US2854807A. Lawn mower blade assembly. Google Patents

Publication number US2854807A US2854807A US587040A US58704056A US2854807A US 2854807 A US2854807 A US 2854807A US 587040 A US587040 A US 587040A US 58704056 A US58704056 A US 58704056A US 2854807 A US2854807 A US 2854807A Authority US United States Prior art keywords blade drive shaft lawn mower assembly blade assembly Prior art date 1956-05-24 Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Expired. Lifetime Application number US587040A Inventor Robert N Byler Nathan R Hendricks Current Assignee (The listed assignees may be inaccurate. Google has not performed a legal analysis and makes no representation or warranty as to the accuracy of the list.) BYLER Original Assignee BYLER Priority date (The priority date is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the date listed.) 1956-05-24 Filing date 1956-05-24 Publication date 1958-10-07 1956-05-24 Application filed by BYLER filed Critical BYLER 1956-05-24 Priority to US587040A priority Critical patent/US2854807A/en 1958-10-07 Application granted granted Critical 1958-10-07 Publication of US2854807A publication Critical patent/US2854807A/en 1975-10-07 Anticipated expiration legal-status Critical Status Expired. Lifetime legal-status Critical Current

Links

- 238000010276 construction Methods 0.000 description 24

- 240000000218 Cannabis sativa Species 0.000 description 8

- 230000000414 obstructive Effects 0.000 description 8

- 241001494496 Leersia Species 0.000 description 4

- 230000035882 stress Effects 0.000 description 4

- 229910000975 Carbon steel Inorganic materials 0.000 description 2

- 239000010962 carbon steel Substances 0.000 description 2

- 230000000875 corresponding Effects 0.000 description 2

- 230000000994 depressed Effects 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 230000035939 shock Effects 0.000 description 2

Images

Classifications

- A — HUMAN NECESSITIES

- A01 — AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01D — HARVESTING; MOWING

- A01D34/00 — Mowers; Mowing apparatus of harvesters

- A01D34/01 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus

- A01D34/412 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus having rotating cutters

- A01D34/63 — Mowers; Mowing apparatus of harvesters characterised by features relating to the type of cutting apparatus having rotating cutters having cutters rotating about a vertical axis

- A01D34/73 — Cutting apparatus

Description

Oct. 7, 1958 R; N. BYLER ETAL LAWN MOWER BLADE ASSEMBLY Filed May 24, 1956 IN V EN TOR5. E fiend/v raQ/vEK United States Patent (3 LAWN MGWER BLADE ASSEMBLY Robert N. Byler and Nathan R. Hendricks, Dallas City, 111.; said Hendricks assignor to said Byler Application May 24, 1956, Serial No. 587,040 2 Claims. (Cl. 56-295) This invention relates to blades for rotary lawn mowers and refers more particularly to a rotary lawn mower blade assembly which is rigidly mountable on the drive shaft of a rotary lawn mower, the blade assembly construction being such that the blade is deformable upon impact with a relatively heavy or immovable object.

Previously, conventional lawn mower blades have been extremely heavy and rigid in construction. Additionally, conventional lawn mower blades are usually mounted between rubber or fiber discs designed to permit the blade to slip therebetween if it should strike relatively heavy or immovable objects. Such blade construction and mountings have proved unable to avoid heavy damage to the drive shaft, engine, and often the mower housing itself when the massive rigid conventional blade strikes objects or the like of considerable mass especially at the high rates of revolution employed in the lawn mowers of today.

Another very serious objection to such conventional lawn mower blade construction and mountings is that the friction mountings permit oblong or eg.shaped wear of the central blade opening used to mount the blade on the drive shaft. Once such asymmetric wear of the blade opening has taken place, the blades cannot be balanced relative the drive shaft in rotation and set up a great deal of vibration which causes wear in the motor, noise, etc. This lack of balance is independent of whether or not the blades are balanced in the sharpening thereof as the uneven wear at the central opening in the blade causes shifting of the blade relative the drive shaft and unbalance automatically results.

Therefore, an object of the present invention is to provide a lawn mower blade assembly wherein the blade assembly is rigidly mounted on the drive shaft, the blade itself being of very light weight construction and resiliently deformable on impact with a relatively massive or immovable object.

Craftsman Lawn Mower Mulching Blade Replacement #942-0741A

Another object of the invention is to provide a lawn mower blade assembly wherein the lawn mower blade is rigidly mounted on the drive shaft, the blade itself being of light weight and resilient construction to be deformable on impact with relative massive or immovable objects, the blade, however, being strong enough due to its unique construction to easily withstand the ordinary stresses of grass cutting even in the heaviest type of grass and underbrush generally encountered by rotary lawn mowers.

Another object of the invention is to provide a lawn mower blade assembly with a rigidly mounted blade on the drive shaft, the blade itself being resiliently deformable and light weight and so constructed as to bend down on impact with a relatively massive or immovable object to engage the ground and stop the engine in a relatively resilient manner without transmitting a sudden jarring shock to the drive shaft or to the engine itself.

Another object of the invention is to provide a lawn mower blade assembly wherein the blade is rigidly mounted on the drive shaft yet the blade itself is exceedingly light weight and resiliently deformable, the lightness of the blade making it easier to stop with a minimum of strain and stress on the drive shaft and connected parts thereto.

Another object of the invention is to provide a lawn mower blade assembly with a lawn mower blade which is rigidly mounted on the drive shaft, the blade itself being resiliently deformable and of light weight and also easily repleaceable in the blade mounting in the manner of a razor blade in a razor.

Another object of the invention is to provide a lawn mower blade assembly wherein the lawn mower blade is rigidly mounted on the drive shaft, said rigid mounting permitting accurate balancing of the blade itself since oblong wear of the central opening in the blade for mounting it on the drive shaft is eliminated, thereby also eliminating the vibration problem common to conventional lawn mower blades.

Another object of the invention is to provide a lawn mower blade assembly wherein the lown mower blade is rigidly mounted on the drive shaft, the type of rigid mounting employed predefining the deformation area of the blade should it strike a relatively immovable or massive object.

Yet another object of the invention is to provide a lawn mower blade assembly wherein the blade is rigidly mounted on the drive shaft, the blade itself being of very light construction and resiliently deformable on impact with relatively heavy or immovable objects, the blade additionally being formable with ends depressed to provide a blowout action for the cut grass, while yet retaining all of the advantages of the deformable construction.

Other and further objects of the invention will appear in the course of the following description thereof.

In the drawings, which form a part of the instant invention and are to be read in conjunction therewithQan embodiment of the invention is shown and, in the various views, like numerals are employed to indicate like parts.

Fig. 1 is a partial view of the underside of a conventional lawn mower, the inventive lawn mower blade assembly being shown mounted on the drive shaft of the rotary power source.

Fig. 2 is a view in exploded form showing the various parts of the inventive lawn mower blade assembly before assembly thereof and positioning on the drive shaft of a rotary mower.

Fig. 3 is a side sectional view through the center of the assembled inventive lawn mower blade assembly of Fig. 2.

Referring to the drawings, in Fig. l is shown the inventive lawn mower blade assembly mounted on the underside of a conventional lawn mower, only a part of which is shown. Top plate 10 carries power source or motor (not shown) having exhaust 11 extending through plate 10. The motor is fixed to circular plate 12 by bolts 13.

Depending skirt 14 extends downwardly from the top plate and encloses most of the blade rotation area. Handle 15 is attached to the top plate 10, only one of the arms of the handle being shown. Drive plate 16 is attached to the motor and extends through the bearing 17 centrally of the top plate 19. The component parts of the inventive lawn mower blade assembly will now be described relative Figs. 2-5 before the assembly on the mower is set forth relative Fig. l.

The blade 18 itself is of relatively light construction and readily deformable upon striking a relatively immovable or massive obstruction. As a specific example of such light blade construction, a 16 gauge 1045 grade carbon steel strip one inch wide is readily employable for a blade inches in diameter. Sharpened portions 19 are positioned on opposite sides of blade 18 and at opposite ends thereof. Opposite the sharpened portions 19 are conventional upwardly angled portions 20 for creating an upward flow of air within the lawn mower housing. Said upwardly angled portions 20 are on opposite sides of the blade 18 and the opposite ends thereof. Central opening 21 is formed in the blade for mounting thereof on the drive shaft 16. The outer ends of the blade 22 are preferably slightly downwardly angled to create an outward flow of air to move cut grass outwardly in the housing thereby avoiding pile up of the grass above the blade in the housing. Blade 13 is angled in cross section as shown at 23 on both sides of the central opening 21. The cross-sectional angling produces a concave surface 18a on the underside of the blade 18 adjacent opening 21 and corresponding convex surface 18b on the upper side thereof. Such angling of the blade adds strength and rigidity to the relatively light blade in the normal operation of grass cutting and also predisposes the blade to downward deformation upon striking an obstruction. Such angled portion of the blade preferably extends past the inner end of the sharpened portions 19 and into the downwardly angled portions 22 for strength in said areas. The angling of the blade is preferably symmetrical for balance.

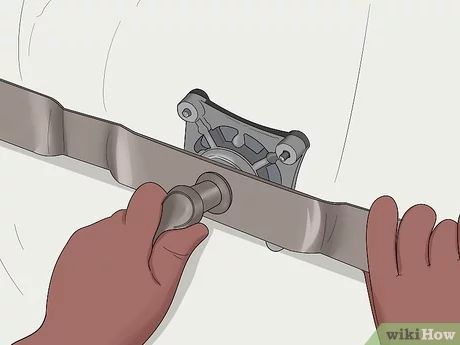

The means for rigidly mounting the blade 13 on the drive shaft 16 comprise a top piece with a drive shaft engaging portion 24 thereof having a slot 25 in the drive shaft receiving opening or orifice 26 therein to permit keying of the top piece to the drive shaft in a rigid manner. Arms 27 extend outwardly away from the central opening 26 to overlie the blade 18 on both sides of the central opening 21 therein. The top piece has a concave underside 28 to fit the convex portion of the blade i8 and contact it along essentially the entire length of the top piece. Bolt opening 29 extends through the lower portion of the top piece into opening 26. The width of the top piece is preferably essentially equal to the width of the blade and the edges 3t) thereof adjacent the edges of the blade 18 are in line therewith. The bottom piece of the blade mounting means comprises a channel 31 which is angled in cross section to match the grooving or angling of the blade in cross section. The width of the bottom piece channel is preferably slightly greater than that of the blade and at least equal to that of the top piece. The bottom piece has a central hole 32 therein matching the central opening 21 in the blade and opening 29 in the top piece. Upwardly extending edges 33 of the bottom piece are of such length as to extend past the edges of the blade and the lower edges a of the top piece to lock the blade firmly between the top and the bottom pieces.

The means for joining the blade assembly together and mounting it on the drive shaft l6 comprises bolt 34 and washers 35 and 36. Bolt 3′ is of sufiicient length to extend through the washers 35 and 36, bottom piece channel 31, and the top piece bolt opening 29 to extend upwardly within the top piece drive shaft orifice or opening 26 whereby to engage and thread into a threaded opening (not shown) in the end of the drive shaft. When the bolt 35 is threaded into the opening in the end of the drive shaft and the key slot 25 is fitted over a key on the end of the drive shaft the blade 18 is rigidly mounted on the end of said drive shaft and will not slip relative thereto upon striking any object.

In operation, with the blade 18 rigidly mounted on the drive shaft 16 as shown in Fig. l, the blade will rotate until it strikes a relatively massive or immovable object. Since the blade is angled in cross section and the central portion of the blade is gripped between the top and bottom pieces, the blade will readily bend downwardly between the point of impact and the end of the top and bottom pieces adjacent the point of impact. As the blade is deformed downwardly and backwardly, the velocity thereof is reduced in a relatively smooth and resilient fashion compared to the sudden shocking stop encountered with conventional blades. If the resistance encountered by the blade is suflicient, it will bend downwardly until it contacts the ground and digs thereinto and thus will come to a stop.

To replace the blade, the bolt 34 is merely unthreaded from the drive shaft, the lower piece removed, the old blade removed and a new blade inserted between the top and bottom pieces. If no damage to the original blade results from striking any heavy or immovable object, the blade may easily be removed, as described, for sharpening and balancing and replaced between the top and bottom pieces. Since the blade is rigidly gripped between the top and bottom pieces and held by bolt 34 relative thereto, there can be no oblong or asymmetric wear of the central opening 21 in the blade. Therefore, if the blade is balanced in the sharpening operation the blade will be balanced when returned to the drive shaft and put back into use. Thus it is seen that the blade may be removed if deformed or if sharpening is needed and a new blade or the old blade after sharpening replaced easily in the assembly as if replacing a razor blade in ‘a conventional razor.

From the foregoing it will be seen that this invention is one well adapted to attain all of the ends and objects hereinabove set forthv together with other advantages which are obvious and which are inherent to the structure.

It will be understood that certain features and subcombinations are of utility and may be employed without reference to other features and ‘subcombinations. This is contemplated by and is within the scope of the claims.

As many possible embodiments may be made of the invention without departing from the scope thereof, it is to be understood that all matter hereinbefore set forth or shown in the accompanying drawings is to be interpreted as illustrative and not in a limiting sense.

In a lawn mower blade and blade mounting assembly for use in rotary lawn mowers employing an elongate, substantially horizontal rotatable blade having sharpened portions on opposite sides of the blade and on opposite ends thereof mounted on a substantially vertical drive shaft, the blade having a central opening therein for mounting thereof on the lawn mower drive shaft, the improvement which comprises the blade of relatively light construction whereby to deform readily upon striking a relatively massive obstruction at the operating speeds of the mower, the blade angled in cross section on both sides of the central opening to increase the rigidity thereof so as not to flutter in operating rotation at said operating speed, rigid mounting means for the blade comprising a top piece at least substantially conforming to and fitting the convex surface of the blade, a bottom piece at least substantially conforming to and fitting the concave surface of the blade, and means engaging said two pieces and blade to fix them to the drive shaft and relative one another whereby neitherthe blade nor the mounting means will slip relative one another or the drive shaft when the blade strikes a relatively massive 1,794,178 obstruction. 2,081,807 2. A mounting assembly as in claim 1 wherein the 2 43,502 bottom piece has upwardly extending flanged edges past 2 651 159 the lower edge of the top piece. 5 2,635,160 2,760,327

How to Replace your Lawn mower Blade in 3 Minutes EASY WAY

Karcher Feb. 24, 1931 Gabriel May 25, 1937 Flanigan June 30, 1953 Rountree Sept. 8, 1953 Kuhary et a1. Aug. 3, 1954 Bovee Aug. 28, 1956 Caldwell et a1. Mar. 26, 1957 Miller June 18, 1957 Rosenberg July 23, 1957

Priority Applications (1)

| US587040A US2854807A ( en ) | 1956-05-24 | 1956-05-24 | Lawn mower blade assembly |

Applications Claiming Priority (1)

| US587040A US2854807A ( en ) | 1956-05-24 | 1956-05-24 | Lawn mower blade assembly |

How to Change a Lawn Mower Blade

This article was co-authored by Grant Wallace. Grant Wallace is a Landscaper and Owner of Grantlanta Lawn in Atlanta, Georgia. With over seven years of experience, he specializes in lawn maintenance and landscape installation. In 2012, he earned his BA from the University of West Georgia. Grant has been profiled in Shoutout Atlanta, Canvas Rebel, and Voyage ATL.

This article has been viewed 387,277 times.

If you’re noticing missed patches in grass you know you mowed over, your mower just isn’t cutting it any more. Blades wear out with use and need to be changed occasionally to make your mower more efficient. You’ll keep your lawn healthier and you’ll need to mow less frequently with sharp, clean blades. Replacing them is an easy project that won’t take up much time, as long as you approach it correctly. See Step 1 for more information.

Inspecting and Removing Old Blades

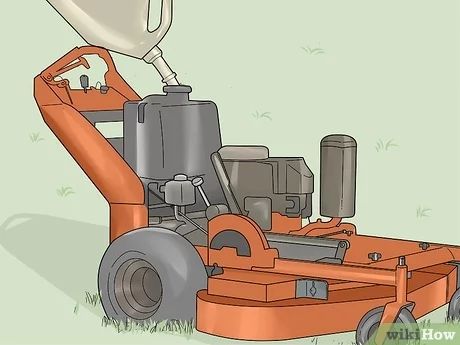

- It’s also best to do this when there’s no gas in the mower. Wait until you use it all up to change the blade, or you might consider draining out the gas with syphon hose. Typically, self-syphon pumps are sold at any hardware or automotive parts store. This prevents gas spillage onto the mower body.

Unplug the spark plug. It’s best to stay on the safe side and prevent a short-out or electrical flare-up if any oil or gas should come in contact with the spark plug. It shouldn’t be a problem if you hold the mower properly, but it’s still best to be on the safe side. [2] X Research source

- Pay attention to the position of the blade as you’re removing it. You’ll mount the new one in the same orientation, usually with the sharp edge of the blade going counter-clockwise with the turning of the assembly. Again, this may not be true on all mowers, so pay attention to the way this blade is installed and install the new blade accordingly.

Installing New Blades

- Some mowers feature a bottom cap on which two shorter separate blades are attached, while some newer push mowers feature a single longer blade, that looks kind of like a ruler. Tilt the mower back to inspect the blade, or talk to someone at the hardware store about the type of blade appropriate for your brand of mower. You can also check in the owner’s manual, if you have it. [4] X Research source

- Alternatively, you can salvage the old blades and have them sharpened if they seem to be in decent condition. If the blades are worn out, with chips or chunks out of the metal, it’s probably wise to get a new set.

- Most blades are either specific or universal fit. Be sure you have the same length as the old blade before mounting the new one, and make sure the clearance from the lawn mower deck is the same. Tighten the new blade onto the bolts carefully, since it’ll likely be much sharper than the old one.

- It’s a good idea to wear thick mechanic gloves when doing the job, to keep your hands safe. It’s also advisable to use a small piece of wood to stop up the blade from turning while you reinstall it. You can jam a small piece of wood between the blade and the mower deck to keep things from turning. [6] X Research source

Check the blade for play. Be sure the blade is mounted correctly and has no wobble when you move it up and down, firmly. Remove any jacks or props used to hold mower in place and wait about 30-60 minutes for oil to return to motor to prevent issues or motor damage. Check the oil before use to ensure it is within the proper limits.

- After a quick inspection, you should be able to start up your mower and start cutting that grass much more efficiently with your new blades.

Expert QA

Grant Wallace is a Landscaper and Owner of Grantlanta Lawn in Atlanta, Georgia. With over seven years of experience, he specializes in lawn maintenance and landscape installation. In 2012, he earned his BA from the University of West Georgia. Grant has been profiled in Shoutout Atlanta, Canvas Rebel, and Voyage ATL.

Residential homeowners who only mow their grass a couple of times a month only need to sharpen their mower blades about once or twice a year. To check your blades manually, remove the spark plug from the mower and run your finger along the blade. If it feels dull or round, it likely needs to be sharpened.

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

It depends on the definition of stripped. Is it the head of the bolt or the threads? If it’s the head of the bolt it may be tricky, but an EZ out and a drill tap would get the job done, or a good pair of strong vice grips and a little heat from a propane torch should also assist with removing the bolt. If it’s stripped threads on the bolt then probably take the bolt to your local hardware store and get an exact copy of the bolt depending on the threads (if it’s coarse, fine or whatever). I am fairly certain it’s a 3/8 fine thread on lawnmower blades, though.

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

The sharp edge of the blade should be installed facing the grass. If the blades have tabs to fit into the housing, then go ahead and fit the tabs into the housing around the shaft. Always wear gloves though (preferably leather).

Thanks! We’re glad this was helpful. Thank you for your feedback. As a small thank you, we’d like to offer you a 30 gift card (valid at GoNift.com). Use it to try out great new products and services nationwide without paying full price—wine, food delivery, clothing and more. Enjoy! Claim Your Gift If wikiHow has helped you, please consider a small contribution to support us in helping more readers like you. We’re committed to providing the world with free how-to resources, and even 1 helps us in our mission. Support wikiHow

Ultimate Guide for Lawn Mower Blades with Expert Guidance

The blades are the most essential part of a lawn mower as it is responsible for cutting the grass efficiently and accurately.

A wrong choice can lead to irregular cuttings which ruin the look of your landscape. If you are wondering whether all the blades are same then you are wrong.

Lawn mower blades come in different types, choosing the right one among them is quite challenging, especially if you don’t understand the differences.

We have created this guide to help people make an informed decision while purchasing lawn mower blades. In this article, you can see in-depth differences between lawn mower blade types

Types of Lawn Mower Blades

In-depth Description of Each Lawn Mower Blade

Below is a clear analysis and description of each law mower blade along with its merits and drawbacks. Read the information thoroughly to understand which one suits your lawn mower better.

Standard or Straight Blades

They are known as medium-lift or standard mower blades. They are commonly found on regular lawnmowers, or ones that spin horizontally. Lawnmowers that release debris from the side are often fitted with this mower blade type. Though they’re referred to as straight blades, these generally have a small curvature on the ends.

A reason behind the small curve along edge is that it helps create an uninterrupted flow of air when the blade turns and creates an action of cutting and sucking. Suction is created by the soil that pulls grass up and allows for accurate cut. But straight blades produce a small amount of suction because their edges are inclined. This leads to a tiny quantity of air moving across blade.

Before deciding on blade type, be aware of the kind of lawn you will be cutting. While many people choose straight blades because of their superior efficiency on dry and damp surfaces however, they’re only suitable for areas with large grass patches. The advantage of these blades is swiftly cutting the grass that is dense, and send it to the bagging process effortlessly.

However, one of the disadvantages of the blades might not be capable of cutting through smaller bunches of grass, which could result in a sloppy cutting process. In this regard it is recommended to choose a different type of blade in the event that your yard is shady areas of grass. Another disadvantage of straight blades is the small suction power which cannot be sufficient to push grass debris out of the bag. This could create a blockage within chute.

Benefits of Standard Lawnmower Blades

- The slightly curled ends aid in suction.

- It can cut through thick grass patches easily.

- Ideal for all kinds of soil.

- Cuts both dry and damp surfaces with great efficiency.

Drawbacks of Standard Lawnmower Blades

- The tendency to blockage in chute and restricts storage space in bag.

- Might not be capable of cutting small clumps creating uneven lawns.

Low-Lift Blades

They are designed to mowing soil that is sandy due to low suction capacity. The blades’ edges are also less curly than standard ones.

The suction is low, which doesn’t allow grass to get up too high. This keeps the grass well-anchored for cutting and then discharged to the side. In the same way, this doesn’t allow dust to pick up with it. Therefore, it settles on ground without being blown around in the air that you breathe.

The blades that are low-lift are typically about 3-4 inches long and demand less energy for the engine of your lawnmowers. Because they don’t burden the engine to much it is given a longer life span.

Blades that have more suction will deteriorate more quickly than blades that have low lift. The dust can settle into the deck, causing blades to wear away prior to the expiration date they were originally scheduled for.

Thus, if you depend on durability over time, blades with this type of design are a suitable choice. Blades with low lift are also suited because of their capacity to operate quietly. They don’t produce much noise since they don’t require any power to work effectively.

Benefits of low-lift Blades

- Needs more power for function

- Ensures effective yet silent mowing

- Perfect for mowing sandy terrains

- Comes with durability and longevity

The High Lift Blades

It is easy to distinguish High-lift blades from their distinct vertical angles along the edges. This allows for maximum airflow through the blades and results in a suction vertical like none other.

The Rapid circular movement of the blades keeps the grass straight in preparation for the accurate trimming. It lets you cut your lawn with more accuracy and give it a clean and clean look.

High-lift blades are available from the length between 1 – 21 inches and are suitable to yards that have tall grass. The suction force is strong and ensures that there isn’t an accumulation of grass inside the chute, thereby preventing obstruction. This is why people who like bagging tend to lean toward such blades.

However, this feature renders it unsuitable for mowing on sand-covered terrains. Due to the high flow of air through the mower, it is possible that blades can be prone to pull in sand and dust as well as the grass.

As we all know dust may settle on the mower’s deck. This can cause it to wear away in a short time. In addition, the quick and continuous rotation of the blades requires more power to generate more suction. Additionally, this could lead to damage to the lawn mower sooner than anticipated.

Benefits of high-lift Blades

- Provides elegant finish

- Capable of sucking out and storing the leftover remains

- Perfect for clipping tall-grass clippings

Drawbacks of high-lift Blades

- The power drains out quickly

- Not suitable for using on sandy soil conditions

- They wear out quickly

Mulching Blades

They are also called a multi-purpose blade. They have a curved surface which permits it to work in different ways. The blade first raises grass and precisely cuts it into pieces. The cuttings or clippings will be taken towards the deck, which is where they will be cut into small pieces. Then, the inside curvature of blade generates the pressure of air that blows away the tiny pieces of clippings.

You can use them to fertilize the soil. Finer grass fragments are better as they will absorb nutrients by the soil.

The sharper and more curvier edges, along with cutting edges generally let mulching blades chop grass in smaller bits and then to expel them back into the ground. While mulching blades create lesser suction but lift the tall grass and straighten them enough to cut it.

If you’re looking the lawn to appear beautiful and also help to fertilize your landscape parallelly using mulching blade, it’s the perfect choice. Indeed, it is the best way to get rid of mowing debris that is not needed anymore.

Benefits of Mulching Blades

- Can work for different purposes at same time

- Comes with numerous curves which allow accurate cutting

- Ensures soil enrichment

- Perfect when you are not clearing clippings

Drawbacks of Mulching Blades

- Cutting dense grass can lead to blockage or clogging

- Has low suction which can make it unfit for cutting dense and tall grass

Gator Blades

Just like mulching blades similar to mulching blades, blades of gator are ideal to fertilize the soil. In reality the gator blades have been modified to accomplish the job more effectively.

The blades are specifically designed to generate maximum suction over the grass, pulling it upwards. This is due to an exact angle of those teeth on the mulching blade. It is an inferior blade that pulls grass upwards so that the grass will be cut with precision.

Unique angle that the gator’s teeth have will push the grass towards its sharp edge while the mower moves. This allows smaller grass pieces to cut again and again. It is possible to cut tall grasses into small pieces using this blade with ease.

To maximize the benefits of this method, put a mulching tool on the blade. The mulching kit can help spread the fine pieces grass so that they settle on the soil in a uniform way.

Finely cut grass adds essential fertilizers to soil. This will greatly increase the yield when you’re trying to plant fruit and flowers in your backyard.

It is also possible to collect all of the pieces that have been chopped into the grass collector bag. This can save you your time as well as effort taking care of the yard. It also helps in making your garden look attractive. Therefore, you’ll benefit by both sides.

Benefits of Gator Blades

- Curved teeth lift the grass upwards

- Suitable for fertilizing soil

- Ideal for mulching leaves

- Precise cutting job

Some Frequently Asked Questions

No, not all lawn mower blades are the same. Each type of lawn mower has its own specific blade type that is designed to work best with that particular mower. For example, a riding lawn mower will have a different blade than a push lawn mower. The blade on a riding lawn mower is designed to be able to cut through thicker grass and will be much sharper than a push lawn mower blade.

is the best way to locate replacement lawn mower blades. The OEM number refers to the manufacturer’s numerical part number for the blade. Most cases, you will only need to enter this number and the manufacturer name into an online search engine or store to get some promising results.

The length of the mower blade and the center hole size are the two most important factors to consider when buying lawn mower blades. If your mower requires it, make sure to get a blade that has the correct outer holes. If you’re mowing cool-season grasses, use high-lift blades.

The great thing about it is that many standard lawnmowers are capable of being modified for mulching. For best results, it is important to follow the steps below: Install a suitable mulching mower blade; and. You will also need to install a restriction plate.

If your grass tips are becoming ragged and brown, you will know it is time to sharpen your lawn mower blades. This can cause your grass to lose its ability to store water and make it more susceptible for disease. Some manuals for lawn mowers recommend sharpening or changing blades every 25 hours.

Some people believe that replacement blades should not be sharpened until they are used. This is because of the powder-coated finish that is applied by the manufacturer to most blades. This coating is thicker around the blade’s cutting edge, and can feel dull to the touch.

A good rule of thumb for homeowners is to replace their mower blades every year. Regularly sharpening your mower blades will extend the life of your blades. If you decide to sharpen your mower blades at home, make sure you wear protective gear and disconnect spark plugs.

A dull lawnmower blade can cause your lawn to look yellow, brown or raggedy. A dull lawnmower blade can pull up parts of your grass, as it pulls on the whole plant rather than cutting through the grass blades cleanly.

A new, sharp blade will give you a clean, neat shave. Your grass will experience the same effect. Sharp cutting blades make your lawn look great, and keep it healthy. The mower blades that are too dull or damaged can cause a bruising to the edge of your grass blade. This will leave a ragged end and not a clean cut.

Most mower blades will last 100 to 200 hours in normal conditions. If you purchase high-quality blades, the number of hours could be up to 400. You can use a grinder or a metallic file to sharpen your blades if they become dull. However, this will only work for about 2 to 3 times.

Mower blades today are made of low-carbon alloy steel. Most of the latest mower blades are rigid in nature but softening makes them bendable if they strike a rock or piece of wood. Because these blades are designed for being soft, it makes lawn mowing safer.The blades made from a harder steel alloy do not bend, but instead break. This can lead to steel bits flying around, especially when the blades spin at very high RPMs.

Design-wise, almost all of the lawnmower blades are interchangeable between single-blade and multi-blade lawnmowers. The dimensions of the blades are the only thing that will vary. Multi-blade mowers require that the blades overlap slightly to achieve consistent and clean cuts.This means that the two-blade mower blades may be slightly shorter than the single-blade blades. If the lawnmower mounts and blade match, the different types of lawnmower blades can be interchanged.The best one for you depends on your personal preferences and lawn conditions. Depending on what type of mower you use, certain blades might perform poorly. A mulching blade, for example, can be attached to a regular mower. However, it must be equipped with additional accessories to ensure that it does a good job of mulching.

Mower blades may vary in their dimensions, shape, and type of mounts. These are important details when it comes to lawnmower blades. Not all blades will fit into every lawnmower.The blades’ diagonal length can range from 6 to 32 inches. The width of the slit can vary from 1.5 to 4.25 inches. The blade’s thickness can vary from 0.01 to 0.33 inches.There are two options for the number of holes in the blade: one or three. They can also come in different shapes. Blades with two outer holes may require a blade adapter. A blade with only one center hole will work fine.

Few Words to Wrap Up…

The efficiency and quality of cutting depends mostly of the blades of lawn mower blades. Having a wrong blade can mess the look of your beautiful landscape. To help you figure out the right one, we have compiled a list of the lawn mower blades and detail description along with it. Consider the tips to find out which one is suitable for your grass cutting requirements.

If you still have any dou

Which Side Of The Lawn Mower Blade Is Up? (2023 Guide)

Owning a lawn mower is a great way to save some money and maintain more control over your lawn and yard. But, it can come with some unexpected maintenance, and it’s alright if you don’t already know how to keep your lawn mower in good condition.

If you want to keep your lawn mower working well, you need to know how to install your lawn mower’s blade.

Don’t worry if you’ve looked at lawn mower blades and been completely baffled by them before.

I wrote this guide because I’ve been there, and I know how important proper blade installation can be. After all, getting the installation right is critical for the life of the blade, the function of the lawn mower, and the appearance of your lawn.

In this guide you’ll learn:

- Why lawn mower blade direction matters

- How to tell which side of your lawn mower’s blade is up

- And much more!

Why Does It Matter Which Side Of Your Lawn Mower Blade Is Up?

If you’re in a hurry, this video will help explain why it matters which side of your lawn mower’s blade is up, why it matters, and how to install the blade.

Use the Cutting Edge

Most walk-behind lawn mowers rotate the blade to the right, or clockwise. That means that when the blade is spinning, the cutting edge should spin to the right. However, this isn’t 100% foolproof.

Some lawn mowers do spin counterclockwise. It’s rarer, but you have to know which direction your lawn mower spins to be sure. Your lawn mower’s user’s manual should be able to tell you which direction the blades spin.

The Wings Face Up

On most lawn mower blades there will be a small part of the blade that isn’t flat, but angled up. This little wing on the blade is designed to encourage air movement, helping pull your grass upward for an even cut.

The wings on lawn mower blades are always designed to point up toward the lawn mower’s cutting deck. The same is true for the more extensive wings on mulching blades. If your lawn mower blade has wings, those wings should point toward the lawn mower and away from the grass.

Those three techniques should help you figure out which side of the lawn mower blade is up on pretty much any lawn mower blade. Assuming you know which direction your lawn mower spins the blade, that is the most fool-proof method, but the other two options are usually easier and faster ways to tell.

How To Tell What Kind Of Lawn Mower Blade You Need?

There are two basic kinds of lawn mower blade to choose between, and getting the right one can make a significant impact on your lawn mower’s performance. Most lawn mowers are compatible with both types of blade.

It’s important to remember that not all blades are created equal, and just because a blade is the right length doesn’t mean it’s compatible with your lawn mower. You always need to check your lawn mower for which blades are compatible.

Regular Lawn Mower Blades

Regular lawn mower blades are the simplest option. They are blades that are designed to get the job done without any bells and whistles or extra functions. These blades leave clippings relatively long, but they can also provide a more even mow than more complicated blades.

It’s important to have a good cutting edge on these blades since they are really reliant on cutting power to get good results.

Also called standard or medium-lift blades, these blades are typically on lawn mowers with side-discharge designs.

High Lift Blades

High lift blades are generally used for lawn mowers that have a bagging function because they provide more airflow that helps to move the grass clippings into the bag. These blades also provide higher suction, which means that they cut the grass at a more consistent height by pulling the grass up straighter.

Mulching Blades and Gator Blades

Mulching blades and gator blades both provide even more suction and cutting power in order to process the grass into smaller pieces. Of the two blade types, mulching blades are gentler. They process clippings into smaller chunks to distribute back over your lawn to act as a protective layer over the top soil.

However, mulching blades are not typically a good idea if you’re trying to bag your grass clippings at the same time. They just don’t move the clippings toward the bag very effectively.

Gator blades process the grass clippings even smaller than mulching blades. They are designed to get the clippings small enough to eventually mix into the top soil of your lawn where they will decompose and replenish the soil.

My Final Thoughts On Which Side Of The Lawn Mower Blade Is Up

Knowing which side of your lawn mower is up might seem like a simple thing, but it’s incredibly important. Choosing the right side of your lawn mower blade will help maintain the health of your lawn and can even reduce the maintenance on your lawn mower itself.

Learning how to install your lawn mower’s blade properly shouldn’t be difficult, but it is an important step if you want to keep your lawn mower in good condition. Hopefully this guide will help you decide which kind of blade is right for your lawn, and learn how to install it successfully.