How to measure rotary cutter blades

Whether you’re new to rotary cutting or you’ve been doing it for a while, you may have some questions about the different sizes of rotary cutters and want to know “How to measure rotary cutter blades“.

Let me start from the beginning. Rotary cutters were created by the founder of OLFA in 1979 as a faster, more efficient way to cut fabric.

This really revolutionized the quilting industry. Any time you’re using a rotary cutter, you should also be using a rotary mat. This will help protect your work surface and prolong the life of your blade.

Today, there are four standard sizes rotary cutters in the industry. 18 millimeters, 28 millimeters, 45 millimeters, and 60 millimeters. The size references the width of the blade.

To find the size of the blade that’s right for your project consider what you’ll be making, the type of material you’ll be cutting, and the types of cuts you’ll be making.

You may find that you have a preference for one size over the other, and in the end, it’s really all about what works for you.

Types of rotary cutter

Other than the brand, the rotary cutter can be differentiated by the sizes of the blade, handle manufacturing, left-handed rotary cutter, and right-handed rotary cutter.

What is the difference between a 28mm, 45mm and 60mm rotary cutter?

The 18 Millimeter Rotary Cutter is the smallest size and is best suited for intricate or detailed cutting.

Think about when you’re cutting applique, curved quilt pieces, templates, trimming seams, or cutting out garment patterns.

The 28 Millimeter Rotary Cutter is a good fit for working on small-scale projects like miniatures or fitting into tight corners.

It also works well for cutting curves and garment patterns.

The 45 Millimeter Rotary Cutter is the original and most popular size rotary cutter.

Use this size for all your general cutting, making strips, squaring up your blocks, just about anything.

With this size, you can cut up to eight layers of fabric at one time.

The 60 millimeter is the largest size rotary cutter available.

Some people like this size for all their general cutting, but I usually set it aside for when I’m working with thick or demanding fabrics, like home decor outdoor fabrics.

Because of the larger blade, this is also a great tool for squaring up your quilt before binding.

It’s able to easily glide through all three layers of your quilt top, the batting and your backing material.

What size rotary cutter is best for fabric?

For fabric, 45mm size is the most popular one since the position of that cutter is in the middle of all available sizes So that people feel comfortable with it and feel it’s flexible.

Fabrics are generally not that thick and can be cut by 45mm. even this size of the cutter can cut eight layers of fabric, which is more than enough for the people who are working.

what size rotary cutter do i need

Rotary cutters are an essential tool for any crafter, quilter, or seamstress. Deciding the right size of rotary cutter is an important decision that can have a huge impact on the finished product. The size of the rotary cutter you choose will depend on what kind of project you are doing, as well as your own personal preferences and comfort level.

Rotary cutters are available in a wide range of sizes, and the options can be overwhelming. However, knowing the size you need is very important! The right cutter will allow you to work efficiently and produce high quality results.

Can you cut curves with a rotary cutter?

Though rotary cutter is not made for curve cutting but for flawless line cutting. The smallest size of the rotary cutter can be used for the curve cutting.

Many of the users use 28mm only for curve cutting. If you get comfortable with the rotary cutter, it is also possible to cut any kind of curve in the competition with scissors.

The best tip I can give you for curve cutting, First, draw the line on the fabric. If you draw the line and perfectly run the cutter over the line, you can surely get awesome results. Hold your cutter 60-degree angle when you are cutting on the line as it will help you to see the drawing line more clearly.

How many layers can a rotary cutter cut?

The different size of cutter has different number of fabric cutting ability.

18mm can cut around 3 to 4 layers of fabric.

28mm can cut around 5 layers of fabric.

45mm can cut 8 layers of fabric.

60mm can cut around 10 to 11 layers of fabric.

this is a approximate value of every blade, this can be differ for fabric to fabric.

how long does a rotary cutter blade last

Rotary cutters have become an essential tool in the quilting and crafting world. Whether you are a professional or beginner, having a sharp blade is key to efficient and accurate cuts. But how long does a rotary cutter blade actually last?

The life expectancy of rotary cutter blades is heavily influenced by cutting conditions. The materials used to make the blade, such as the alloy and hardness, are also factors that determine how long it can last. Some materials are more difficult to cut than others, and this will also affect the life of the blade.

why does my rotary cutter skip

Rotary cutters are an invaluable tool for quilting and other fabric-based crafts. They make it easy to cut out precise shapes and even lines quickly and accurately, but occasionally they can start to skip or hesitate as you use them. If this happens, it’s important to understand why so that you can correct the issue and get back to your project. Here are common causes of a reluctance to cut and how to fix them:

One of the most common issues is dull blades. Blades should be replaced periodically because they will eventually lose their sharpness and cause skipped cuts. To fix this issue, simply replace your blade with a new one and ensure proper alignment with the cutting line on your mat.

Another possible cause of skips could be due to incorrect grip pressure – if you hold too tightly onto the cutter it won’t move freely through the material resulting in missed cuts. It’s important to grip lightly so that you don’t apply too much pressure. If you have tried the above fixes with no improvement, it is possible that there is an issue with your mat.

To conclude, choosing the right size of rotary cutter an essential part of your quilting profession. I hope, this article is helped you to know about the sizes of the rotary cutter and from the total explanation, you can choose the right one for you.

Lawn Mower Blade Tip Geometry

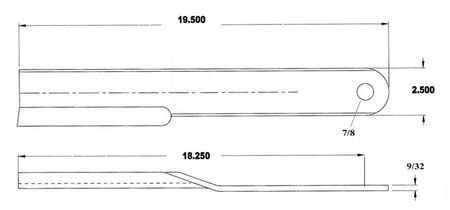

It is a common misconception that rotary lawn mower blades have dimensions of a length, width, and thickness. A rotary lawn mower blade does not have a length but rather a diameter. Lawn mower blades are measured from TIP to TIP. It is this tip or cutting tooth that does the vast majority of the cutting work.

A lawn mower blade just lying on a table may look like the shape of a rectangle but when it is in motion it is a disc. Think of how a circular saw cuts with its many teeth (cutting tips), and of course because wood is much more dense more cutting tips are required. A lawn mower blade however only needs two cutting tips because a lawn is a far less dense material than wood.

Another example if you have experience with machining is that a lawn mower blade is like a fly cutter or endmill, see examples below.

With experience you will notice that the majority of wear on a used lawn mower blade is at the tip. The tip will become a radius (rounded). The process of sharpening a lawn mower blade is to grind the cutting edge back until a new tip emerges.

Cutting Edge Reliefs Angles

Relief: to reduce pressure or stress

Relief Angle: angle that allows chip and material clearance

Relief Angle 1: Diameter Relief Angle

This relief angle is necessary to have the tip or cutting tooth of the blade out at the furthest diameter. The tip is the part of the blade that makes first contact with the grass, and by the image to the right you can see if the blade were truly a rectangle that the corner of the lift would contact the grass tearing it as the mower moves forward. This relief angle is typically 1-2 degrees.

Relief Angle 2: Cutting Edge Relief Angle

This relief angle is the cutting edge face it is typically 30 degrees as an industry average. It allows clippings to flow over the blade and eventually exit the deck.

Relief Angle 3: Land-side Relief Angle

This relief angle can be built into the blade, or created by the pitch of the deck. This angle allows the underside or land-side of the blade to clear the cut grass without causing damage to it.

The three of these reliefs together make up the three sides of the pointed tip or cutting tooth of the blade.

Set of 3. 72 Mower Blades-Befco C180 Blades

Set of 3. 72 Grooming Mower Blades-High Lift Length: 24-1/2 (648MM) Width: 2-3/8 (60MM) Thickness: 1/4 (6MM) Center Mounting Hole: 3/4 (19MM) Fits: Befco Models C16/C26/C30-RD6/C50-RD6 Grooming Mowers Fa…

Set of 3. 72 Grooming Mower Blades-High Lift

- Length: 24-1/2 (648MM)

- Width: 2-3/8 (60MM)

- Thickness: 1/4 (6MM)

- Center Mounting Hole: 3/4 (19MM)

Befco Models C16/C26/C30-RD6/C50-RD6 Grooming Mowers

Farm-Maxx Models FMR-72 Grooming Mowers (Made in India)

IronCraft (Titan®) Models SGM-72 Grooming Mowers

Blue Diamond® Models 72 Grooming Mowers

Made in Italy of high quality boron steel for long life.

Nationwide Fast Easy Shipping

Fast shipping anywhere in the United States

We carry all the top brands

We take pride in offering the best customer service!

Related Products

Set of 3. 84 Mower Blade-Befco C210 Blades

Set of 3. 84 Grooming Mower Blades-High Lift Length:28.5 Width: 2-3/8 Thickness: 1/4 Center Mounting Hole: 3/4 (19MM)

Set of 3. 60 Mower Blades-Befco C150 Blades

Set of 3-60 Grooming Mower Blades-High Lift Blades Length: 20-5/32 (512MM) Width:2-23/64 (60MM) Thickness: 1/4 (6MM) Center Mounting Hole Diameter: 3/4 (19MM)

Set of 3. 48 Mower Blades-Befco C120 Blades

Set of 3- 48 Grooming Mower Blades Length: 16-1/2 (419mm) Width: 2 (50.8mm) Thickness: 1/4 (6mm) Center Mounting Hole Diameter: 3/4 (19mm)

Set of 3. 72 Mulching Blade. 5812714

Set of 3. 72 Mulching Blades Length: 24 5/16 (618 mm) Width: 2 3/8 (60 mm) Thickness: 1/4 (6 mm) Center Hole Diameter: 3/4 (19 mm)

Set of 3. 72 Farm-Maxx, IronCraft® Grooming Mower Blades

Set of 3. 72 Grooming Blade. 60 x 6 x L-618 Length: 24-1/2 (648MM) Width: 2-3/8 (60MM) Thickness: 1/4 (6MM) Center Mounting Hole: 3/4 (19MM)

Customers Also Viewed

Set of 3. 60 Mower Blades-Befco C150 Blades

Set of 3-60 Grooming Mower Blades-High Lift Blades Length: 20-5/32 (512MM) Width:2-23/64 (60MM) Thickness: 1/4 (6MM) Center Mounting Hole Diameter: 3/4 (19MM) Fits: Befco Models.

Set of 3. 48 Grooming Mower Blades Fits: Sicma, Phoenix, Farm-Maxx, First Choice, Farmtrac

48 Grooming Mower Blades Set of 3 Length: 16-45/64 (424MM) Width: 2-23/64 (60MM) Thickness: 5/16 (6MM) Center Mounting Hole: 3/4 (19MM) Fits: Sicma/ Phoenix/ Farm-Maxx/ First Choice/ Farmtrac.

LVA12790. PTO Shaft Series 6 W/Slip Clutch

Universal Drive Shaft W/Slip Clutch. Series 6 1-3/8 Z6 to 1-3/8 Z6 on both ends Safe Usable Length End to End: 33.27 Collapsed to 42.3 Extended BD2/6 1200 Nm Clutch (Enclosed.

LVA14549 Bevel Gear Matched Set

Bevel Gear, Tiller ST-STB-Matched Bevel Gear Set Includes: 4722236 Input Shaft Z6/Z13 and 4728005 Gear Z23 (Replaces separate gears) Fits: John Deere® Models 681 Rotary Tillers Sicma Models.

Set of 3. 48 Mower Blades-Befco C120 Blades

Set of 3- 48 Grooming Mower Blades Length: 16-1/2 (419mm) Width: 2 (50.8mm) Thickness: 1/4 (6mm) Center Mounting Hole Diameter: 3/4 (19mm) Fits: Befco Models.

Set of 3. 72 Grooming Mower Blades Fits: Sicma, Phoenix, Farm-Maxx, First Choice, Farmtrac

Set of 3 Blades for 72 Grooming Mower Overall Length: 24-1/8 (618MM) Width: 2-11/32 Thickness: 1/4 (6.4MM) Center Mounting Hole: 3/4 (19MM) Lift: Approximately 1-5/32 (28MM) Fits.

Bushing 3rd Lower Point

Bushing 3rd Lower Point for John Deere® Quick Attach Fits: John Deere® Models 647/655/665/673/681 Rotary Tillers Phoenix Models T4/T5/T10/T15/T20/T25 Rotary Tillers Replaces: John.

Farm-Maxx Mini Round Hay Baler Model FMRB-330

Farm-Maxx Mini Round Hay Baler Model FMRB-330 Video of Baler in action FMRB-330 Round Balers feature robust construction for years of trouble free baling. The superior design and simple plug.

Ultimate Guide for Lawn Mower Blades with Expert Guidance

The blades are the most essential part of a lawn mower as it is responsible for cutting the grass efficiently and accurately.

A wrong choice can lead to irregular cuttings which ruin the look of your landscape. If you are wondering whether all the blades are same then you are wrong.

Lawn mower blades come in different types, choosing the right one among them is quite challenging, especially if you don’t understand the differences.

We have created this guide to help people make an informed decision while purchasing lawn mower blades. In this article, you can see in-depth differences between lawn mower blade types

Types of Lawn Mower Blades

In-depth Description of Each Lawn Mower Blade

Below is a clear analysis and description of each law mower blade along with its merits and drawbacks. Read the information thoroughly to understand which one suits your lawn mower better.

Standard or Straight Blades

They are known as medium-lift or standard mower blades. They are commonly found on regular lawnmowers, or ones that spin horizontally. Lawnmowers that release debris from the side are often fitted with this mower blade type. Though they’re referred to as straight blades, these generally have a small curvature on the ends.

A reason behind the small curve along edge is that it helps create an uninterrupted flow of air when the blade turns and creates an action of cutting and sucking. Suction is created by the soil that pulls grass up and allows for accurate cut. But straight blades produce a small amount of suction because their edges are inclined. This leads to a tiny quantity of air moving across blade.

Before deciding on blade type, be aware of the kind of lawn you will be cutting. While many people choose straight blades because of their superior efficiency on dry and damp surfaces however, they’re only suitable for areas with large grass patches. The advantage of these blades is swiftly cutting the grass that is dense, and send it to the bagging process effortlessly.

However, one of the disadvantages of the blades might not be capable of cutting through smaller bunches of grass, which could result in a sloppy cutting process. In this regard it is recommended to choose a different type of blade in the event that your yard is shady areas of grass. Another disadvantage of straight blades is the small suction power which cannot be sufficient to push grass debris out of the bag. This could create a blockage within chute.

Benefits of Standard Lawnmower Blades

- The slightly curled ends aid in suction.

- It can cut through thick grass patches easily.

- Ideal for all kinds of soil.

- Cuts both dry and damp surfaces with great efficiency.

Drawbacks of Standard Lawnmower Blades

- The tendency to blockage in chute and restricts storage space in bag.

- Might not be capable of cutting small clumps creating uneven lawns.

Low-Lift Blades

They are designed to mowing soil that is sandy due to low suction capacity. The blades’ edges are also less curly than standard ones.

The suction is low, which doesn’t allow grass to get up too high. This keeps the grass well-anchored for cutting and then discharged to the side. In the same way, this doesn’t allow dust to pick up with it. Therefore, it settles on ground without being blown around in the air that you breathe.

The blades that are low-lift are typically about 3-4 inches long and demand less energy for the engine of your lawnmowers. Because they don’t burden the engine to much it is given a longer life span.

Blades that have more suction will deteriorate more quickly than blades that have low lift. The dust can settle into the deck, causing blades to wear away prior to the expiration date they were originally scheduled for.

Thus, if you depend on durability over time, blades with this type of design are a suitable choice. Blades with low lift are also suited because of their capacity to operate quietly. They don’t produce much noise since they don’t require any power to work effectively.

Benefits of low-lift Blades

- Needs more power for function

- Ensures effective yet silent mowing

- Perfect for mowing sandy terrains

- Comes with durability and longevity

The High Lift Blades

It is easy to distinguish High-lift blades from their distinct vertical angles along the edges. This allows for maximum airflow through the blades and results in a suction vertical like none other.

The Rapid circular movement of the blades keeps the grass straight in preparation for the accurate trimming. It lets you cut your lawn with more accuracy and give it a clean and clean look.

High-lift blades are available from the length between 1 – 21 inches and are suitable to yards that have tall grass. The suction force is strong and ensures that there isn’t an accumulation of grass inside the chute, thereby preventing obstruction. This is why people who like bagging tend to lean toward such blades.

However, this feature renders it unsuitable for mowing on sand-covered terrains. Due to the high flow of air through the mower, it is possible that blades can be prone to pull in sand and dust as well as the grass.

As we all know dust may settle on the mower’s deck. This can cause it to wear away in a short time. In addition, the quick and continuous rotation of the blades requires more power to generate more suction. Additionally, this could lead to damage to the lawn mower sooner than anticipated.

Benefits of high-lift Blades

- Provides elegant finish

- Capable of sucking out and storing the leftover remains

- Perfect for clipping tall-grass clippings

Drawbacks of high-lift Blades

- The power drains out quickly

- Not suitable for using on sandy soil conditions

- They wear out quickly

Mulching Blades

They are also called a multi-purpose blade. They have a curved surface which permits it to work in different ways. The blade first raises grass and precisely cuts it into pieces. The cuttings or clippings will be taken towards the deck, which is where they will be cut into small pieces. Then, the inside curvature of blade generates the pressure of air that blows away the tiny pieces of clippings.

You can use them to fertilize the soil. Finer grass fragments are better as they will absorb nutrients by the soil.

The sharper and more curvier edges, along with cutting edges generally let mulching blades chop grass in smaller bits and then to expel them back into the ground. While mulching blades create lesser suction but lift the tall grass and straighten them enough to cut it.

If you’re looking the lawn to appear beautiful and also help to fertilize your landscape parallelly using mulching blade, it’s the perfect choice. Indeed, it is the best way to get rid of mowing debris that is not needed anymore.

Change Blades on a Rotary Cutter

Benefits of Mulching Blades

- Can work for different purposes at same time

- Comes with numerous curves which allow accurate cutting

- Ensures soil enrichment

- Perfect when you are not clearing clippings

Drawbacks of Mulching Blades

- Cutting dense grass can lead to blockage or clogging

- Has low suction which can make it unfit for cutting dense and tall grass

Gator Blades

Just like mulching blades similar to mulching blades, blades of gator are ideal to fertilize the soil. In reality the gator blades have been modified to accomplish the job more effectively.

The blades are specifically designed to generate maximum suction over the grass, pulling it upwards. This is due to an exact angle of those teeth on the mulching blade. It is an inferior blade that pulls grass upwards so that the grass will be cut with precision.

Unique angle that the gator’s teeth have will push the grass towards its sharp edge while the mower moves. This allows smaller grass pieces to cut again and again. It is possible to cut tall grasses into small pieces using this blade with ease.

To maximize the benefits of this method, put a mulching tool on the blade. The mulching kit can help spread the fine pieces grass so that they settle on the soil in a uniform way.

Finely cut grass adds essential fertilizers to soil. This will greatly increase the yield when you’re trying to plant fruit and flowers in your backyard.

It is also possible to collect all of the pieces that have been chopped into the grass collector bag. This can save you your time as well as effort taking care of the yard. It also helps in making your garden look attractive. Therefore, you’ll benefit by both sides.

Benefits of Gator Blades

- Curved teeth lift the grass upwards

- Suitable for fertilizing soil

- Ideal for mulching leaves

- Precise cutting job

Some Frequently Asked Questions

No, not all lawn mower blades are the same. Each type of lawn mower has its own specific blade type that is designed to work best with that particular mower. For example, a riding lawn mower will have a different blade than a push lawn mower. The blade on a riding lawn mower is designed to be able to cut through thicker grass and will be much sharper than a push lawn mower blade.

is the best way to locate replacement lawn mower blades. The OEM number refers to the manufacturer’s numerical part number for the blade. Most cases, you will only need to enter this number and the manufacturer name into an online search engine or store to get some promising results.

The length of the mower blade and the center hole size are the two most important factors to consider when buying lawn mower blades. If your mower requires it, make sure to get a blade that has the correct outer holes. If you’re mowing cool-season grasses, use high-lift blades.

The great thing about it is that many standard lawnmowers are capable of being modified for mulching. For best results, it is important to follow the steps below: Install a suitable mulching mower blade; and. You will also need to install a restriction plate.

If your grass tips are becoming ragged and brown, you will know it is time to sharpen your lawn mower blades. This can cause your grass to lose its ability to store water and make it more susceptible for disease. Some manuals for lawn mowers recommend sharpening or changing blades every 25 hours.

How to sharpen rotary mower blades FULL GUIDE

Some people believe that replacement blades should not be sharpened until they are used. This is because of the powder-coated finish that is applied by the manufacturer to most blades. This coating is thicker around the blade’s cutting edge, and can feel dull to the touch.

A good rule of thumb for homeowners is to replace their mower blades every year. Regularly sharpening your mower blades will extend the life of your blades. If you decide to sharpen your mower blades at home, make sure you wear protective gear and disconnect spark plugs.

A dull lawnmower blade can cause your lawn to look yellow, brown or raggedy. A dull lawnmower blade can pull up parts of your grass, as it pulls on the whole plant rather than cutting through the grass blades cleanly.

A new, sharp blade will give you a clean, neat shave. Your grass will experience the same effect. Sharp cutting blades make your lawn look great, and keep it healthy. The mower blades that are too dull or damaged can cause a bruising to the edge of your grass blade. This will leave a ragged end and not a clean cut.

Most mower blades will last 100 to 200 hours in normal conditions. If you purchase high-quality blades, the number of hours could be up to 400. You can use a grinder or a metallic file to sharpen your blades if they become dull. However, this will only work for about 2 to 3 times.

Mower blades today are made of low-carbon alloy steel. Most of the latest mower blades are rigid in nature but softening makes them bendable if they strike a rock or piece of wood. Because these blades are designed for being soft, it makes lawn mowing safer.The blades made from a harder steel alloy do not bend, but instead break. This can lead to steel bits flying around, especially when the blades spin at very high RPMs.

Design-wise, almost all of the lawnmower blades are interchangeable between single-blade and multi-blade lawnmowers. The dimensions of the blades are the only thing that will vary. Multi-blade mowers require that the blades overlap slightly to achieve consistent and clean cuts.This means that the two-blade mower blades may be slightly shorter than the single-blade blades. If the lawnmower mounts and blade match, the different types of lawnmower blades can be interchanged.The best one for you depends on your personal preferences and lawn conditions. Depending on what type of mower you use, certain blades might perform poorly. A mulching blade, for example, can be attached to a regular mower. However, it must be equipped with additional accessories to ensure that it does a good job of mulching.

Mower blades may vary in their dimensions, shape, and type of mounts. These are important details when it comes to lawnmower blades. Not all blades will fit into every lawnmower.The blades’ diagonal length can range from 6 to 32 inches. The width of the slit can vary from 1.5 to 4.25 inches. The blade’s thickness can vary from 0.01 to 0.33 inches.There are two options for the number of holes in the blade: one or three. They can also come in different shapes. Blades with two outer holes may require a blade adapter. A blade with only one center hole will work fine.

Few Words to Wrap Up…

The efficiency and quality of cutting depends mostly of the blades of lawn mower blades. Having a wrong blade can mess the look of your beautiful landscape. To help you figure out the right one, we have compiled a list of the lawn mower blades and detail description along with it. Consider the tips to find out which one is suitable for your grass cutting requirements.

If you still have any dou