How to Cut Ceramic Angle Grinder Cutting tiles correctly with an angle grinder at home will not chip. Find out how you can cut an angle grinder neatly and which disc is right for this. Finisher’s advice.

How to cut ceramic angle grinder

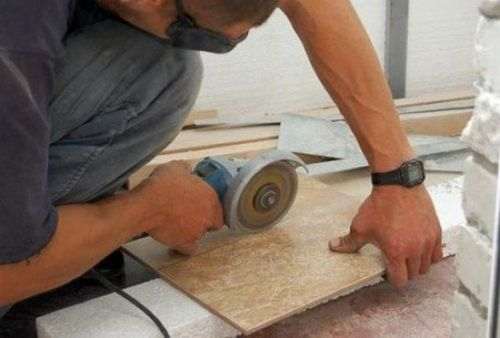

One of the tools used to cut ceramic tiles is the grinder angle grinder (angle grinder), commonly referred to as an angle grinder.

- Safety instructions for working angle grinder

- Ceramic Cutting Discs Angle Grinder

- Stone discs

- Dry cutters

- Segmented dry cutters

- Solid dry cutters

- Direct Cutting Ceramic Angle Grinder

- Angle Grinder Cutting Large Holes

- Grinder cutting rectangular holes in tiles

- Shaped tile cutting angle grinder

- Summary

The price range of various grinder models makes it available not only for professionals, but also for home craftsmen, so when using an angle grinder, you need to know not only the capabilities of this power tool, but also the rules for handling it in order to avoid injury.

Angle grinder is best used with adjustable speed

At home, a small grinder is used, designed to work with discs with a diameter of 100-125 mm and performing many operations. The tool can be equipped with a speed controller.

Direct Cutting Ceramic Angle Grinder

On the front side of the ceramic tile, a cutting line is applied with an alcohol marker. The angle grinder is turned on and given a couple of seconds to set the set speed.

The optimum rotational speed of a disc with a diameter of 100-125 mm when cutting ceramic tiles is 6-8 thousand rpm. The tile is placed on a flat wooden surface, secured with a clamp through a rubber sheet gasket, or you can simply press it against the board with the sole of your foot (wearing safety shoes!).

Cutting ceramic tiles can be straight and curly

Exactly along the intended mowing line, an incision is made with a depth of 1-5 mm, depending on the material and thickness of the tile. Start cutting slowly from the edge of the material, then move the angle grinder faster so the cut is smoother. Once the cut has been made, the tile can be broken by placing a pair of nails underneath it opposite the beginning and end of the cut.

Stone discs

Stone discs are several times cheaper than dry cutters, but they wear out during operation and must be replaced with new ones. In addition, they are thicker than dry cutters, so the thickness of the mowing line for cutting with a stone nozzle is wider and, accordingly, more dust is generated during operation.

In the process of cutting with a stone nozzle, it is necessary to control the condition of its cutting edge, if a chip or burr forms on the edge, the disk must be replaced immediately, since such damage is fraught with destruction of the nozzle and causing injury.

Required tools and materials

Cutting ceramic tiles is a laborious process that requires maximum concentration. The difficulty is largely due to the fact that the tiles are made of durable material. Dust-free tiles can be cut and sawed down with a tile cutter, but such a tool is not cheap. This is almost impossible with conventional cutters and saws, and the cut will most likely be uneven and unattractive. A regular angle grinder is best suited, with a cutting wheel that allows you to neatly cut tiles even at home.

Despite the fact that this process is relatively difficult, if you get the hang of it, it does not take much time and does not require much effort. This task can be handled by an ordinary homeowner who has not dealt with such work and can even cut off a hog without the help of a tile cutter.

You can cut tiles using the following tools:

- Special tile cutter;

- Diamond tools;

- Angle Grinder.

For cutting ceramic tiles, those that are diamond-coated are suitable. Their use minimizes the formation of cracks and chips. It is forbidden to use discs used for metal work, as they will only damage the tile. Even if you manage to cut with such a circle, it will be uneven and of poor quality. This is due to the sliding of the disc on the tile, due to which the presence of small cracks is inevitable. At the same time, when it comes to home surface finishing, you can ignore these damages, since they will surely disappear during subsequent processing.

Be sure to carry the following attributes with you:

- Glasses;

- Mask;

- Thick gloves.

Please note that the selected angle grinder or grinder must have a speed regulator, since many modern inexpensive tools do not have this function. Such models operate at the highest speed, which is why it is impossible to cut tiles with their help.

We cut the tiles correctly

When using tiles for wall decoration, a situation will surely arise when you need to cut off part of the slab so that it fits into the remaining space. over, a similar procedure will be required regardless of which type of tile you choose. Cutting is required most often when unique patterns are created on the walls or various decorative objects are formed using tiles.

If you have already prepared all the attributes you need for work, you can consider how the tile should be cut correctly. An angle grinder is an excellent assistant in this matter, since with its help you can create not only straight cuts, but also curly cuts. Next, we will look at how to cut tiles in various ways.

A straight cut is as simple as possible:

- First, you need to fix the tile on the plane so that it does not slide or ride on it.

- The part of the tile that needs to be cut must remain in weight. The surface line will be the guideline for the notch mowing line;

- Take an angle grinder so that you can see the cut line. If you hide it from yourself, you will not be able to make an even cut.

- You need to direct and move the blade towards you, not away from yourself. This is the mistake many newbies make. Hold the tool firmly and level so that it does not walk in different directions, otherwise the cut will be ugly. Holding the angle grinder crooked can damage the disc, as it can fly off.

A round hole is made as follows:

- Initially, you must use a marker to draw the required hole. Draw on the glossy side of the tile.

- Then you need to determine the center of the circle. This can be done using straight lines drawn crosswise.

- Gently file the tile with an angle grinder from the inside in a circle until we go deeper.

- The angle grinder must be turned so that the blade gradually fits into the outlined circle.

- When the cut is deep enough, you need to cut the drawn cross along the drawn lines, after which you carefully take out the resulting 4 sectors of the circle.

You need to cut the tiles only on the front side, since this is the only way to get a cut without various defects. Consequently, all possible damage will be concentrated on the back of the tile, which will be hidden with tile adhesive.

It is best to measure and mark the tiles to be cut from the start.

To cut at a 45 degree angle, follow the instructions below:

- It is important to note that cutting the tiles obliquely is more difficult than making a straight cut. However, this is much easier than creating curly elements. You need to start by doing.

- The angle grinder must be turned so that the disc is at the angle you need, while you must carefully drive the blade, removing excess, so that at the end an even angular cut is obtained.

- Perfectness can be achieved by using ordinary sandpaper, which is best fixed on a block.

How to cut tiles with an angle grinder?

When doing renovations, many homeowners find it necessary to cut ceramic tiles that can be done using an angle grinder. This tool allows you to do this work at a high level, with minimal risk of chips or cracks. In this article, we will show you how to cut ceramic tiles using an angle grinder.

Straight cut

It is not difficult to master it, at the same time the cutting line is clean and without chips. When performing the work, the tiles are securely fixed on a flat surface, marked with a pencil or felt-tip pen. The part to be cut should hang freely from the table. The cutting tool is at right angles to the workpiece. Carefully, without jerking, drive the angle grinder slowly along the marked mowing line. The tool should be moved towards you so that the marked line is visible.

How to get rid of dust when cutting tiles

Cutting tiles with an angle grinder is not very difficult, but it generates a lot of dust. There are tricks that can help reduce dust formation. Specialists use special tile cutters for this, but buying them for a one-time job is impractical due to the high cost. Therefore, when processing parts, the craftsmen act differently. First, a layer of glaze is cut through, it almost does not dust, the main dust appears when a layer of fired clay is processed. Then it remains to gently break the ceramic tile and process the edges with an abrasive material.

A common way to get rid of dust is to moisten the workpiece. For this, water is constantly poured into the working area with a diamond wheel. After each pass of the tool, fill the seam with water or install a special device for supplying water to the working area. This device attaches directly to the protective cover of the angle grinder. As a result, the workpiece is processed without dust.