CRAFTSMAN

Find the CRAFTSMAN original equipment parts and accessories you need to keep your lawn mower, snow blower and other outdoor power equipment performing strong. These parts and accessories are designed and engineered to exact standards to provide reliability and optimal performance. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment parts and accessories.

Can’t find your part? Customer Service can help. 1-855-971-2271 Monday. Friday, 8:30 am. 5:00 pm EST CHAT WITH US

FIND PARTS BY DIAGRAM

Find the original equipment parts and accessories for your CRAFTSMAN outdoor power equipment on our Parts Diagrams. The Parts Diagram helps visualize components found on your equipment. If you can’t find what you’re looking for or need assistance installing the new part, call 1-855-971-2271.

FIND PARTS BY MACHINE TYPE

CRAFTSMAN original equipment parts can help you maintain your CRAFTSMAN outdoor power equipment long-term. Find parts by machine type: Riding Lawn Mower, Walk Behind Lawn Mower, Garden Tiller and Snow Blower to repair your machine.

Help keep your CRAFTSMAN riding lawn mower running strong year after year with original equipment parts. SHOP PARTS

Find the parts you need to keep your CRAFTSMAN push mower operating in peak condition. SHOP PARTS

Whether you’re cultivating your entire lawn or just a small garden, find the CRAFTSMAN garden tiller parts you’ll need to get the job done. SHOP PARTS

Avoid waking up to that fresh snowfall with a snow blower that doesn’t work! Regular maintenance and replacement of your CRAFTSMAN snow blower parts will keep you ready all winter long. SHOP PARTS

FIND PARTS BY PART TYPE

Find parts by part type: Blades, Belts, Tires and Wheels, Engine Parts, Cables, Attachments and Accessories, Pulleys and Spindles.

When you need blades to deliver a clean cut and a healthier-looking lawn, look no further than CRAFTSMAN original equipment blades. CRAFTSMAN blades are designed to provide a precise fit with every blade change. Heat dipped for durability and flexibility, these blades have been tested for thousands of hours to meet equipment standards. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment blades. SHOP PARTS

CRAFTSMAN original equipment belts are manufactured to equipment specifications so you can attain a precise fit with every belt change. These belts have been designed to combat conditions. Made with durable, high strength materials, they’re designed to be flexible enough to withstand continuous bending around pulleys. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment belts. SHOP PARTS

CRAFTSMAN original equipment engine parts are specifically designed for your outdoor power equipment’s engine. Shop air filters, oil filters, fuel filters, spark plugs and more. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment engine parts. SHOP PARTS

When it’s time to replace the cable in your CRAFTSMAN outdoor power equipment, you’ll find the exact part you need. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment cables. SHOP PARTS

A properly working pulley helps your machine perform with maximum power. You can find the exact part you need when it’s time to replace a pulley on your CRAFTSMAN riding lawn mower or snow blower. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment pulleys. SHOP PARTS

A proper-fitting tire will help your CRAFTSMAN riding mower, walk-behind mower and snow blower to have a smooth and sturdy ride. Replace tires and wheels as they wear to help make sure your CRAFTSMAN outdoor power equipment runs at optimal performance. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment tires and wheels. SHOP PARTS

Find the spindle assembly parts you need to help maintain your CRAFTSMAN lawn mower’s performance so your lawn looks pristine. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment spindles. SHOP PARTS

Do more with your CRAFTSMAN outdoor power equipment with a wide variety of attachments and accessories including baggers, mulch kits, sun shades and more. Protect your CRAFTSMAN outdoor power product investment with CRAFTSMAN original equipment attachments and accessories. SHOP PARTS

SUPPORT RESOURCES

Enter the product code shown on the product serial number. Then select your language, click “Search,” and download your manual. FIND OPERATOR’S MANUALS

With our easy-to-use online Service Locator, you will get information on your current location and closest service locations, as well as their contact information and driving directions. You can choose to view the service points either conveniently on a map, or a list. FIND SERVICE LOCATIONS

Have your CRAFTSMAN equipment registered Online now. If you don’t know your model and product serial number, call 1-855-971-2271 and we will be glad to assist you. REGISTER YOUR PRODUCT

Briggs And Stratton Flywheel Nut Size

The flywheel on your small engine holds the momentum created by combustion in order to keep the crankshaft spinning between power strokes. By dispersing air around the engine block, the fins help cool. The fins also blast air across a pneumatic governor’s air vane, ensuring that the engine speed remains constant.

Finally, if a lawn mower or tiller blade collides with a rock or curb, the flywheel key may absorb the damage, considerably lowering replacement expenses. Always inspect the key and the keyway, which is the key’s slot on the crankshaft, for damage by removing the flywheel. The soft metal key removes any play between the flywheel and the crankshaft.

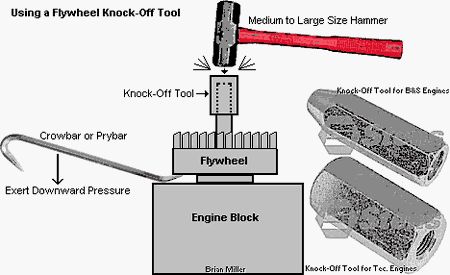

A flywheel key could be simple to remove, yet as with any engine, and not only Briggs Stratton lawnmowers, the flywheel can be hard to remove. To do so, the use of a flywheel puller is needed.

In our guide, you can learn the Briggs and Stratton flywheel puller bolt size. By the end, you’ll also find a guide how to remove the flywheel from your mower. (Read Briggs And Stratton Oil Capacity Chart)

What Size Bolt Is On A Briggs and Stratton Flywheel?

Briggs Stratton small engines, are found in lawnmowers, rototillers, and snow blowers. Each model can use a flywheel-based ignition method.

Magnets on the flywheel’s side spin past the ignition coil, telling the coil to ignite the engine by sending an electrical charge to the spark plug.

If the engine flywheel is broken and needs to be replaced, as well as if you need to access the ignition parts and components, it must be removed.

A simple socket wrench set will suffice for the most of the job, but a specialized flywheel pull tool will be required regardless of model. (Read Briggs And Stratton Engine Starts But Won’t Stay Running)

Flywheel Removal Tips

Do flywheel bolts have reverse thread?

The thread on the flywheel bolt/nut is standard (right tight, left loose). So, anything that prevents the flywheel from turning will suffice.

How should I remove the flywheel on a Briggs and Stratton engine?

Some Briggs engines include a flywheel clutch holding the flywheel in position. Others only have a cup and retaining nut to keep the flywheel in place. To keep the flywheel from sliding, unscrew the flywheel retaining nut with a socket wrench while gripping the flywheel with a strap wrench. (Read our Briggs And Stratton Snow Blower Reviews)

How can I remove the flywheel from the crankshaft?

Grab the flywheel strap wrench tightly and alternately but equally tighten the flywheel puller bolts with a socket wrench to remove the flywheel from the crankshaft.

After the bolts are evenly tightened, the flywheel will pop free from the crankshaft. With the flywheel strap wrench removed, lift the flywheel off the crankshaft.

Latest Posts

We are reader-supported and this article may contain affiliate links. As an Amazon Associate, we earn from qualifying purchases. This does not cost you anything

Introduction: Mower Kicks BackReplace the Flywheel Key

About: I miss the days when magazines like Popular Mechanics had all sorts of DIY projects for making and repairing just about everything. I am enjoying posting things I have learned and done since I got my first to… About Phil B »

Your mower does not start. Sometimes it fires weakly, but yanks the starter cord from your hand.

Your flywheel key is sheared and it needs to be replaced. The flywheel moved and sheared the key. Now the engine timing is very much incorrect. The spark comes at a time that makes the engine want to run backwards, but it cannot.

As a safety precaution, always remove the spark plug wire before working on a small engine.

Step 1: Why?

The flywheel key shears to protect the crankshaft from twisting, which would cause a very expensive repair. A soft key allows the flywheel to move on the crankshaft when your mower blade hits a tree root, an old stump, a large dried clod of dirt, etc. If the mower blade is loose, that will cause enough shock to shear the flywheel key, too.

Pictured is a repair I made to the blade holder. It had two raised tips to fit the blade slot. Those had become battered and the blade had some looseness, no matter how tight the center bolt was. I drilled out the tips and replaced them with hardened bolts. (Because of space limitations, I had to grind one side of each bolthead away at the top of the blade holder. This blade is actually a thatching blade. Somehow it is causing flywheel keys to shear. I think I will no longer use a thatching blade on this mower.)

Step 2: A New Key

Although sold by Sears, my mower engine is made by Tecumseh. There are several flywheel keys used on Tecumseh engines. Even if your mower is sold by Sears, you can take the Sears model number to your local mower shop and they can find the correct key for you. The key shown is part number 611004. It has a wider, thicker portion at one end. That end faces down on my engine. I was assured the key and flywheel would fit only when the key is in the correct position. (The photo is from Google Images.) A new key is about one dollar (US) in cost.

Step 3: Begin

The first step is to remove the gasoline tank. You will need to remove the oil dipstick first and set it aside someplace clean where it will not attract dirt. Set the tank aside, even though connected by its rubber hose. Set it with the cap upward so gasoline will not leak out. Also remove the red cooling shroud.

Step 4: Prepare to Loosen the Flywheel

Most people will not have a factory issue flywheel puller in their toolbox. You do not need one, if you are careful. Remove the starter rope cup and put the nut back onto the threaded portion of the crankshaft. Turn it until the face of the nut is exactly flush with the top of the crankshaft.

Step 5: Pry and Tap Sharply

Use a long screwdriver to pry from below the flywheel. Do not pry too hard. You do not want to crack the crankcase. At the same time, tap sharply on the nut. The nut protects the threads. Turn the flywheel a quarter turn after 3 or 4 taps. It will come loose more easily than you would expect. When it breaks loose, remove the nut and lift the flywheel off.

Step 6: Remove the Old Key Fragments

The old key will come out in pieces. Use a finish nail to pry what is left out of its keyway.

Step 7: Insert the New Key

Insert the new key with the wider, thicker end downward. You can see the new key properly installed on the shaft.

In the photo the green spring attaches to the automatic engine brake. Before placing the flywheel back onto the crankshaft, tie the dead man’s clutch lever against the mower handle so it is held as when you are mowing.

Step 8: Install Flywheel

Place the flywheel on the crankshaft. It should slide down smoothly over the new key. Oil the threads on the end of the crankshaft. Place the cup, the washer, and the nut onto the crankshaft. Begin to tighten. Never pry against the flywheel cooling fins. They break easily. Turn the flywheel a couple of times to make certain it turns smoothly and nothing is obstructing it. If you did not tie back the dead man’s clutch, you will hear a terrible scraping sound. Torque the flywheel nut. The recommended specifications are usually around 33 foot pounds. On some engines the figure will be 35 or 39 foot pounds. In general, if you are shearing a lot of flywheel keys for no reason, the nut is not yet tight enough.

Step 9: Top Off the Oil

When turning the engine while the oil fill is open you are certain to have some oil belch out of the engine. Top off the engine with new oil. Usually you fill to the level of the opening.

When you place the cooling shroud back onto the engine, you will guide the oil fill tube back into the fill hole on the engine. There is a rubber gasket that goes around the fill tube. It is easy for this to become separated from the fill tube during removal. Be sure this gasket is in place before you finish.

When all of the shrouds are back in place, untie the dead man’s clutch and put the spark plug wire back onto the spark plug. Check the oil just to be safe. Push the primer bulb three times. Grab the dead man’s clutch and pull the rope. The engine should start on the first pull of the rope.

Person Made This Project!

Did you make this project? Share it with us!

Project-Based Learning Contest

Colors of the Rainbow Contest

Комментарии и мнения владельцев

I installed a new flywheel key sold to me by local Ace Hardware for mower with Briggs Stratton engine. Put mower back together. Pull rope would not pull out. When I took that part off again, I inspected and it is not cracked that I can see and pulls out nicely. The key seems a hair bigger than the one I could get at Amazon that is specificly for this mower engine. Ace said this would work. the key causes it to be just slightly off center. I’ve attached a picture. What do you think?

Hi I had a question since I am not really that mechanical with engines. My JS40 Walk behind mower was running ok and then all of a sudden I went to start it and the pull chord just locks up and will not turn the flywheel. First I thougt it was a spark plug so I replaced it. nothing. Then I seen it could be a flywheel key and I removed it and it looks perfectly fine? Any advise? Because the chord is still working off the engine but so hard to pull and make the flywheel move?

If you take the spark plug out, can you turn the engine by means of the mower‘s blade, or is it very difficult to turn? (Do not turn the engine with your hand on the blade underneath unless you have removed the spark plug. You do not want it to start accidentally with your hand under the mower.) If you remove the plastic oil fill tube, is there oil up to the top of the engine casting where the plastic fill tube fits into the hole on the metal crankcase casting, or can you barely see any oil? I am wondering if the engine was run without enough oil and the rings may have seized in the cylinder. You can try putting a spoonful of oil in the spark plug hole and slowly turning the engine slowly in a clockwise direction to see if it loosens up. (I once ran a small 2-cycle engine with a gas oil mixture that was too old. After a few minutes the engine rings seized. I thought I had ruined the engine, but a little oil in the spark plug hole after letting it cool and slowly turning it with a long wrench brought it back.) it will probably be best if you keep the mower level so oil does not flow into parts of the engine where it does not belong,

I hit a rock in my yard and my Briggs and Stratton mower stopped running. It sounded like the most common issue with this would be the fly wheel key. I took mower apart and replaced the fly wheel key and tried to start the mower. The mower started but with low power and only lasted about 30 seconds. I then did this all over again with the same results. This time I heard a bit of rattling before it died. Any suggestions on what this might be?

The flywheel key is supposed to prevent damage to the crankshaft by absorbing the sudden deceleration and shearing. If and when it does not, there is the possibility the crankshaft bent. Remove the spark plug and set the mower up on its side, the side that does not allow the oil to get into everything. Look at the crankshaft closely as you turn the blade. Is there any wobble? There are ways to straighten a crankshaft. It might be time for a different crankshaft from a donor engine, or a different engine.

I have lawn mower Craftsman model # 917.377823. I am having problem to fix it. flywheel key has been sheared. I did replace key on new one. After I was able to start engine for testing, after running engine about 2 minutes I turned off engine, but after I could not start it back. After dissembling I realized it sheared key again. Any advice about this problem will be appreciated.

I ran into the same problem. I found the torque specifications for the crankshaft nut on my engine. I believe it was around 30 or 35 foot pounds. That was just the minimal amount needed to keep the flywheel from shearing the key again. would have helped, but I am cautious about torquing more than specified.

Phil B,I just took apart my lawn mower, replaced the key, put it back together and she runs like new!

2 hours, including improvising a jig for my bearing puller and a trip to the hardware store for a new key. Next time I could do it in 30 minutes.

Bill, Welcome to Instructables. I am glad you found my Instructable and that it solved your problem. I hope you enjoy Instructables. I am eager to see anything you might want to publish here. Once I had a situation that caused our mower to shear the flywheel key often. I eventually made timing marks on the engine shrouds so I could check the timing before the work of tearing into the engine. Here is the AC powered timing light I made.

My BS mower stopped working after running over a small piece of styrofoam. Initially, it would sputter for about 10 seconds before dying. Now it does that the first try, and nothing after that. I’m not much of a repair guy, but I’ve checked the carb, gas line, replaced filter, spark plug, gas oil, cleaned everything out with compressed air. Thought it might be the flywheel key, but couldn’t get the 15/16˝ nut that covers it off, even with PB Blaster and a blowtorch. Starting to think I should bite the bullet and take it to a repair shop, but worried about the cost. Anything I missed?

Please add to the checklist below a look for loose screws or hardened gaskets that do not allow the carburetor body to seal completely against the intake mount on the engine block. This is something that you cannot detect visually, but any screw even a quarter of a turn loose can allow air to leak into the gas/air mixture. That makes the mixture extra lean and lessens the engine’s ability to draw fuel into the combustion chamber. If gaskets are ten or so years old, they are probably too hard to seal well. You can get some gasket material and cut your own gaskets using the old gasket or the flange on the carburetor as a guide.

I’ve checked many of these things already. I need to check compression and the carburetor diaphragm. it could very easily be one of those. Thanks a lot for the thorough check list!

The symptoms you describe seem to be consistent with an engine timing problem caused by a sheared or partially sheared flywheel key. I have always been able to remove the flywheel nut on the crankshaft with a long wrench handle and the blade as levers to work against one another. That must have been some piece of Styrofoam.

I usually go through a process of steps when checking a small engine to discover why it will not run. You may have already covered these. Be sure to look at the final paragraph marked IMPORTANT. It is crucial on certain popular B S engines.

Fuel flows into the carburetor float bowl freely?

No dirt obstructing the idle mixture screw valve?

Clean air filter? (Test by removing the air filter and starting the engine. Air filters can appear clean to the eye, but are not.)

Adequate compression? (If you have a compression tester, you need 60 psi at minimum. Or, if you spin the top of the flywheel clockwise rapidly by hand, it should bounce back in the reverse direction on the compression stroke, not just stop and wheeze a little.)

Briggs & Stratton Lawn Mower Small Engine Flywheel Key 222698S

Clean, new spark plug? (Spark plugs can appear clean, but degrade with age so that they do not fire under the pressure of the compression stroke.)

A good blue spark when the engine is cranked? (Remove the spark plug from the engine, but leave it attached to the plug wire. Wrap some bare copper wire around the threads and fasten the wire to the engine frame for a good ground. Deactivate any dead man clutch that cuts the spark out. Spin the mower engine and look for a blue spark. The fatter the spark, the better.)

Engine timing? (This is the matter addressed in this Instructable. It is necessary to remove the nut and washer holding the flywheel on the crankshaft and seeing if the keyways in both the flywheel and the crankshaft align exactly.

Briggs & Stratton Riding Mower Engine Fan Blade #796084

IMPORTANTMany vertical shaft B S engines use a rubber diaphragm in the carburetor. This diaphragm is about 2.5 x 3.5 inches in size (just guessing from memory) and it has a stiff wire fastened to its center. After 5 or 6 years these diaphragms stretch and do not pulse properly any longer so that the choke plate is not controlled properly in the carburetor. Unscrew the top half of the carburetor after removing the air filter and replace the diaphragm if the mower is more than 5 years old. There is no way to tell visually that this diaphragm is defective, but replacing it makes a big change in the way the engine starts.

I think one of these checklist items should help you find the problem.

O’Reilly Auto Parts Store Services

Most O’Reilly Auto Parts locations can resurface your vehicle’s drums and rotors if they measure within specs and aren’t showing signs of extreme wear. Surface finish is crucial to proper vehicle braking and pad life and should always be part of a complete brake job. Please contact your local O’Reilly Auto Parts store for pricing and availability on drum and rotor resurfacing.

Battery Testing. Free

Extreme temperatures in both winter and summer play a large part in battery failures. Bring your battery into any O’Reilly Auto Parts store for a complete diagnostic check at no charge. Our Parts Professionals can test your battery, and if it’s about to fail, help you find the right Super Start battery for your needs.

Alternator Starter Testing. Free

Alternator: To maintain the battery and keep up with the electrical system demands of your vehicle, the alternator has to put out between 13.5 and 14.8 volts. If you are having charging system issues and suspect the alternator, your local O’Reilly Auto Parts store can test it, on or off the vehicle, to determine where you may have a problem.

Starter: Starting system problems are common, but not all problems are caused by a faulty starter motor. If you are having intermittent starting problems, stop by your local O’Reilly Auto Parts store and let us test your starting system. If the vehicle won’t start and you suspect the starter is the problem, bring the starter in and our Parts Professionals can bench test it.

Wiper Blade Bulb Installation. Free

Our Parts Professionals will install wiper blades and replacement bulbs free of charge (with purchase of wiper blades or bulbs). Whether you’ve bought front or rear wipers (or both), headlights or tail lights, we’d be happy to install them for you.

Restrictions apply. See your local store for details.

Bilingual Team Members

Our team members are here to provide great customer service. We are proud to say that in some locations we have bilingual team members who will help you find the parts you need. The additional languages vary store- to-store. Check the services offered at the store nearest you.

Loaner Tool Program

Many vehicle repairs require tools that will only be used once. The O’Reilly Auto Parts Loaner Tool Program is available at all of our locations, covering a wide range of tools that cover almost any job. A deposit is required which is fully refundable once the tool is returned. See available loaner tools

Custom Paint Mixing

Collision repair professionals and do-it-yourselfers alike turn to O’Reilly Auto Parts AutoColor for unmatched quality and service. O’Reilly Auto Parts stocks industry-leading products such as 3M, Evercoat, Hutchins, Nason and Sata among others.

- Over 500 O’Reilly AutoColor custom paint mixing locations across the US

- A full line of automotive, custom, fleet and industrial paint

- One of the nation’s largest inventories of auto body equipment and supplies

Check Engine Light Testing. Free

A check engine light is often the first warning of a potential problem. O’Reilly Auto Parts offers free check engine light testing to help you diagnose the problem. Most of our stores can loan you a code reader for OBD 12 systems for vehicles from 1996 and up, except in areas where it is prohibited by law. Also, our stores now offer Trouble Code Support, and they can provide you a print out to identify your code. Further diagnostic or repair service is not offered, but our stores are happy to refer you to a local professional. For more details on the loaner code reader and Trouble Code Support, please call your local O’Reilly Auto Parts store.

Custom-Built Hydraulic Hoses

O’Reilly Auto Parts has over 1,300 locations that can custom-build hydraulic hoses. Whether you have a hay baler or a forklift, O’Reilly Auto Parts has hoses and fittings to help you complete the job.

- 2 wire low-pressure, 4 wire high-pressure 1/4- 3/4 and in several locations up to 1-1/4

- A full line of Gates fittings, hose and equipment to make or repair your own hoses

- Hydraulic fluids in 1, 5 and 55-gallon quantities

- Non-conductive hose and fluid available for specialty applications

Fluid Battery Recycling. Free

O’Reilly Auto Parts collects used motor oil, automotive batteries, transmission fluid, gear oil and oil filters for recycling.- free of charge!

- Get it taken care of hassle-free

- Thousands of convenient locations

- 10 O’Reilly Gift Card for any unbroken automotive battery you may have

- Absolutely free

It is required that containers are returned to customers. Environmental laws can vary by state and city and in some municipalities some stores cannot recycle oil. It is best to contact your local O’Reilly Auto Parts store for availability and details. Used antifreeze/coolant is considered hazardous waste so we are unable to recycle it in our stores. Most cities and counties have hazardous waste collection sites. We suggest calling your city or county administration or search their website for hazardous waste disposal. (Other restrictions may apply)

Not all services offered at every location. Check your local store for available services and more details.