How to Remove Dried Grass from Lawn Mower Deck (My Go-To Method)

I have two different lawn mowers in my shed. One is a push lawn mower, and the other is a riding lawn mower. One thing I have perfected over the years is figuring out how to remove dried grass from the lawn mower deck, including the very stubborn grass mixed with dirt.

So, if you are struggling to find an easy and thorough method of cleaning your lawn mower deck, then let me share with you the two methods I use. Let’s take a look.

Best Way to Remove Dried Grass from Lawn Mower Deck? (The Short Answer)

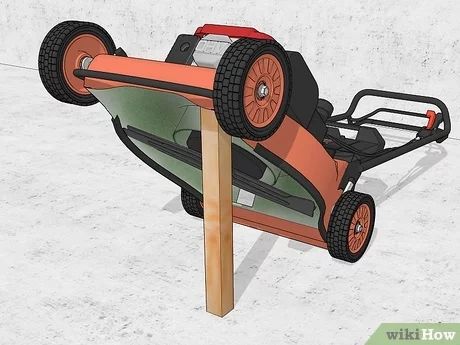

For smaller push lawn mowers, I find the best way to clean the deck is to tip the mower over and use a selection of cleaning tools, including scrapers, screwdrivers, and a garden hose. For larger lawn mowers, I find that removing the cutting deck gives better access and allows for a more thorough job using the same cleaning tools.

Why Dried Grass on a Mower Deck Can Be a Big Problem

The space under the cutting deck needs to be kept clear of dried grass and dirt so that the blades can do their job efficiently. This includes things like cutting, mulching, shredding, and generating enough airflow to make the bagging and discharge systems work properly.

If you have large amounts of grass stuck to the inside of your cutting deck, you might find that your lawn mower won’t cut your lawn evenly and that your deck and chute are continuously getting clogged. This is definitely an issue if you are trying to use a collection bag on your lawn mower.

How to Remove Dried Grass from Lawn Mower Deck (This Usually Works Great)

So, let me share with you my two methods for cleaning cutting decks. These methods give me really good results and don’t cause any problems with the function of my lawn mower. Let’s take a look.

Push Lawn Mowers Deck Cleaning

- Wet Down the Dried Grass – The first step is to soak the dried grass so it’s not so tough. For this, I just use a steady stream from my garden hose.

- Allow the Dried Grass to Soften Up – Once I have the grass soaked with water, I then give it five or ten minutes to really soften up. I find the longer I leave the lawn mower, the easier it is to remove the grass.

- Scrape Off the Bulk of the Grass – Next, use a two-inch scraper and start working on the dried grass. For tighter spaces, I switch over to a long-handle flathead screwdriver. I don’t try to get all the grass off in one go. I just go for the bulk to start with.

- Re-Wet the Remaining Grass – Again, spray dried grass and allow it to really soak in. Letting it sit for five or so minutes really helps.

- Continue Scraping – So, here we are going to repeat the cleaning process. This time, I like to also use kitchen non-scratch scouring pads. One of those green scouring pads you use to clean cooking pots.

- Rinse Repeat – Next, I grab my garden hose, rinse the area, and then go back to the previous steps. My lawn mower deck looks pretty good after a couple of goes with soaking and scraping.

While you’re getting your hands dirty, it makes sense to check that the blade is also nice and clean too, as a dirty blade can also affect cutting/mower performance. I put together a guide about the process I go through to do that too, which I’ll link to below.

Riding Lawn Mower Deck Cleaning

When it comes to how to remove dried grass from a lawn mower deck on a riding lawn mower, the only difference for me is how I get to the underside of the deck. So, for the push mower, I tip the mower, and for my riding lawn mower, I remove the cutting deck.

Usually, this process requires you to remove the deck belts and then remove a few clips holding the deck bracket in place. So, once the deck is disconnected from the lawn mower, you should be able to slide the deck out and flip it over.

Next, I use the same cleaning tools and techniques I use on my push mower to remove the dried grass.

Things to Be Careful of When Trying to Remove Dried-On Grass from a Mower Deck

When you are cleaning a mower deck, there are a few things you will want to be careful of. This could save you from some pretty extensive repairs. Let’s take a look at what these are.

Tilting Over the Lawn Mower

If you are about to head out to clean the deck on your gas-powered push lawn mower, then you’ll want to make sure that you tilt over your lawn mower the correct way. If you happen to do this incorrectly, then you’ll end up filling the carburetor and the air filter will oil from the bottom of the engine.

So, when you tip over your lawn mower, make sure you tip it the right way with the air filter pointing upward. This will save you from having to spend more time fixing your lawn mower’s carburetor and air filter.

Removing Paint From Inside the Cutting Deck

If you go too hard with the scrapers and other tools, then you might end up removing some paint from the inside of the lawn mower deck. Unfortunately, this will end up rusting and causing you a whole bunch of new problems. Rust on the underside of the cutting deck can lead to problems like holes and a weakened deck.

So, if you do happen to chip off or blast off some paint, be sure to repair it so that it doesn’t lead to rust. If you skip this process, then you’ll probably be carrying out rust repair to your cutting deck at some point in the future.

Getting Water into Pulleys

When you are working on larger decks, like a cutting deck on a lawn tractor, then you’ll have a number of pulleys that drive the blades. These pulleys are sealed to keep the grease inside, but high-pressure pressure washers have enough power to get past the seals. Just be careful how close you get to the deck pulleys.

Getting Water into the Fuel Tank

The next item I see giving people trouble is getting water into the gas tank when using garden hoses and pressure washers. Anytime I use one of these tools to clean my mower deck, I put a plastic bag between the gas tank and the filler cap.

To do this, all you need to do is remove the gas cap, place a plastic bag over the gas tank, then replace the filler cap. This stops any water from getting through the filler cap vent and into the tank.

Getting Water into the Engine

The last thing to watch out for when cleaning a mower deck is getting water into the engine. There are two places where this can happen. First, water can get into the air filter, which runs into the carburetor and then into the cylinder head. Second, water can seep through the seal in the drive shaft.

Again, like a pulley on a cutting deck, you need to be careful not to blast water with a pressure washer against the drive shaft seal. If you do, then you could get water into the sump of the engine, which will lead to problems with lubrication and corrosion.

Why I Don’t Use Pressure Washers to Remove Dried Grass

I have a pressure washer in my garage, and I use it a lot but not for cleaning my lawn mower deck. This is because they cause more problems than they are worth and can make a real mess by blasting grass clipping all over the place. Usually, I find that you spend more time cleaning up your work area after using a pressure washer than you do actually cleaning the intended object.

About Tom Greene

I’ve always had a keen interest in lawn care as long as I can remember. Friends used to call me the lawn mower guru (hence the site name), but I’m anything but. I just enjoy cutting my lawn and spending time outdoors. I also love the well-deserved doughnuts and coffee afterward!

How to Remove a Lawn Mower Deck | Gravely®

Leave a Reply Cancel reply

Copyright © 2010. 2023 LawnMowerGuru.com, All Rights Reserved.

Affiliate disclosure: As an Amazon Associate, we may earn commissions from qualifying purchases from Amazon.com. You can learn more about this here.

How to Remove Grass Buildup from Your Lawn Mower Deck

Lawn mower maintenance is an important part of overall lawn maintenance. Without regular cleaning, cut grass can accumulate on the underside of your mower deck, and this buildup can reduce airflow to the engine and interfere with your mower’s performance. Keep reading to learn how to solve this common problem, and prevent it going forward.

If you have any questions about lawn mower maintenance, feel free to ask the friendly staff at AJ Cycle Trike Conversions. You can find us in Jasper, IN.

Gathering Supplies

Removing grass buildup from your mower deck is a simple task that you can do at home, but you will need the right tools for the job. Round up a pair of gardening gloves, a flat pry bar, an air hose with a nozzle or wand, dish soap, a pressure washer, and a metal putty knife or wire brush. You are also going to want some kind of non-stick cooking spray, or a graphite, silicone, or Teflon spray.

Cleaning the Underside of the Mower Deck

The first steps to removing grass buildup from your mower deck are to empty your mower’s gas tank and remove the spark plug. Now tilt the mower so that you can access the underside of the deck, and secure it in place. Detach the mower blade, and then you can get to work using your flat pry bar to dislodge clumps of grass from the underside of the deck. Your metal putty knife or wire brush can scrape off smaller remnants of grass, and your air hose can take care of any leftover bits. If there is any grass remaining, remove it with your pressure washer.

Now inspect your mower’s air filter to determine if it needs to be replaced. If you have a washable filter, you can blow off any grass and debris with your air hose, then wash the filter with dish soap and water. You can then use your air hose to blow-dry the filter. Just make sure the filter is completely dry before you re-install it.

Your mower deck should also be completely dry before you proceed to the next step. Once again, your air hose can be used to speed up the drying process.

When the deck is dry, you can coat the underside with your non-stick cooking spray. This leaves behind a slick surface that will deter further grass buildup, and make it easier to remove next time. As an alternative, you can use graphite, silicone, or Teflon spray. These products are going to cost more, but yield better results.

When you have finished all these steps, you can re-install the mower blade, replace the spark plug, and refill the gas tank.

Preventing Grass Buildup

The best way to prevent grass buildup is to do your mowing when the grass is dry. Whenever possible, wait for at least a day or two after a rain shower to mow your lawn. You might be surprised at how long your grass holds onto moisture, and wet grass is the number one culprit behind grass buildup.

Frequent mowing will reduce grass buildup, as longer grass is more likely to form clumps. Mowing at full throttle can also help, as your mower will eject grass clippings at a faster rate.

If you continue to encounter this problem, you may want to consider upgrading to a high lift mower blade. This style of blade boosts airflow and propels clippings with greater force, minimizing the potential for buildup.

When you are ready to upgrade your mower, head to AJ Cycle Trike Conversions. We proudly serve Jasper, IN, along with our neighbors in Evansville, IN.

Mower Deck Belt Replacement – Step by step

Replacing belts on your mower is like replacing tires on your car; there are only so many miles in them. Replacing a deck belt can be a challenge, especially if the mower throws the belt and you don’t know the routing, but we’ll get it figured out!

Getting the correct belt is the first important step. Some manufacturers place a label detailing the belt part number and belt routing. Try under the hood or under the footrest; if not, check out “Belt routing.”

Deck types vary. Some are easy to work on, some not so much. It’s important to check over the deck looking for any damaged or loose components, especially if your old belt was damaged and not just worn out. You don’t want to damage the new belt needlessly.

Most mowers won’t require deck removal to fit the belt; others will. So take some time and consider the routing, don’t put extra work on yourself. Take lots of photos; it saves time and head-scratching later.

What’s Involved?

Fitting the new belt means removing some plastic protective covers. And in most cases, it involves wrapping the belt around the pulleys and making sure the belt guide (guide not on all pulleys) is on the outside of the belt. The last pulley to fit is the crank pulley (engine pulley).

Tensioned or Not

A tension-ed belt is a deck drive belt that is always tight on the pulleys. Push-button blade engages type mowers usually run an always tension-ed belt. Replacing it will require manhandling the belt onto the side of the crank pulley, then turning the crank pulley clockwise by hand until the belt slips on.

If your mower has a lever, then you likely have a slack belt which is then tensioned by moving the blade to engage the lever. This type of belt is easier to replace and will take no time at all.

Tensioned – This type of belt is always tight on the pulleys.

Un-Tensioned – This type of belt setup is slack on the pulleys until you engage the blades.

What Deck Type?

Cutting deck setup types vary from side discharge; rear discharge; mulching decks; front decks; cutting, and sweeping.

They may have features such as single-blade; twin-blade; tri-blade; tensioned belt; manual tensioned belt; electromagnetic blade engagement; fan assisted deck; timed overlapping blades, and so on.

The one thing they all have in common – is the deck drive belt. It’s how engine power is transferred into cutting power.

Timed Deck

A timed deck means both your mower blades are set at a fixed angle in relation to each other. The toothed belt maintains the blade position; this allows the blades to overlap.

Part 6 MTD Deck Removal

Some say the overlapping blades give a superior cut; I like the lawn finished with the overlapping twin cut, especially the smaller decks.

This deck type is also referred to as an interference deck. They call it Interference because if the blades go out of time, they’ll smack each other.

Resetting the timing of the blades or replacing the belt is a job that can be done without much difficulty, but it does require removing the deck, tension assembly, and various plastic guards. No special tools are needed.

Rear – Rear discharge is great at collecting grass but doesn’t like long grass so much.

Timed – Timed deck has a toothed belt that can break or slip out of time. Timing the blades allows them to overlap.

Mulching – Some decks will have a flap that closes off the chute when the operator wants to mulch.

Side Discharge – Side discharge is great for tall grass and rough terrain.

Measuring The Belt

A belt will be marked with a type code, length, and part number. Belts are usually measured by their inside length (Li) or outside length (La); if you can find this info on the side of your old belt, great! But usually, it’s worn away.

Some mowers like Husqvarna place a sticker inside the hood with a list of helpful part numbers like belts, filters, plugs, etc.

What Belt Width? – The width and depth of a belt are also very important. A new V belt should fit snugly into a v pulley; the belt should sit just proud of the pulley’s shoulder. A belt that sits further down into the pulley is worn out.

What Belt Length? – If your belt was shredded, then you’ll need your make and model number to order the correct belt. An easy way to measure an old belt – use a string to follow the outside of the belt; now measure the string.

This measurement will be marked on belts by the letters La (outside measurement); alternatively, run the string around the inside of the belt; this measurement is the Li measurement.

A faster way to measure an intact belt is to make a circle of the belt and measure inside to inside, then multiply by 3.14. The result is the Li belt size.

Sizing – Sometimes easier said than done!

Markings – Check under the hood of your mower; you may get lucky with a part number sticker, but be cautious with the Husqvarna labeling; they are often wrong belt part numbers.

Check your old belt for markings; if none, get the tape and some string. These belts are measured in mm.

Pulley – The new belt will be the full width of the pulley. Worn belts usually stretch in length and become narrow in width.

Check Belt Routing

Belt routing, needless to say, is important. On some mowers, it’s possible to put a belt on the backways, which makes the blades turn backward. Not much use for yard work.

If you can, make a diagram or take some pictures of the old belt in place. First, you’ll need to remove both plastic protection pulley covers, one on each side. Some mowers have a handy sticker showing the deck belt routing under the footrest.

That’s great advice, but what if your belt has snapped or derailed? Then you’ll need to check out the links below. Bear in mind, even if you don’t see your maker in the list, check the link out anyway because lots of make share the same decks.

Look at the pulley configuration to see if yours looks similar.

Belt Routing Links

The following link to Google belt routing pictures:

Sticker – Check under the footrest of your mower; some models have a belt routing sticker. This sticker is on a Husqvarna tractor.

Check out the Amazon link below for deck belts.

What Belt Type?

Belts are belts, right? Well, No. The correct belt is crucial. An ill-fitting or wrong-type belt will cause endless trouble. Throwing the belt, vibration, poor cutting, and collecting, and because the belt doesn’t fit correctly, it won’t last very long. I had one customer who fitted a belt that was so tight it broke the end of the crankshaft. Ouch!!

There are many different types of belts; however, when it comes to lawnmowers, they are usually fitted with a standard V-type belt. Other belts used are AA belts, timed belts, and poly V belts.

Sure, you can fit a basic quality belt with a polyester cord, but it’s going to wear out quickly; for durability, you’ll want Kevlar; they cost more but last a lot longer. Some models will only work well with OEM belts, like John Deere and MTD.

I recommend fitting only OEM (Original Equipment Manufacturer). Fitting a belt can be a challenge. Reassembling and discovering what doesn’t work right can be demoralizing.

V Belts

V belts are so-called because of their cross-section shape (wider at the top than the bottom). They are used almost exclusively to drive power from lawn tractor engines to their transmissions. They are also used to drive deck blades. The V belt drives power from one side of the belt only.

They come in different heights/widths and are marked type A, B, C, D. The most common V belts used on mowers are the A and B types, and obviously, they come in a long list of lengths.

Each belt is marked by type and belt length; it may also have a part number. Unfortunately, the markings usually wear off, making the ID process difficult.

AA Hex Belts

The AA belt is a double-sided hexagonal belt; it is mostly used on tractor mower decks to drive the blades. The belts are unique as they have the ability to drive from either side of the belt.

AA Hex Type – This is a double-faced belt; it gives greater flexibility to deck design, as it allows both sides of the belt to drive. It’s used on higher-end tractor decks.

Toothed (Timed) Belts

A mower-toothed or timed belt does two jobs, it transfers power and, at the same time, keeps the mower blades from hitting each other. The toothed belt is a very exact belt in that the teeth of the belt must match that of the mower cogs.

Timed Belt – This type of belt has become more popular in recent years. It’s fitted to mower decks with overlapping blades.

A Type

A Type.This is the most common type of lawn tractor belt; it’s used by many lawn tractor drive systems and most decks too.

B Type

The B-type belt is a heavy-duty A belt; it’s an older well-fed brother.

Check Belt Wear

Belts have a difficult job and can be the cause of various issues. Regular inspection will tell you if your belt is at the end of its life. Things to look for are flat-spotting, glazing, cracking, fraying, and contamination.

As you know, a V belt should sit just proud of the pulley shoulder; if it’s a lot lower than the shoulder of the pulley, it’s worn out.

How Long Do They Last?

The life of a belt is hard to gauge, it really depends on how much grass you’re cutting and how heavy the workload is, but usually, we’re talking years. Typically a belt should be changed after 3-4 years, but we know this doesn’t happen.

A worn or damaged pulley can shorten the life of your belt. An engine or transmission oil leak can destroy the belt, you can try cleaning it, but it causes slip. A derailing belt can get twisted and damaged, and a mower that throws belts regularly probably has a worn or damaged pulley.

But the real killer of belts – tall, heavy grass jams the blades, which causes flat spots on the belt. The flat spot will then cause a lot of vibration, which in turn can throw the belt.

Belt damage is usually caused on the first cut of the season when the grass is heavy. So if your grass is tall and heavy, just take a little off on the first pass and make a second pass with the deck a notch lower. Yes, it’s twice the mowing, but it’s better for your mower and your lawn.

Flat Spot – Flat spotting is usually caused when the blade jams, but the engine pulley keeps running. This has a grinding effect on the belt.

The flat spot will cause excessive vibration in the mowing deck. The fix is – Replace the belt.

Blistering – This can happen when a belt gets old, and the material starts to break down. Your mower won’t cut or collect very well. Better to take care of it now, before it breaks.

Glazing – This belt has a shiny hard surface that is not much good for traction. A belt like this will cause horrible vibration in the mowing deck.

Frayed – Wear and tear, this belt is at the end of its useful life.

Cracked – Natural wear and tear

Check Pulley Wear

A pulley’s job is to route the belt around the chassis of the mower or mowing deck and transfer power from the engine pulley to the driven pulleys. As a rough guide, pulleys usually wear out at the same time as a belt, so best to check them while you have the belt removed.

Tension and idler pulleys should move freely, be quiet when spun, and should feel smooth when turned. If they’re worn, now’s the time to take care of it; when a pulley bearing breaks, it will likely damage the belt.

Spin To Test

You don’t need to remove them to check. Spin them while the belt is off; they should be smooth and quiet. Changing them now is easy.

Bearings

Most pulleys come with the new bearings pressed in place; the exceptions are driven pulleys (Mandrel, engine, or transmission pulleys).

Pulley Types

Pulleys come in all sizes, some metal and some plastic. Tensioners and idlers will have a bearing fitted, and when it wears out, the whole pulley is replaced. Pulleys are usually broken into two main types, flat or V.

A flat pulley is not a driven pulley; it runs on the back of the belt, which isn’t powered (unless it’s on a AA belt).

A V pulley can be driving, driven, tensioner, or idler. A V pulley is described as a driven pulley if it’s connected directly to the output, such as a transmission or a blade Mandrel.

The driving pulley is the engine pulley; it’s the pulley supplying the power. Both the driven and driving pulleys are fixed to shafts using a key and key-way.

A tensioner pulley is part of a moving arm, which, when operated, applies tension to a belt. A tensioner pulley can be a flat or V pulley.

A stationary pulley is usually known as an idler, and its job is to route the belt around the chassis of the mower or mower deck; they can be flat or V-type.

Pulleys – Metal or plastic, V type or flat, driven or idle. So many choices.

V Pulley – This is a V pulley; the driving side of the belt is making contact with the pulley.

Flat Pulley – A flat pulley on a V belt setup is never a driven pulley. Its job is to change the direction of the belt and guide it to the next pulley.

Fitting A Belt

Fitting a cutting blade deck belt that is just worn is the easiest, as you can see the routing of the old belt, and make a diagram or take pictures. Removing the old one also gives you an idea of how challenging fitting the new one will be.

As you know, there are a few variations of deck belt setups; most mowers will have one belt to drive the blades that are either a tension-ed or a un tension-ed belt. The belt can be fitted to both of these types of setups without removing the deck from the mower.

The timed belt setup is a little more involved but not complicated. It has two belts as do so some of the larger John Deere mowers. They can be a challenge as they have many pulleys, and you’ll need to remove the deck.

Pulley Covers

Likely you’ll have already removed the two plastic pulley protection covers, one on each side of the deck. Usually, 2 or 3 screws on each side. They’re not there to protect the pulley. They’re there to protect us from catching body parts in the pulleys.

The latest generation mowers are far more challenging to access as the nice people in the health and safety dept. have been working nights and weekends to find new ways to challenge us.

Removing Belt

Here’s a quick run-through of what we’ll be doing, but it’s all covered in the steps below with pictures. With the covers removed, start by removing the belt from the engine pulley. Often the engine pulley will have a belt guide; its job is to prevent the belt from derailing. Depending on the type of belt guide (if fitted), you may need to remove them first.

As you know, some belts will be tensioned all the time. By tension-ed, I mean the belt is tight around the engine pulley all the time.

The belt tensioner will allow for movement (it’s spring-loaded) so the easiest way to do this is by pulling the belt over the side of the engine pulley and then, with both hands, turning the engine pulley until the belt falls off (Removing the spark plug makes turning the pulley easy).

With the belt off the engine pulley, it’s easy to guide it off the other pulleys. Check your old belt against your new belt, just to be sure.

The un-tensioned belt is simple to fit, and by un-tensioned, I mean the belt is loose around the engine pulley until you engage the blades. The belt can usually be maneuvered around the guides without much trouble.

As with the tension-ed belt, remove the belt from the engine pulley first.

Fitting Belt

Reference your diagram or pictures of routing. Refitting the belt is identical except in reverse order, fitting the engine pulley last by pulling the belt onto the side of the pulley and turning the engine over.

Timed Belt

Most mowers have a simple deck belt setup, like the one covered in this guide is more complex. The demo mower used here has two deck belts driving the mowing deck.

The first one is the main input belt which is powered directly by the engine. This belt is easy to replace, and you don’t need to remove the deck, just some plastic covers.

The second belt is the output belt, and it turns both blades in time. This allows the cutting blades to overlap and catch that annoying tuft of grass you sometimes see in the middle of your cutting strip.

To replace the output belt also known as a toothed belt or timed belt, we need to remove the deck from the mower. It’s not difficult to do, and the whole job shouldn’t take more than an hour.

This guide covers a timed deck belt replacement procedure. Most timed decks will look something similar. It’s more complex than other deck belt setups but not difficult to work on. In this guide, I will: remove the deck; inspect belts; replace the belt; tension the belt; set the timing of the blades.

Tools

No special tools are needed on this mission, but an impact gun would make life a lot easier. When you try to open bolts attached to pulleys, they tend to spin, which is a real pain. Sure, you can wedge it or grab it with grips, but you risk damaging the face of the pulley, and that in turn can damage your new belt. Nooo!

The impact makes small work of pulley bolts, and the better brands have a torque setting built-in which makes reassembly a gift. It’s a super tool to have in the trunk of your car; it makes changing a wheel look NASCAR slick. So treat yourself or drop a few hints before fathers day.

Chute – On this model mower, the chute is fitted through the center of the mower. Not all mowers will have a chute like this. If your mower is side discharge, then you don’t have one.

Remove – As said earlier, you may not need to remove your deck to fit a belt. On this model mower, removing to fit the belt just makes life a little easier.

Pins – Locate the deck arms. Most mowers will have one at each of the four corners. The deck will be fixed to the deck arms with Cotter pins. (Some may have nuts and bolts) Remove the two front pins and the two rear pins.

Slide – The deck will be free to move forward, which allows you to remove the deck drive belt from the engine drive pulley. In some cases, you may have a cable to remove; this depends on the blade engage type.

Push – With all pins removed and belt off, just push the deck sideways and it will pop off the arm bushing mounts. Apply some grease when refitting. Hey, I make that sound easy!

Inspect – Go ahead and turn the deck over to inspect the blades and blade boss (blade attachment). It’s likely that the blades are damaged; if they are, replace them.

Bent – If your blades are bent or worn, now is the time to take care of them. Replacement blades are easy to fit when the deck is off.

Boss – When your blade hits something hard, the blade boss pins are designed to break; this saves damaging more expensive components.

Replace – Check washers and bolts for damage. Blade bolts and washers are specially designed, so only use the original kit.

Remove – Remove plastic protection covers.

Pulley – Remove the drive belt tension assembly.

Key – Remove and store the key and the spacer ring safely.

Remove – Remove the timed belt protective cover.

Belt – Remove the broken belt, and check for damage.

Loosen – Loosen both pulley bolts; the bolts are positioned on the underside of the pulley.

Remove – Remove the two guide bolts. Remember to fit these after fitting the belt, but tighten them last.

Loosen – Loosen the two guide bolts.

Loosen – Loosen the lock-nut on the adjusting bolt, and thread it all the way out.

Push – Now push the tensioning assembly in all the way so it hits the adjusting bolt.

Set to 90° – Set the deck blades at 90° to each other.

Mark – Now mark the two main blade pulleys and the deck body as per the picture. Marking them with paint gives us a clear reference point when fitting the new belt.

Align – Keep your paint marks aligned and fit the belt to the tension assembly last.

Check – Check your paint marks again; it’s OK if you’re out by one or two teeth.

Routing – This is a typical timed belt routing.

Adjust – Adjust belt tension first, and tighten down the lock-nut. Do not tighten pulley bolts or guide bolts at this stage.

Check – Check belt tension as you adjust. Leave some play in the belt; it should deflect by about 1/2″ at its longest run.

Check 90° – Check that the blades are at 90 degrees. If all is OK, go ahead and fit the guide bolts, but don’t tighten them yet. Tighten the two pulley bolts, and now tighten the four guides.

Rebuild covers and fit the deck in reverse order; that wasn’t so bad!

Related Questions

Why does my deck belt keep breaking? Common reasons new belts keep breaking:

Why does my mower deck shake? Mower decks commonly shake because:

- Engine not at the correct rpm

- Engine not running correctly

- Blades damaged

- Deck belt damaged or worn

- Spindle bearing damaged or broken

As you’re a MacGyver type, you’ll likely find the Riding mower troubleshooting and the Video repair library useful.

Hey, I’m John, and I’m a Red Seal Qualified Service Technician with over twenty-five years experience.

I’ve worked on all types of mechanical equipment, from cars to grass machinery, and this site is where I share fluff-free hacks, tips, and insider know-how.

And the best part. it’s free!