Any power tools begin to fail over time. Faults are divided into mechanical and electrical. Of electrical malfunctions, malfunctions associated with the failure of the brushes work are most often encountered. In second place: failure of the armature bearings. Failures associated with failure of the stator or rotor are less common.

And how to determine the malfunction of the stator, rotor of the Makita 2450 and 2070 rotary hammer, replace the brushes? And here we will be helped by the circuit diagram of the Makita 2450, 2470 punch.

How to repair or replace Makita 2450 and 2470 rotary hammer drills

The fact that the replacement of the rotary hammer brushes is required is indicated by increased sparking in the area of the rotor collector, burning smell, and heating of the brush holders.

In a new or repaired perforator, the spark under the brushes is evenly, of constant length and there is no separation of the spark in a circle.

The wear of the bearings, damage to the insulation of the rotor or stator is clearly indicated by a spark around the entire circle of the collector. The appearance of this kind of spark indicates the burnout of the collector plates, the failure of the rotor or stator.

How to remove the electric brush punch Makita

As a rule, it is recommended to change the brushes after 70. 120 operation of the power tool.

To replace the carbon brushes pos.65, they must be reached.

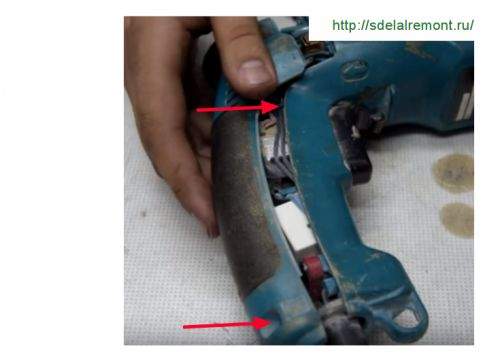

The back cover must be removed from the punch; it is fastened with three self-tapping bolts.

Remove the cover

Disconnect lead wires. Using a screwdriver, remove the latches on the brushes and release them.

Remember! During long-term operation of the tool, it is not allowed to reduce the length of the working part of the brushes from the nominal by 1/3 (about 8 mm).

When one brush is worn, both are subject to replacement.

Real and fake brushes

By the way, a fake can also work well if made from the right material and strictly according to the drawings.

How to make brushes yourself?

The cheapest way to pick up electric brushes is from other models of electric tools by grinding them to the right size with a regular file. This is economical but they will last less than the original ones. It is possible as an option to adjust the carbon rod of the battery or other elements.

Various batteries

It is necessary to take the battery and remove the central carbon electrode from it. It is necessary to grind the electrode with the help of files to the required dimensions of the old electric brush. (This is informational information and is not essential for the application)

It is worth noting that the quality of graphite directly affects the life and sparking.

Homemade carbon rod brushes

After making sure that the brushes are worn, select analogues.

Brush installation

Before you insert the brushes into place, it is necessary to clean the brush holders from soot. This is done with rags soaked in a solvent. It is preferable to remove carbon deposits in the form of particles obtained by intense sparking with a small file. The cleaned brush holders are put in place, brushes are inserted into them and clamped on top with latches.

Brush installed in brush holder

How to determine the integrity of the stator without disassembling the punch

To determine the integrity of the stator, it is necessary to ring its windings, measure the resistance of the winding and the insulation resistance.

Stator and rotor continuity diagram

Video: How To Remove Anchor From Makita 2450 Hammer

To measure the resistance of the winding of a Makita puncher, one end of the tester must be connected to the freed brush holder, and the other at one end of the plug. If the appliance does not show anything, replace the other end of the plug. If the resistance is infinity, the stator is open and requires replacement or repair. Do not forget, you can not do without the circuit diagram of the Makita 2450.2470 rotary hammer.

Simple wiring for a commutator motor

If some resistance is shown, it is important to measure its exact value. As a rule, the stator winding resistance of a Makita 2450 rotary hammer at a temperature of 20 ° C lies within 25 Ohms.

To understand in more detail why sparking of the collector of the anchor occurs and which brushes are better? It will help to understand the video, at the end of the video review important tips for choosing brushes

Video: how to pierce an anchor and pick up brushes

How to remove the stator of a Makita 2450 and 2470 hammer drill for accurate diagnosis and repair

To remove the stator pos. 59, it is necessary to remove the brushes, unscrew the four screws that secure the cover of the mechanical unit. They twist at the end of the lid.

Pulling the black housing and the green in different directions, you will release the housing with a stator. The stator is fixed in a green case.

To remove it, you need to remove the plastic gasket pos. 58 and knock on the end of the case with a wooden mallet or bar. The stator will stick itself out, it will remain to pull it out, blow it and check it completely.

And here is the stator

If you have a short circuit tester, you can immediately check the stator for a short circuit. The device is called IK-32.

The procedure for checking the stator windings

For an accurate test, disconnect the two stator windings from each other in an electrical circuit. Check the resistance of each winding, they must be exactly the same. With a difference of resistances, a winding with a lower resistance most likely has an interturn circuit.

Do it yourself check the stator of the Makita 2470 and 2450 rotary hammer

Diagnostics of the anchor, stator with a short-circuit device and homemade

Video: Diagnostics of the anchor and stator Short Circuit Indicator. Checking the anchor. Checking the stator.

How to check the suitability of a Makita rotary hammer rotor

The validation of the rotor in a Makita puncher begins with its dismantling from the housing.

But first, you need to conduct external research. If the spark from the brushes on the collector in the rotor covers the weight of the collector, if the hammer does not develop speed during operation and its power drops, this is the first sign of a rotor malfunction.

How to get the rotor out of the housing

To get the rotor out of the housing, it is necessary to separate the black and green housing, as in the case with the dismantling of the stator.

Pull out the rotor

Having disconnected the stator housing, take the gear housing (black) in the right hand, and the rotor in the left and pull it in different directions until they are completely disconnected. The rotor is held in the gearbox due to the friction of helical gears.

And this is the rotor

Carefully inspect the rotor manifold. It should not be scratched by brushes. Collector lamellas must be clean.

Clean collector

To check the integrity of the collector, you must use a short circuit detection device. It is easiest to make a chain ring according to the circuit diagram of a Makita 2470.2450 rotary hammer. By the way, you can make such a device yourself if you know how to communicate with a soldering iron.

Short circuit probe circuit

If you are convinced of a rotor malfunction, you can install a new one, or you can try to recover a failed one.

Installation and assembly of a new rotor

Rotor replacement does not require special knowledge and can be performed by any user.

The rotor is inserted into the mechanical block with a helical gear to a snug fit.

Remember! It is very important to correctly install the bearing pos. 56 and the rubber ring 10 pos. 77.

In the Makita 2450 rotary hammer on the rotor, from the manifold side, the bearing 607LLB pos. 56 or domestic analogue 80017 is used, and from the impeller side of pos. 53, the bearing 609LLU pos. 51 or analogue 80019 is installed.

Properly installed rubber ring 19

After installing the rotor, closing it with the casing, put the electrobrushes in place and check the performance of the punch.

Video: how to check the anchor, stator

Video: The hammer rotates and does not twist. How to fix it? Do not forget to read the description of the video!

Video: Lubricating sealed ball bearings, trick

Video: disassembling the punch makita HR2450 5 minutes before m

Everything! You have accomplished a difficult task. The hammer drill works.