Preparing a Commercial Lawn Mower for Spring

Warm weather is coming, have you done your lawn mower spring maintenance? If you want your mower to perform reliably and last for years, we recommend you follow these guidelines before you start cutting.

Lawn mower engine oil changes

The obvious point here is to complete an oil change at the intervals recommended in your engine manual. If you can’t remember the hour reading at your mower’s last oil change, stay on the safe side and change it, along with the oil filter.

How to change lawn mower engine oil

Easy-to-read and understandable engine oil change details are outlined in the engine manual for your unit.

- Stop the unit, wait for hot parts to cool and remove the engine key.

- Position a drain pan under the oil drain hose.

- Remove the drain plug and allow all oil to drain.

- Remove and discard oil filter and install a new filter. When installing a new filter, apply a thin layer of oil onto the oil filter gasket.

- Reinstall drain plug and tighten to specification.

- Remove cap / dipstick from engine oil fill port.

- Fill engine with oil of correct weight / viscosity rating and quantity.

- Reinstall cap / dipstick, wait a few seconds and remove. Check the oil quantity and make sure it’s within the markings on the dipstick. Ensure cap is secure before attempting to start the engine.

Yard Force 21” Lawn Mower Self-Propel Spring Repair

How to change lawn mower air filter

Details are listed in the lawn mower engine manual, but it’s as simple as removing the air filter cover from the engine and remove the air filter. If the engine air filter is soiled or damaged, dispose filter and install a new air filter; if air filter appears clean and in good condition, reinstall the filter. After filter is installed, reinstall air filter cover.

Hydro Gear transaxle maintenance

If you don’t remember when the transaxle oil was changed, err on the side of caution. Transaxle oil is a heat transfer, and once it breaks down, it’s no longer an effective lubricant for critical mechanical components in a transaxle. A new Gravely zero turn lawn mower will need the transaxle oil changed after the first 75 hours of operation, but then only every 400 hours after that.

Change Hydro Gear transaxle oil

Changing transaxle oil is just as easy as changing engine oil:

- Park the unit on a flat, level surface, wait for hot parts to cool and remove the ignition key.

- Place a drain pan under the transaxle being serviced.

- Remove the filter guard and filter from the transaxle. Dispose the filter; retain the guard.

- Remove the transaxle vent port plug and allow oil to drain.

- Wipe filter mounting surface clean and lubricate gasket on filter with clean hydraulic oil.

- Reinstall filter and filter guard.

- Add manufacturer’s recommended oil type and volume to the transaxle oil expansion tank until oil reaches top of vent port.

- Reinstall hydraulic oil vent port plug.

- Add oil to transaxle oil expansion tanks until fluid level reaches cold fill mark.

- Purge hydraulic oil system.

Purging Hydro Gear transaxles

When transaxle oil is changed, air s can get caught in the transaxles, requiring the need to purge air from the transaxles immediately after completing service. When purging is complete, recheck the transaxle oil expansion tanks and add oil so it reaches the cold fill line in each tank, if necessary.

The transaxle purge procedure is somewhat involved, so please refer to the operator’s manual for your unit for detailed illustrations and instructions. If the process seems too complex, please leverage the skill and experience of an authorized Gravely dealer.

Sharpening professional lawn mower blades

Sharp and balanced blades have a better cut quality and they reduce the need to mow the same area twice and waste time.

If there’s no access to a lift, blades can be accessed and removed easily after removing the mower deck. Gravely designed the process so one person can do it without special tools, but again, handling mower blades is a delicate process, so please turn to a Gravely dealer for service help.

Remove lawn mower deck

The steps below are an abbreviation of the procedure’s detailed instructions in the operator’s manual. As always, follow the safety instructions in the manual while completing service.

- Park the unit on a flat, level surface and remove the ignition key.

- Remove the left belt cover.

- Remove the spring from the anchor bolt to release PTO belt tension.

- Remove the PTO belt from the engine clutch.

- Raise deck to highest position.

- Loosen front jam nut on eye bolts to reduce deck lift assist spring tension.

- Remove lift assist springs.

- Place wood blocks under each side of deck.

- Lower deck to lowest position so deck rests on blocks.

- Remove hardware retaining deck lift links to deck lift brackets.

- Move deck lift links away from deck lift brackets.

- Slide deck out from under unit.

Removing lawn mower blades

Follow the safety instructions in the manual before starting a service procedure because the blades are sharp and can cut if not handled carefully.

- Rotate the deck so its underside is exposed.

- Position a wood block between baffle and blade to prevent blade from rotating.

- With either a breaker bar or an impact gun, remove hardware retaining the blades.

Inspect the blades for wear, cracks and damage. If the blade is worn too far, is cracked or damaged, dispose it. Blades that are dull but in good shape otherwise can be sharpened according to the manual’s instructions. Remember, the maximum amount of material that can be removed from a lawn mower blade over the life of that blade is one-half inch.

Checking lawn mower blade balance

Whether the blades have just been sharpened or not, they should be checked for balance before each season. To check blade balance, slide the blade onto a screwdriver, shoulder bolt or pin and position it horizontally. If the blade moves, it will need more material removed from the heavy end of the blade. After the blades pass the balance test, they can be reinstalled.

Remember to double-check the orientation of the blade when reinstalling. Blades must be installed with the cutting edge facing away from the top of the mower deck.

Clean mower deck

Mower decks packed with grass clippings, dirt and debris can damage your mower, affect cut quality and hurt lawns. Grass, dirt and debris holds moisture that corrodes bare metal on the spindles and mower blades. Additionally, grass-packed cutting decks can harbor fungi and bacteria that can spread to other lawns and damage them.

Grass buildup around the discharge area can prevent clippings from discharging evenly and could lead to clumping. Grass buildup under the deck can also affect the aerodynamics of the cutting chamber, disrupt the air lift under the deck and diminish the cut quality.

Check mower belts

While the deck is removed, inspect the mower belts for cracks, signs of wear or damage. If belts (PTO belt, mower drive belt, transaxle drive belt) appear unacceptable after a visual inspection, replace them according to the procedure in the operator’s manual. Don’t leave these to chance, because a busted belt on the jobsite will cost a lot more time than it will today.

Greasing a lawn mower

Lack of lubrication can wear critical components like bearings. Aside from applying a thin layer of oil to all pivot points and pin connections on the mower, there are typically only two or three lubrication points on a Gravely mower.

Locate the grease fittings on the caster fork hubs and the caster wheel hubs. Pump grease into each fitting until grease squeezes past the bearing seals at the top of the caster fork hubs and on the sides of the caster wheel hubs. Wipe away the excess grease.

If seat adjustment slots are visible on the bottom of the seat, apply a small amount of grease to the seat adjustment tracks and move the seat back and forth to spread grease along the tracks. All lubrication points for your mower can be found in the operator’s manual.

Charging a lawn mower battery

Mowers with discharged batteries don’t start. If the lawn mower battery was connected to a battery tender or trickle charger during storage, it should be in good shape. If the battery was left unattended, charge it to the voltage specified in the manual, but don’t fast charge the battery.

Clean battery terminals

Typically, corrosion is more likely to form on the positive battery terminal, but corrosion on any terminal should be cleaned. Disconnect the battery cables, brush away corrosion with a wire brush, coat the terminals with dielectric grease or petroleum jelly and reconnect the battery cables with the original hardware.

Zero turn mower adjustments

A zero turn mower is most comfortable and operates most effectively when adjustments are checked and returned to specification. Make comfort adjustments to the seat and steering levers for the operator that will be using the machine. Check the following items according to the directions in the operator’s manual for your unit:

- Parking brake

- Transaxle neutral position

- Tire pressures

- Deck level and pitch

Zero turn lawn mower parts

Replacement and maintenance parts like belts, blades, lubricants and oils, can be sourced from your nearest Gravely dealer. Experienced Gravely dealers know exactly what their customers and their mowers need to continue performing at their best throughout the season.

Don’t forget …

Smart landscapers know that during the busiest time of the season, replacement parts are in high demand at dealerships. Stay sharp this season by visiting your Gravely dealer and stocking up on a season’s supply of wear parts like belts and blades.

How to Perform Lawn Mower Maintenance in 9 Steps for a Picture-Perfect Lawn

Neglecting your lawn mower is a surefire way to ruin your lawn. It will also cost you more because you’ll need to purchase a new lawn mower sooner or repeatedly pay for costly repairs.

Performing regular maintenance on your lawn mower should help you keep it working for between 10 and 15 years. Take a look at our top lawn mower maintenance tips and get the most from your lawn mower.

Bonus tip: make sure you read your owner’s manual as there is a lot of information specific to your mower model inside.

Why Do I Need to Perform Lawn Mower Maintenance?

It’s important to perform lawn mower maintenance because it keeps your mower running in prime condition. A well-maintained lawn mower will cut your grass better and make clean cuts, which helps lessen the likelihood of your lawn getting a disease. Plus, maintenance helps extend the life of your mower, cutting down on additional costs for you.

How Much Does Lawn Mower Maintenance Cost?

The price you’ll pay to maintain your lawn mower depends heavily on the type of mower you have. But here’s a quick look at some common maintenance tasks and their costs:

- Spark plug replacement: 5–20

- Lawn mower oil: 5–10

- Lawn mower air filter replacement: 10–15

A new lawn mower can cost up to 3,200, so it’s worthwhile to maintain your investment to ensure it runs well for years.

When to Perform Lawn Maintenance

Getting in the habit of yearly mower maintenance ensures you can keep your machine in great condition. You also need to do a little ongoing maintenance throughout the growing season.

- Winter maintenance: Before you put your lawn mower up for the winter, you’ll need to change the oil, drain the fuel, replace the spark plug and air filter, sharpen and balance the lawn mower blades, and possibly fog the engine.

- Maintenance best practices: Every time you use your lawn mower, you should check the tires before you begin, and clean the mower deck when you finish.

How to Perform a Seasonal Lawn Mower Maintenance Routine

Make these maintenance tasks part of your regular seasonal garden maintenance routine to ensure you don’t overlook them.

Replace the Spark Plug

Before you begin any lawn mower maintenance, remove the spark plug. This ensures your safety as the lawn mower cannot accidentally start.

Lawn mower spark plugs degrade rapidly. They are vital to the engine’s functioning, but thankfully they’re inexpensive, too. They’re also easy to change. Simply grab the wrench, remove the old spark plug, and replace it with a new one. Just remember not to overtighten it to avoid any problems with starting the mower.

Change the Oil

While you don’t necessarily need to change the oil in your mower unless it’s showing signs of being contaminated or too old and viscous, it’s a good habit to develop. At the end of each season and before you put the mower up for the winter, remove the drain plug beneath the oil tank on the mower and allow the oil inside to drain.

Some lawn mowers don’t have drain plugs, in which case you’ll need to turn the lawn mower on its side and allow it to drain the oil via the fill hole.

Once the oil tank is empty, sit the lawn mower the right way up or replace the drain plug. You can then refill the tank with the correct type of oil. Check your owner’s manual if you’re unsure of which time the oil is suitable for your machine.

Drain the Fuel Tank

If your lawn mower won’t start, the culprit could be old gas. Leaving gas in the tank can also damage, and eventually corrode, the fuel tank. Therefore, at the end of each season, you’ll need to either use up or drain all of the remaining fuel in the tank. If you choose to drain and dispose of old gas, remember that you are dealing with an extremely volatile and flammable substance, so take all sensible precautions. Leave the fuel tank empty over the winter, and add new gas in the spring.

Clean the Mowing Deck

You should get in the habit of cleaning the mowing deck each time you finish cutting the lawn. Cut grass, dirt, and debris get caked onto the area above the blades, known as the mowing deck. Once it dries, it becomes incredibly hard and difficult to remove. It also traps heat, which can eventually cause your lawn mower’s engine to overheat. Plus, it can potentially block the discharge chute.

After you finish mowing, disconnect the spark plug, turn the lawn mower on its side, and use a wire brush to remove all of the grass clippings and debris that accumulated during the mowing session. Doing this after each cut makes it far easier, as the clippings are still wet and easy to remove.

At the end of the growing season, you should do a more thorough cleaning of your mowing deck. Remove the spark plug and flip the mower over onto its side (carburetor-side up). Remove all accumulated debris from the mowing deck, then give it a thorough clean with a stiff brush and some hot soapy water. Allow the mowing deck to dry while you’re doing the other end-of-season lawn mower maintenance tasks, then give the deck and blades a lubricating coating to prevent rust. Then you can put the mower away for the winter.

Replace the Air Filter

Like spark plugs, air filters are inexpensive but crucial to the performance and efficiency of your mower. At the end of each season, it’s a Smart idea to change your air filter if you have a removable one, or thoroughly clean the filter if you have a permanent one. A new or clean air filter significantly improves the efficiency of your lawn mower and decreases the demand placed on the engine. You’ll need to check your owner’s manual to see how to change the air filter on your specific mower model.

Check the Carburetor

The carburetor needs cleaning approximately every two years. A dirty or underperforming carburetor results in a noticeable drop in performance, and eventually stops the lawn mower working altogether. Dust, dirt, and debris can clog the internal and external parts of the carburetor, which slowly decreases performance.

While cleaning the carburetor isn’t particularly difficult, it’s best to let a pro handle this part for you if you’re not comfortable or don’t know your way around an engine.

Sharpen and Balance the Blades

Having sharp, well-balanced blades ensures your lawn mower performs well and your grass stays healthy. Even if you have no nicks in the blade, and your lawn is relatively free of sticks, stones, and other debris, the blades do wear down and get blunt. Damaged or blunt blades tear the grass rather than cutting it cleanly, causing extensive damage, and leaving your grass at greater risk of disease and poor health. Sharpening your mower blades is one of the easiest ways to keep your lawn lush and green.

With a little know-how and experience, you can sharpen your own blades with a vice and a metal file or rotary tool, or a specific blade-sharpening tool. However, if you don’t know what you’re doing, you can cause further damage to the blades and, therefore, your grass. So, it may be a good idea to take the mower to a repair shop or hire a mobile mower servicing company.

Fog the Engine

Fogging a lawn mower engine involves removing the outer plastic shell or engine housing and spraying fogging oil into the carburetor and inside the spark plug. This provides a waxy, protective coating that limits the risk of moisture getting inside the engine and causing issues.

Check the Tires

Before and after each use of your mower, it’s good practice to check the tires. Whether you have a ride-on mower with inflatable tires or a self-propelled mower with hard tires, it’s important to check that they remain in good condition. Even with molded wheels, if they’re chipped or significantly damaged, they can impair the performance and balance of your mower.

Don’t let cutting grass cut your spirit—if you’ve got a broken mower, there may be an easy fix

Additional Tips for Taking Care of Your Lawn Mower

Taking care of your lawn mower will not only extend its life but also help ensure it cuts your grass well, keeping it green and healthy.

Here are a few additional maintenance tips to add to your routine:

- Replace the blade if it has dents or cracks—sharpening it won’t work and it can damage your yard if used.

- Before you start mowing each time, remove rocks and any other items (small children’s toys or pet items) from your yard that could damage your lawn mower.

- If you’ve watered your lawn recently or it’s rained, wait to mow your lawn until it’s dry to prevent the deck from getting clogged with clippings.

- Inspect the cord and battery on electric mowers to ensure both are still in good condition.

- Replace the fuel filter on riding mowers and make sure the tires are at proper inflation levels.

DIY vs. Hiring a Pro

While you can take care of most of the day-to-day maintenance yourself for annual servicing and repair tasks, you may prefer to hire a lawn mower repair service.

The servicing is relatively inexpensive and helps to reduce repair costs and maximize the lifespan of your mower seed and have to replace it as often. You can hire a local lawn mower repair service to perform a yearly service and tuneup.

Scheduling this annually with a professional is a great way to make sure it gets done every year too, as it can sometimes be an easy task to forget until things go wrong,” says Tara Dudley, Angi Expert Review Board member and owner of Plant Life Designs. “Preventative maintenance is key!

FAQs About Lawn Mower Maintenance

Do I need to lubricate my mower blades?

It’s a good idea to lubricate your mower blades and mowing deck with something protective like WD40 that prevents rust and helps stop grass and dirt from sticking to the blades and deck.

Can you tip a lawn mower on its side?

Yes, you can tip a lawn mower on its side as long as you turn it with the carburetor side upwards. This prevents oil from leaking into the carburetor and reducing performance. You can also tip the mower backward as long as it’s stable while you’re working on the deck or blades for safety.

How sharp should lawn mower blades be?

Lawn mower blades should be sharp enough that you can feel the sharpened edge, but not sharp enough to cut you when you touch them. Over-sharpening blades to a fine, razor-edge poses a safety risk and decreases the blade’s life because it causes extra wear; the thinner edge is sharper but weaker and will require more frequent sharpening.

Lawn equipment maintenance log

Working in the landscaping industry, you know that the process to keep not only vehicles running as they should, but equipment maintained and employees happy is an ongoing challenge. There’s a myriad of moving parts that goes into a safe and successful business.

To keep track of the many moving pieces and ensure your equipment and team are set up for success, checklists are a critical part of staying organized. Not only do they help to ensure that your equipment is where it needs to be before and after a shift, but they can also help prevent small problems from becoming large problems over time.

So what checklists should your team be implementing on a regular basis?

In this post, we’ll cover 5 helpful checklists to consider implementing as a manager or owner in landscaping.

Daily Driver Vehicle Inspections

When it comes to the reliability of a large fleet of dump trucks and similar vehicles, few things are as important as ensuring you have a daily driver vehicle inspection report submitted by your drivers. Even if a daily DVIR isn’t required by law, checking critical components like tire tread or trailer tires can save you tons of money in the long run.

Landscaping equipment aside, maintenance on even a small fleet of work trucks can get extremely expensive over time.

Here are a couple of simple DVIR checklist items to consider adding to your walkaround inspection process:

- Setup and spacing on cones around truck or trailer

- Vehicle parking check

- Clean dash free of paper or debris

- Cleanliness of truck inside and out

- Checking the gauge on the instrument cluster

- Checking the engine oil

- Tool box is organized

- Load securement with tie downs

- Trailer bed clean of debris

These are just a few simple checks that can be performed daily to ensure undocumented damage and other problems associated with a lack of proper vehicle inspections.

Instead of using paper for their DVIRs, Belknap Landscape started using the Whip Around app for this purpose. To see how they benefitted from this technology, check out the case study here.

Employee Health and Wellness

As a result of COVID-19, one practice that is especially important for your drivers and crew members in landscaping is completing employee health and wellness checks as a part of the daily inspection process. This is one of the ways the Whip Around app is making it easier for shift leaders to follow safety protocols and best practices by adding in COVID-19 cards for employees using the app.

One practice to include at a bare minimum is having temperatures taken upon arrival to work and before employees interact with other employees or customers. Other common checklist items to include in this type of checklist are:

- Do you have cold symptoms or have you been feeling extremely weak/tired lately?

- Fever or chills?

- Persistent Cough?

- Any loss of taste or smell?

- Any muscle or body aches?

While cold and virus checklists are obviously important, other checklists can be loaded in to the Whip Around app that deal with more seasonal complications related to allergies, like pollen sensitivity.

While there isn’t any one-size-fits-all approach to employee wellness, building out these types of checklists can not only help protect people, but it also can give managers more information at their disposal when managing their workforce.

Landscaping Equipment and Assets

When it comes to efficiency on-the-job, asset and equipment inspections play a key role in productivity. With so many assets being used on a daily basis in landscaping, keeping an accurate inventory on hand (including service histories) can also help immensely when it comes time to create maintenance budgets.

Simple Lawn Mower Tune-Up and Maintenance

Outside of vehicle inspection forms that may be the responsibility for drivers, you may even decide to delegate the task of performing daily equipment inspections on blowers, chainsaws, weed trimmers, and other pieces of equipment to shift leaders.

Since leaving equipment behind is a common occurrence in landscaping, something as simple as performing a count on all assets used to ensure they return to your trailer can help prevent these issues from occurring.

While it may take an extra 2 minutes to scan a trailer for this equipment, it can help eliminate lost equipment over time. Here are a few items from a simple yes/no checklist to give you an idea of what you can do to ensure equipment doesn’t get left behind on jobsites:

- Lawn mowers (4)

- Weed eaters (4)

- Leaf blowers (2)

- Rakes (8)

- Shovels (8)

- Pump sprayers (5)

Creating a Preventative Maintenance Schedule

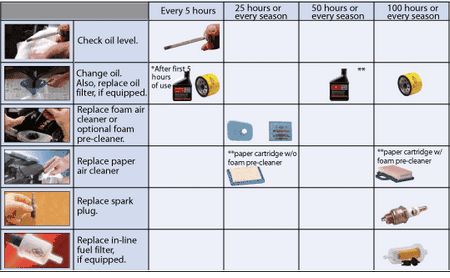

For lawn mowers, tractors, or any other piece of equipment you may have deployed, it’s also not a bad idea to set up preventative maintenance schedules based on engine hours or mileage.

By performing daily (or even periodic) inspections on this type of equipment with an inspection solution like Whip Around, you’ll never forget a routine oil change, since reminders are automatically sent based on whatever threshold you set.

This also makes it much easier to create and send work orders to your mechanic for routine maintenance tasks.

Proof of Service for Landscaping Tasks

If you’re like many landscaping companies that service several locations each day, proof of service may be something you will need to provide in the event of a complaint. One of the best ways to prevent these instances from occurring is to require photos be taken, which will also generate a timestamped record you can refer to.

Depending on your business, it may even make sense to require a series of photos or steps be taken to ensure your team completes important task at each location. Especially for newer team members, it may be easy to forget tasks without a list on hand, so it’s a good item to have as a reference point.

With the Whip Around app, setting up custom checklists or even documentation is easy, ensuring your crew knows what is expected of them at each location throughout the day.

Annual and Periodic Inspections

When it comes to planning for your new fiscal year, one of the most important inspections to complete is an annual equipment inspection. Since this will obviously be the most thorough inspection of the year, it’s a good idea to have a process for conducting it.

While it may not make sense to require time-consuming daily inspections beyond a simple count of inventory, more periodic inspections performed weekly, monthly, or semi-annually is a great idea to have peace of mind that your equipment is in good working order and safe to use.

A few of the common annual or periodic inspection items that may fall into this category are:

- Lawn mower blades

- Engine oil levels

- Fuel

- Tire pressure or tread

- Fluid checks

- Traffic cones, safety vests, related equipment

- Aerator inspection

One of the benefits of using technology to your advantage when it comes to more frequent inspections is that you can also use this data to help automate preventative maintenance tasks in a more proactive way.

Whether it’s viewing a simple dashboard that indicates the age of your equipment or detected faults, you can avoid downtime by retiring or servicing certain pieces of equipment before they cause major problems on-the-job.

How to Create Custom Landscaping Inspection Forms with the Whip Around App

With so many other responsibilities to think about on a daily basis, it can be hard to squeeze in time to print out or organize what exactly makes sense to inspect. With Whip Around, you can easily different types of custom forms with just a few clicks, or even start with a template.

Whether your landscaping company focuses on tree removal, lawn care and maintenance, landscaping design, or you are full-service, any custom form you can think of can be imported and available to your crew prior to beginning work each day.

Get Started Today

Instead of relying on paper forms or outdated processes that are hard to keep track of, the Whip Around app makes it simple to perform vehicle and equipment inspections with ease, in addition to simply keeping track of all of your assets in service or out of service.

To see how easy you can make inspections for your team, request a demo of Whip Around to explore the platform and mobile app, or start your free trial. Our team would be happy to share a few examples of how our app is helping other landscaping companies know what’s going on with their assets at all times.

Lawn Mower Inspection Checklist: Spring Fall

Many lawn mower components can hold up year after year. The issue with mowers begins when regular maintenance fails and care at the end and beginning of the mowing season becomes neglected. I find going over a lawn mower maintenance checklist every fall and spring gives me peace of mind that my machine won’t let me down when I need it most.

Modern mowers are very efficient and can take a bit of beating, but well-maintained push mowers and riding mowers can last much longer and cost less to operate than ones that are ridden hard and put away wet. The fall and spring checklist is mostly the same operations that must be performed in reverse order to work correctly.

In some cases, you can identify the problem in the fall and fix it in the spring, and a lawn mower maintenance log can help you stay on top of all your turf tasks.

How Do You Inspect a Lawnmower?

In most cases, you will only do a deep inspection of your mower once or twice a year. There are, however, some occasions when you would want to inspect your mower in the middle of the growing season. If you suspect dull mower blades, notice leaking near the fuel tank, hear strange engine sounds, or mow over something other than grass clippings, you should kill the engine and check the condition of your machine right away.

To inspect your mower, look over the outside, top, and bottom, and check the accessible internal parts related to the suspected issues. The most common places that need inspection are the lawn mower blade and mower engines, oil and gas tanks, and plugs and inlets. Once you know what the problem is, you can see if it can be cleaned and repaired or if it needs to be replaced.

What Is on a Lawn Mower Inspection Checklist?

Most parts of a mower should be included in a lawn mower maintenance log and can be examined throughout the mowing season. On the day mowers are brought out in spring, and when they are stored for winter, extra maintenance should be implemented. Mower user manuals will have a lawn mower maintenance log that you can follow to keep mower tune-up up to date.

| Procedure | Purpose | Process |

| Run Mower Until It’s Warm | Gets fluids moving and helps with oil and fuel maintenance | Start the mower for at least 10 minutes or begin maintenance immediately after the last mow of the season |

| Change Oil/Engine Fogging | Properly lubricates internal components and protects from rust and water damage during storage | Empty old oil and replace with clean oil rated appropriate by your mower manufacturer and run the engine while spraying a special protective oil inside the carburetor before final storage |

| Replace or Clean Air Filter | Allows better air intake into the engine for efficient combustion and fewer emissions | Take out the filter and clean it if barely used or replace it if it is old and worn out |

| Remove or Stabilize Fuel | Prevents old fuel from going stale and not combusting after storage | Siphon out the old fuel and run the engine until it cuts off or add a fuel stabilizer to bond alcohol and petroleum for up to a year |

| Take Out Spark Plug | Prevent false starts and examine core and filaments | Open the cover and detach the plug wire and tuck it aside to prevent contact, or completely remove the plug and store it separately |

| Clean and Sharpen or Relace Thin Mower Blades | Make sure blades are safe to continue using and help ensure clean cuts on turf | Use a hose to spray off the debris and use sharpening tools when the blades are dry to keep them well-honed |

| Replace Worn Belts and Gears | Keep the engine operating and prevent injury during use | Check for cracks or components that have worn thin and need to be replaced |

| Clean and Polish Mower Deck | Expose any damage and hidden areas that need attention and prevent damage from neglect and dirty storage habits | Spray down with a hose or pressure washer and brush out stuck debris; wipe surfaces with proper cleaners and polishers for a sleek and shiny mower |

| Check and Tighten All Nuts and Bolts | Prevents weak connections and accidental disconnections during mower operation | Tighten all connections to ensure brakes, fluid lines, wheels, and engine parts are sturdy and well seated |

| Inspect Fluid Tubes and Seals for Leaks and Cracks | Avoid leaks and waste of fuel and other fluids due to cracks and corroded seals | Clean fluids off of tubes and lines and, check all fittings, replace cracked parts immediately |

| Lubricate Joints, Bearings, and Friction Points | Keeps moving parts from wearing down from friction and prevents rust and other oxidation effects during storage | Use WD-40 or another spray lubricant to cover all s, ears, and bearings that move and touch |

| Long-Term Storage | Keeps electrical parts safe and presents fires or corrosion | Remove the battery and spark plugs and store them in a cool, dry place |

Spring Maintenance Checklist

When the temperatures rise and the grass starts growing, it is time to pull the mower out and get it ready to go. The amount of work that you will need to do in the spring depends on what you accomplished in the fall. Going through the complete checklist, regardless of what you did in the fall, is still a good idea in case there were storage mishaps by rodents or other pests.

Replace any belts or blades you removed or repaired, and make sure all attachments are tight and installed correctly. The electrical components, like the battery and spark plugs, will need to be replaced and reconnected. Close up all engine parts and makes sure all connections are clean and tight.

Fill the fuel tank if it was empty or top it up if a stabilizer was used and it was not filled in the fall. Check the oil levels and make sure all lines and tubes are connected and primed. Roll the mower out into the lawn and start it to make sure everything is working and connected correctly.

Fall Maintenance Checklist

After a heavy landscaping season, most mowers will need a bit of TLC. It is usual to have to clean, repair, or replace some key part of a mower every season, so make sure to count on that. Winter storage is the longest stretch of time a lawn lays dormant, and so it is the longest time our machines are stored. Store your mower correctly by checking off these items on your list every autumn.

At the end of the mowing season is when you should give your mower a deep clean. It is difficult to perform any of the other autumn maintenance tasks with a dirty mower, so a thorough cleaning is always a good first step. Once the mower is free of mud, dirt, and clumps of turf, you should be able to see what needs work almost immediately.

Take care of the engine and fluid next to make sure everything inside will still fire easily in the spring, and no expensive repairs will be needed. Add a fuel stabilizer or remove all gas to avoid stale petrol in the engine over winter while checking the fuel filter. Make sure to change the oil and replace the fuel filter to get everything ready for storage.

Remove the spark plug and battery if applicate to prevent false starts and potential storage fires. Now is a good time to clean any corrosion off of terminals and replace old or leaking electrical components. Keep the electrical parts outside of the mower and store them in a cool, dry place all winter.

The blades will need to be replaced if they are worn down and thin or, at the very least, sharpened. Now is a good time to really give the blades a good edge and clean and lubricate the bottom deck areas. Give the entire mower another wipe down and make sure it is clean and dry before covering or moving inside until next spring.

The Only Landscape Maintenance Checklist You’ll Ever Need

A landscape maintenance Checklist is a simple list that you can use to monitor regular landscaping tasks and the maintenance of your equipment.

A landscape maintenance Checklist is a simple list that you can use to monitor regular landscaping tasks and the maintenance of your equipment.

Every employee should have a yard maintenance Checklist they will be required to fill out and submit to you. Likewise, you should also have a lawn and yard maintenance list to ensure that your customers and equipment have been taken care of.

Let’s examine what should fit onto a weekly landscape maintenance Checklist and why your business can benefit from this system.

Why Should You Have A Landscape Maintenance Checklist?

The yard work Checklist may seem like nothing more than an extra administrative burden, but it has value.

The most apparent benefit is quality control. If you are not present at a customer’s property, you rely entirely on your employee to tell you what work has been performed. A lawn maintenance Checklist provides you with physical evidence of that work.

If a customer is unhappy or an employee claims they completed a task, your lawn care Checklist helps to resolve the confusion.

Another reason to use a Checklist for lawn and yard maintenance is upselling. Checklists remain standardized so you can easily bundle items together and show customers other possibilities.

Checklists can be utilized on both the customer-facing side and internally. Innovative businesses may use a lawn care Checklist template as part of their sales strategy.

Checklists also have value in managing your equipment. Improperly maintained equipment will incur more repair costs and downtime. Ensuring that tools are properly cleaned and winterized will help you get the most out of your capital investments.

In short, creating a Checklist for landscape maintenance takes only a few minutes but provides countless benefits.

The Only Landscape Maintenance Checklist Your Team Needs

Several sections make up a lawn maintenance Checklist. Businesses may use more than one Checklist for managing internal operations, payments, as well as lawn and yard maintenance services.

Let’s break down a master Checklist into sections. Feel free to change each section to suit your organization.

Basic Lawn Care Services

Keeping a yard in tip-top shape means regular maintenance tasks. These essential services will form part of the packages you offer to your regular customers in most cases.

Some of the core services you will find on this part of your yard work Checklist include:

- Lawn Mowing. Keep grass cut to a reasonable height. Resolve rutting, alternating patterns, and deformation.

- Trimming. Cut back overgrown hedges and trees. Remove any crossing branches and branches growing below the canopy.

- Pruning. Remove infected or dead stems, twigs, and branches to keep trees and hedges looking clean.

- Waste Removal. Take away any debris, such as leaves, twigs, dust, or any contaminants that have made their way into the yard. All litter and waste should be removed after each visit.

These tasks will form part of a weekly yard maintenance Checklist to ensure a perfect lawn and yard every time.

Landscape Maintenance Schedule Checklist

Basic maintenance tasks will keep a lawn looking pristine, but additional tasks are necessary to prevent yard degradation. These tasks generally won’t be carried out every week but on a seasonal basis.

Regular customers committed to a more comprehensive landscape maintenance Checklist will generally have a separate Checklist assigned to their profile.

- Fertilization. Soil testing and determining which nutrients the soil needs. Apply the necessary nutrients at each interval.

- Aeration. Ensure sufficient holes have been inserted into the soil to allow light, water, air, and nutrients to pass through.

- Overseeding. Create thicker grass for brighter colors and to obscure weed growth.

- Dethatching. Introducing thatch obstructs the grass from receiving nutrients and water. Check for the presence of thatch and, remove it, if necessary.

- Weeding. Stop weeds from encroaching upon the lawn. Weed control may include physical removal or spreading chemical weed killers.

- Mulching. Lock in moisture to reduce the presence of weeds and improve general soil health. Check the soil’s moisture and apply the necessary organic matter.

- Staking. Control the direction of tree and hedge growth by placing ties around trees. Remove stakes after one year to eliminate tree girdling. Check the condition of stakes regularly.

- Artificial Lawn Maintenance. Remove dirt and debris from artificial lawns. Cross-brush the grass to avoid matting. Rinse the turf regularly to prevent pollen accumulation.

- Sod Maintenance. Manage and maintain sod regularly through regular watering and mowing throughout the spring and summer.

- Pest Control. Armyworms, fire ants, grubs, and other insects pose a threat to any yard. Check for the signs of infestation and take the necessary steps to control and eliminate pests.

- Irrigation/Drainage Maintenance. Inspect irrigation/drainage systems for leaks and remove blockages.

Not all of these services will be relevant to every customer’s yard. Inspect every yard and make tailored recommendations for ensuring the yard remains in good order.

Lawn Customization Checklist

Offering lawn customization services is something more and more customers expect. Not everyone wants the same yard as their neighbors.

If you choose to offer customization services, you’ll need to invest in additional internal organizational strategies. Platforms like FieldRoutes help you maintain unique user profiles, so you know what each client expects from you when delivering regular maintenance services.

Here are some of the aspects to take into account when preparing a lawn customization Checklist.

- Climate Conditions. The climate impacts everyone’s lawn. Minute adjustments to temperature, humidity, and sun exposure can change everything. Log these important statistics for each customer.

- Site Details. Is the yard flat or undulating? Laying turf and performing other tasks may require grading first.

- Existing Vegetation. Field technicians need to know the current state of the lawn so they can attend the worksite armed with everything they need.

- User Profile. If you need to create a lawn designed for a specific user, put together a user profile. Soft lighting, water features, and color schemes all help to give your clients what they want.

Lawn customization features elevate your business above your competitors. Go the extra mile and provide a fully personalized service to your customers.

Equipment Maintenance

Equipment maintenance is as necessary as the services you offer. You have downtime, a significant repair bill, and lots of unhappy customers with broken equipment. Regular maintenance will maximize the lifespan of your tools and equipment.

- Refuel Daily. Ensure your operations never grind to a halt by refueling everything daily. Larger lawn care businesses may even choose to invest in an underground storage tank.

- Blade Maintenance. Change all lawn mower blades daily and sharpen once per week. Maintain multiple sets of blades to ensure they remain in good condition.

- Power Washin. Opt for a power wash of all machines, including mowers, trimmers, and blowers, to prevent a buildup of dirt, oil, grease, and grass.

- Trimmer Lines. Inspect trimmer lines to spot any problems early.

- Grease. Apply grease to hedge trimmers if required the following day.

- Oil. Check oil levels and reapply as necessary.

- Hand Tools. Wash hand tools every day if they were used. It’s better to avoid doing this on the job to keep things efficient.

It’s also wise to log the usage hours of each piece of equipment to ensure that you can put aside some funds to replace older pieces before they break down.

Perhaps the biggest mistake made by lawn care businesses is only replacing equipment when they finally die. Older pieces of equipment can still be stored for occasions where other commonly used tools are temporarily out of commission.

Customer Payment Checklist

Managing your customers can be tricky when creating personalized checklists for each one. Beyond a yard work Checklist, you also need to consider customer payments.

Staying on top of customer payments ensures you never work for free and avoid payment disputes.

- Direct Payment. Did your client pay directly for a whole year, per month, or after each visit? Direct payments are the easiest to track, especially if they make advance payments.

- Installment Payments. Some clients prefer to cover a contract in installments. Many lawn care maintenance services provide this option, but you need to ensure your customers do not enter arrears.

- Discounts. Some regular customers may receive discounts on their regular contracts. Has the discount been applied to their final bill? How long should that discount be applied to their contract?

Your employees should make sure to check this part of the job off their list if taking payment in person.

On the back-end side of things, plenty of platforms, such as FieldRoutes, can automatically generate invoices, send reminders, and ensure each customer’s account remains in good standing.

Conclusion

Your landscape maintenance checklist is the cornerstone that ensures you stay organized. Running a business with multiple employees increases the likelihood of confusion and misunderstandings. A Checklist creates a paper trail to help resolve problems.

Join the digital revolution in lawn care and landscaping with FieldRoutes. Our state-of-the-art platform helps you manage everything from customer payments to organizing your jobs.

To learn more about how FieldRoutes can change your business, schedule your free demo for a one-on-one demonstration of our lawn care software now.

Subscribe to our weekly email newsletter Join our email list to stay up to date on FieldRoutes news, promotions, webinars, and other handy resources.