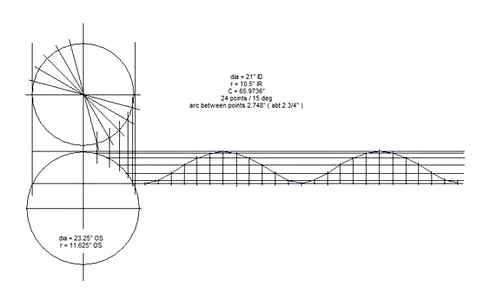

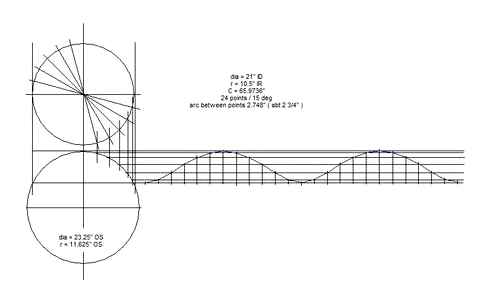

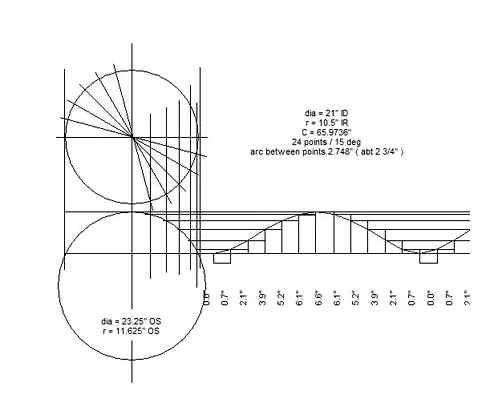

How to cut a corner grinder along a round pipe for exactly 2 parts

The first method is not entirely convenient, but quite accurate. Suitable in cases where you are in the tundra and there is nothing at all, except for a pencil and roulette. A couple of times I had to use it. The diameter of the pipes does not matter.

An important condition is the presence of a flat plane near the cut. It can be the edge of the pipe, a bell, a worn or a ground clutch, a seam or any other concentric circle.

Risk notes the place of the cut. We measure the distance from the risks to the flat plane. We rearrange the roulette along it and make risks in a circle using a given size. We get a circle from the crook.

Squeeze

Widely replicated on the Internet. We take a sheet of paper or a newspaper. We wrap the pipe so that the edges come together at one point. The edge of the newspaper. this is the plane of the cut. We carry out a pencil or marker. the markup is ready.

I do not see restrictions on the diameter of the pipes here. The only question is what to take for wrapping. For marking new pipes of large diameter, roll paper is suitable (for example, facsimile). For old rusty pipes, we made clamps of steel tape width about fifteen centimeters.

Materials can be different: painting tape, roll sandpaper, a roll of penofol.D. The denser and wider the tape, the more precisely the marking.

a way to divide (saw) a round pipe along exactly in half or in 4 parts

But how to make tags from two ends, and so that they, when cutting out the pipe along?

Thank you, signed up, you have an interesting channel, very sensible and just explain!

Until I cook.I use the method for marking and cutting bamboo)

I did not understand one end divided into 4 parts, and the second end how to mark it so that I got together with the first. Why do I need one marked end.

Thank you, very useful and instructive information.

Signed, watched a really useful video! I got the question of Ka to cut into two parts a pipe of 110 mm x 4000 mm along to make the drain zloba in a bitone.billed floor in front of the drainage house, I began to think how to prevent the “screw” idea with the corner came to the stat! Thank God there is 35×35 corner 4 meters.))))) Vidos useful thanks✋

Actually showed two ways. Just the second method. three different improvised materials for measurement, and the principle is one. Make a turn and put tags. You can still take a stick, for example, to crank it around the pipe. There will be a “fifth” method that is a mirror reflection of the “method” with the surface of the table. Only here they turn the table around the pipe itself, and not the pipe roll on the table. ) But a method with tags. worker.

You have a little reservation when marking with paper. The distance between the marks is not divided by 4, but by 3. You have part between the marks, and the labels 4.

With pi friendship already apart? ))))) Switched to disks. So many troubles.

To apply longitudinal risk to the pipe. After marking the end, it should be fixed on a hard ruler (corner, channel, etc.n) a pair-three clamp/wedge so that the cutting of a devil pressed by a clamp to the slider (conveniently a rubble of a rectangular pipe) coincides with the beginning of the markings, and stretch the slider along the forming.When cutting a round pipe into equal parts, you should adhere to one side of the scorch (I hold the “corner grinder” with my left hand behind the case, leading the disk with the visible side of the risk, which is highlighted by the remaining sheave of sparks). It is easiest to make a reliable damn from a drill drill, taking a handle of 4-5 mm wire to its shank at 4 points: you can hang on a nail/pin and will not ride.The winning plate can be sharpened with Crohhnflex Circle Circle. If there is no familiar turner with a circle of brand 64C.

Friends, did not show the easiest way, in the Комментарии и мнения владельцев reminded. Using the roulette k1nfajgydiat = 3s k1nfajgydiat = 3s

How to cut off a profile pipe evenly

You can cut the profile pipe about the same, but it will be easier to use a square. The device is alternately applied to each side, for which the cut element will need to be wired, and marking is applied. Next, the pipe must be fixed motionlessly and you can start work. Any suitable tool can be used for sawing. If you have to cut a lot of pipes, it is advisable to make full.fledged patterns from scraps. In this case, measuring and intraities will have to be done only once.

When it is necessary to cut a large diameter pipe, you can use a number of special devices and tools. This may be required if, for example, it is necessary to repair the pipeline.

- Corner grinder. The use of corner grinder is justified in terms of the accessibility of the tool and comparative cheapness of work. However, in this case, it is not worth counting on greater performance, in addition, the work in this way is associated with a considerable risk.

- Roller machine. Such devices are also often called pipelines. In fact, such a device is the same angular grinding, but more adapted for this type of work. The machine includes a special bed, where the cut.off element is fixed, as well as a clip with installed cutting rollers, which perform direct work. It is important to understand that each machine should be purchased for specific tasks, that is, to the size of the pipes.

- Gas cutting. This option is most often used when working with large diameters. Cutting is carried out due to the effects of high.intensity flame, and the waste produced by the gas is blown. The method can be considered the most practical and effective.

Gas cutting in this case the fastest option

View gas cut on AliExpress →

There are other options for the implementation of the task, such as the use of plasma, hydro.carbonated or laser cutting, however, in private use, they are practically not used.

How to cut a cast.iron pipe

If the pipe is made of cast iron, then in order to cut it evenly, you will have to apply certain knowledge. The fact is that this material is characterized by high fragility, which means that before cutting off such a pipe, you need to determine the algorithm of action.

- We mark it similarly to steel pipes.

- At the venue of the saw, you need to put a wooden beam as a support.

- Next, you need to perform a cut several millimeters throughout the circumference.

- After that, a chisel is inserted into the groove and you need to deliver a sharp and strong blow with a hammer.

As a result, it will split along the line, forming a fairly even cut place, which, if necessary, can be additionally processed.

View a pipeline for steel pipes on AliExpress →

Which tool can be used to cut plastic pipes

If we take into account that the people in our country are artisan, then for cutting pipes they manage to use the most unimaginable improvised means. But do not think that such a cut contributes to the good quality of the future pipeline. Therefore, we consider tools that allow the most qualitatively to cut plastic pipes:

- Kryzuvka for metal;

- self.locking knife (with small cloves);

- scissors for cutting pipes made of plastic;

- roller.type pipeline;

- battery pipeline;

- Guillotine pipeline.

Cutting pipes with a hacksaw for metal or knife should not be considered seriously, since their use leads to the fact that the end of the pipe is blinking, burrs that have to be eliminated with sandpaper or cleansing with a knife. In any case, the quality of the cut suffers. These methods can be used for single cuts. If the pipeline has a complex configuration and many joints of individual sections, then these tools are better not to use. Pipe cutting scissors are used mainly for cutting pipes from plastic polymers.

The sharpened knife blade is fixed only on one side of the tool. At the site of the second blade there is a fairly wide base with a slot intended to receive a cutting plate. Work with such scissors is carried out exclusively due to the muscular strength of a person. A rounded rack is placed between the handles of the scissors, which, after closing the handles of the scissors, pushes the blade in the direction of the base.The pipe cutting process is as follows:

- On the surface of the pipes, they put a well.visible mark, putting the cut place with it;

- The base is located on top of this mark, controlling through the cut of the base its position;

- Then, having attached strength, they crash into the pipe and, gradually increasing the effort, produce the final cut of the pipe.

In order not to cut metal pipes or a sheet of iron in the eyes, some home builders use grinding machines to make home.made products, rigidly fixing them on a vertically installed spindle. When moving the tool from top to bottom, a stable uniform section of the part located under the disk occurs, if the metal guides are fixed on the machine bed, when applying the workpieces on them, any desired cutting angle can be obtained.

Cutting pipes of large diameter

The metal profile of large diameter has thick walls and a large weight, if for cutting thin.walled parts (wall thickness up to 2 mm) you can use thin discs in size about 1 mm, then 2 mm is taken for cutting thick.walled metal. Disk circles. Accordingly, it is more convenient to cut thick walls with a large diameter disk using a powerful large.scale construction grinding machine. Household appliances do not have enough power to quickly work, and their small discs are quickly polished.

When performing work, they are guided by the following rules:

- When cutting heavy pipes, they should be placed on a flat surface or on low supports, so that when cutting the last section it does not change its position or does not fall, not allowing the cutting tool to compress its walls.

- If the surface is flat, each line is completely cut, turning the part, with uneven support, the last jumpers are slightly cut off, which allows you to divide the workpiece under its own weight, after which the protruding area is crushed.

- When working with a grinder for cutting heavy metal elements, it is necessary to use a protective coating. The probability of disk stratification into individual elements is too high.

How to cut along

Another commonly questioning question is how to cut the pipe with a corner grinder along. Here the algorithm of actions will be approximately the same as with transverse cutting. It is important to pay attention to marking.

You can, for example, use the painting thread, which is usually used when marking the walls. In this case, it is necessary to hardly fix the pipe. The process of sawing itself must be carried out carefully and slowly, since when sawing long elements there is a high probability of sliding of the cutting disk from the marking line.

How to cut thin.walled pipes

Another type of pipes is thin.walled products. Usually they are made of non.ferrous metals, such as aluminum or copper. Cutting thin.walled pipes is characterized by greater complexity, since there is a high probability of element deformation. In this case, you can use any filler, like sifted sand.

As a tool, you can use a corner grinder, a knife for metal or a special machine. It all depends on the specific situation.

Cutting metal pipes is quite time.consuming, but quite feasible process. At the same time, work with round pipes, fundamentally do not differ from cutting the profile pipe. The main thing is to remember that when performing work, it is necessary to follow the safety rules.

Exact Tools Unique Pipe Cutting System

Cutting asbestos.cement pipes angular grinder

The most common way is the cutting of asbestos-cement pipes with an angle grinding machine (it is also an angular grinder, corner grinder; something like Bosch Gws 850 CE Professional or Makita GA5030K).

In this case, there are 2 types of work depending on the equipment used:

- Corner grinder with stone disk. For cutting this method, the efforts of two people will be required. One of them should cut the pipe with a corner grinder, and the second should be a very thin stream of water to the place of cutting. In this case, the dust from cutting will not fly around the room, but drain in the form of dirt down.

- Corner grinder with diamond disk. Here you will need a respirator, construction glasses and other protective equipment. To reduce the amount of dust that enters a person during cutting, it is necessary to produce this process in the open space from the leeward side so that all dust flies to the side. If you cut the pipe in winter, then it can be put directly on the snow so that the particles of the material remain below.

And if not, alternative technologies

If you do not have an angle grinding machine, you can use a cutter or a hacksaw. Consider these technologies of cutting pipes from asbestos cement.

How to cut drain pipe lengthwise to use as a goat trough.

- Hacksaw. It is quite possible to cut the pipe with an ordinary hacksaw, but you will need a lot of efforts and time. Initially, the pipe should be wetted, since in raw state asbestos cement is cut much easier, and if you saw the pipe in dry form, the process will become extremely tiring and ineffective. Then it is worth outlining the fishing line for the trimmer of the cut, moisten rags in water and lay them for several hours along the expected section of the cut. Wet asbestos cement will be much more elastic and easily moved. Do not press hard on the pipe during cutting so that it does not split.

- Cutter. To do this, you will need a cutter similar to a cut for plastic, but large and made of high.quality metal. The pipe should be put on a flat plane and apply a scratch on the cutter in the form of a straight segment. Then deepen it a millimeter and further. Under the scratch you can put a small rail inside the pipe and break along the cut line. In this process, a lot of dust is not formed.

The above methods of cutting asbestos cement are the most popular, but if they are not suitable for you, you can use alternative technologies:

Classic ax. You need to take an ordinary ax and cut the pipe on the intended lines. It should be understood that at the same place you need to apply a lot of strokes to initially break the pipes, and then the process will go much faster. Of course, it will not work to cut the pipe evenly, but it will turn out efficiently and quickly.

Circular. You can cut the pipe from asbestos cement using the circular. Instead of usually a disk, you need to install a disk with carbide tooths on it.

Chering nail. If you did not have at hand all the listed tools, you can use the most primitive method. First, a fishing line for a trimmer is planned on the pipe, then a slate nail is taken, which breaks out a fishing line for a trimmer along the entire circumference length. The more often the holes are located, the better. It is best to put a thin oblong object under the pipe, for example, a tree bar. At the end, you need to carefully break the pipe along the line with holes. The cutting line for the trimmer of the cut will not be perfectly flat, in any case, it all depends on the number of holes made and the accuracy of the breakdown.

Hello all visitors! The task is to be cut: cut a sewer pipe 110 mm evenly and along. I am going to beat off a fishing line for a cutting trimmer using a plumb line. But cut the plastic than? cut a lot. 50 meters. Electric? Then which files are better to lay? With an ordinary hacksaw, please do not advise. it is torn and split. I tried it already. Maybe someone will tell you something?

Quickly, but give the casing, and molten plastic can make you a skin burn. The jigsaw is slower, but not much. The saw will go on plastic, it is universal.

Rules for cutting pipes from different metal

Corner grinder even in the hands of the master is a rather dangerous tool. When working with it, the precautions should be observed, and be as concentrated as possible. Otherwise, you can not only damage metal blanks, but also injure yourself.

Know how to correctly cut the pipe under 45 degrees with a corner grinder, each specialist in working with metal should. The circle of the disk should be installed by the pattern up, and clamped by a special nut. Different metal pipes are cut in compliance with some rules.

Work with aluminum blanks

Aluminum belongs to soft types of metal, so another type of disk is used to cut the corner grinder. When working with soft metals, such as aluminum or copper, it is impossible to make a cut at a time. The cutting disk is simply knitted in the material.

A special disk is performed very carefully. The same slic should go through several times.

Cutting aluminum pipeline

How to cut cast iron pipes

Cast iron is characterized by increased strength, but at the same time it is a fairly fragile material. For sawing pipes from cast iron, it is recommended to use disks with diamond spraying. You can cut the fragile material with a corner grinder only in a straight line.

Important! It is necessary to carry out work with sawing cast iron, steel, and aluminum is necessary only with the use of personal protective equipment (in a respirator, in protective glasses and gloves). During the cutting process, a large amount of dust is formed.

Cutting pipes of large dimensions

Corner grinder is often used to cut large diameter pipes. Large.sized metal products have thicker walls and large weight. To work with large metal blanks, it is more convenient to choose large drives.

Heavy unbearable products are required to be firmly installed on low supports or on a flat surface, so that when cutting the final site they will not change their position.

When working with large pipes, you should choose the correct direction of rotation of the circle of the corner grinder disk. Otherwise, the tool is difficult to keep in a fixed position, and the disk grows too quickly.

Features of cutting thin.walled pipes

Sawing thin.walled metal rolling has its own characteristics. When cutting these products, there is a large risk of crushing edges at the rolls of cuts. To prevent this, experts recommend filling the pipes from the inside.

A wooden stick of suitable diameter or sand may come as a filler. For a thin.walled profile, when cutting a corner grinder, thin cutting discs are selected. Work with such material is carried out much faster.

Cutting a gas pipe

Methods of cutting metal pipes at an angle

Sprinkle the pipe or cut it into pieces in several ways. Of the available tools, the angular grinder copes with this task. But the biggest problem is the need to correctly mark the cutting lines. They can be different, most often you have to withstand either a right angle relative to the axis of the pipe, or 45 degrees. Techniques are somewhat changed depending on which products need to be cut:

pipes for laying the water supply, gas and for wiring heating;

profile products for assembling the gates, visors, other metal structures;

Large diameter pipes. as a rule, it is rarely necessary at home, where the widest clearance only in the sewers;

Pipes made of steel, cast iron, thin.walled from non.ferrous metals and soft alloys.

Both problems are solved quite simply even without using a special pattern of the angle of the pipe.

Cutting under 45 degrees

One of the private examples of this situation is the need to cut off a metal pipe at an angle of 45 degrees. Such cutting of the material is often required when laying water communications or heating systems. In this case, you have to deal with steel pipes. For these purposes, familiar cylindrical pipes are usually used. If we are talking about the installation of some metal structures, then profile pipes of rectangular or square section are more often used. The main problem here is that in order for the combined elements to match, the incision should be as smooth as possible, which means that especially close attention should be paid to the markup of the material.

In the case when cutting is required at an angle, a simple square sheet of paper can be used as a marginal template. It must be folded strictly diagonally, and then wrap the pipe with a template. In this case, it is necessary to carefully ensure that the side of the sheet, which is located closer to the end of the pipe, is perpendicular to its central axis. Further, using the marking material, a number of dashed lines are applied and after the marking is made throughout the circumference, the template can be removed.

Photos of the template for cutting pipes. side view

Cut marking under 45 using a template

If there is a cutting of a profile pipe, then it is advisable to make a special template from the same pipe, but a larger section. At the same time, you will have to use measuring devices only once. To mark the markings, you will need to use a transporter or a construction square. After sawing off the template, the pipes that are subject to cut can simply be inserted into it and mark it. This approach will significantly save work time and cut a profile pipe under 45 degrees will be convenient.

As for what to use during work, here it is worth choosing the most suitable and familiar. It can be a simple hacksaw for metal, and an angular grinder with an installed cutting disk.

Cutting under 90 degrees

When there is a need to cut under 90 degrees, the situation is still easier. In the case of cylindrical elements as a template, you can use the same sheet of paper with which the pipe turns around. It is important to ensure that the edge of the leaf is even and coincides throughout the circumference. After applying the marking, the cut element is fixed and the cut is made.

The video shows the process of cutting the pipe under 90 degrees.

How to cut off a profile pipe evenly

You can cut the profile pipe about the same, but it will be easier to use a square. The device is alternately applied to each side, for which the cut element will need to be wired, and marking is applied. Next, the pipe must be fixed motionlessly and you can start work.

Any suitable tool can be used for sawing. If you have to cut a lot of pipes, it is advisable to make full.fledged patterns from scraps. In this case, measuring and intraities will have to be done only once.

Cutting pipes of large diameter

When it is necessary to cut a large diameter pipe, you can use a number of special devices and tools. This may be required if, for example, it is necessary to repair the pipeline.

- Corner grinder. The use of corner grinder is justified in terms of the accessibility of the tool and comparative cheapness of work. However, in this case, it is not worth counting on greater performance, in addition, the work in this way is associated with a considerable risk.

- Roller machine. Such devices are also often called pipelines. In fact, such a device is the same angular grinding, but more adapted for this type of work. The machine includes a special bed, where the cut.off element is fixed, as well as a clip with installed cutting rollers, which perform direct work. It is important to understand that each machine should be purchased for specific tasks, that is, to the size of the pipes.

- Gas cutting. This option is most often used when working with large diameters. Cutting is carried out due to the effects of high.intensity flame, and the waste produced by the gas is blown. The method can be considered the most practical and effective.

Gas cutting in this case the fastest option

There are other options for the implementation of the task, such as the use of plasma, hydro.carbonated or laser cutting, however, in private use, they are practically not used.

How to cut a cast.iron pipe

If the pipe is made of cast iron, then in order to cut it evenly, you will have to apply certain knowledge. The fact is that this material is characterized by high fragility, which means that before cutting off such a pipe, you need to determine the algorithm of action.

- We mark it similarly to steel pipes.

- At the venue of the saw, you need to put a wooden beam as a support.

- Next, you need to perform a cut several millimeters throughout the circumference.

- After that, a chisel is inserted into the groove and you need to deliver a sharp and strong blow with a hammer.

Direct cut

You can make an even cut at an angle of 90º only after applying the marking. Use a sheet of paper or painting tape. The latter is preferable, because it is attached directly to the surface and does not shift.

The sequence of actions looks like this:

- A section of the desired length is measured with a tape measure, they note this place with a dash marker.

- Further, tape is glued along the resulting label around the circumference of the pipe. The more even you glue the sticky tape, the better. optimal that the wide edges come together as precisely as possible. This will allow you to make an accurate cut of the pipe on the mark.

- The next step, the pipe is fixed in a vice or pressed to a flat plane so that it does not shift during operation, and a smooth seam turned out. Note that one end of the pipe must be left in a free position, so that during cutting the disk is not clamped by the walls. Cutting start from top to bottom.

- The last thing to follow is how to saw off the pipe with a corner grinder. To do this, you need to lead the disk as accurately as possible along the edge of the sticky sticky tape.

In cases where pipe products with large sections are cut, the work must be performed in small sectors. To do this, the pipe will have to constantly turn around the axis at the end of the next incision.

When working with cast.iron pipes, the action scheme will be slightly different. First, a continuous incision is performed throughout the diameter of the product, then with the help of a chisel and the hammer the resulting gutter is gradually drunk, as a result of which the pipe should split strictly along the cut line.

How to cut along

Another commonly questioning question is how to cut the pipe with a corner grinder along. Here the algorithm of actions will be approximately the same as with transverse cutting. It is important to pay attention to marking. You can, for example, use the painting thread, which is usually used when marking the walls. In this case, it is necessary to hardly fix the pipe. The process of sawing itself must be carried out carefully and slowly, since when sawing long elements there is a high probability of sliding of the sloping disk from a mowing marking fishing line.

Most often this has to be done when installing a water supply and heating and assembly of frame structures. You can cut the pipe under 45 degrees with a corner grinder according to the marking, which is made either by a sheet of paper of the same A4 format or use a regular school (drawing) isosceles square.

Methods of cutting metal pipes at an angle

Sprinkle the pipe or cut it into pieces in several ways. Of the available tools, the angular grinder copes with this task. But the biggest problem is the need to correctly mark the spit line of the cut. They can be different, most often you have to withstand either a right angle relative to the axis of the pipe, or 45 degrees. Techniques are somewhat changed depending on which products need to be cut:

pipes for laying the water supply, gas and for wiring heating;

profile products for assembling the gates, visors, other metal structures;

Large diameter pipes. as a rule, it is rarely necessary at home, where the widest clearance only in the sewage system;

Pipes made of steel, cast iron, thin.walled from non.ferrous metals and soft alloys.

Both problems are solved quite simply even without using a special pattern of the angle of the pipe.

Other tools for cutting plastic pipes

They are rarely used when there is no pipeline at hand:

- Corner grinder. for cutting pipes, a cutting disk for metal will be required. The main point in the operation of the corner grinder is the exact regulation of the effort, it is impossible to crush too much on the tool.

- Electricity is the most convenient way in the absence of special scissors. It is likely to get an oblique cut, so for greater accuracy during operation, the pipe must be turned several times.

What is categorically not recommended to cut pipes:

- Ribbon saw. its blade moves too slowly and if it is not insufficient enough, the probability of damage to the internal diameter of the pipe is great, which leads to chips and cracks.

- Circular machine. Since plastic pipes are flexible, pushing them into the machine often causes a pipe displacement and blow, which is dangerous for a person producing a cut.

Cut the pipe at an angle of 90 degrees

To mark the cut [water and gas pipes] at right angles, you can use a sheet of paper of the standard A4 format, wide isolation or construction tape. If you wrap a fairly wide material around the pipe so that its edges are definitely coincided with the imposition, you get the perfect fishing line for a cutting trimmer. If the tape or the tape is tightly glued to the metal, you can go right along the edge.

It is important to be able to properly use the grinder, keep it with a certain effort and follow the safety rules. The described technique is the simplest, it is suitable for cutting a large diameter pipe.

Which tool is used

As noted above, the main tool for cutting metal parts in domestic conditions is an angle.grinding machine, in its absence, you can use a hand hacksaw for metal or an electrician, which can also cut metal materials with a special canvas with a diamond coating.

For cutting corner grinders, cutting electric contest discs are used not intended for grinding operations. As an auxiliary tool, roulette, a metal ruler, various types of clamps, pencils and markers for applying marking will come in handy.

Tools for home and semi.professional use

To arrange water supply systems or sewage systems, heating and ventilation circuits in home construction or in the provision of construction services, they often use tools from this category.

Among the most common devices can be called:

- Cutters with the design of the secateurs. Such a tool is used to cut pipes from polymers, the cross.section of which does not exceed 75 mm. Attach the effort to work allows the dentate mechanism of the device. In the design of such a cutter, a special shelf is provided, on which the pipe is laid, which ensures the evenness of the incision strictly under 90º. for such tools can be very different, it all depends on their quality, dimensions, capabilities, manufacturer and other factors.

- Disk type pipeline. In this device, the cutting of the pipe is performed by a special disk, which is made of durable material and has sharpened edges. With the help of a lever, the cutting disk is pressed to the surface of the pipe and is carried out along its section. “How to choose a pipeline for steel pipes and how to use it”.

Such a tool will be the best solution for cutting pipes from PVC used in assembling internal and outdoor sewage systems. At the same time, metal.plastic pipes cannot be treated with such a pipeline, since the material is deformed from the load.

How to perfectly cut a steel pipe along

- Guillotine knife. The principle of its action is probably familiar to every educated person. There is a blade in the upper part of the structure, which drops down on special grooves and performs an even clear incision. For convenience, you can get an electric drive device. Such a device is easy and convenient to cut a large number of pipes. At the same time, in places of sale you can also find tools with a screw mechanism.

- Kryazuvka for metal. At first glance, a simple tool can be successfully used to cut a pipe from any material. The main thing is not to overdo it in the process so that the saw canvas does not break from excessive efforts.

Since it will not quite be quite possible to saw off the pipe with a hacksaw, there will still be burrs, the ends will have to be cleaned with a file or shaver. Otherwise, when connecting pipes, insufficiently tight seams may be enough.

Cutting cutter

Electric saw is ideal for cutting a large number of PVC pipes. Electric cars, however, roads. If you already have one or you have access to it, and you know how to use it safely, you can use the existing wooden blade to cut the pipe from the PVC without buying a special blade. Be sure to read and understand the instructions attached to the end saw.