Weights for your power tiller with your own hands

Weights are mainly used in tractors that are designed to plow land.

The weight of the tiller increases the weight of the machine and restores balance to ensure leveling on sloping terrain. This increases efficiency and simplifies the work with farm equipment.

Also power tillers are great for carrying small loads on any road. Exactly because of this they became just necessary in the countryside, where there are not always flat excellent roads. And the weighting agent makes it possible to use the farm equipment in this capacity.

Began to look for a reason why a single axle tractor gets stuck

The power to the tractor is enough, even though it is petrol-powered. The big 5/12 wheels provide excellent traction There is only one reason. the small weight of the walking tractor (125 kg according to the data sheet).

Started looking for a way to fix a problem like this.

- 1. Make a mold-weight in the sand and pour molten lead in it (too complicated).

- 2. Make weights out of a mixture of concrete and gravel (cheap, but not durable).

- 3. Fill some container with sand and suspend it from a single-axle tractor (unreliable, inconvenient).

What if you increase the weight of the motor block with metal weights?

I went to the office of ferrous metals reception, where I found some different weights from old industrial scales of the USSR, a pair of pancakes from a sports barbell with the weight of 10 kg. two clutch baskets with flywheels from VAZ 2101.2107 and a 25 kg counterweight from a tractor.

In a local shop with spare parts for power tillers I bought an additional section of cutters for power tillers. faceted tube with diameter of 32 mm and a length of 15-20 cm. on which four blades of cutter are installed. Now I had all parts of future weights assembled.

First of all, installed on the “back” motoblock (that is, on the gearbox, where the battery is supposed to be installed if it was included in the kit) a pair of U-kilogram weights from the scales. I had previously welded the kettlebells together. I attached it to the gearbox frame with two 12 mm bolts. I used a second pair of 12mm bolts to fasten the same weights to the tiller arm of the power tiller.

Then I welded a frame from 40/40 mm angle bar to support a 25 kg tractor weight. It looks like a pancake, 30 cm in diameter and 8 cm thick, in the middle of which there is a slit in the shape of the letter T. I put the weight in the frame and tightened it with a nut, so it wouldn’t fall off while working. I put the construction on top of the weights. The weight of the walking tractor became 48 kg more!

What is it for??

The kettlebells are mainly used in power tillers, which are more suitable for plowing.

The weighting agent increases the weight of the power tiller and normalizes the balance, thus stabilizing it on an inclined plane and on hard ground. This increases efficiency and makes it easier to work with the machine.

And also the engine blocks are great for carrying small loads on any road. That’s why they were just necessary in the countryside, where there are not always flat, good roads. And the weighting agent also allows you to use the machine as a weight.

How to make your own?

Weights are attached both to the very body of the motoblock, and to its wheels. In principle, the role of this very weight can be any object. But it is better to take care and make more or less professional equipment. Let’s see how to correctly make them.

For creation will be useful such components:

But it is also impossible not to mention the necessary tools:

Because of these actions, the weight of the power tiller increases by 40-60 kg. It is better not to use concrete for this purpose.

The list of tools and equipment

As a rule, on each dacha plot there is a sufficient number of metal products and a set of devices for carrying out a wide range of works.

In order to make weighted weights wheels for the motor-block with their own hands, will need the following tools and materials:

- tape measure;

- welding machine;

- construction level;

- angle grinder with discs for cutting and sanding metal

- Electric drill with drill bit set;

- Small steel or aluminum barrel with a twist-off cover;

- pancakes from a barbell weighing 5, 10, 20 kg;

- 30-50 mm steel angle

- paint brush;

- automotive paint.

Checking Supermarket Scales. To Make Sure You Get What You Pay For

Weigh single axle tractor so that it is always possible to quickly dismantle attached implements. They are not needed when mowing grass or performing other work that does not require a firm grip on the ground. Extra weight in such cases will disturb and lead to overconsumption of fuel.

Types of weighting devices

Depending on how they are installed and their design, these devices are roughly divided into several types.

Wheel weights for power tillers

This is the weight most often used, and it is attached to the brackets on the outside or inside of the wheels.

Frame weights on the body

They are used if you need to increase the weight of your power tiller even more; they are made of small weights or bars. Special constructions are fixed on the frame of the equipment with bolts and in such a way that they do not touch the moving elements of the equipment.

Densifiers for power tillers

These attachments are needed if more traction is needed to increase the tractive power of the. this prevents the machine from slipping under high loads.

Choosing weights on the wheels of a power tiller or on its body, you should pay attention to the following characteristics:

- the width of the additional equipment;

- diameter of the structure (for attaching to the wheels);

- Weight of weights (starts from 20 kg and can increase the pulling power of a power tiller by 20% on average).

How to make weights for a power tiller with your own hands?

The weighting of a power tiller can be done in two ways:

The first option

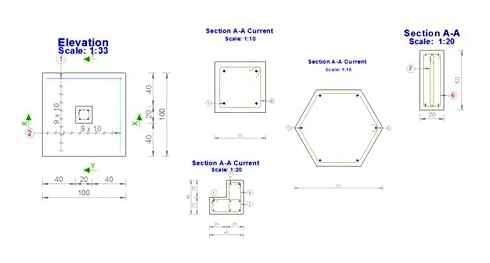

In the first case, an additional frame is welded to the body of the motor block, but in such a way that there is unobstructed access to the engine (after all, you have to periodically change the oil, etc.).п.). Metal pancake is bolted to the installed framework with an approximate weight of 30-40 kg. If necessary this weight can be removed from the power tiller.

Second variant

Before you make weighted weights on the wheels for a power tiller with your own hands, you need to prepare the necessary materials. So, you will need:

- 5 kg weight. 2 pcs;

- Metal pancake. 2 pcs;

- VAZ clutch housing. 2 pcs;

- motorcycle cotter pin. 2 pcs;

- hexagonal piece of cast profile.

If you do not have everything from the list below at home, you can go to the salvage yard. 99.99% chance that you will find the missing items.

Also don’t forget to prepare the welder (1), the angle grinder (2) and the drill (3). Without these appliances you can not do without. First you will have to use an angle grinder to cut off 2 pieces of hexahedron about 5 cm. then you need to drill holes in them for cotter pins. Then each piece is welded to the pancake. The pancake, in turn, is welded around its circumference to the flywheel. Lastly, the weight is attached to it, also by welding. We do the same thing with the second set of tools.

The final chord. to make holes in the inner axis of the wheels for the cotter pin, then it will be possible to attach the weighting agent for the tiller, which you have made yourself. The cotter pin can easily be fixed with a steel wire.

Some models are equipped with grousers. specific spiked wheels. They can be either basic, that is attached directly to the axle, or removable. to be put on top of the main support wheels and fixed with special attachments. These models are very handy for working the ground on slopes, but as practice shows, you also need to install weighting plates for the tiller arms.

Now you know how to weight your single-axle tractor with your own hands. Such upgrade options are suitable for Neva, Salyut, MB-1, Mole, Oka and other power tillers.

Counterweight on a single axle tractor. self-made weights on wheels, how to weight the Neva with your own hands

Using a variety of weights for power tillers, landowners can greatly increase the functionality and scope of these machines. Moto-blocks and power tillers are indispensable aides in earthmoving operations on large and small plots, transportation of goods to short distances.

Less time and effort is spent on the ground with their help. However, in some cases, even the most advanced and expensive equipment, such as the domestic single-axle tractor Neva, can not cope with some tasks. When lifting virgin lands, working on slopes and in damp soil, the wheels of the machine slip, since it lacks its own mass for reliable traction.

In order to weight the machine, a variety of factory-made and homemade weights are used.

Since the store of agricultural equipment can be located at a considerable distance from the dacha site, many property owners make devices for weighting on their own.

Sometimes homemade weights for a power tiller are installed in order to balance its center of gravity. This modification is required when planting or using an adapter.

Let’s consider how you can make weights on a single-axle tractor with your own hands, using tools and equipment that are at hand.

List of tools and equipment

As a rule, each dacha plot has a sufficient number of metal products and a set of devices for a wide range of works.

To make the wheel weights for your power tiller with your own hands, you will need the following tools and materials:

- measuring tape;

- welding machine;

- spirit level;

- angle grinder with discs for cutting and sanding metal

- power drill with drill bit set;

- small steel or aluminum barrel with an unscrewed lid;

- Weights of 5, 10 or 20 kg;

- 30-50 mm steel angle;

- paint brush;

- car paint.

Weigh single axle tractor in such a way, that it is always possible to quickly dismantle attached implements. They are not needed when mowing grass or performing other work that does not require a firm grip on the ground. Excessive loads in such cases will be in the way and cause unnecessary fuel consumption.

Machine wheel weighting

The most common way to weight a machine is to install additional weights on the wheels. The discs, axle and hub are strong enough to handle the added weight of up to 50 kg. There are various ways to make weights for power tillers Neva, Ugra, Kaskad, Rusich, Nadezhda, Forza, Salyut, Mole.

The first method is to make a load out of hollow steel drums.

This is the easiest and most affordable option that does not require serious financial costs.

The work is carried out in this sequence:

How does a Mechanical Scale work? (Spring Scale)

- The metal barrel is cut with an angle grinder into 3 parts (the bottom and top should be 10-15 cm high. depending on the size of the power tiller).

- Bottom and top parts are welded along the cut. The seam can be reinforced with a strip of metal.

- 4-6 through holes are drilled in the billet for bolts, if necessary, they are reinforced with steel washers.

- The hollow tanks are secured to the wheel rims with long bolts and nuts.

- Sand and granite crumb or other loose material is poured inside the nozzle. Water is added to increase its density.

- The lid is screwed on.

This weighted unit can be used in the most extreme conditions. When the need for additional weight is no longer necessary, it can be quickly removed, emptied and put away for storage. It is always practical to have cotter pins with your power tiller to quickly weight it down as needed.

The second method is the production of removable weights from steel. You will need a hexagonal iron bar, the size of which coincides with the hole in the axis of the chassis of the unit. In addition you need to have two 20-kilogram pancakes from the bar.

Subsequent work consists of these steps:

- Two 5- to 6-cm-long pieces are cut from the profile.

- Pieces of the profile are welded to the discs at the hole for the fingerboard.

- In the axis of the machine and in the profile through holes are made for cotter pins.

- Made weights are hooked to the motoblock and fixed with cotter pins.

If it becomes necessary to increase the weight of the wheel, you can weld 10-kilogram pancakes from a bar to the plates. To give the wheel an aesthetic look, old clutch baskets from VAZ are welded to the weights. On top of the basket is applied paint, the color that suits the owner best.

The third way to weight the wheels is to make additional weight from reinforced concrete. These weights are made in the following way:

- A flask is made of sand or gypsum, its walls and the bottom are strengthened with cement mortar or liquid glass.

- A volumetric frame is made of steel sheet and reinforcement, the center of which is a full-body hexagon with a pre-drilled hole for the cotter pin.

- Heavy concrete is produced using fine crushed granite and lead filler.

- The mortar is poured into the mold, carefully compacted and leveled.

- After the concrete gains strength, its surface is treated with impregnation and painted.

It is recommended to leave threaded embeddings for additional weighting of concrete attachments.

belarus-09n single axle tractor. reviews, Комментарии и мнения владельцев and suggestions

majkl wrote: Such a question. how do you think who, and most importantly. why twisted “schmorglka?

In the store, the boys twist. If the guys at the factory didn’t have time to overtorque when the MB was checked. It’s not the normal position of the starter handle.

Michael wrote: The guys in the store turn them over. if the guys at the factory didn’t have time to twist it when they checked the MB. This is not the normal position of the starter handle

And fuck it. ,Why such “pre-sale preparation”?

Michael, the normal situation is as follows?

Mastera wrote: I don’t know about you and mine says so

To quote the owner’s manual: “Section 6.6 How to break in the tractor.A new single axle tractor must be run-in for 50h before use.The engine parts break in during the running-in period, which helps to increase the service life of all parts and assemblies.Make sure to run in under partial load on light transport jobs.”

bulbash wrote: A new single axle tractor should run in for 50 h before operating it

Much! Two tanks of gasoline with an engine oil change

SER2009 wrote: A lot! Two tanks of gasoline and an oil change in the engine

This is your opinion, and I just quoted from the factory manual

.It does not mean that the 50 hours on the pads, just plow, mill, drive with a fully loaded trailer (most likely, these works. a significant load on the drivetrain) should be after 50 hours of work. this is my opinion

Michael wrote: In the store, the guys twist. If the guys at the factory didn’t have time to twist when they checked the MB. That’s not the normal position of the starter handle

And fuck it. ,Why such “pre-sale preparation”?

Michael, and the normal position is this?

Michael wrote: In the store the guys twist it. If the guys at the factory did not have time to twist when they checked the MB. That’s not the normal position of the starter handle

And nah. ,Why such “pre-sale preparation”?

Michael. I started the engine from the right side when I bought it, but this fall I started it from the left side.

Marosz wrote: I started the engine from the right side when I bought it, but this fall I started it from the left side

This is when looking in the direction of travel of the power tool?

Marosz wrote: I started the engine from the right side when I bought it but this fall I started from the left side

This is when viewed from the direction of travel of the powerhead?

Yeah. Wiped the lanyard hole on one side when it was on the right side. Now wiping on the other side. And then I’ll probably have to buy a new cover or come up with something.

Marosz wrote: I started the engine from the right side when I bought it but this fall I started it from the left side

That’s if you look in the direction of travel of the tiller?

Yeah The lanyard hole on one side wore out when it was on the right side. Now wiping from the other side. And then I’ll probably have to buy a new lid or figure something out.

Marosh. That’s starting to bother me, too. I would only like to cut a bigger hole, and make a cord guide out of four small bearings, making a square hole. Do you think it makes sense to try? Or it could be simpler?

Marosh wrote: Wiped the hole for the lanyard on one side when standing on the right side. Now I’m wiping from the other side

And I thought that the shmork twist to not trample cultivated soil when starting

Marosh. Vladimir S Here, it doesn’t wear out! Roller from the building material market, under the round rope. Roller on a bearing. You can put the snotlout anywhere, even to the handles.

My thoughts are only in my head. I’ll take the swarm to the country for the weekend.

Vladimir S. wrote: I want to cut a bigger hole, and the guide on the cord to make four small bearings,

It is possible of course. But the budget options also rule. In the tin to insert a piston (bushing, drilled bolt, weld-soldered smooth washers). My DM-1 has a soldered washer, the Chinese have a sleeve made from a bolt. You can drill a bolt without a turner:

Paul-61 wrote: In the tin to put a piston (bushing, drilled bolt, weld-solder smooth washers). My DM-1 has a soldered-in washer, the Chinese have a sleeve made of a bolt.

Sometimes I transport a single-axle tractor on a trailer and I have to start it up directly on the trailer. Rope in this case is located at an angle to the hub and erases not only the bushing, but wear itself and as a consequence breaks on a very inopportune day. The roller is more reliable.

Majkl, if I’m not mistaken, you have a Lydian cutter.Previously read that it suits you completely, despite the low-slung chain gear housing. At the same time, it turned out to be an advantage (in comparison with the angular Smorgon-very high rpm in the factory mill

).Please tell me which sprockets (number of teeth) were in the factory, and what have you changed?Where did you look for the necessary sprockets and what revolutions of the cutter became after the conversion (at least approximately)?

Marosh wrote: You may not burn four 20-liter canisters in a season. So there is nothing to count, and neatly every spring 1.1 liters to the very cork