Ignition problems

The chainsaw ignition system is a whole complex of elements with which a spark appears when the engine starts. It is needed in order to set fire to fuel and bring the engine into a state of full-fledged long-term operation.

The main element of the ignition system is the spark plug, which should be ignited whenever the engine is in the desired cycle.

And although the system is reliable and thoughtful, sometimes it needs to be repaired, so the user needs to know how his chainsaw is arranged, and also what he can do to repair its ignition system.

A chainsaw is not such a complicated device. However, if a malfunction is detected, it is necessary to have at least basic knowledge in order to find and eliminate the defect that has arisen. Let’s look at the main malfunctions of chainsaws, find out what they are connected with, and also analyze the main steps to fix breakdowns.

The most important thing, before starting repair, is the correct determination of the malfunction. And there can be several reasons for the inoperability of each element. Therefore, before you start disassembling the chainsaw, you need to try to determine what the denial of work is associated with.

As a rule, a failure in the operation of chainsaws is caused by a malfunction of the engine or the occurrence of breakdowns in its other nodes.

Engine failures include:

- ignition failure;

- malfunctions in the fuel supply system;

- malfunction of the piston or cylinder.

In other nodes, most often malfunctions arise due to failures of the brake mechanism, lubrication system, the operation of the clutch, tire, etc.

Let’s look at both groups of faults, so that you can determine the cause of the breakdown on your own, if necessary, without contacting a repair shop.

The most vulnerable element of the carburetor engine is the spark plug. It also allows you to judge the probable causes of malfunction of individual units of the gasoline engine. The following procedure is recommended.

-

Remove the candle and inspect it. A dry candle with a light brown tint of the electrodes can be considered good.

Soot on a spark plug

Chainsaw ignition coil

During installation of a new electrical module on the engine, the magneto clearance should be adjusted. The optimal distance between the flywheel and the ignition coil for most chainsaws is 0.2-0.4 mm.

The gap between the magneto and the flywheel

With such a small gap, it will not be possible to use an accessible measuring tool for direct measurement. In practice, a template is used for the Husqvarna saw in the form of a gasket cut from a thin and flexible sheet material of the required thickness. It is clamped in the space between the flywheel and the coil when it is installed, and then pulled out.

To avoid resorting to adjusting the ignition, operate the tool carefully, avoiding impacts. In particular, this applies to chainsaws with electronic chips in the ignition system, as they are very sensitive to mechanical damage.

- The engine will not start;

- Starts up, but stalls;

- unstable;

- does not develop power, i.e. normally works at idle, but stalls under load.

When repairing a chainsaw at home, you need to act by exclusion. checking one by one our client remains the possible causes of the malfunction, starting with the development of those whose verification and elimination of which takes less time (see here for a device that does not operate a two-stroke engine).

Ignition system Almost all types of engine malfunctions listed above can be caused by ignition system malfunctions. Therefore, when they occur, it makes sense to start troubleshooting with a candle. This is all the more justified because the state of the latter can provide useful information about the operation of the fuel system. So, if a problem occurs, you need to turn out the candle and inspect it.

The wire is disconnected, and the candle is twisted with a special key.

If the candle is dry, it means that the problem is most likely not in the ignition system, but in the fuel mixture not entering the cylinder. You can wrap the candle back and take up the fuel system. If the candle is heavily sprayed with the fuel mixture, then there is an excess of it. This may occur due to misregistration of the carburetor or violation of the start rules.

The presence of a large amount of black soot also indicates a malfunction in the fuel system.

The ratio between oil and gasoline in the mixture may be violated, the carburetor is not adjusted, or poor-quality oil is used. The candle is washed in gasoline, cleaned with a needle or an awl of carbon deposits, clean the electrodes with a fine sandpaper and put in place.

In all these cases, it will not be superfluous to check the gap between the electrodes of the candle. Depending on its brand, it should be in the range of 0.5-0.65 mm. It is necessary to check the sealing gasket of the candle. If it is worn or damaged, the tightness of the combustion chamber may not be ensured, which leads to a decrease in compression in the cylinder and problems in the engine.

Even if in the case of checking the spark plug there is good reason to believe that the fault is in the fuel system, you need to check the spark plug for a spark. The ignition module of a foreign chainsaw then you need to check the gap between the coil. At least in order to be sure that everything is in order with this. How to check the ignition coil of a chainsaw tester, husqvarna module. For this:

- put on the spark plug cable;

- using pliers with insulated handles, thread or nut the candles onto the cylinder;

- pull the starter handle and look. there is a spark or not.

Read:

If there is no spark, you just need to replace the candle. If the new candle does not have a spark, it is necessary to check the condition of the high-voltage wire for an open and contact with the candle.

The reason for the absence of a spark can also be a faulty ignition module or a violation of the gap between it and the flywheel magnetic circuit. It should be 0.2 mm. Violation of the gap becomes especially likely if before that the saw was disassembled with the flywheel and the ignition module removed. The clearance is set using a 0.2 mm thick gasket placed between the flywheel boss and the ignition module. Defective ignition module must be replaced.

Having checked the ignition system in this way and not having detected a malfunction, we can proceed to the fuel mixture supply system.

Fuel supply system. If inspection of the spark plugs found that fuel does not enter the cylinder, you need to consider all the possible reasons for this. It could be:

- the fuel does not flow from the tank due to a clogged hole in its cap (breather), while a vacuum is created in the tank that prevents fuel from flowing out;

- contamination of the fuel filter installed in the tank;

- not receipt or insufficient intake of the fuel mixture from the carburetor into the cylinder.

To diagnose the first two reasons, it is enough to disconnect the fuel hose from the carburetor and see if fuel flows out of it or not. If it flows fully, the breather and filter can not be checked, if it does not or weakly flows, we can assume that the cause of the malfunction is found. Each motorist will need to know how to check the ignition module in case of a malfunction.

The breather is cleaned with a needle. The fuel filter is removed through the filler hole of the empty fuel tank with a wire hook, together with a suction hose, from which the filter is disconnected and cleaned or replaced with a new one. Chainsaw manufacturers recommend changing the fuel filter every three months.

How to check the ignition coil on a chainsaw

hello everyone free skype consultation: opk.vitek TEL: 380979677418.

Inadequate intake of the fuel mixture from the carburetor into the cylinder or a violation of the correct ratio between fuel and air mixed in the carburetor can occur for several reasons: due to clogging of the air filter, unregulated carburetor, clogging of its channels or mesh filter.

As a rule, repairing chainsaws is not complete without cleaning the air filter, since it gets dirty quite quickly. When this happens, air intake to the carburetor decreases, the fuel mixture at the outlet of it turns out to be too enriched, which disrupts the normal operation of the engine. Carefully remove the dirty filter for cleaning so that dirt does not get into the carburetor. The filter should be cleaned or washed in water with some detergent, dried and installed again.

The carburetor’s misregistration is eliminated by its adjustment. This is usually done with three screws. maximum and minimum idle speed and propeller. Adjustment must be carried out in strict accordance with the instructions, non-observance of which can lead to engine damage. Some saw manufacturers leave only one adjusting screw (idle).

Model selection

- Chainsaws

- Spare parts for the Chinese chainsaw 45, 52 cu. Cm

- Spare parts for Chinese chainsaws 38 cubic meters.

- Spare parts for the Chinese chainsaw 25 cubic meters.

- Spare Parts of Chinese Calm 660

- Spare parts for Partners 350, 351, 352, 371

- Spare parts for Partners 340S, 350S, 360S

- Spare parts for Husqvarna 137, 142

- Spare parts for Husqvarna 230, 235, 236, 240

- Spare parts for Husqvarna 365, 372

- Spare Parts for Calm 180

- Spare parts for Calm 210, 230, 250

- Spare Parts for Calm 290

- Spare Parts for Cali 361

- Trimmers

- Spare parts for Chinese trimmer 33, 43, 52 cc

- Spare parts for Chinese trimmer 26 cm3.

- Spare parts for Husqvarna 125, 128

- Spare parts for Champion T283, T284

Chainsaw ignition system. device, check and adjustment

Technical parameters are directly related to the design of the tool and the principle of its operation. For example, power, permissible dimensions of the saw set depend on the volume and type of engine. From the design and materials used. weight.

In general, the design of the chainsaw is a motor, torque transmission mechanisms and a saw blade. Between a motor and a chain connect the gearbox (transmission system) and the clutch system. The saw blade is a tire with a chain placed on it. Since the chainsaw engine is two-stroke, it has 2 tanks. oil (for chain lubrication) and fuel (for fuel mixture).

The fuel mixture is used, and not gasoline, due to the structure of a two-stroke engine that does not have a separate tank for lubricating its internal elements.

The work of the tool is as follows: when the user pulls on the "string" of the starter, the crankshaft spins. In the event that there is a sufficient amount of fuel mixture in the tank, then at one of the revolutions the spark plug fires. a spark ignites the mixture.

When it burns, it emits increasing gases in volume that push the piston. This element is connected via a connecting rod to the crankshaft, which by inertia goes to the second revolution, thereby continuing the process again without the participation of external forces. When the saw starts, the engine begins to unwind the drive sprocket.

On it, in turn, the saw blade is attached, and the chain driven by an asterisk starts to “walk” in the grooves of the tire. The chain is lubricated automatically when driving. at the end of work, turning off the chainsaw, you will notice that a certain amount of lubricating oil flows out of it.

This is unspent oil left in the grooves. Specifications

The size and capacity of the engine directly affect the power of the saw itself, the larger it is, the more energy is released for the movement of the piston. The volume also indicates how much fuel the saw produces in a given time. It should be borne in mind that if the engine size does not match the power of the saw, this reduces its service life due to inefficiency of use.

The volume of the tank for the fuel mixture is from 0.3 to 1 liter. Accordingly, the oil tank is 1.5-2 times smaller. Such a difference in volumes helps to use the fuel mixture and oil at almost the same speed (about 30-50 minutes) at full load on the tool.

In household class saws, the engine capacity reaches 40 cc, which is 1.5-2 hours without refueling. Semi-professional saws that can work for 8 hours have an engine capacity of up to 60 cc, and professional saws up to 121 cc. High-volume models are additionally equipped with start-up facilitators.

The larger the engine capacity, the more powerful the saw, and, therefore, more productive. The speed and intensity of the cut depend on the power. This indicator is measured in “horsepower” or in kW (1hp = 0.735 kW). Depending on the power, the saws are divided into classes and applications. Up to 2 kW. domestic From 0.74 to 2.94 kW. semi-professional

From 2.94 to 5.15-6 kW. professional

Chainsaws with high power require additional physical effort during operation and knowledge of safe use techniques, since it is quite difficult to operate such a tool. The power of the equipment may decrease due to the natural wear of the components, the use of low-quality fuel mixture and improperly selected saw set.

Weight

Nominally, the weight of the saw is the sum of the weight of the engine and the body with handles. Knowing the weight, you can also get an idea of the functional equipment: Household saws weigh an average of 2 to 5 kg.

They do not need a lot of power and the main requirement for them is the convenience and simplicity of performing periodic small works (harvesting firewood, cutting branches). Semi-professional saws weigh slightly more. 5-7 kg, which indicates a higher power, and, accordingly, an expansion of the front of work.

Since this type of saw is often used as delimbers, lightweight tires are provided in the design.

In fact, the master, when using a chainsaw, experiences the load not only of these elements, but also of the weight of the saw headset, completely filled tanks for fuel and oil. Therefore, if a small mass is an important criterion, it is worth giving preference to household and one-handed saws. they are easier than others.

This parameter becomes decisive when choosing a tool for crowning. cutting the upper branches and the entire crown of the tree. A heavy chainsaw in this case is not only ineffective, but also dangerous. low maneuverability, and the mass and vibration of a powerful engine will quickly lead to fatigue of the master, it is difficult to keep it on weight and it is completely impossible to do it with one hand.

Video: How to Test a Chainsaw Ignition Module

Therefore, for this type of work and recommend a specialized, lightweight tool.

It should also be borne in mind that people who are contraindicated in intense physical exertion are not recommended to use chainsaws whose weight exceeds 5 kg.

To work with a professional tool, you need good physical preparation, because for such saws for safety reasons, there is no belt fastening due to the great risk in case of unforeseen complications in the work (tree fall, for example). The operator must have time to release the tool, and not to be released from it.

A gear emphasis facilitates management on professional saws. It is located on the case next to the saw bar, so when this element rests on the tree trunk, the saw is easier to hold. it is no longer on its weight.

The tire is one of the main parts of the saw apparatus. It is a support for the chain and a channel for its lubrication (due to the movement of the chain shanks in the grooves during operation).

An important characteristic of a tire is its length. It is she who determines the maximum thickness of the barrel that the tool can saw. The longer the tire, the greater the depth of cut.

So the entire saw set will wear out much faster and fuel consumption will increase. Chainsaws with short and standard (30-40 cm) tires are more likely to be found in the domestic class, and for professionals, lengths from 45 cm to 1 meter are possible.

It should also be borne in mind that with an increase in the length of the tire, the recoil force increases with the resistance of the material.

Chain pitch

The saw chain is part of the saw unit. Consists of riveted links (teeth). Its parameters are chain pitch, profile height, thickness of the leading link and cutting depth. The main step among them is the chain pitch. this is the distance between three consecutive rivets on a chain divided by 2.

The chains are divided into five groups, depending on the step size: 14 inches (6.35 mm)

Rarely used miniature chains. They are mounted on low power one-handed saws.

0.325 in. (8.25 mm) and 38 in. (9.3 mm)

With this step, low-profile chains go. than 80% of the saws produced worldwide are equipped with similar chains. They are also the safest for inexperienced users due to their low likelihood of a shock back and low vibration during operation. 0.404 inches (10.26 mm) and 34 inches (19.05 mm)

This step is distinguished by a chain with increased productivity, which has large links. These chains are used on harvester equipment and powerful felling saws. A big step, due to this, and a larger layer, removed in one pass, but, accordingly, the resistance of the processed material is also greater. Additional properties

The presence of anti-vibration system

First of all, the use of such a system is necessary on professional models of chainsaws, as prolonged work with a powerful vibrating tool adversely affects the joints and can lead to serious consequences.

Dependence of the impact of the chain elements on the material: less step. less removable layer in one pass, respectively, and the resistance of the wood is also less. As a result, the level of vibration naturally decreases.

In the absence of a normal anti-vibration system in the instrument, several years of operation can lead to sad consequences, ranging from circulatory disorders in the hands and ending with more serious diseases.

However, some household chainsaws do not have an anti-vibration system.

Its absence is explained, firstly, by the short duration of the use of tools, and secondly, by the fact that they do not develop high power and chains on them with a smaller step.

When purchasing a chainsaw, buyers often ask about the speed of sawing wood with a specific instance of a chain saw (for example, whether it is necessary to “press” the entire tool when working). We answer: first of all, it depends on the state of the saw headset and, in particular, the chain.

- Coil resistance measurement. This method is not always applicable: firstly, it is necessary to know the resistance parameters of the coil. Secondly, the ignition, in addition to the inductor, contains semiconductor elements to form the desired high-voltage pulse. Therefore, when you try to call the magneton through the high-voltage and negative wires, we get either the “Chain break” indication or a huge resistance. If the circuit still rings, this is most likely a sign of malfunction.

- Using a device that tests spark. It is mounted in an open circuit between the spark plug and the high voltage ignition coil. The device is expensive and is used mainly in serious service centers.

- With a candle. Turn out a candle and attach its case to the cylinder. Pull the starter and observe the spark between the contacts. This method is approximate and does not give a complete picture of the state of the ignition coil, since the spark plug is not under pressure, and the flywheel will rotate faster due to the lack of compression in the engine (the spark plug is turned out)

- The "barbaric" path. It is used at your own peril and risks in desperate situations.

- remove the cap from the candle and insert a nail into it. Caution, do not damage the inside of the cap, and then lay it on the candle and use. A hat in a nail is better to bite off. Otherwise, it can be difficult to extract it.

- put the nail 6-7 mm out of the cylinder.

- “Start” the engine, that is, follow the usual steps at the factory. This will make the ignition system work. Please note that the candle must be screwed into the hole for the candle.

- Look at the presence and color of the spark. Ideally, the spark should be “strong” and bright blue. Everything else is a malfunction.

- Important points:

How to check the ignition coil

Modern electronics has revolutionized the world in many ways. Even tools such as chainsaws have been affected by high technology. Today’s saws are light and powerful. Electronic ignition systems are one of the most significant factors in this evolution. Below are interesting materials about such an important component of a chainsaw as an ignition coil.

Not too many years ago, the ignition systems used in professional saws were cam. They were heavy, complex, expensive and prone to all sorts of problems. especially on rainy days. Even when the saw “had a spark,” it was often difficult to start. Some saws barely produced enough energy to give a flash at the crankshaft speed. And the constant twitching of the starter handle was the norm.

Today’s systems are small, lightweight, and durable. Compared to earlier ignition systems, they are almost trouble-free. A modern coil is professional and almost always serves the entire life of a chainsaw. While changes to the ignition systems were overwhelming, work problems can sometimes occur. Often these problems are easily fixed by yourself and do not require a trip to the workshop for expensive repairs.

Some early electronic ignition systems consisted of two parts. a launch module and a coil. Today they are combined in one part. On saws with dual ignition systems, the trigger module can be replaced without changing the coil. This is an easy job, as the trigger is usually installed with a pair of screws.

When replacing this part, simply remove the old module and install the new one in its place. Just make sure the new module has a good foundation. If you notice any corrosion on the mounting connections or if the screws were not tight, this could be your ignition problem. Modules should be well connected.

Replacing the coil is a little more difficult. The ignition coil is mounted in the fan housing next to the flywheel. The module, in contact with the magnetic field of the flywheel magneto, produces energy for the spark and contains a link to the ignition timing. When replacing a coil, remove the old coil and inspect it.

Even if you do not see any damage, check the crankshaft bearing. If you feel movement and play in this bearing, replace the bearing. Also inspect the flywheel. If everything looks good, install a new coil. The base of the coil should be installed about 1. 1.5 mm above the magnets on the flywheel.

When replacing a coil, the gap should be set ideally to ensure that the flywheel does not touch the coil anywhere it rotates. It is also not permissible to use thick cardboard and thick paper, the clearance should be appropriate, pay special attention to this.

Today’s ignition systems have changed and have features that change momentum depending on the speed of the saw. Such a “curve” is programmed in the “chip” and helps the saw to produce more energy, so the changed pulse gives more time to burn the fuel, thereby receiving more energy stored in the fuel. In addition to more power, some ignition systems make starting up the saw easier.

While ignition systems are becoming more powerful and powerful, the components themselves are becoming smaller and more durable. Nowadays, failure of the ignition coil of a chainsaw is a rarity.

Ignition systems have come a long way in the last ten years, but engineers say new technologies will drive even greater improvements in coming years.

I hope this information helps you diagnose and resolve problems with your saw’s ignition system. If you did not manage to eliminate the breakdown, we are always glad to see you in our workshop. We offer only high-quality repair of chainsaws. Phone of our workshop 8 (499) 390-93-49

Before working with the ignition coil, it is worth checking the operability of the entire circuit. Follow these steps:

- visually assess the absence of cracks and visible defects on the coil housing

- pollution of conductive elements and components

- operability and insulation of high-voltage wires, wire contacts, reliability of their fastening, absence of rust in the places of fastening

- check the condition of the candle cover: it often disconnects from the high-voltage wire and tries to restore it using "improvised" methods. Remember: any “snot” in this place reduces the quality of the electric arc of the candle

- check the condition of the candle. The quality of our gasoline does not allow the candle to "live long",

- check the operation of the circuit breaker. This is especially important for Chinese saws and trimmers.

The meaning of these actions is to exclude from the list of possible failures all elements of the circuit, with the exception of the coil. If everything is in order, we move on.

In most modern models, chainsaws and trimmers do not require setting the ignition time. This angle is determined by the position of a special groove on the flywheel for the keyway to the crankshaft and magnets mounted on the same flywheel.

It is only necessary to correctly set the gap between the flywheel and the ignition coil. The gap may vary depending on the model of tool. Usually it is 0.2-0.4 mm. Since the flywheel is round, a conventional car probe will not work for this purpose. Technically, it would be wise to expose the gap with a special pattern.

But it is not always possible to purchase. The acquisition of such an expensive template for a one-time use is unreasonable. Instead of a corporate template, you can use a strip of plastic water bottles. Cut a strip of the bottle in a place where there is no embossing. Then the steps for setting the clearance are approximately the same for the chainsaw and trimmers:

- Loosen the ignition bolts.

- Point magnets on the flywheel to the ignition coil

- Clamping the flywheel between the flywheel and the coil, tighten the mounting bolts.

- Remove strip

- Rotate the flywheel 360 degrees several times, making sure that it does not cling to the coil anywhere.

All. The gap between the coil and the flywheel is set.

Repair of the ignition coil is impossible and impractical. Below is a list of ignition coils that can be purchased on our website.

This part of gasoline saws includes a number of interconnected parts through which sparking occurs at the time of starting the engine. Their main purpose is to ignite the combustible mixture so that the engine can enter the operating mode.

Despite the thoroughness of this part of modern chainsaws, it periodically also needs not only repair, but also the correct adjustment. And what you need to know for this, and will be discussed in this article.

In addition, the shape of the cutting tooth and the chain pitch make a significant contribution to productivity.

But there is no doubt that, by informing us of such indicators, the manufacturer thereby assumes responsibility for the level of equipment operation. And, knowing the cutting speed, you can expect that your chainsaw is capable of this without threatening its integrity.

Air filter installation

The meaning of the presence of an air filter in chainsaws is that it keeps dust, sawdust and other small particles from getting into the engine and chassis.

The protection system in this case is two-part: the impeller mounted on the motor shaft will become the first barrier, and the air filter itself, kapron or felt, will be the next. This element retains most contaminants and is easy to clean or replace during maintenance.

It can also be impregnated with special oils that increase the capture coefficient of microparticles and prevent their "cementation".

Chain brake

This function is a direct necessity, proceeding from the features of the operation of the chainsaw: with a “reverse impact” or accidental break of the chain, irreparable harm may be caused to the operator.

Therefore, the best solution in this case is to stop the circuit. It occurs through a mechanism that is activated by the chainsaw shield.

If the saw’s hand rests against it, then through the lever the force is transmitted to the brake and the chain is blocked. This can happen automatically.

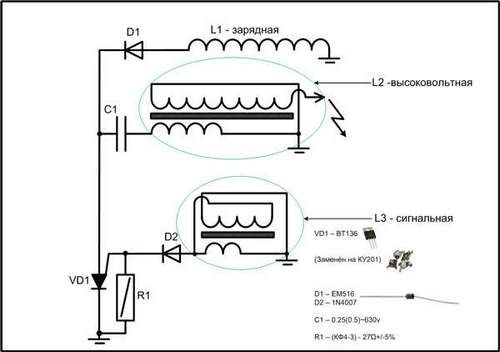

The standard carburetor engine ignition system consists of:

- magneto;

- spark plug;

- an electric cable connecting them to each other;

- engine shutdown keys.

Ural chainsaw ignition scheme

Magneto is a type of alternator that supplies electricity to a spark plug. It consists of a fixed winding of an inductor and a permanent magnet mounted on a flywheel that rotates with the crankshaft of a gasoline engine. A moving magnetic field creates an electromotive force in the low-voltage winding, which is transformed by the transformer into voltage with a potential sufficient to produce a spark.

For contact magnetos, the first output of the high-voltage winding is connected to the spark plug, and the second through the mechanical switch to ground. At a certain moment, a special structural element makes contacts, which leads to a sharp increase in the voltage in the network and the passage of sparks in the interelectrode space of the candle.

The ignition circuit of a chainsaw with a contactless magneto is based on the operation of the control coil, which plays the role of a voltage supply regulator. The electronic unit also includes a diode, capacitor and thyristor, which transmits current with a voltage of a certain value. When it opens, the capacitor is intensively discharged, forming a current in the turns of the primary winding, which is inducted into a high voltage voltage, which gives a breakdown on the spark plug installed in the cylinder. The electric network operates in a pulsed mode to the beat with the rotation of the crankshaft and the translational movement of the cylinders.

- First you need to set the multimeter so that the arrow of the device is located at around 200 ohms;

- After that, you need to open the operating manual of the chainsaw and study the optimum resistance indicated there for the primary winding of the ignition coil. As a rule, this indicator ranges from 3 to 5 ohms;

- Next, you need to connect the primary ignition coil to the device. If the performance of this part of the coil is normal, we begin to check its secondary winding;

- We study the operating instructions again and look at the optimum resistance values indicated for the secondary winding. It is worth noting that this part of the element has great indicators, so the multimeter should be set so that its arrow is located next to the 20K indicator;

- Next, we connect the device to the hole of the coil into which the wires are inserted. If the multimeter shows normal values, then the coil is fully operational. However, if the resistance on the device display is far from the parameters specified by the manufacturer, then the coil will have to be changed.

- remove the cap from the candle and insert a nail into it. Caution, do not damage the inside of the cap. then he put on a candle and exploited. A hat in a nail is better to bite off. Otherwise, it can be difficult to extract it.

- put the nail 6-7 mm out of the cylinder.

- “Start” the engine, that is, follow the usual steps at the factory. This will make the ignition system work. Please note that the candle must be screwed into the hole for the candle.

- Look at the presence and color of the spark. Ideally, the spark should be “strong” and bright blue. Everything else is a malfunction.

- Important points:

Read:

Read:

Replacing Wear Parts

If you do not replace the wearing parts in time, their excessive wear will adversely affect the other parts of the chainsaw. In particular, if you do not change the tire and the drive sprocket in time, increased vibration will adversely affect the crankshaft bearings. 2 how to check magneto ignition module.

Chainsaw ignition module. The maximum depth of the tooth sprocket should be 0.5 mm. In practice, sprockets often operate to a wear depth of one mm or more. not suspecting that this leads to an increased load on the crankshaft bearings and their accelerated failure. When 3-4 chains are worn, it is necessary to change the tire itself, by this time its wear reaches its limit values.

The chainsaw tire wears out especially in the area that is cut most often, usually. this is the underside of the guide rail. For uniform wear, each time the chain is replaced, the tire must be turned 180 ° relative to the horizontal axis.

When installing a new chain, put a new drive sprocket. Since under normal load the service life of the drive sprocket is twice as long as the service life of the chain, it is advisable to use one sprocket for alternating operation of the two chains. Thanks to this, the sprocket and chains wear out almost simultaneously.

Read:

Why you need a good spark.

Read:

The quality of the spark determines its ability to ignite a properly formed air-fuel mixture under operating conditions. A weak spark under high pressure and temperature in the combustion chamber cannot do this. Ignition occurs later or does not occur at all. There is unevenness in the engine, the engine is not gaining momentum, there is vibration, detonation, the starter can have a “rear impact” effect.

How to check the ignition coil on a chainsaw

to all the great skype welcome advice: opk.vitek TEL: 380979677418.

HOW TO DIRECT IGNITION IGNITION, CHAPSOLE Partner, McCulloch, Jonsered, magnetic clearance

The video talks about the ease of adjusting the magnetic gap using the wall of a plastic bottle. Repairs.

The insidiousness of such a breakdown is that the diagnosis below does not give one hundred percent confidence in the efficiency of the ignition coil. Such an implicit breakdown, when there is a spark, but this is not entirely correct, is often misleading and makes it possible to write off problems with the ignition coil in case of a carburetor malfunction.

Typical actions in such cases. this is an increase in fuel supply. It turns out that a spark can ignite such a spark, but the correct one does not. But the use of enriched mixture leads to rapid wear of the cylinder-piston group and muffler. Therefore, in such controversial situations, re-check both the carburetor and the ignition coil.

The insidiousness of such a breakdown is that the diagnosis below does not give one hundred percent confidence in the efficiency of the ignition coil. Such an implicit breakdown, when there is a spark, but this is not entirely correct, is often misleading and makes it possible to write off problems with the ignition coil in case of a carburetor malfunction.

Typical actions in such cases are to increase the fuel supply. It turns out that a spark can ignite such a spark, but the correct one does not. But the use of enriched mixture leads to rapid wear of the cylinder-piston group and muffler. Therefore, in such controversial situations, re-check both the carburetor and the ignition coil.