Sharpening frame saws

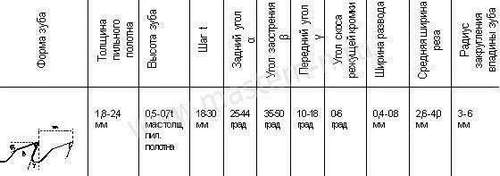

During operation, the cutting edge of the saw teeth becomes dull, which prevents sawing. Tool steel saws are usually sawn to a sharpening of 5-6 cubic meters. woods, saws with flattened tooth. about 20 cubic meters, stellated saw up to 80 cubic meters Blunt saws should be sharpened correctly, observing the basic parameters of the teeth, which are listed in the table.

Estimated values of tooth divorce in mm, (accuracy 0.05 mm). freshly sawn conifers (spruce, pine, deciduous., fir). 0.6-0.8. freshly sawn hardwoods (beech, oak). 0.5-0.6. dry, hard and frozen wood. 0.4-0.6. wood with loose, felt-like fibers. 0.7-0.9

Sharpening of teeth should be done on special grinding machines using conventional bakelite grinding wheels. Grinding is carried out over the entire tooth profile, which allows you to remove microcracks formed in the saw blade under tensile load and prevent possible breaks of the blades.

Installation of saws on a sawmill

In order to avoid “pulling” the saws and to obtain high precision sawing, it is necessary to correctly install the saws in the grips (homer). The sawing accuracy depends on this no less than the tension of the saws. When installing saws, always follow the following table:

Knowing the size A, which depends on the width of the saw blade and the required inclination of the saws, the saws should be installed in homer. In this case, you should control the distance from the back of the saw to the holder of the homer, which should be equal to:

Above C = A-K / 2-U, Bottom D = A-K / 2 U / 2

fig. 1 correct installation fig. 2 wrong, size A, not in accordance with table 1 fig. 3 wrong, size A, not measured in the middle

Be sure to adjust the parallelism of the saws in the set. Set it in parallel with the feed direction, which will avoid the friction of the saws in the cut and prevent them from being pulled to the side. At the end of work, loosen the tension of the saws in the frame and be sure to follow this rule in the winter.

Frame saw operation

In order to achieve the greatest efficiency of work at the sawmill, it is necessary to fulfill a number of simple and at the same time necessary conditions that are crucial. These include the following: 1) frame saws should be appropriately tensioned by rolling or by hammering; 2) the mounting plates must be riveted to the saw exactly one opposite to the other and perpendicular to the back of the saw; 3) the saw should be flat without dents or bulges; 4) the saw must be sharpened correctly; 5) the saws must be correctly installed on the sawmill. Unfortunately, in practice, many saw cutters do not give due attention and “close their eyes” to some inaccuracies, considering them insignificant. As a result, they cannot obtain the accuracy and quality of sawing, and often this attitude to work even leads to breakage of the saws and holders. Rolling frame saws can significantly increase the straightness of sawing. There is no need to over-tension the saws. As a result, both saws and holders will always be in good condition. The presence of stresses in the saw blade can be easily checked as follows: bend the saw as shown in fig. 1 and attach a small straightedge in the middle of the saw blade. A strained saw on the concave side should have a gap of 0.6-0.8 mm, depending on the width of the saw blade. On the convex side, the ruler should touch the saw in the middle, and there should be a corresponding gap at the edges. When bending the saw blade in the opposite direction, there should be similar gaps. For a saw that has no stress in the saw blade, the test bar will fit snugly against the blade without gaps.

Video: Sharpening Band Saws In Winter

The mounting plates must be riveted to the saw exactly one opposite the other and perpendicular to the back of the saw. If this rule is not observed, there is a high probability that the plates under tension can bend or come off and ultimately the saw may fail. Mechanical defects. dents, bulges can lead to increased friction of the saw blade on the material being sawed, its excessive heating and, as a consequence, to loss of stress. As a result, this will lead to a decrease in the accuracy of cutting. High-quality and continuous operation of frame saws is possible only if they are sharpened correctly. When sharpening frame saws, the following features should be taken into account: 1. During work on frame saws under the action of tensile forces and resistance to cutting along the serrated edge, microcracks form, which can increase over time and reach significant dimensions. In the final case, catastrophic damage to the saw blade. breakage can occur. In this regard, the sharpening of frame saws should be done along the entire tooth profile and only on special grinding machines. 2. When sharpening frame saws, make sure that the correct sharpening angles are set correctly. The rake angle should be between 10-18 degrees, depending on the type of wood and the season (the harder the wood. the smaller the angle). The back angle should be approximately 25-44, and the point angle should be 35-50 degrees. 3. Sharpening of saws from both tool steel and saws with stellated teeth is made by bakelite circles at a speed of about 50 teeth per minute. 4. The abrasive wheel should have a slight inclination relative to the front edge of the tooth within 3-5 degrees. This is ensured by tilting the axis of the grinding machine spindle with respect to the vertical movement guide. If this requirement is not observed while lowering the abrasive wheel along the serrated edge, the tooth tip is annealed and, as a result, the tool resistance is lost to 40 5. During sharpening, the tooth height should not decrease, which should be within 0.5-0.7 steps. Reducing the height of the teeth adversely affects the removal of sawdust from the cut and increases the risk of overheating of the saw blade. 6. The saw is considered blunt and requires sharpening if the radius of curvature of the serrated edge exceeds 0.1 mm. Indirectly, the sharpness of the teeth can be judged by trying to draw a fingernail along the tip of the tooth. A dull saw cannot leave marks on the fingernail. 7. The most critical moment is the installation of saws on the sawmill. For the correct implementation of this operation, we consider in more detail 8. The most critical moment is the installation of saws on the sawmill. For the correct execution of this operation, we will consider in more detail During the sawing process at the sawmill, the log or beam moves in the direction of saw delivery with the feed speed V. over, in order for all the saw teeth to work equally, it is necessary to tilt the saw at an angle corresponding to the selected feed speed. The figure below shows the phases of movement of the saw in the tree and the value of the inclination of the saws to ensure high-quality sawing.

The inclination of the saw set is necessary in order to ensure the optimal supply of Sz and the same load on the teeth, as well as to make the saw travel from BDC to TDC free. The inclination of the saws must always correspond to the selected feed rate of the beam. If the inclination of the saws is insufficient, then the beam will impede the free movement of the saws at TDC. If the inclination drank more than necessary, part of the lower teeth will not work. The inclination of the saws per stroke of the saw frame (in mm) should be determined by the following formulas: U = 0.7 Sz, mm where Sz. submission for one stroke of the saw frame or U = 700 V / n, mm where V is the feed speed (m / min) n is the frequency of movement of the saw frame (1 / min) To recalculate the inclination over the entire length of the saw, U should be multiplied by a factor, taking into account the length of the saw and equal to the ratio of the length of the saw to the stroke of the saw frame (at L = 1250 K = 3). In order to avoid “pulling” the saws and to obtain high precision sawing, it is necessary to correctly install the saws in the grips (homer). The sawing accuracy depends on this no less than the tension of the saws. When installing saws, always follow the following table:

Phases of movement of saws in a tree and determination of inclination

During the sawing process on the saw frame, the log or beam moves in the direction of the saw set with the feed speed V. over, in order for all the saw teeth to work equally, it is necessary to tilt the saw at an angle corresponding to the selected feed speed. The figure below shows the phases of movement of the saw in the tree and the value of the inclination of the saws to ensure high-quality sawing. The inclination of the saw set is necessary in order to ensure optimum feed. Sz and the same load on the teeth, and also that the saw drifts from BDC to TDC was free. The inclination of the saws must always correspond to the selected feed rate of the beam. If the inclination of the saws is insufficient, then the beam will impede the free movement of the saws at TDC. If the inclination drank more than necessary, part of the lower teeth will not work. The inclination of the saws per stroke of the saw frame (in mm) should be determined by the following formulas: U = 0.7 Sz, mm where Sz. submission for one stroke of the saw frame or U = 700 V / n, mm where V is the feed speed (m / min) n is the frequency of movement of the saw frame (1 / min) To recalculate the inclination over the entire length of the saw, U should be multiplied by a factor, taking into account the length of the saw and equal to the ratio of the length of the saw to the stroke of the saw frame (at L = 1250 K = 3).