Information about the manufacturer of the grinding machine 3D692

Manufacturer of a grinding machine for circular saws 3D692. Vitebsk factory of tool-grinding machines Vizas, founded in 1897.

Since 1940, the company specializes in the production of grinding equipment and today is the only CIS manufacturer of machines for the manufacture and sharpening of any cutting tool. The plant’s products are operated in more than sixty countries around the world.

Machines manufactured by the Vitebsk grinding machine factory, Vizas

3D692 semi-automatic grinding machine for circular saws. Purpose and scope

In the late 80s, the 3D692 machine was replaced by a more advanced model. 3E692.

Semi-automatic grinding for circular saws 3D692 is designed for sharpening circular segment saws for metal according to GOST 4047-82 and GOST 18210-72 according to the tooth profile and transition cutting edges by the periphery of the abrasive wheel, tucked in radius.

The processing of the ledge on the front face at an angle of 28 ° on the slotted tooth saws according to GOST 18210-72 on semiautomatic devices is not provided.

Semiautomatic device can be used in various industries:

- in mass and mass production at specialized tool factories for the primary sharpening of circular segment saws;

- in grinding departments of all enterprises using circular segment saws.

Semi-automatic accuracy class. P according to GOST 8-82.

3D692 Main dimensions and seats of the grinding machine for circular saws

The main dimensions and seats of the grinding machine 3D692

- a) for saws 275.250 mm

- b) for saws 410.1430 mm

- D = 70 mm for saws with a diameter of 410.510 mm

- D = 80 mm for saws with a diameter of 610.710 mm

- D = 120 mm for saws with a diameter of 810.1010 mm

- D = 150 for saws with a diameter of 1430 mm

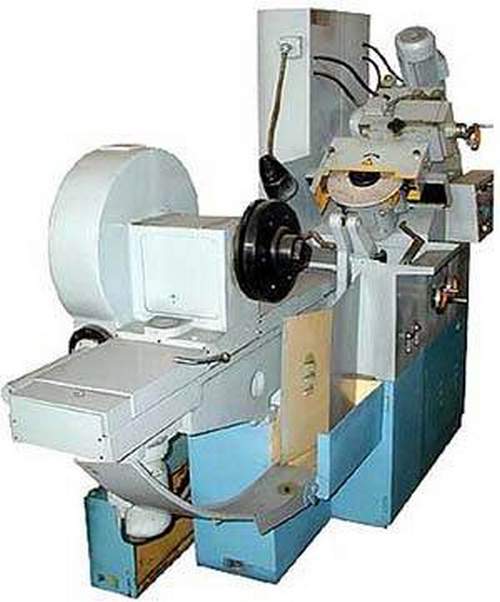

General view of the grinding machine for circular saws 3D692

Photo of a grinding machine for circular saws 3D692

Photo of a grinding machine for circular saws 3D692

Video: Modernization of the Machine for Sharpening Circular Saws

Photo of a grinding machine for circular saws 3D692

Niche of interchangeable fists of the machine 3D692

Photo of a grinding machine for circular saws 3D692

The location of the components of the grinding machine for circular saws 3D692

The location of the components of the grinding machine 3D692

The specification of the components of the grinding machine 3D692

- Bed. 3D692.10.000

- Drive box. 3D692.20.000

- Grinding granny. 3D692.30.000

- The editing mechanism. 3D692.31.000

- Automatic feed mechanism. 3D692.32.000

- Grandma products. 3D692.40.000

- Saw brake. 3D692.41.000

- Fencing. 3D692.51.000

- Fencing. 3D692.52.000

- Electrical equipment. Location on the machine. 3D692.80.000

- Electrical equipment. Location on the closet. 3D692.81.000

- Electrical equipment. Remote Control. 3D692.83.000

- Electrical equipment. Relay block. 3D692.84.000

- Electrical cabinet 3D692.85.000

- Tank U36-692.000

A set of accessories. 3D692.90.000

Device for control of teeth of saws. 3D692.95.000

Location of the controls of the grinding machine 3D692

The location of the controls of the grinding machine 3D692

The list of controls of the grinding machine 3D692

- Main switch

- The handle of the grease pump guides and headstock screws

- Saw holder fixing handle

- Saw brake clamp button

- Nut for fixing the position of the cooling nozzle

- Cooling nozzle rotation lock button

- Cooling tap handle

- Saw setting scale

- Button to move the diamond along the axis of the grinding wheel

- Diamond Wheel Flywheel

- Edit button rotate

- Grinding wheel displacement square when machining saw teeth

- Saw rotation direction switch

- Tumbler switch "Adjustment mode. Work"

- Cooling toggle switch

- Limit lock button

- Index of displacement of the grinding wheel when machining the profile and transition edges of the saw

- Set allowance limb

- Grinding wheel feed wheel

- Emergency nursing lamp

- Signal lamp "Cycle"

- Signal lamp "Slotted tooth"

- Nursing Speed Switch

- Button "Stop rotation of the saw"

- Lamp "The machine is on"

- Button "Saw rotation start"

- Tumbler switch "3mm stock allowance"

- Button "Start grinding wheel"

- Grinding wheel double stroke controller

- Grinding wheel dressing toggle switch

- Button "All stop"

- Interchangeable Fist Niche Door

- Grinding wheel for setting the amount of movement of the grinding head

- Differential flywheel (dovor saw when setting)

- Flywheel

- Saw brake lever

- Cabinet door for interchangeable fists and gears

- Interchangeable Gear Niche Door

- Saw guard lock handle

- Number of teeth between automatic feed

Kinematic diagram of a grinding machine for circular saws 3D692

Kinematic diagram of the grinding machine 3D692

The scheme of the location of electrical equipment on a grinding machine for circular saws 3D692

The scheme of the location of electrical equipment on 3D692