Can an angle grinder be lubricated with lithol

Lubricants for gearboxes and bearings (e.g. tapered bearings) differ in properties. Bearing materials must have high adhesion. The lubricant should stick firmly to the gear teeth during operation. Gearboxes are lubricated by splashing.

Suspended lubricant forms a kind of mist during operation. In addition to adhesion, there must be other qualities. For example, the resistance of the grease to high temperatures is important. It should easily withstand high temperatures and not melt at them.

There are several ways to reduce the frictional effects on the interacting gear elements of the angle grinder. The choice of what to lubricate the friction nodes, is made from such options:

- the use of expensive special lubricants for gearboxes from well-known brands;

- the use of universal compounds suitable for any power tool;

- Lithol or solidol lubrication of the gearbox;

- Use of self-made lubricant.

Application of special materials. the best solution. When choosing grease for the gearbox, it is recommended to give preference to compositions produced under the same brand as the angle grinder itself. For example, if the machine brand AEG, then the lubricant should buy the same brand.

When using specialized products, the service life of the angle grinder increases significantly, as the manufacturer takes into account all the features and nuances of operation of their own equipment. The disadvantage of using brand materials is their high cost, which can affect the family budget.

Specialists and craftsmen for maintenance recommends buying any budget does not branded composition, designed specifically for gearboxes. You can also use a lubricant used for the CV joints of front-wheel drive vehicles operated under significant loads. It can be easily purchased at any auto shop. This option is much worse than using branded materials. This is connected with the fact that the specifics of friction units of two different mechanisms are not taken into account.

The most unfavorable solution. the use of lithol or solidol, as both of these materials are not designed to lubricate friction units heated to high temperatures. Some owners of bolt cutters use only these compounds, which causes their machines to fail to last through the manufacturer’s stated service life. In the pursuit of profit here and now, they do not consider the future costs of purchasing new tools or replacing expensive parts.

Brands and their characteristics

Tips for choosing a fluid will help you buy a quality and suitable product. The peculiarity of foreign manufacturers is that they use ointments for their products. Such masses have a special development technology. All types of liquids have different markings. Combinations of letters and numbers are coded for certain characteristics.

For example, one of the most expensive imported ointments has the following characteristics:

- is used for molybdenum;

- has the second class by viscosity properties;

- preserved ISO standards;

- German DIN standards were applied during the development of the grease;

- belongs to K type.

You will have to pay a lot for a grease with these characteristics. It is called Makita. It can be purchased in tubes. High price can be considered a plus for quality and durability of use. Therefore, cheaper lubricants are also available on the Russian market. High of greases from foreign manufacturers increased interest in domestic products.

Russian-made fluids are suitable for various types of tools and are of the same quality. Peorators, drills, gearboxes. they all have their own type of grease.

Lithium greases have good reviews. They are good at repelling water, as well as designed to work at different temperatures. Organic and inorganic ingredients contribute to thickening.

Tsiatim-203 is used for closed types of bearings. It’s not a good idea to grease other bearings.

There are also pigmented greases, they differ in their color. There are blue and dark purple VNIINP greases. You’ll pay more for the first grease than for the second. That’s why they buy it less often. Although the quality of the product is quite good and worth the money spent.

Is it possible to lubricate the gearbox with lithium grease??

It should be noted that many brushcutter owners on the expanses of the former CIS countries for the grease gears use regular Lithium-based Lithol-24 or grease for Cables. It’s easy to fill a gearbox with a 5cc medical syringe.

The most popular gear lubricant is liquid. Contains petroleum-based or vegetable oils. This type of lubricant is used for both worm and gear gears. It effectively protects friction parts, removes heat, decreases noisiness of the mechanism during operation.

What grease for bearings?

No squeak or rattle

| The best greases for heavy-duty joints | 1 | LIQUI MOLY LM 50 |

| 2 | SKF LGWA 2 | |

| 3 | Motul Tech Grease | |

| Best general purpose greases | 1 | GAZPROMNEFT EP 2 |

This standard applies to antifriction multi-purpose waterproof greases Lithol-24 and Lithol-24RK, designed for use in the friction units of wheeled and tracked vehicles, industrial equipment and marine machinery for various purposes, operating at temperatures from minus 40 to plus.

What’s a good grease for bearings?

No squeak or rattle

| Top Grease for Heavy Duty Connections | 1 | LIQUI MOLY LM 50 |

| 2 | SKF LGWA 2 | |

| 3 | Motul Tech Grease | |

| Best general-purpose greases | 1 | GAZPROMNEFT EP 2 |

Clean shaft from dirt and lubricate it with grease “Shruz-4” or “Lithol-24,” not forgetting to clean and lubricate the coupling (sleeve) with the splines in the gearbox. Install the shaft in the boom, and the rod in the lower gear of the lawnmower and align the hole on the boom with the hole for the central screw.

Field of application

Like any grease, Lithol is used where there is friction, rotation, and corrosion protection required. In simple terms, in any kind of mechanism.

- sliding and rolling bearings (both embedded and open in the housing);

- any hinge regardless of the load;

- gears (excluding gearboxes and transmission units);

- pinion-rack gears:

- sliding surfaces of industrial machines. Lithol is practically beyond competition;

- electric contact nodes.

Water resistance test of greases, including Lithol. video

And, of course, the principal use of greases is in the automotive industry.

- Adjustable (adjustable) hub unit bearings;

- axle-shaft bearings;

- constant velocity joints;

- thrust bearings and crosses of driveshaft;

- joints of steering mechanism (if there are grease nipples);

- steering rack (under the protective dust covers);

- traction mechanisms (cords in sheaths, rods, etc.).);

- door hinges, covers;

- embedded sealed bearings;

- friction bearings (except cardan shaft bed);

- bearings of alternator and other engine attachments;

- various guides (power window, sunroof, etc.);. door locks.);

- precision actuators with low axial load;

- door locks;

- electrical pads and connectors (straight through contacts);

- battery terminals (to protect against oxidation).

Use as a friction reduction agent, only in internal cavities. Must not come into contact with the environment. It is not because grease is afraid of air: it just accumulates dust, dirt and abrasive particles.

In friction parts this leads to increased wear: i.e. it works “in reverse. You should periodically replace the grease in critical components.

This consumable is not capricious at all: you can apply it with a brush, screwdriver, an old ruler, or even with your finger. The grease is not toxic (no more than any petroleum product). After handling the substance, simply wash your hands with laundry soap and water. Of course, if you get it in your eyes, please consult a doctor.

Remember the fire hazard! Lithol 24 is flammable in contact with open flame!

Turning on the Mikrotik Cloud feature

And so, run the utility winbox, in case you are using Linux, this utility works perfectly through Wine, about the installation of which there are several articles on the site for Debian, Ubuntu, Fedora. Authorize and go to the IP item and in the drop-down list select Cloud:

In one of the old publications there was a description of a Mikrotik RBM33G motherboard capable of working simultaneously with two cellular modems. Below I will make a short description of how to configure RouterOS to distribute traffic between two lte interfaces.

In the test I will use two Quectel EP06 modems.

Angle Grinders. 5 Common Issues & How to Fix Them

Microtic RBM33 board with two EP06 modems

Microtik Router OS is a very flexible operating system and has a huge number of settings, the configuration I proposed is one of the possible, but not the only. In general the situation of using two gateways simultaneously for Internet access is not standard and has a lot of implementations, and in any case there will be some crutches, anyway spoiling the overall picture, but let’s not speak about bad things for now.

First, let’s do the standard Mikrotik RBM33G setup for Internet access via modem:

- Let’s reset configuration

- Combine all LAN interfaces into a bridge

- Hang address space of 192.168.5.0/24

- Setting up the DHCP server on the bridge

- Configure the firewall

- Set up NAT to access the Internet from our subnet

From now on, you should have internet working through one of the lte interfaces, the other will be idle.

How to properly lubricate an angle grinder

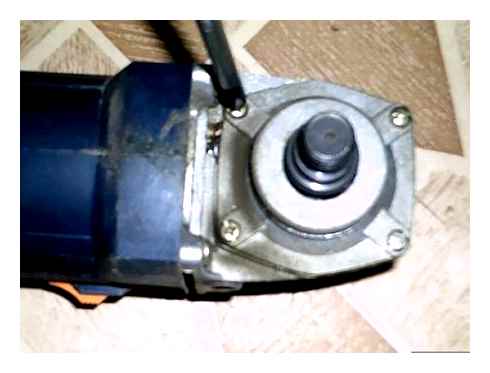

Lubrication of the angle grinder gearbox is carried out in several steps.

Removal of old grease

Removing old grease is the first step in gearbox maintenance. It is necessary to remove the old layer for several reasons:

Bosch angle grinder Greasing

- The used lubricant is not able to fulfill its functions;

- there are small particles in it, formed in the process of wear and tear of the rubbing elements;

- the old grease will be mixed with the new one, it will make the node not work properly, replacing it will not work at all.

Remove waste with disposable paper towels, rags, or a handy rag. All gearbox parts which have been removed must be thoroughly washed in solvent or gasoline, and allowed to dry before mounting. Residues from cleaning agents can also mix with new grease and change its consistency, resulting in poor performance.

Lubricating the bearing

The gear bearings should be lubricated, filling any gaps that may exist. Squeeze out the lubricant until excess lubricant flows out the back of the tube, this is an indication of the fill level required.

Lubrication step on the gear unit

The gears should be filled with as much grease as is necessary to completely coat the gears.

Control the sufficiency of lubricant for the gearbox angle grinder is performed by turning on the angle grinder for a short time. If in 3-5 minutes of operation the temperature of the assembly has increased and some lubricant is observed leaking out, some of its volume should be removed. To do this, the gearbox is disassembled again, and the excess grease is removed with a cloth or rag.

When checking the opposite situation can be observed, when when you turn on the angle grinder appeared noise. This means that the grease is not enough and it must be added.

When using an angle grinder requires periodic checks of the sufficiency of lubrication of the gearbox elements, the quality of available grease.

Domestic producers’ greases for machine tool bearings and gearboxes

With the rise in price of foreign lubricants, domestic lubricants have become especially popular.

Russian lubricant manufacturers have learned to produce high-quality lubricants that fit any tool.

Lubricants have been developed for the gearboxes of grinders, rotary hammers and drills.

Particularly popular are the products of Nanotech Metal Plak Elektra. The range of lubricants available from this company allows you to choose the right lubricant for each component

Bearing grease for angle grinder

Three bearings are mounted on the angle grinder. Two bearings are mounted on the rotor of the tool, one bearing is mounted on the shaft of the driven helical gear with a larger diameter.

Bearings already filled with grease are used in angle grinders. But from improper use, overheating of the tool, the grease leaks.

How to choose the right grease for angle grinder bearings?

Bearing grease must meet the following requirements:

- increase sliding;

- reduce friction between the component parts;

- evenly distribute heat and act as a coolant;

- prevents corrosion;

- Protect wood from dirt and dust;

- work in the required temperature range up to 150C;

Operating conditions of electric motor bearings differ from those of a gearbox bearing not only because of temperature requirements but also because of operation modes, loads, frequency and speed of rotation.

The lubricant for electric motor bearings must have protective properties, preventing penetration of dirt, dust and moisture onto the bearing parts.

Russian market offers a wide range of foreign greases intended for bearings operating in various conditions. But their cost makes us look for cheaper Russian lubricants of the same quality.

Among domestic greases we can recommend the following ones: Cyatim-221, VNIINP-246 (GOST 18852-73), VNIINP-235. Lithium greases are well proven. Lithium greases are highly effective

Lithium greases have proven to be good.

Because they are highly water repellent, they have a wide temperature range. The role of thickener in them is played by organic and inorganic substances. For closed bearings it is best to use CYATIM-203, VNIINP-242 greases.

Among the pigment greases for electric motor bearings the blue grease VNIIMP-246 and the dark purple ointment VNIINP-235 are widespread. The first grease is less widespread than the second one because of its high price.

At today’s Russian market the domestic producers of lubricants are presented in a wide range of products.

Gear lubricant for angle grinder

Grease for the gearbox of angle grinder differs from the grease for bearings in the main feature. increased adhesion. It must hold firmly on the teeth of the gearbox at high rotation.

In general, the process of gear lubrication in angle grinders is due to fine sprinkling of the lubricant and its suspensions. Gearbox works like an oil mist. Therefore, the requirements for gearbox grease are somewhat different.

In addition to increased adhesion, the gear lubricant must be highly heat-resistant and not melt at elevated temperatures.

Gear lubricant for angle grinder with your own hands

And whether it is possible to compose a grease for the gearbox of an angle grinder with your own hands

And the answer to this question is yes.

Since the main technical characteristics of lubricants for the gears of angle grinder are presented above, they can be taken as a basis for composing a grease of the desired characteristics with their own hands.

High adhesive grease should form the basis for homemade gear lubricant. It must adhere firmly to the contacting parts.

Grease for CV joints has a higher adhesion. A CV joint is a joint in a front-wheel drive vehicle that is subjected to high levels of contamination, impact loads, temperature fluctuations and moisture.

Add some liquid grease (MC-20) as the basis for CV joint grease, and use it as a solid lubricant to give the grease consistency you need. MS-20 oil should be applied drop by drop, by thoroughly mixing the mass with a home-made mixer.

Mixture of Ciatim-221 and TAD-17 grease gives good results, with Ciatim as base.

Viscosity

The most important physical property of grease is viscosity. Viscosity determines the thickness of the lubricant layer depending on load, speed of rotation and contact surfaces. Viscosity should meet the bearing requirements. Most general purpose greases have a base oil viscosity of approximately 220 centistokes. This type of grease is suitable for medium loads and medium speeds. If the bearing speed is higher than average, the viscosity has to be lower.

| Operating temperature | DN (speed factor) | NGLI class |

| from.30 to 100°F (from.34.4 to 37.7°C) | 0-75000 | 1 |

| 75000-150000 | 2 | |

| 150000-300000 | 2 | |

| 0 to 150°F (from.17.7 to 65.5°C) | 0-75000 | 2 |

| 75000-150000 | 2 | |

| 150000-300000 | 3 | |

| 100 to 275°F (37.7 to 135°C) | 0-75000 | 2 |

| 75000-150000 | 3 | |

| 150000-300000 | 3 | |

| Depends on other factors such as bearing type, thickener, viscosity and base oil type |

There are many ways of determining viscosity. If you know the value of the speed factor discussed above, you can use the standard charts to determine the lubricant viscosity for a bearing at operating temperature. In the above example (fan bearing), the speed factor NDm was 293125; therefore, the base oil viscosity should be about 7 cSt. The bearing was running at about 150°F or 65.5°C. With the standard viscosity index (equal to 95) this equates to the ISO 22-32 base oil viscosity grade. If you used a standard all-purpose grease, the bearing would get 10 times the viscosity it needs. Although not necessarily a bad thing, in this case, it is too high a viscosity factor.

Excessive viscosity can lead to overheating and increased energy consumption. Both are detrimental to the bearing and the grease. The higher the operating temperature of the bearing, the lower the viscosity of the grease becomes. This can lead to higher lubricant consumption and requires more frequent lubrication. Energy consumption can also increase over time, resulting in unreasonable extra costs. Also, too much viscosity results in more friction.

As for conventional greases, they can be used to lubricate bearings at speed factors up to 500,000. If the speed factor exceeds this value, a high-speed grease must be used. Some greases on the market can operate at speed factors up to 2000000. However, it is worth noting that all lubricants are different, and not all of them can be effective at different speeds.