Do-it-yourself edge trimmer

How to make a two-saw edging machine with your own hands

Edge trimming machine is designed to remove the edge from the surface of wooden blocks and boards. This operation can be done on an ordinary band saw. But at the same time, it is difficult to achieve precision in processing and creating the product with the required geometry parameters.

Edge Trimming Machine Design

Double Saw Trimming Machine

Before you begin to make a hemlock with your own hands, you need to familiarize yourself with the specifics of its layout and design. This woodworking equipment is required to complete specialized production lines and is designed for pre-processing lumber before grinding.

Trimming machines are standard equipment. They consist of a frame that performs two functions. There are mechanisms for sawing on it, and it can also serve as a conveyor for feeding blanks. An alternative is the rigid fixation of the wooden part on the surface of the working frame.

Depending on the design features, the following types of woodworking edge trimming machines are distinguished:

- the method of supplying materials. manual, automatic or semi-automatic. Manual models are simple in design, but at the same time they have a small indicator of performance. They are the best option for self-manufacture;

- by the number of saw blades. one and two-saw. The former are intended for one-sided processing and are used extremely rarely. The optimal result is achieved after the use of two-saw models, since cutting occurs simultaneously along two edges of the workpiece;

- movable or stationary carriage with saw blades. For the manufacture of homemade woodworking equipment, it is recommended to make a subcutaneous carriage. This will allow you to control the processing process. But factory models are made with a fixed carriage. This improves productivity.

Additionally, in a manual woodworking machine, you can provide a system for removing cut products. chips and wood dust. To do this, you can use a standard chip vacuum cleaner or its equivalent.

The optimum power of the power plant should be from 4 kW or more. This is necessary for the simultaneous processing of workpieces using a manual two-saw woodworking machine.

DIY recommendations

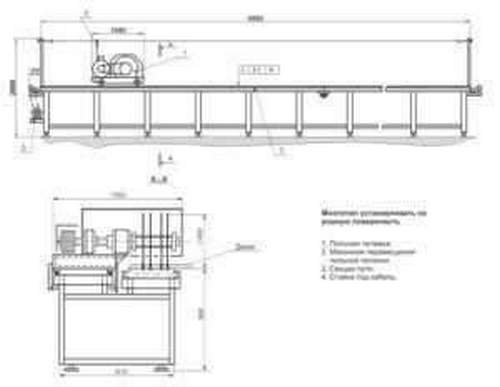

General outline of a trimming machine

At the first stage, it is necessary to draw up a diagram of the equipment design. It should include an accurate drawing, which indicates the location and main characteristics of the constituent elements. Without this, it will be impossible to make a high-quality and reliable edge trimming machine.

The best option for self-production is a design with a movable carriage. For its implementation, you can use a two-saw or four-saw cutting unit, controlled by a manual mechanism. The last edge trimming machines will be able to form two blanks in one pass. But at the same time, their work will require a powerful power plant.

Structural elements of manual woodworking equipment:

- support frame. The workpiece will be fixed on it. It is best to make it welded from shaped tubes of square section. The top will be designed to move the carriage. Roller guides are mounted between the side machines. With their help, you can feed blanks with a large mass. Clamps or devices similar to them can be used to fix wooden parts;

- movable carriage. A power unit is installed on it, which is connected to the drive shaft using a belt drive. For mounting disks, a special shaft should be made with the possibility of changing the position of the disks. The carriage is moved along the frame guides with the help of wheels.

In addition, a lifting unit should be provided to adjust the depth of cut. Thus, it is possible to significantly increase the maximum thickness of the workpiece.

The control unit must be located on the side of the equipment. To increase the safety of operation of the woodworking machine, it is necessary to install a shield on the carriage. This way you can prevent chips from entering the motor.

Equipment Tips

Model with two electric motors

To miss the design, two power plants can be mounted on a makeshift edge trimmer. This will make it possible not to make a belt drive system, which will greatly facilitate the manufacturing process.

To move the carriage along the guides, you can make a long handle. Next to it are usually buttons for activating / deactivating electric motors. This will make it possible to control the processing process from a safe distance.

In addition, the following additional components can be installed on edge trimming machines:

- a ruler;

- depth gauge cut;

- protective mechanism to prevent engine overheating.

Most often, for the manufacture of such, improvised components are used. Therefore, it is impossible to give clear recommendations on the assembly. Technology directly depends on the characteristics of the constituent elements.

For example, you can see the design and operation of a homemade woodworking edge trimming device:

Edging machines

The production of lumber from logs is accompanied by the formation of rounded waste. On large equipment with a circular saw, it will not work to process them into products suitable for further use. For such needs, it is advisable to have a continuous edge trimming machine with one or more saws. You can get your own assortment of building blanks with a thickness of 0.5 cm and above: whetstone, thin edged board, rail, lamellas, glazing bead.

Trimming machine SKIL-1

Various solutions in the design of the machine

Depending on the intended purpose, the installation location, the edge trimming woodworking machine can combine such design solutions:

- internal combustion engine or electric;

- the carriage with cutting elements is driven automatically / manually;

- the number of saws doing simultaneous cutting (1, 2, 3.).

Common for the edge trimming machine are a frame with guides for moving the carriage, clamps. clamps for the workpiece, a control unit, an optional laser line that simplifies positioning operations.

Models for industrial production are distinguished by an automatic device for feeding wood under a fixed carriage. They are supplied with systems for removing sawdust, dust, waste.

Features of work

If a single-saw unit is installed on the edge trimming machine, then one side of the board is cut first, and the second. in reverse. This option is suitable for small processing volumes. The time and cost cutting machine can be cut with a multisaw edging machine, having, if necessary, up to 14 simultaneously working saws. Cutting is done in 1 pass of the carriage.

Circular saws on the trimming machine taiga are installed with rotation in opposite directions.

Manually adjust a two-saw (and more) edge trimming machine, setting the gap between the cutting disks, manually. Later models of two-saw edge trimming machines are equipped with electronic control; there is no need to mechanically reconfigure the machine with your own hands. The rotation speed is changed by a switch, a laser ruler is used to accurately position the board on the table.

Trimming principle

Maintenance of this type of equipment during their work is performed by 2 people.

How to make a manual machine

You can make an edge trimming machine yourself after some preliminary preparation. It is necessary to determine the basic parameters of future equipment, develop drawings of a trimming machine, and provide for basic and auxiliary equipment. It is useful to take into account the technical solutions of standard analogues of well-known manufacturers. Each home-made option is more widely used, if unified by raw materials, products.

The initial data can serve as the technical characteristics of the taiga installations:

- an engine with a power of 5.5 kW for a single-saw k1 to 15 kW for a two-saw k-2m;

- circular saws ø 450. 500 mm;

- rotation speed. 3000 rpm;

- adjustable distance between saws 50. 340 mm;

- cut depth 85. 105 mm;

- the permissible size of the boards is 6.5 × 0.6 m.

Video: How to Make a mechanical feed blank on a saw

The bed for placing the workpiece is welded from the channel to the size of the workpieces inside the passage of the cutting body. The main criterion is stability, lack of vibration during operation. Height 1 m. Guides for carriage rollers are welded along the longitudinal sides.

A homemade unit is best done with a movable saw unit. This will allow you to control the feed rate and the quality of the cut, reduce the marriage.

The moving part is assembled from 2 U-shaped posts connected by a crossbar. This is the frame for hanging the trimmed saws with a drive.

Cut cleanliness can be increased by setting up gear up to 5000 rpm. The engine for a home-made cutting unit is taken from 4 kW (single-saw) and above, the Ø of the blade for a single-saw edge trimmer is from 250 mm.

As the number of drives increases, performance improves. Trimming three-saw unit will effectively cut the beam, glazing bead, rail with a minimum of cost.

If you find an error, please select a piece of text and press CtrlEnter.

Edge trimming machines: two-saw, one-saw

Any wood processing enterprise from small to large is faced with the problem of a large amount of waste when processing logs. The sawmill machine makes a rough trimming of the log, cutting it to a square beam, and then, if necessary, dissolving it into bars or trim boards of the required size. It is not rational to process rounded waste at the sawmill.

Wood Trimming Machine

However, this waste can be of great benefit and additional profit. Small edged boards, glazing beads and many other useful products are made from them. For this purpose, an edge trimming machine is installed at each woodworking enterprise.

See also: "Varieties of Prom machines."

Application and principle of operation

Each woodworking enterprise tries to minimize production waste and use wood as efficiently as possible. Edge trimming machines allow you to complete these tasks.

Most often, sawmills install domestic equipment, such as data centers 450, Taiga, Cedar, and more. In everyday conditions, they often use machines made by themselves from improvised materials.

This equipment allows you to trim the rounded edges of the booties and croakers and get an edged board. Also, the edge trimming machine allows you to dissolve boards into bars and workpieces with a thickness of 5 mm or more. Such products are in great demand, as they are used in construction and decoration.

See also: technical characteristics of the four-sided woodworking machine.

Design features

It is quite difficult to unambiguously describe the design features of woodworking machines, since edge trimming machines have a large number of classifications.

Electric edging machine Altai

By the method of powering the engine, the equipment can be:

The saw unit can be guided manually or automatically using an electric drive.

By the number of saws, the edge trimmer can be:

- single saw. Allows you to make one cut in one pass. To trim the second side, the workpiece must be rotated;

- two-saw. In one pass, the board is cut from two sides. In the domestic market are represented by the data center models 450, Taiga K2M and many others;

- multi-saw. One pass of the material on the working surface allows you to immediately cut the shalevka into bars or boards of the desired size.

Any machine consists of a bed on which workpieces and carriages with an engine that rotates circular saws are laid. It can cut pieces of any length and width, which greatly simplifies the work and reduces the amount of production waste. to the menu

Principle of operation

In general terms, any edge trimming unit for wood type TsOD 450, Taiga and others. single-saw, two-saw or multi-saw works the same way. A wooden blank is laid on a stanitsa along which one or several circular saws moves. The carriage on which the saws rotate is manually moved by the machine operator for special handrails.

See also: parameters and advantages of Corvette sawing machine models.

The single-center data center 450 requires two passes for trimming the edges on both sides. Typically, such equipment is designed so that cropping can be done by moving the carriage in both directions.

Edge trimming machine "KEDR" (Two-saw, 15 kW)

A two-saw machine, on which circular saws rotate in different directions, performs trimming at once from two sides, thereby significantly increasing labor productivity.

Multisaw edge trimming machines are designed for sawing wood blanks into bars or boards of the required size. On such an aggregate, up to 14 circular saws can simultaneously work in parallel.

A two-saw and multisaw edging machine of the type TsOD 450 or Taiga requires adjustment of the distance between the saws. This process on older models is performed mechanically, with their own hands.

The new sawing machines for wood are equipped with electronic controls, which automatically arrange the saws in the right position with an accuracy of millimeter. In addition, the new models, such as the data center 450 or Taiga, are equipped with a laser ruler for setting blanks and switching saw rotation speeds. to the menu

How does a trimming machine work? (video)

Common models and manufacturers

On the domestic market, you can find a trimming machine of various modifications of domestic production. This is due both to the cost and the quality of the units. Foreign models are less common, but they are much more expensive.

Among the single-saw machines for wood, the most popular brands are Cedar and Taiga.

The two-saw machine is represented by models of the data center 450, Taiga K2M, Vanguard, etc.

The widest selection, both among domestic and among foreign manufacturers, multi-saw machines.

Sawmills Altai DPU-500

Multi-saw units belong to domestic production:

Foreign manufacturers offer the following models:

- MS Maschinenbau (Germany);

- Wood-Mizer HR1000 (Germany), etc.

See also: making a tape and circular sawmill with your own hands.

Do-it-yourself machine

It is very difficult to make a two-saw unit with your own hands. Yes, and it is unlikely that it is needed for domestic purposes. Therefore, we will take a step-by-step look at how to make a single-edge edging machine for wood with your own hands.

We note right away that the production of such an aggregate will cost quite expensive. But if you have a lot of unnecessary metal products, old engines and other things lying around in your home gadgets, then it’s quite possible to take up such work.

Scheme of options for cutting logs on a trimming machine

To make a trimming machine, we need:

- Metal pipes, channels and corners.

- Electric motor

- Shafts, for example, from agricultural machinery.

- Circular Saw.

- Tools for working with metal (angle grinder, drill, welding machine).

- Connecting elements (bolts, nuts, couplers).

Work stages

First you need to make a strong, reliable, stable bed with your own hands. A poor-quality bed leads to vibrations, which, in turn, becomes the cause of crooked cuts and damage to the saw. For the manufacture of the desktop, metal channels are suitable.

We will make a bed with parameters of 6500 × 2500 mm and a height of 1000 mm with our own hands. To do this, we need to weld a frame of channels and weld legs to it.

Next, we weld corners to the top of the frame along the longitudinal sides and make a groove for installing the shafts on which the cutting carriage should move.

The letter “P” welds the metal channel to create a carriage and welds the transverse crossbar on which the saw will move.

Install the engine. His choice must be approached especially responsibly. When using a circular saw with a diameter of 250 mm, we need a motor that can provide a rotation speed of at least 5000 rpm.

Homemade woodworking saw machine

We fasten the engine to the bed so that it rotates the saw parallel to the longitudinal edges of the bed.

All welded and bolted joints need to be done with your own hands as reliable as possible. Do not forget that the rotation speed is high, and, therefore, the likelihood of serious injuries is the same.

See also: "How to make a HDTV machine with your own hands from a welding machine?".

Main page »Wood

Do-it-yourself multisaw machine

How to make a do-it-yourself circular sawmill

The modern circular sawmill is a convenient, functional tool for cutting wood.

With its help, even alone you can cope with a significant amount of work in a short time.

But not everyone is willing to pay for the purchase of a circular sawmill. over, many believe that it is much better to make a circular sawmill exclusively with your own hands from improvised materials. What can be advised to those who decided to take such a step?

If you set yourself this goal, then the circular saw blade is best made of duralumin or steel sheet, the thickness of which is at least 3 mm.

over, the diameter of the disk should be in the region of 500 mm. How many teeth should a disc have? If we talk about creating sawmills for cutting a tree, then only 2-3 will be enough.

do-it-yourself trimmer

Such a disk can easily cope with the cutting of most breeds. And the self-made or purchased disk sawmill equipped with it will be quite functional.

In addition, when answering the question of how to make a power-saw bench at home, it is necessary to clarify the engine power. It should be about 2 kW.

Equally important is the correct rail design.

Its simplest option is a p-shaped saddle. It is formed from boards in the form of a log, freed from knots and roughly processed by a planer. An engine with a circular saw is attached to the saddle.

But the most responsible thing that you have to do if you need a home-made, but at the same time high-quality circular sawmill is to make cutting teeth.

The main requirements for them are quality material, the right cutting angle and careful balancing. The best material for making cutting teeth is high-speed steel. And the blanks from which they will be cut most easily are a carbide plate or a broken drill. The cutting angle of future teeth should be 30 degrees.

In this case, the rear angles should be equal to at least 15 degrees. And remember, if the cutters are not well balanced, you will have to deal with rubbing them against the walls of the cut.

And, of course, it is necessary to pay special attention to ensuring the proper level of safety when working with such machines.

Subject to all these recommendations, a circular sawmill made do it yourself, will please you with its quality.

Application and types of edge trimming machines: two-saw or one-saw

Disk two-shaft multisaw machine "Avant-garde MD2-22"

The Avangard-MD2-22 circular multi-saw machine is designed for sawing two-edged timber with a width of up to 600 mm from any, including hardwood, wood species into boards with the help of circular saws corresponding to various wood species.

Sawing is carried out in a vertical plane by moving the timber with track conveyors relative to vertically located saw blades mounted on a common shaft.

The main design features of the machine are:

– The method of supplying the beam to the sawing zone by means of a track chain.

– The drive of the saw shafts is coaxial through self-centering couplings.

– The machine is equipped with automatic pneumatic clamps of the material being cut to the track chains at the input and output of the machine.

– The removal of sawdust from the sawing zone is carried out by a conveyor belt feeding the sawdust to the suction bell.

The machine does not require a special foundation and, if there are certain skills for installing the equipment, it is installed on a hard, level foundation in a short period of time.