How to make a concrete ironer with your own hands

Pouring horizontal surfaces with concrete mixtures is a laborious process, the result of which is estimated by the strength and smoothness of the upper layer.

The initial leveling of the solution is made by the rule after which the crests remain. The ironer helps to get a flat surface. This device is included in the set of tools of professional builders.

For one.time work, it is impractical to purchase an industrial stem, since the tool can be made independently from improvised materials.

Application of the ironer

This is a special tool with which the concrete surface is finally aligned.

During the pouring of a concrete base, the initial smoothing of the mixture is carried out by the rule, focusing on the established beacons. This tool evenly distributes the mixture over the concrete surface, leveling the bins, filling the pits and cleaning the resulting tubercles.

But even high-quality laying of concrete leads to the formation in it, after 1-2 hours, bumps. This phenomenon is associated with the release of “concrete milk” from a solution, so you need to make a thinner smoothing, removing excess water. At this stage, the master works as a glades, which performs the following functions:

pros

Grolling of concrete gives it the qualities and type of independent flooring. Smooth surface, aesthetic appearance determine the use of this type of concrete floors for a variety of buildings:

- Anchor for concrete

- Concrete proportions for the foundation

- How to choose a concrete impregnation

- Vibrator for concrete

- Liquid glass for concrete

- Characteristics and use of concrete B25 (M350)

- workshops, household premises of enterprises;

- airports, stations;

- corridors, foyer of educational, medical institutions;

- shopping centers, pavilions;

- water parks, pools;

- Cinemas, exhibition complexes.

There are two methods of grinding concrete screed: wet and dry. The same consumables, tools are used.

Wet grinding

Used to process floors of increased strength with fillers from solid rocks of decorative stone. expensive: more consumables are required.

Grinding removes up to 5 mm concrete of the upper layer.

The work with a hand tool is complicated by dirty splashes, sludge, interfere with the control of the purity of surface processing. You have to remove dirt, water, dry the surface of the floor.

When stripping concrete coating, abrasive circles with solid.grained inclusions, or particles of different sizes are used.

Varieties of the process

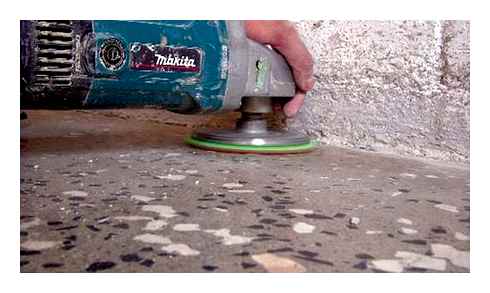

Grinding the concrete floor with an angular grinder can be carried out in a dry and humid way, however, the price of the work carried out from this will not change. Wet grinding is used to grind the mosaic floor or floor, which is covered with marble chips. With this type of grinding in work, it is necessary to use abrasive segments. Thanks to this, you can get an almost perfect floor surface, which in appearance is no different from the polished surface.

However, it is better to use a dry method of grinding for a concrete floor. But dry grinding takes much more time compared to wet processing. In the process of work, a lot of dust rises into the air, which is not as dangerous as a wet cement sludge that strongly covers the eyes. As a result of this, the visibility of the work is much better and the master can timely eliminate all errors. Industrial vacuum cleaners can be used to remove dust.

The choice of tools

The tool necessary to polish concrete can be found in any construction store. Most often on sale there are corner grinders of European and American manufacturers. The use of corner grinder compared to other grinding tools will complicate the work somewhat, but there is no point in buying a very expensive machine for repairing the house at home. With the help of corner grinder, you can easily polish the surface in hard.to.reach places where a large car cannot pass. For corner grinders you will need two nozzles: a diamond bowl and an abrasive disk. The greater the circle of corner grinding, the greater the load will be able to transfer the tool.

It is necessary to handle the corner grinder very carefully and accurately, since the circle may jump off the object or even for a person.

The probability of the danger of such a plan is another reason to verify as the acquired tool. With the help of corner grinder, you can easily polish and create an even beautiful surface.

The choice of tools

The tool necessary to polish concrete can be found in any construction store. Most often on sale there are corner grinders of European and American manufacturers. The use of corner grinder compared to other grinding tools will complicate the work somewhat, but there is no point in buying a very expensive machine for repairing the house at home. With the help of corner grinder, you can easily polish the surface in hard.to.reach places where a large car cannot pass. For corner grinders you will need two nozzles: a diamond bowl and an abrasive disk. The greater the circle of corner grinding, the greater the load will be able to transfer the tool.

It is necessary to handle the corner grinder very carefully and accurately, since the circle may jump off the object or even for a person.

The probability of the danger of such a plan is another reason to verify as the acquired tool. With the help of corner grinder, you can easily polish and create an even beautiful surface.

Material for grinding

To obtain a qualitative result, you cannot rush with work. Grind absolutely any concrete, but the main thing is to get the desired result, and it depends on the brand and age of fillers and coating. The layer can be pulled up to 3 cm. It is permissible that the presence of pits and tubercles with a difference between them is no more than 5 mm.

In order to choose the material, you need to take into account why this room is intended. The cost of grinding works also depends on this. The most optimal filler for grinding concrete screed is crushed stone of metamoic rocks and small fractions. If polishing work is needed in the future, it is better to use marble crumbs or gravel granite, creating an original surface.

Small fractions are ideal for grinding. Paul with marble crumbs is easily processed quite easily. The most difficult to process will be granite and sedimentary gravel. To carry out grinding work, it is better not to use too much filler density. However, the low density reduces the quality of the floor.

Preparation of the base

The preparation process includes the release of the surface from furniture, removing the old layer of varnish, repair or dismantling of rotten, fragile elements of the floor, examination of fasteners

Before you start processing the floorboard with your own hands, you need to process its surface. It is necessary to produce such manipulations:

- Take all the furniture and extra objects from the room.

- Tear off the plinth.

- If there was already any finish on the floorboard, then it needs to be removed. For example, varnish can be washed off using special chemicals or using the thermal method.

- All nails or screws that protrude above the surface of the pine board, it is advisable to drown the wood inside. Otherwise, you can damage a grinding machine.

- The old parquet must be carefully examined. If there are unstressed elements, then they need to be well fixed with self.tapping screws.

During operation, you need to consider electricity consumption by equipment. The network should withstand the power of the device.

In addition to preparing the base, you need to get used to the equipment. Before involving the machine, it is necessary to insert sandpaper in it. Then tilt the device and include it in the outlet. Next, gradually lower the machine in a horizontal position. This procedure is necessary so that the device does not break out of the hands. The grinding of a wooden floor should be made with all responsibility. Try to monitor the operation of the engine of the device. Do not forget to insert a new sandpaper as it was erased.

Advantages and disadvantages

The main advantage is that today in stores a large range of apparatus for grinding concrete is presented in stores. They are quite easy to use, do not require special skills to work.

One of the significant advantages of the units is a wide range of nozzles that increase the functionality of the grinding machine.

In addition to all of the above, the equipment can work without breakdowns for a long time.

The main disadvantage in a large amount of dust, which is formed during the operation of a grinding machine for a concrete floor. Also, the disadvantages include the fact that additional materials will have to lay out a considerable amount of money.

Advantages and disadvantages

The main advantage is that today in stores a large range of apparatus for grinding concrete is presented in stores. They are quite easy to use, do not require special skills to work.

One of the significant advantages of the units is a wide range of nozzles that increase the functionality of the grinding machine.

In addition to all of the above, the equipment can work without breakdowns for a long time.

The main disadvantage in a large amount of dust, which is formed during the operation of a grinding machine for a concrete floor. Also, the disadvantages include the fact that additional materials will have to lay out a considerable amount of money.

Wooden floor grinding: technology for obtaining an even and smooth foundation

The wooden floor consists of many elements, in the process of laying which it is very difficult to achieve a perfectly flat surface. Often there are minor defects, scratches, differences.

Do.it.yourself repair and restoration of parquet (read more)

Such problems are characteristic both for the new coating and for the old surface. One of the effective ways to eliminate all the shortcomings and flaws of the coating is the grinding of the floor, which can be carried out by manually or mechanically.

One way to eliminate minor defects, scratches and differences on a wooden floor is grinding.

DIY grinding machine for concrete

Concrete grinding: like and what is done?

The floor surface before using the final coating must be more even. Therefore, before it is exhausted, impregnated and treated with walls or floor with a paintwork, you need grinding concrete floors.

Grinding machine for concrete eibenstock

However, this procedure asks not only only the main knowledge, but of a certain experience that we will share later.

1 type of processing

Grinding the concrete floor or walls at home can be carried out in several ways. wet or dry. The choice of technology determines its cost, the equipment is then always used monotonous.

Wet grinding of concrete with a corner grinder is usually carried out for processing marble or mosaic coatings. Such a way involves the operation of abrasive parts, which provides an actually impeccable surface, which will visually even distinguish from polished.

The specialists advise grinding concrete walls and floors using dry technology. In contrast to the wet, dry way is more labor.intensive and takes not just time. This development allows us to reveal incorrectness and errors to our client so that you can find and eliminate them.

Grinding the concrete floor according to this technology contributes to the spread of dust and dirt in the room, to remove which it is normal to use a powerful vacuum cleaner.

one.1 equipment for grinding

Mosaically grinding machine for concrete is sold in almost any construction store. You, customers are offered equipment of South American or euro production. cars, often have not yet established themselves for reliable and effective equipment. To complete the tasks on your own, you need a grinding machine for concrete or an ordinary corner grinder and a diamond cup

Of course, a specialized tool with a diamond circle of grinding is considered the highest quality in terms of efficiency, since it is equipped with a system of planetary mechanism. Such machines are equipped with a disk with installed auxiliary wheels moving in one direction.

Read how can you cut polycarbonate at home

Diamond nozzles are installed on wheels, in terms of its functions no worse than diamond cups. Therefore, domestic craftsmen, even using ordinary corner grinder (diamond cup), can polish the floor at home no worse than the car.

Specialized equipment is equipped with speed adjustment functions.

When grinding with a wet method, the machine allows the use of water to collect dust and dirt. As practice shows, the more the weight of the equipment, the higher the quality of the surfaces will be higher. The cost of a grinder for concrete is usually high, but if necessary on sale you can find less expensive equipment.

If you do not have a grinder on concrete, then for these purposes you can apply the usual corner grinder and a diamond cup, instead of a traditional disk. Using a corner grinder, the process will take a little more time, but if you do everything with your own hands

for the home, it makes no sense to purchase expensive equipment.

Concrete Hand Grinders

After all, a grinder on concrete will not go to those places where a diamond cup on a corner grinder will reach. You will need not only a cup, but also abrasive wheels (circle). If there is a lot of work, it is better to buy discs in advance, a few pieces.

Homemade grinding machine for floors. Himself a forehead

Simple design of a home.made grinding machine

, not expensive in the assembly, while it gives an excellent result.

Grinding and polishing machine for concrete

and polished a Husqvarna PG 400, I sell.

As practice shows, the larger the diamond circle (disk, diamond cup), the greater the load on it can be laid. When performing work, it is necessary to be the most careful, since with incorrect movement of the hands a diamond circle

(disk) can bounce and cause injury.

one.2 initial stage

Grinding the concrete floor is carried out in several stages. The first stage is considered one of the most basic. Consider the step.by.step preparatory process:

- First of all, you need to remove the old coating with your own hands. As a result, scratches may remain on the floor or surface of the walls, which can be rid of which can be polished with a long grinding. Accordingly, the costs of the initial stage may increase.

- Diagnostics with your own hands are diagnosed using a three.meter level. When identifying tubercles or potholes, it will be necessary to use a diamond disk (circle) with a large number of diamonds in the circle matrix (disk). All cracks should be shown.

- The next step is the tapping of all walls or gender for identifying areas with a lack of strength. The level of surface strength should be maximum.

- It is important to check the voltage in the room where you will work. Stable voltage is the main aspect in working with a grinder on concrete or corner grinder.

Read Repair of the Poorater cartridge with your own hands

one.3 Preparation

- In order not to spoil the disk when processing walls or flooring with your own hands, the surface must be checked for the presence of reinforcement in it. In the presence of reinforcement, it must be carefully cut out with a corner grinder.

- After removing the old coating of the walls or floor, you need to get rid of all irregularities. for this, use the method of milling or shot.brown cleaning or a specialized tool. According to experts, the most optimal in this case will be a diamond circle (disk) with a granularity of 30 microns, this will eliminate the excess frozen cement.

- To get rid of cracks and other defects, you can use epoxy mastic. it allows you to perfectly fill all existing irregularities. Keep in mind that the mastic should fill the cracks in such a way that the grinder on concrete passes through the flaws without problems and does not cling to them.

2 Grinding procedure

The concrete grinder must be used two weeks after the screed dries. Such an interval must be withstanded so that the surface becomes more durable and ready for subsequent work. If you do not wait for some time, then the diamond circle (disk) of the tool will simply tear out crushed stone added to the composition of concrete.

Grouting fresh screed

There is a special technology for working with a fresh screed, which is practiced after 4-20 hours from the date of filling. It allows you to create strong, wear.resistant coatings for commercial and industrial facilities and even floors for open areas. For work, use a helicopter for grinding. a special type of grout machine. It is manual or self.propelled, equipped with a diesel, electric or gasoline engine.

Such a technology helps to compact the upper layer of a filled screed. First, the gross stripping of concrete is done with the use of tops based on cement. After 10-16 hours, finish grinding is carried out with rubbing the drainage of the impregnation. For a decorative effect, they are carried out along the screed with tops with the addition of pigments.

What is the grinding of the floor for

Concrete floors with proper grinding, which is made in accordance with modern technologies, became much more popular than other coatings. Thanks to grinding, the surface becomes more practical, since the coating reduces the cost of restoration and care, and the variety of styles helps to make the floor suitable for the design of any room. For the garage, strength is especially important, so you need to learn how to make high.quality grinding with your own hands.

The floor of concrete is called this type of construction processing, as a result of which the past coating is removed, the basis of the floor is aligned, and it is also necessary for gypsum.type screed before applying for the impregnation for strengthening and different coatings.

Typically, preliminary grinding is carried out about four days after casting the base of the floor from concrete, and the final option is done only after the final hardening of the surface.

- increased adhesion to other materials for decoration;

- improving the quality of clutch;

- elimination of the smallest irregularities;

- It is important to remember that grinding cannot change the irregularities of the relief;

How to make a concrete ironer with your own hands. a step.by.step plan, views and use

The ironing iron for concrete is a special device, thanks to which it is possible to smooth the concrete solution on the surface of the floor, walls, ceiling. The ironer allows you to level the plane quickly, simple and efficiently, can be used both after pouring and in the process.

Hooks for concrete are a great opportunity to eliminate the risk of accumulation on the surface of the floor of the moisture, remove all the irregularities and defects from the screed, significantly harden and compact coatings, remove cement milk. A stems are used at various stages of the implementation of the work, which depends on the tasks, the features of the operation of the surface.

The tool can be different. professional and for domestic needs, with different characteristics and parameters, power, additional devices.

If the ironer is needed for concrete to carry out not very large.scale work and the master does not see the point of acquiring the tool, you can design it yourself, spending a little effort and time, but saving a considerable amount.

Advantages and spheres of use of polished concrete floor

The processed concrete floor won largely popular among finishing coatings not only of public, but also in the private category. It is mainly used:

- in medical and educational institutions;

- in shopping and sports centers;

- in water parks;

- in entertainment institutions;

- on cultural sites;

- in suburban areas;

- as a cover of floors in outbuildings and garage buildings;

- Increasingly polished concrete floors can be found in dressing rooms and corridors in the houses of ordinary citizens.

He earned such an extensive scope with his operational characteristics, which largely exceed the advantages of even the highest quality finish coatings:

- The service life is calculated for decades, which is ensured not only by its increased strength characteristics, but also by resistance to saturation of moisture. An ordinary concrete screed without a finish coating or processing does not have such significant advantages;

- The floor polished to gloss is similar to elite bulk coatings;

- democratic value;

- It is an ideal basis in the case when a perfectly flat base for a decorative coating is required;

- does not produce harmful dust during operation;

- Grinding makes it possible to align the foundations even with a strong relief;

- does not require periodic repairs. If such a need arose, then making a “patch” will not be difficult.

So that such properties are the finish coating as long as possible, you need to polish the flooded concrete floor as it should. Polishing, if the pouring is old, is subjected not only to a decorative, but also the main layer. In the case of driving a new concrete floor, you will need to remove cement milk. Also, grinding with special tools of concrete surfaces is an integral part of the preparation of the basis for bulk floors.

Be careful and do not give in to a common misconception. grinding does not solve the problems of adjusting the relief surface. Alignment is carried out at the stage of primary filling or re.closing the concrete layer.

pros

Grolling of concrete gives it the qualities and type of independent flooring. Smooth surface, aesthetic appearance determine the use of this type of concrete floors for a variety of buildings:

- Ironing of the surface of concrete

- Concrete proportions for the foundation

- How much concrete cubes weigh

- Concrete substitute and its advantages

- How many crushed stone in 1 cubic. m concrete

- Concrete brands and their use in construction

- workshops, household premises of enterprises;

- airports, stations;

- corridors, foyer of educational, medical institutions;

- shopping centers, pavilions;

- water parks, pools;

- Cinemas, exhibition complexes.

There are two methods of grinding concrete screed: wet and dry. The same consumables, tools are used.

Material for grinding

There are also a huge amount of materials for grinding. Two nozzles are enough for use within an apartment or private house:

A diamond cup is needed for grinding concrete with a corner grinding of the other nozzles either worse, although cheaper or designed for expensive grinding of the rooms of large volumes, which is simply nothing to the home master.

Particular attention will have to be paid to the choice of filler for concrete. It should be soft varieties of small fractions stone. Remember, grinding concrete with a filler of large gravel is impossible without the use of expensive equipment and nozzles.

Grinder with your own hands. Part 1. Assembly.

It is also worth it to take care of the purchase of impregnation in advance. Thanks to the primary polishing, the upper layer is removed, after which the concrete perfectly absorbs the strengthening waterproofing impregnation. It is she who betrays the effect of gloss and strengthens the surface, protecting it from chips, cracks and moisture effects.

Disk nozzles for grinding

Bulgarian bell nozzles for grinding concrete are most popular. Depending on the degree of processing, they are of two types:

- turtles. This type is applicable for finishing surfaces. Their flexible base is distinguished, on which small diamond crumbs with the addition of polymers are applied. They are quite convenient to use and prompt in replacement, thanks to their attachment system for “Velcro”;

- Planes. The grinding disk of such a concrete plan is used in cases of removing the first black layer. The different signs of the granularity of diamond crumbs gives complete freedom of choice of the type of nozzle in accordance with the type of stone or concrete floor basis.

Cups

Grinding cups of various sizes in concrete are a type of grinding circles used to remove a thicker layer of concrete. Depending on the level of processing, the types of cups are distinguished: