piece is inserted into the device from left to right, precisely observing the orientation on the floor and the wall;

- saw it from the right end, passing the saw through the hole number 2.

Outside

- prepare two pieces of skirting board for the joint;

- Take the first piece and insert it into the tool from right to left so that it lies on the base. as on the floor and leaning against the farthest wall of the fixture as against the wall;

- we saw it from the left end, passing the saw through the holes number 2;

- the second piece is inserted into the tool from left to right, precisely following the orientation of the floor and wall;

- we saw it from the right end, passing the saw through the slots at number 1.

Advice. At joints along walls it is desirable to cut skirting boards at 45 degrees, as a result of such joint the joint place will be practically not visible. The laths to be trimmed are inserted into the tool from both sides, as if leaning against the wall, the trimming occurs through a single technological gap. First, one is cut first, then the second is inserted towards it, the first is pushed aside from the gap, and the second is cut through.

We’ve figured out how to cut a skirting board, as you can see this is not such a complicated process.

How to cut a ceiling skirting and a floor skirting and join correctly

Mounting moldings on the ceiling and floor is the shortest and seemingly easiest stage of repair. But many of you probably had to spend at least an hour trying to cut those 45 degrees. The only exceptions are the lucky ones with a technical turn of mind and those who were geometry-savvy at school.

Today we will tell you how to cut the corner of the ceiling plinth and floor, without resorting to complicated calculations. You will see that it is not at all difficult work, which can be managed in a short time.

Since most rooms are rectangular, when installing the skirting boards are made right angles to the walls (90 degrees). It is necessary to cut the skirting boards at an angle of 45 degrees so that when joining the ceiling skirting boards, a right angle is formed.

Important! The inclination of the mowing line will be different depending on whether we are making an inside or outside angle.

If the ceiling skirting is cut correctly, it is connected in a perfect corner without gaps.

How to cut baseboard corners correctly: consider their type

To cut a corner, you must clearly understand the order of installation of each element. The order of operations depends on whether we are making an external or internal mating. Attention deserves not only the direction of the cut, but also the spatial arrangement of the element. So when thinking about the order of the work, it is necessary to know what kind of angle we are talking about.

Trim an inside corner

To cut an inside corner for a plastic baseboard flooring, proceed in the following sequence given in the table.

When forming an inner corner on the ceiling plinth, the direction of the blade does not change, but the element itself is applied to the inner side, and the lower part should be placed on top.

Sawing an outside corner

Sawing the outer corner is performed in a slightly different sequence.

Attention! Cut the ceiling by analogy with the internal.

How to fit a corner more or less than 90°

No matter how versatile the plinth, it is oriented to form a connection with a standard size of corners. If the junction is made at a different degree, difficulties may arise. Watch the following video to learn how to fit the junction in this situation: