Repair and interior design

Rotary hammer Makita hr2450

First impression

The MAKITA HR2450 rotary hammer is positioned by manufacturers as a tool designed for professional use. From the general characteristics that are indicated on the price tag, you can find out the following features:

- Power drill. 780 watts.

- Type of chuck. SDS Plus.

- Operating modes. three: conventional drilling, drilling accompanied by impact, chiselling (impact without drilling).

- The number of speeds is one.

This information is too small to have a complete picture of the tool. Full trust in the words of the seller is also not worth it: this is an interested person. Therefore, we will be guided by our own impressions and opinions of customers.

During the initial inspection, the Makita 2450 makes a positive impression. The tool is made in a two-color version: blue and black, on the handle there are special rubberized pads. The build quality is quite decent, there are no backlashes, the plastic shell sits like a glove. The product is equipped with a special storage case. This is a very important nuance: some manufacturers do not include a case in the basic package.

The mass of the product is 2.4 kilograms, an additional handle is provided, which allows you to apply more effort when chiselling solid materials. The rotary hammer is equipped with a rather long electric cable. 4 meters. The basic equipment includes a depth gauge for drilling, however, there are no drills.

Makita 2450 SDS Plus x8 is manufactured in China. Manufacturer’s warranty is one year from the date of purchase.

Specifications

The power consumption of MAKITA HR2450 is 780 W, which makes it possible to work with almost any kind of building materials (wood, metal or concrete). The nominal impact energy is 2.7 J. Note that the maximum allowable hole diameter is set for each material. In particular:

- For wood. 32 mm.

- For metal. 13 mm.

- For concrete coatings. 24 mm.

These parameters were obtained by manufacturers as a result of technical tests. It is not recommended to exceed the set values: the likelihood of wear of the electric motor increases, and the life of the tool is accordingly reduced.

The maximum number of revolutions of the chuck in drilling mode is 1,100 rpm. Impact frequency. 4,500 bpm. Please note that these characteristics are relevant for the tool idling. When immersed in the drill in the material, the speed and impact frequency are reduced.

One chuck is included in the basic package. Cartridge Type SDS Plus. By the way, this nuance suggests that the tool is intended for domestic use. Therefore, manufacturers are cunning, declaring this model of a hammer drill as a professional tool. SDS Plus is designed to work with drills whose shank diameter does not exceed 10 mm. In professional rotary hammers, the SDS Max chuck is used, which is suitable for shanks with a diameter of 18 mm.

Of the useful options, the following features can be distinguished:

- Automatic blocking. turns on when the voltage drops in the mains.

- Protective system to prevent debris from entering the instrument.

- Safety clutch. breaks the adhesion of the chuck and engine when the drill is jammed.

- Reverse. reverses the direction of rotation of the drill.

- Speed controller.

Benefits

- Hard case for storage. The presence of this accessory automatically solves the problem with the delivery of the tool to the place of work and simplifies storage. By the way, the external dimensions and internal space are optimized as much as possible: nothing more.

- Three operating modes. This feature allows you to use an electric hammer drill like a drill or jackhammer. In combination with a good power (780 W), the tool shows good performance and functionality. The working bit can be fixed in 40 positions.

- Convenience in operation. The hammer drill weighs only 2.4 kilograms, so you can perform work even with one hand. At the same time, the tool does not slip out of the palm due to rubberized pads. When strobing walls, especially under the ceiling, an extra grip helps a lot. This element is removable, so it can be easily removed if desired.

- Quick detachable SDS Plus cartridge. The advantage of this type of chuck is that the drill shank is fixed at five points. This ensures the reliability of fastening, however, if necessary, you can replace the drill with literally one movement.

- Long cord. The presence of a four-meter cable eliminates the need for carrying during work.

- Protection. This includes a safety clutch and reverse function. When the drill is jammed, the load on the electric motor automatically increases, the winding burns out accordingly, and the tool is sent for repair. Installing the coupling avoids such unpleasant consequences. Thanks to the reverse function, it is possible to pull out a jammed drill without problems without rocking the tool.

- Smooth start. This feature reduces the load on the motor at startup, increasing the life of the tool.

- Strong case. High-strength plastic is used here, so even when dropped, cracks and chips do not appear on the case.

- Acceptable price. The cost of the MAKITA HR2450 electric punch starts from 6,300 rubles.

disadvantages

Customer reviews say that this model has virtually no flaws. However, there are still design flaws. Here are the weak points of the Makita 2450 punch:

- Oil leaks. After lubricating the shank of the drill, part of the oil flows into the chuck during operation.

- Overheat. Buyers note that the perforator gear is very hot during operation. The problem can be caused by poor quality parts (virtually eliminated) or non-compliance with the rules of operation of a power tool. In particular, by exceeding the permissible loads on the percussion mechanism.

- There is no vibration protection mechanism.

- Very poor basic equipment.

Conclusion

The MAKITA HR2450 is well worth the money spent. The tool is suitable for professional and domestic use. Thanks to the expanded functionality it can be used for repair and construction works. In particular, a power of 780 watts is enough to dismantle old claddings, lay hidden wiring and make new communication holes in concrete floors and brick walls.

Subject to the requirements of the manufacturer, the tool can last for a long time without the need for service. If we summarize the identified shortcomings, then we will not see significant problems. Of course, manufacturers could equip their electric tools with drills without introducing buyers to additional expenses. Or eliminate the problem with the leakage of grease from the chuck. But these flaws do not affect the performance and functionality of the product. Therefore, the MAKITA HR2450 rotary hammer electric, with a power of 780 W can be rated at 8 points out of 10 possible.

Even very reliable Makita rotary hammers break down over time.

Any breakdown is eliminated, you only need to have straight arms and perseverance.

In addition to electrical malfunctions, rotary hammers are also subject to mechanical breakdowns.

The work of rock drills with solid materials in a dusty environment shortens the life of the machine and requires user intervention to perform preventive maintenance.

Repair of the mechanical part of the Makita 2450 and 2470 puncher

Any repair of the tool begins with the determination of the nature of the malfunction and disassembly.

A Makita 2450 and 2470 rotary hammer can be repaired by a user with basic locksmithing skills and knowledge of electrical safety requirements.

This article discusses the mechanical part of the Makita puncher, the main malfunctions and how to solve them.

Dismantling the mechanical part of the Makita 2470 rotary hammer

To get to the mechanical part of the punch, you need to remove or disassemble the cartridge.

Dismantling the quick release chuck

Place the hammer drill on the back of the cabinet on the surface of a table covered with a clean cloth or paper. Using tweezers or a screwdriver, remove the rubber tip 35, item 1.

Carefully loosen the annular spring, pos. 2, the clutch cover, pos. 3, the steel ring, pos. 4. You will reach a steel ball with a diameter of 7 mm, pos.20.

Now you can remove the case of the mechanical part

It is black.

Using a screwdriver, unscrew the four screws at the end of the case.Holding the black case with your right hand, press the end of the shaft from which the cartridge was disassembled with your thumb. The plastic case is easy to remove.

Next, remove the gearbox shaft.

To disconnect the mechanical part from the electric, you must first remove the electric brushes.

Remember! In the lower part of the body, the rotor is held by electric brushes, which must be removed.

After checking that the electric brushes are disconnected from the lamellas of the rotor, use a screwdriver to pry the metal case of the perforator at the border of the green plastic case.

Now we proceed to disconnect the rotor from the mechanical part of the punchpa The rotor is held in the mechanical part due to helical gears of the gearbox.

If you take the rotor case in one hand, and the mechanical part in the other case and pull it in different directions, swinging, you will separate these two nodes.

You get such a knot in the old grease.Next, unscrew the two M4 × 12 bolts, pos. 43, using the hexagon, item 2666273-7 with the internal hexagon head.

Pull out the shaft with the intermediate spur gear 10 pos. 80, art.226399-7.

from the inner case pos. 49, art. 153687-8. Clean parts from old grease.

You get such a mountain of clean details.Now carefully review the details, immediately discard the rubber rings, picking up new ones.

Replace defective parts with new ones.

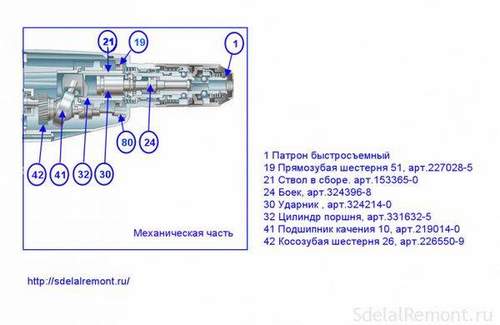

Mechanical makita 2450 and makita 2470 rock drill

Common mechanical problems with Makita rotary hammers include:

- destruction of the quick-release cartridge;

- bearing failure;

- breakdown of the shock mechanism;

- punch barrel wear;

- wear of rubber strikers and striker;

- gear breakage.

Repair of the perforator cartridge is done to replace the anther and rubber ring, as well as the conical spring and the steel ball, which provides clamping of the working tool (drill). What does the working tool indicate? namely, the drill is poorly held in the cartridge.

The main reason is the wear of a steel ball 7.0 pos.20, art. 216022-2. Ball wear occurs from contamination of the barrel of the cartridge due to ingress of dust and dirt.

The general view and arrangement of the Makita rotary hammer cartridge is shown in the photo below.

Do-it-yourself makita 2450 rotary hammer cartridge repair is easy to do. The cartridge must be disassembled, freed from old grease, discard rubber parts, replace defective ones.

complex failures require knowledge of the mechanical design of the Makita 2450 rotary hammer.

Having determined the nature of the malfunction of the Makita rotary hammer, proceed to disassemble the mechanical part called the gearbox.

Disassemble the mechanical part according to the attached video.

Release it from the old grease.

Carefully inspect all parts, their integrity, level of wear. All rubber products during any disassembly require replacement.

Video: Makita 2450 Difference From 2470

Consider repairing a perforator barrel. We will analyze the mechanism completely.

Video disassembly, lubrication and assembly of the Makita rotary hammer

Repair of parts of a shaft of the Makita 2450 puncher

Remember! In the lower part of the body, the rotor is held by electric brushes, which must be removed.

At the next stage, the rotor must be disconnected from the removed mechanism. The rotor is disconnected from the mechanism simply by pulling out, because it is held by the friction of two helical gears.

It turned out such a dirty knot.

Now you need to separate the shaft of the percussion mechanism.

Most often, rubber rings, striker poses wear out. 24, compressor spring pos. 18. and cylinder parts.

Here’s how barrel parts wear out and collapse during improper use of the tool.

Consider the most difficult malfunction. failure of the shock mechanism.

The characteristic signs of failure of the impact mechanism is the absence of impact and the unpleasant noise of a working punch in the “Impact” mode.

Such a malfunction is typical for those perforators that during operation were pressed strongly against the work surface.

Having disassembled the gearbox, we remove debris and pieces of foreign objects. We find the defective part and clean everything from the old grease.

Very often the striker pos. 24 is destroyed, art. 324396-8, which is part of the trunk.

metal ring pos. 27. art. 324216-6.

Discard damaged parts, replace with new ones, cover with a thin layer of grease. Parts are ready for assembly. But more on that in the next article.

How the punch works and works

You can almost always find a puncher in a set of a home master. Replaceable nozzles do this tool universal and irreplaceable. Let us consider in more detail what nodes it consists of and how they work correctly.

What is a punch

The controls are located on the tool body, as can be seen in the following photo:

The internal device of the punch can not be understood without disassembling it. The following main components are hidden in the plastic case:

- electric motor;

- safety clutch;

- “Drunk” bearing;

- flying piston;

- cartridge.

The principle of operation of the punch consists in turning the rotation of the electric motor into a shock-rotational movement of the nozzles. The electric motor drives the rest of the hammer mechanism. A safety clutch ensures the safety of specialists during operation. A drunk bearing drives the piston, creating an impact force, and the cartridge provides clamping nozzles. Now let’s talk more about each of these nodes.

Electric motor

The main parts of the electric motor are the stator and rotor.

The stator windings create a constant electromagnetic field inside which the rotor rotates. There are several windings on the rotor. The findings of the coils are connected to the contacts of the armature. At the same time, one of the windings is included in the electrical circuit. Power is supplied through graphite brushes to the armature contacts. By switching the windings, a slip field is created, due to which the rotor rotates.

The electric motor in the tool can have a horizontal and vertical arrangement. Horizontal is usually used in lightweight rotary hammers, while medium and high power models are equipped with a vertical electric motor.

In the latter case, a gearbox is added to the design of the hammer, changing the direction of rotation, increasing the torque and impact force of the tool.

The operation of the electric part of the hammer is regulated by the trigger by pressing a button on the handle.

Safety clutch

To stop the rotation of the cartridge, if the working nozzle is jammed, a safety clutch is installed in the perforators. This is a necessary element: without using it, a powerful tool is turned out of hand, the continuation of independent rotation of the punch easily leads to injuries to the worker. Two main types of coupling devices are used in rotary hammers: friction or cam.

- Under normal operating conditions of the tool, the friction clutch discs are pressed tightly against each other. this transfers the rotation force to the rest of the mechanism. If rotation is difficult, the wheels slip without overloading the drive.

- In the cam clutch, both of its halves have beveled protrusions included in the grooves of the counterpart. The coupling halves are connected with a spring of a certain stiffness. If the force on the percussion mechanism exceeds the pressure of the spring, the protrusions come out of the grooves, disengaging the clutch. During this, a characteristic crack is heard, for which a cam clutch is often called a rattle.

Shock mechanism

The percussion mechanism in the designs of perforators is of two types:

The most widely used is the electro-pneumatic option. The “drunk” (swinging) bearing and piston together constitute the percussion percussion mechanism.

When the main shaft rotates, the swinging bearing performs translational movements, transferring force to the ram of the pneumatic cylinder. The air in the cylinder pushes the piston with the striker. The working part of the cartridge is subjected to strikes, the drill clamped in the cartridge hits the material being processed.

Cartridge

The cartridge for the punch is designed so that the user has the opportunity to quickly change the nozzle without making long breaks in work. We are talking about cartridges of two main types:

The tool shank for the SDS-plus chuck is clamped with two locking balls.

SDS-max chucks clamp tools with other shanks for a more secure hold.

What can a tool do?

The following main operating modes of the punch are distinguished:

- rotation punch. allows you to drill a concrete wall;

- impact without rotation. to hammer concrete;

- rotation without impact. with a nozzle under the drill allows you to drill like a drill.

Those who often work with a hammer drill know that in addition to drilling and chiselling walls, such a tool can also shatter walls for wiring. Making a shtroba in concrete with this tool is quite simple. First, a series of holes are drilled on marked fishing lines. Then a lint between the holes is broken with a lance or spatula. Such use of a rotary hammer is not typical, but allows you to refuse to purchase additional tools.

Strobing with a perforator allows you to get not such an ideal result as after a stroborez, but subsequent plaster hides all the defects.

Safety operation

The puncher is an electromechanical tool, so you need to use it, observing safety measures.

- Before starting work, you need to make sure the integrity of the electrical cord. A damaged plug or insulation on the cord may result in electric shock. Cracks in the case can also be source of danger.

- Replaceable nozzles must be securely fastened, otherwise during operation they can pop out of the cartridge and cause injury.

- Drilling material is necessary without touching the rotating part of the tool: sharp edges easily damage your hands and other parts of the body.

- The nozzles become very hot during rotation, so after finishing work you must not touch them with your bare hands in order to avoid burns.

To operate a power tool correctly is to maintain health. Be sure to follow the safety rules and wear personal protective equipment: gloves, a mask or glasses, special work clothing.

Timely punch repair: how to disassemble a Makita punch?

Today, developers offer buyers hundreds of different apartments and houses. Often, residents want to slightly change their parameters, making housing more convenient and comfortable. Makita punchers will allow to carry out repair work efficiently and quickly. Factory parts and good build quality will extend the life and help to avoid failures during the restoration process. The article will give an idea of the main advantages of the products of this manufacturer.

Makita rotary hammer device

Among users, the Makita rotary hammer has established itself as the tool with the greatest functionality. It is durable and does not require special skills for use, is lightweight and comfortable while working.

The design provides a special protective system designed to limit the spread of dust. With timely cleaning, the tool will work efficiently throughout its entire service life.

Makita is widely used in people who prefer to do repairs on their own. The tool is simple to operate, the financial maintenance costs are minimal, inexpensive.

The manufacturer presents the following specifications:

- Total weight. 2.04 kg

- SDS system allows you to mount drills

- You can hammer and drill

- The system has three modes of operation

- The largest number of beats per minute. 4500

- Translational Strength. 2.7 Joules

- The power supply network is 780 watts.

Why is a Makita puncher undesirable to hammer?

Often the equipment fails, and the drill flies out of the punch. This happens for various reasons. Many users of Makita rotary hammers are faced with the fact that their device does not hit, but drills at the same time. You can fix the breakdown yourself. The most common causes of malfunctions are presented below:

- Countershaft wear

- Deformation of clamping units

- Damage to the connecting rod system

- Lack of lubrication for proper operation

- Damage to shock components

Makita rotary hammer: DIY repair

Self-repair of the tool is allowed in the presence of special skills and knowledge.

Diagnostic and troubleshooting technology are identical to other devices. To begin with, you should disassemble the tool by removing the case, and then remove obsolete grease and dirt.

Nodes that have stopped working are recommended to be replaced. After that, all the constituent elements of the mechanism are set to their original position.

For correct operation, it is recommended that you carefully examine each repair point. To restore the functionality of the cartridge 2010, the mode switch and the housing, the following steps should be performed:

- Remove cartridge

- Remove switch

- Repair defects in the inside of the case

- Lubricate and replace worn parts.

How to disassemble a puncher and gearbox?

When disassembling the gearbox, it is recommended to adhere to the following instructions:

- Install the hammer drill on a hard surface by lifting its barrel up

- Pull the shell with forward movements, pressing the tool to the table. This position prevents accidental displacement of the constituent elements.

Makita rotary hammer assembly

After the repair is completed, all the removed parts should be returned to their original position. It is recommended that a fresh coat of grease be applied to all necessary parts.

Before assembling, the body is cleaned with kerosene or gasoline. The peeled shell is returned to the place. The mode switch must not be in it.

Circuit diagram Makita HR 2450

The Makita-2450 rotary hammer system consists of many complementary components and a list of spare parts. Among the most significant elements, the features of which should be taken into account during repair work, the following stand out:

- Ring locking device. It is designed to hold the spherical element fixing the drill. The washer and spring guide it

- Snap ring It is necessary for the correct removal of the cartridge cover

- Four screws connect the gearbox and motor, eliminating vibration. The circuit has a large number of rubber components. Often they cause a malfunction.

Descriptions of the mentioned nodes will be enough for a quality repair.

Makita rotary hammers by right are one of the best in the modern market. The 2470 is a bit improved, but that doesn’t make the device durable. Timely repairs will maximize the period of correct operation. This article helps to understand the features of the work of the main nodes. To eliminate the most common types of malfunctions, these materials are enough.

Instruments

31 vote Vote for! Voice against!

A rotary hammer is a construction tool that performs a wide range of work. He makes holes in those materials that can not drill drills. And also indispensable when performing redevelopment of housing. Makita produces a wide range of tools for repair and construction, among which there is a large selection of punchers.

- General and technical specifications of the Makita HR 2450 rotary hammer

- Operation of the Makita HR 2450

General and technical specifications of the Makita HR 2450 rotary hammer

The Makita HR 2450 rotary hammer is declared by the manufacturer as a professional tool for large and long-term loads. It is operated in three modes. drilling and hammering, without hammering and chiselling. Equipped with an electronic speed controller, this indicator can be adjusted for bases of different strengths. The working parts in the apparatus change quite easily, but at the same time the coupler clutch holds them tight. When the voltage drops in the network, the device is automatically blocked. The Makita HR 2450 hammer drill has a labyrinth system of protection against small building debris.

General technical characteristics of the model:

- Shank SDS-plus.

- Functionality. 3 modes.

- Impact. 2.7 J.

- Motor power. 780 watts.

- The largest hole diameter indicator for concrete drill bits is 24 mm.

- The largest hole diameter for wood is 32 mm.

- The largest hole diameter for steel is 13 mm.

- Electronic reverse.

- Protective sleeve available.

- Torque frequency controller. available.

- The number of idle revolutions is 0-1100 rpm.

- The number of strokes is 0-4500 beats / min.

- Cable length. 4 m.

- The weight of the device is 2.4 kg.

Operation of the Makita HR 2450

Before starting work, you must make sure that the trigger switch is functioning and easily returns to shutdown mode if you release it. After connecting the power, the work starts by pressing the power button, the speed of work is determined by the pressure on the button. To stop the drill, the switch is fully released. If the shutdown button is locked, then to shutdown you must squeeze it to the end and then turn it off.

To turn on the reverse movement, it is necessary to turn the switch to position “A”, the drill will begin to move to the right. In position "B" it moves in the opposite direction. Before drilling, make sure that the direction of rotation is correct. To change the settings, you must wait until the drill stops completely. When setting the reverse movement of the drill, the power button is only half-squeezed.

Impact rotation is ideal for working in hard materials. To set this mode, it is necessary to fix the lock button with your finger and then turn the mode change knob to the symbol “drill-hammer”. For operation of the device in this mode, a bit with a tungsten carbide alloy tip is optimally suitable.

For work on soft substrates and medium-density materials, the rotation mode is optimal. Its installation is carried out by the mode change knob, it is switched to the symbol “drill”. The drill with a spiral or a drill on a tree is ideally suited to carry out these works. For scraping, splitting or crushing the material into pieces, the shock mode is optimal. It is set with a mode change knob, it is turned to the “hammer” position. The pyramidal chisel, a chisel for scraping, etc. are suitable for performing these works.

It is forbidden by the operating rules to switch the mode during the rotation of the device, as this will lead to its breakdown. It is also necessary to ensure that the installation switch is exactly at one selected position, and not between them.

The device is equipped with a torque limiter. If the motor reaches a critical speed level, it will automatically shut off, the bit will stop rotating. When the limiter is turned on during operation, it is necessary to immediately disconnect the device from the network, in order to avoid rapid wear of its components.

The Makita HR 2450 rotary hammer model is equipped with a depth gauge, which allows you to make holes of the same depth. To set the optimal hole size, loosen the handle, insert the depth gauge into the hole located on the side, set the required depth and fix the handle on the side.

New entries:

It is easy to join the traditions of French cuisine by tasting at least once the traditional bouillabaisse dish. The recipe is classic.

Stew DishesShare on Facebook VKontakte Twitter Odnoklassniki Juicy, nutritious, aromatic stew is affordable.

Options for bulk pie with jam Bulk pie with jam. an option for quick and tasty baking.