Running glass cutting at home

A lot depends on this stage, and the preparation process itself depends on which glass you decide to use for cutting. New glass, bought specifically for the goal, just wipe it, and it is best to use the old newspaper for this (this will avoid divorce and settlement of small villi). With the former, the material will have to work, spending much more effort. Firstly, it must be thoroughly washed, using special means to wash the glasses. Secondly, degrease with a rag, moistened, for example, in kerosene and, finally, dry in a closed room in order to avoid dusting to the surface.

In addition, the preparation of glass involves its cutting. As you know, you are unlikely to be able to achieve absolutely no.free production when working with glass, especially if you plan to get a product of a not quite correct geometric shape. However, the exact calculation will lead to a reduction in possible waste to a minimum. At this stage, a more rational solution would be to combine the longer side of the glass with the long side of the workpiece. Keep in mind that the resulting scraps should not be thrown away, they can be used in the future to create new products.

Turned glass cutting instructions

The high strength and hardness of the surface determines that during cutting, quite serious problems can occur. When considering how to cut off the hot glass, attention should be paid to the points below:

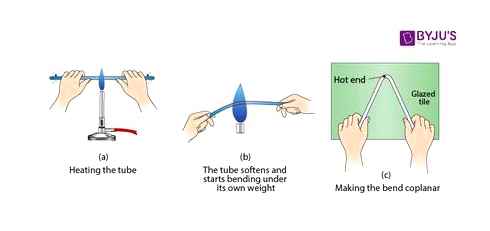

- Preparation of the workpiece is carried out by annealing. This technology involves uniform surface heating. Due to this, the voltage is eliminated, which is formed inside the material at the time of its hardening. Due to such a voltage, it becomes much more difficult to achieve the required size.

- The annealing process provides for water heating to a certain temperature, after which the workpiece is lowered into it. It is worth considering whether the car glass or decorative use should be at different temperatures, it all depends on the brand of the material.

- Redeeping glass exposure time in water can vary significantly. In some cases it takes about an hour, the most difficult execution options are withstanding for a month.

- After reaching the required temperature, the product is slowly cooled. The work is carried out slowly, due to this, the likelihood of even the smallest defects is excluded.

- As soon as the surface temperature has decreased, you can put on glasses and cut it when using glass cutter. Similarly, you can cut the glass for the phone.

- Before cutting, marking should be carried out. Even and accurate lines are achieved when using a square and other measuring devices.

- Press on the material with average force, since high load can lead to serious defects. The cut is carried out quickly, it is not recommended to re.try to make a fishing line for a trimmer due to the fact that such actions can lead to the appearance of a split and cracks.

- At the time of cutting, you should be careful, since the fishing line for the cutting trimmer will not work out again. After receiving the required mowing fishing line, a rod is placed under it, the product is divided into two parts with a sharp push.

With careful work, you can get a quality cut. You can finish the end surface with a grinding stone.

Running glass cutting at home

Glass is considered one of the most common materials. To increase its strength, hardening technology is used. After such a procedure, the degree of processing of the material is significantly reduced. When considering whether it is possible to cut hot glass, we note that only with the use of special technologies can the appearance of a defect be avoided. Today, cutting of hot glass can be carried out at home, for which a variety of tools are used.

Properties of hot glass

Before the processing of hardened glass is carried out, you should consider its basic properties. These include:

- The structure is characterized by high mechanical strength. Due to this, they can be used in glazing balconies and loggias.

- Strength and hardness allow the use of material in the manufacture of furniture and other products.

- To improve ordinary glass, heat treatment is carried out in a special furnace. Heating the medium is carried out to a temperature of 670 ° C.

- The indicator of thermal resistance increases significantly. In the manufacture of various devices that are operated at elevated temperatures, hardened glass is often used. When heated, the hardness indicator remains unchanged.

As the results of the studies are shown, the hardened glass indicator is 7 times greater than that of the usual.

That is why it is quite difficult to damage the material and conduct its machining.

How to cut off firewall

Glass is a very popular material that is used to build completely different structures. It depends primarily on the physical and chemical properties of this substance.

Today, glass are very popular that can withstand the effects of high temperatures for a long time without losing their main properties. You can learn more about heat–resistant glasses on the website https: // spark-decor.com.ua/ru/ogneupornoe-steklo.HTML.

Main characteristics

Fire.controlled glass is a material that differs from ordinary substance only by resistance to high temperatures. These products can be operated in conditions where this value can reach about 1 thousand. degrees.

In production, such glasses are obtained using additives in the main composition of special refractory joints, for example, AL2O3, B2O3, etc.D. This allows you to develop not only heat resistance, but also heat resistance.

At the same time, these characteristics directly depend on the thickness of the product, the higher it, the better it will tolerate the exposure to the temperature.

Heat.resistant glass can be divided into several main groups:

- Class E. This type of product is used in protection against hot gases and fire. To melt only with prolonged heating.

- Class 1. Such glasses are used to protect temperatures.

- Class r.

- Class w. These glasses are not used as protective material.

It should be noted that refractory products are somewhat different from tempered glass. The latest products are very easily crumble when impact and are not able to withstand high temperature.

Preparation of glass for cutting

A lot depends on this stage, and the preparation process itself depends on which glass you decide to use for cutting. New glass, bought specifically for the goal, just wipe it, and it is best to use the old newspaper for this (this will avoid divorce and settlement of small villi). With the former, the material will have to work, spending much more effort. Firstly, it must be thoroughly washed, using special means to wash the glasses. Secondly, degrease with a rag, moistened, for example, in kerosene and, finally, dry in a closed room in order to avoid dusting to the surface.

In addition, the preparation of glass involves its cutting. As you know, you are unlikely to be able to achieve absolutely no.free production when working with glass, especially if you plan to get a product of a not quite correct geometric shape. However, the exact calculation will lead to a reduction in possible waste to a minimum. At this stage, a more rational solution would be to combine the longer side of the glass with the long side of the workpiece. Keep in mind that the resulting scraps should not be thrown away, they can be used in the future to create new products.

The choice of tools

Glass with all its fragility is a fairly solid material. A traditional tool for cutting it is diamond glass cutter. As the name implies, the cutting tip of this device is made of diamond, the most durable and solid mineral.

Personnel professionals value their tools very much, to protect against premature damage, it is worn in a special case.

For homework, when the need for cutting glass occurs periodically, in one.time cases, roller glass cutter is more suitable. The tool is much cheaper than a diamond analogue due to the use of a solid alloy in the cutting part, and not an expensive diamond.

Roller

A special video is built in a roller glass cutting for cutting glass, which is made of a very durable tungsten.baltic alloy. The usual diameter of the roller is 6.6 mm, such a diameter of the roller allows you to cut glass with a thickness of up to 4 mm.

Diamond

Diamond glass cutter is equipped with small diamond, this diamond cuts glass. The hardness of the diamond is well known and therefore it began to use it for a very long time to cut glass.

Nowadays, as before, diamond glass cutter is considered the best tool to cut off the glass.

Oil

Not so long ago, a glass of glass cutter was replenished with oil windshield.

This is essentially an improved roller instrument, in the handle of which a tank for supplying lubrication to the roller is built. This lubricant binds particles that formed when cutting glass while ensuring smooth movement. This glass cutter can cut glass up to 20 mm.

A couple of acquisition tips

- Before buying any type of glass cutter, it is best to ask the seller to check the tool.

- In the event that the tool suits you, you can buy it, but buy the one that you were shown.

It is not recommended to buy an unexplored tool, since in most cases the cutting edge happens with a marriage.

Preparatory stage

When considering how to cut hot glass, you should take into account the preparatory stage. Thorough preparation allows you to achieve high quality. Running glass at home is carried out taking into account the information below:

- In the production of material, areas with internal voltage regions are formed. With rapid heating and cooling, such areas are redistributed. Inside the glass becomes more viscous in comparison with the outer layer.

- At the time of processing, the workpiece should be securely fixed. For this, a variety of devices can be used.

- The surface of the hot glass should be cleared of polluting substances. An example can be called oil or paint, which can significantly reduce the quality of processing.

In general, we can say that preparation for work is quite simple. However, without a special tool and equipment, it will not be possible to cut it.

Preparation of glass for cutting

The production uses laser cutting glass, requiring specialized equipment. This work can be done at home with your own hands. Particular attention should be paid to thorough preparation of glass and workplace.

The desktop should have a flat surface. This is especially important for working with sheets with a thickness of less than 4 mm. Under a sheet of material of greater thickness, you can put a sheet of cardboard or several layers of old newspapers.

Recently purchased glass does not require any preparation. It is enough to wipe it from dust using napkins or newspapers. Glass, which has already been used earlier, is cleaned using special washing tools. Before sharp, it must be degreased with alcohol, kerosene or any other means for these purposes. To prevent dust particles from getting, this should be done indoors.

It is recommended to determine the opening of the material in advance so that there are as few waste as possible. Large residues are put aside, since they can be useful in the future. It is necessary to prepare a basket or box for small scraps.

In the cold season, when the temperature inside the room is higher than street, the material due to heating changes its properties. You need to leave the glass for several hours in the room so that it is warming, and only then start working with it.

How to cut off glass at home?

Glass is considered one of the most common materials. To increase its strength, hardening technology is used. After such a procedure, the degree of processing of the material is significantly reduced. When considering whether it is possible to cut hot glass, we note that only with the use of special technologies can the appearance of a defect be avoided. Today, cutting of hot glass can be carried out at home, for which a variety of tools are used.

How to cut and cut off glass

Glass glass is quite durable and persistent material.

Despite this, there are still several options by which it is possible to cut it, among which:

- Hydroabraseic cutting. It is supposed to supply water to a special chamber under high pressure. In this case, the water mass and abrasive powder are connected, after which the water through the thin nozzle hit the processed surface. The speed of water supply is 3rd speed of sound, so it will cut any surface, including hot glass.

- Cutting with abrasive circles. The glass is attached to the movable table, after which the structure is lowered onto it on a similar corner grinder equipped with an abrasive circle. Water the cutting zone of lubricating-cohesive liquid with a low supply of the table of the circle, the work will bring the required result.

- Cutting with vacation. The glass is heated to the temperature indicators in which the hardening effect is removed. The material is cut and, if necessary, hardened again.

In theory, such an operation is quite feasible. Experts still advise to purchase ordinary glass, cut it into the necessary details and only then. Tax.

How to cut off glass at home?

Glass is considered one of the most common materials. To increase its strength, hardening technology is used. After such a procedure, the degree of processing of the material is significantly reduced. When considering whether it is possible to cut hot glass, we note that only with the use of special technologies can the appearance of a defect be avoided. Today, cutting of hot glass can be carried out at home, for which a variety of tools are used.

Diagnosis of products

Even despite the fact that at the moment they do not produce dishes from uranium glass, it can be found in our grandmothers. Just in the days of the USSR, yellowish and greenish vases, glasses, ashtrays, beads, interior subject were made. If such gizmos were lying around in the attic, you can consider yourself an honorary owner of a rarity. In order to make sure of the safety of such products, you need to use the UV lamp and the Geiger meter. An experienced collector knows that it is necessary to buy non.credit items only after checking them with a dosimeter. Possessing knowledge about the nomenclature and production technology, we can assume what level of radiation in a particular range of electromagnetic waves should be expected from various products.

Hardened glass is characterized by increased strength. It is used for glazing balconies, loggias and light openings. A variety of furniture and translucent structures are created from this material. If necessary, cut off the hot glass, you need to carefully prepare for this process, carefully studying all the features of the event.

First of all, you should study the properties of hardened glass. At its core, this is thermally polished material. For its manufacture, unlawed and polished glass sheets are used. Directly hardening is carried out in specially designed furnaces for this.

Cutting glass should be done on a flat surface with a bedding or leaf.

In this unit, the glass is heated to 680 degrees. At this temperature, partial softening of the material is noted. Next, rapid cooling of glass under the influence of uniform air flows is performed. First cools the surface layer. The internal during this is subjected to residual compression stress. It is thanks to him that as a result, hardened glass becomes so heat.resistant and mechanically durable.

How they make hardened glass?

The hardened glass differs from the usual in that after heating to a temperature, approximately 660 degrees it is quickly cooled, blowing cold air. It is the rapid cooling that underlies the process called hardening.

The features of hardened glass are:

- High level of mechanical strength.

- Safety. The material is divided into large, non.suffered fragments and is not a traumatic.

- High temperatures resistance.

Thanks to such characteristics, these materials are widely used in construction, in the production of windows or dishes, and automotive industry.

Важно! Есть у такого стекла и недостаток. Достаточно даже слабого удара со стороны торца стеклянного листа, и оно разбивается. Эта особенность используется дизайнерами (создание эффекта “битого стекла” при изготовлении тумбочек или столешниц). Как правило, стеклянные поверхности в этом случае располагаются в 3 слоя (целый — битый — целый).

The procedure for cutting

If the sheet has large sizes, then you should not try to cut it yourself. You can cut such a product without sad consequences only using a laser installation. Naturally, in everyday life it is unrealized. The only correct option for cutting heat.resistant glass at home is a second annealing glass. Consider it in more detail.

Work tools

Before cutting hot glass at home, prepare the necessary tools and devices. So you will need:

Важно! Таких печей было много в лабораториях НИИ, которые в 90-е годы закрывались буквально пачками. Если такой печи нет, можно заказать ее в кузнице (по типу кузнечной).

Важно! В лабораторных печах имеются встроенные терморегулятор и термометр.

- Set of markings (markers, squares, ruler).

- Grinding stones.

- Wood rods.

- Diamond glass cutter.

- Powerful fan.

- Water.

Важно! Работать нужно в защитных приспособлениях — спецодежда, очки.

Preparation, cutting hot glass at home

So, the only way to cut paved glass in domestic conditions is to make it less durable. Eliminate the voltage that appeared during hardening helps annealing. It is made according to this algorithm:

Gorilla Glass Vs Normal Glass Test At Home

Важно! Стекла разных марок имеют разные показатели вязкости. Кроме того, на продолжительность процедуры оказывает влияние размер листа. К примеру, длительность замачивания оконных стекол варьируется от 12 до 16 часов.

- Glass heating in the furnace to the temperature. For various brands, it is 470-680 degrees (Celsius). The necessary numbers can be found in the documentation for glass.

Важно! Компании-производители из США указывают температуру каления по Фаренгейту. Для перевода в привычные градусы по Цельсию надо воспользоваться формулой: ТФ=ТЦ х 9 / 5 32 или справочными таблицами.

- After the temperature has reached the desired peak value, remove and cool the glass. In this case, it is necessary that the cooling is as slow as possible.

- Upon reaching a glass sheet of room temperature, mark the cut line on it. After the manipulations, the glass ceased to be “safe”, “hardened”, but turned into a common.

- Drive the groove on a pre.marked line with glass cutter, and then beat off “all unnecessary” with careful blows. To make the incision more neat, put it under the “groove” made of wood.

- The glass is cut? Now is the time to harden it again. Repeat the first 2 points of the described technology exactly.

- The cooling process when hardening glass should be quick. To do this, install a powerful ventilation device in advance in the room. You can lower the air temperature to 10 degrees, but the ventilation installation is still necessary. You need to blow both sides of the sheet. After the temperature of the sheet has reached room, the procedure can be considered completed.

To process such fragile material as glass, a special cutting tool is required. Of course, glass cutters greatly simplify the cutting process, but you can cope with their work with other improvised objects. If you are faced with the need to cut glass, and there is no glass cutter at hand, we will tell you how to replace it.

Cutting heat.resistant glass

Necessary tools

As previously noted, the cutting of hot glass can only take place when using special equipment and tools. It is as follows:

- Special stove for processing hot glass.

- Thermoregulator.

- The square.

- Surface marking marker.

- Grinding stone.

- Special glass cutter.

- A rod with a diameter of 6 mm, made of wood.

- Eye. When cutting, shavings can form, which flies away from the cutting zone.

Using special equipment, you can cut hardened glass with accurate dimensions and high quality ends.

Why tempered glass randomly explodes

Basic pros and cons of hardened glass

Pros (dignity)

- Safety. In the case of destruction, it breaks up into small fragments that do not pose danger;

- Long service life;

- Mechanical strength. Fifetero large (204-up to 250 MPa) than ordinary glass strength for a break. Stability resistance. A bag with a fraction of lead weighing 45 kg when falling from a height of 1.2 m does not break the tempered glass with a thickness of 4 mm.

- Reliability;

- Attractive appearance;

- Excellent sound insulation;

- Resistance to vibrations and heating. Good resistance to high and low temperatures (their differences), which allows you to use it in glazing facades;

- The ability to create glass of different shapes and sizes;

With all the listed pluses and the optical properties of the glass of the past hardening remain unchanged.