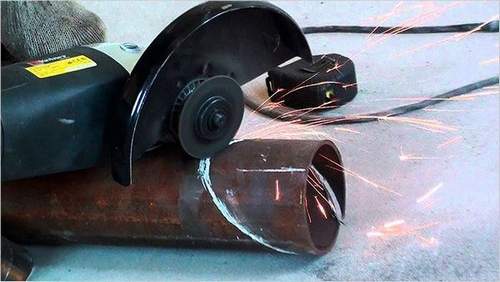

When working with construction or plumbing tasks, you need to know how to smoothly cut a pipe with an angle grinder. In the article, we will consider quick and easy ways, how to correctly cut the pipe with an angle grinder, so that the result is perfect.

Pipe cutting at an angle of 45 and 90 degrees

If you need to cut the pipe at an angle of 45 degrees, which is often required when laying water, heating pipes. Often used steel, cast iron pipes, which have a cylindrical shape. In installation works, rectangular or profile pipes are used. However, the angle grinder should be correctly cut into the pipe so that it can then be connected easily. Therefore, the pipe should be carefully marked.

Some masters try to mark the place of the cut with a tape measure, but we warn that the result is most likely to turn out negative. And for a positive result, consider the following recommendation of professionals.

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe where you plan to cut it straight. The edges of the paper should absolutely coincide with each other. And the side of the paper that was closer to the end of the pipe was perpendicular to the axis. Then, in a circle, mark the cut line.

If you want to cut exactly at an angle of 90 degrees, then solve the problem quickly with the help of paper or masking tape again. Wrap around the pipe so that the ends match. Make a smooth marking and saw off.

How to cut a profile pipe evenly?

Masters advise using a square when cutting a profile pipe. To do this, apply the square in turn to the sides, and smoothly rotate and apply marks. After actions, fix a pipe and cut. Prepare yourself a template that will come in handy in the future and save time. It is better to produce an action with an angle grinder, so the cut will be smoother.

How to cut a cast iron pipe?

Video: How to Cut a Profile Pipe Angle 45

When working with a cast iron pipe, keep in mind that this is a fragile material. Therefore, we will introduce a method by which it will be possible to cut such a metal without damage.

Before starting work, make notes for the cut, as in the work with steel pipes. Place a wooden beam for support. Walk the angle grinder around the circumference of the pipe, making small cuts. Then take the chisels, insert into the groove and apply a strong blow with a hammer. Keep in mind that bakelite cutting discs are used to cut cast iron pipes.

If there is no angle grinder at hand to cut the cast-iron sewer pipe or other purposes, use a hacksaw for metal, chisels or special pipe cutters.

How to cut a gas pipe?

Cutting the gas pipe is a dangerous action, so it is best to entrust it to professionals. But if you are confident in the forces, then for cutting metal, take an angle grinder, welding, hacksaw, gas welding.

- Before work, shut off the riser with gas supply. Then release the rest of the gas from the pipe. To do this, set the gas on the burners and wait until it goes out.

- After the steps, cut. Using the welding method, the metal base burns out when exposed to high temperature. The result is fast and efficient. But remember that cutting or rooting gas pipes again needs experience.

Methods for cutting large diameter pipes

There are a number of reliable tools for cutting large diameter pipes, such as sewers. Next, we consider some of them in detail:

- angle grinder is an inexpensive and affordable option, but is considered not the safest in working with such materials. Once you decide to use this method, then be careful and use protective equipment.

- A roller machine (pipe cutter) is such a tool adapted for such manipulations. The device is attached and removal of material begins. The clamping force is adjusted using mechanical devices. It is important to note that the models of the machine differ in shape, therefore, before using, consider the ratio of sizes with the pipe.

- Gas cutting is the most popular option for cutting larger diameter pipes, sheet metal. The cut is due to the action of a high intensity flame, the metal melts and exits the cut zone with a gas stream. This method is convenient and effective.

How to cut the pipe along correctly?

A quick way to cut the pipe along using an angle grinder:

- Focus on markup.

- Use for this case a masking thread that has found distribution when marking walls.

- Before starting work, fix the pipe and with small movements, carefully saw the pipe.

- Better not be in a hurry, but gently and slowly process the parts of the pipe, so the cutting disc does not come off the marking lines. Remember safety precautions.

How to cut thin-walled pipes?

Thin-walled pipes are made of non-ferrous metals: aluminum, copper. Such work should be done delicately, since there is a high probability of material deformation. For cutting use fillers, for example, sand. Actions can be carried out using an angle grinder, a special machine.

Summing up, we emphasize, that cutting metal pipes is a complicated process, but every interested craftsman can strengthen it. Using the advice of professionals, you can easily cope with the cut of pipes of various sizes and materials. Also do not forget to process the edges of the pipes after cutting with a file or sandpaper. And the most basic thing that you should remember when starting such an action is safety. When starting work, wear a special suit (casing), mask or goggles. Hands should be protected from sparks, so use tight gloves.