Reasons why the STIHL 180 fails to rev

Virtually every hand-held gasoline tool has a two-stroke engine as the power unit. These motors have advantages over four-stroke motors. They have less mass for the same power. But they also have the disadvantages of adding oil to the gasoline and lower fuel economy. You can identify several major malfunctions in the saw’s operation:

- Engine won’t start. Cold engine start and hot engine start. To start a cold engine, the engine turns on suction, which reduces air suction and increases the percentage of gasoline in the fuel-air mixture.

- Your chain saw does not start or stops before it has reached the necessary rpm. You have to use the throttle trigger all the time to keep the engine speed high.

- Engine stalls under load, does not develop optimum performance.

Malfunctions can be caused by mechanical reasons, as well as problems associated with electrical equipment.

External inspection of the spark plug

A visual inspection of the spark plug can tell you a lot about engine performance:

-

The wet end of the bore wrapped around the cylinder is an indicator of a fault in the power train. The fuel mixture is too rich. Carburetor adjustment is necessary. Or the oil to gasoline ratio is incorrect. Too much oil and not enough time to burn it off during the piston stroke. Carbon deposits appear.

Use sandpaper to remove it. Never use an acetylene or gasoline torch to ignite the spark plug. After that the spark plug boot may have come loose.

Why the STIHL chain saw won’t start

For a preliminary diagnosis of the causes check the gas pump, spark plug appearance, fuel flow, carburetor function and condition of the filter. Pay attention to the functionality of the cylinders, pistons, muffler, crankshaft bearings. After service and maintenance try to start the chain saw. Insufficient lubrication of the rubbing parts is also a factor in poor performance.

No spark

Checking the spark on the spark plug. Various factors affect the function of the element. When testing the mechanism, the causes are identified:

Because of the work in such conditions on the contacts of the plug accumulates soot. Corrosion of the conductors causes no spark in half of all faults. This happens because the gap between the modular contacts changes. To check the spark, do the following:

- the tip of the high-voltage cable is removed;

- the spark plug is unscrewed;

- the tip is put back in place;

- The spark plug is leaning against the cylinder with its wide end;

- turn on starter.

Read also: Table for circular saw by hand video

If a bright lightning-like spark appears between the electrodes when starting, the ignition assembly is serviceable. If there is no flash, the entire element is cleaned and the gap between the conductors is adjusted. Sometimes there is no gap between flywheel and ignition coil. When the flywheel rubs, scratches are visible on its exterior.

Faulty ignition coil

The module or coil cannot be disassembled, and its suitability is difficult to ascertain without test equipment. Modern ignition systems are robust, lightweight and small in size. They are characterized by almost fail-safe functionality. Chainsaw malfunction problems due to the ignition coil can be repaired on your own.

Test the leads for damage (incl. ч. Internal), which are caused by vibration resulting in friction. If no cracks are found, the ignition coil needs to be replaced. Sometimes a weak, faintly discernible flashover when the saw heats up indicates a module malfunction. This is caused by an increase in coil temperature, which leads to an increase in transistor resistance.

The peculiarity is that at the beginning of work, the spark can appear, but after prolonged use it becomes dull and disappears. Modern ignition coils are not repaired in the home workshop, so replace them with suitable elements.

Fuel supply

After unscrewing the spark plug, a wet deposit is found on the surface of the spark plug. This indicates an excessive flow of petrol into the combustion chamber. If the tool does not start or stops for this reason, t. к. the fuel does not ignite.

Another delaying factor is a clogged breather. a small hole in the lid of the gasoline tank. Clean it with a needle. otherwise the STIHL MS 180 will not start. To determine the improper fuel supply, the following steps are carried out:

- remove the spark plug;

- Put a syringe of 2cc of petrol in the spark plug hole;

- put the ignition device back in place and put the cap on the high-voltage wire;

- set the lever to the hot start position;

- yank the starter knob a couple of times.

If the tool starts and immediately stalls, the fuel line is tested further. Check the gasoline filter, the splash from the engine crankcase, the integrity of the partition in the pump when unscrewing the cap.

Crankshaft bearing failure

If the bearings are defective, slight play can be felt. To check if this is detected, the STIHL MS 180 handwheel is swung from side to side. Movement indicates that the flywheel is shifted toward the electrodes by its own magnets, resulting in a lack of spark. To remove the mechanism remove the cutter, remove the filter and clutch cover. To stop the crankshaft remove the cover of the manual starter and retighten the two bolts.

Unscrew the clutch with a clockwise wrench. Remove clutch drum and sprocket, replace old clutch and screw in as far as it will go. The crankshaft is blocked so as not to break the starter. Reassemble in reverse order. To tighten, tilt brake handle forward, start tool, then remove brake.

Bearing defects (larger diameter holes in the cage) are less frequent. To determine, disassemble and measure with a micrometer. Broken bearings are indicated by regular knocking. In this case, urgent repair is required, t. к. If the crankshaft is broken, the piston group and cylinder will fail.

The spark plug is flooding

In this case, the spark is unable to ignite the fuel, which in large quantities enters the furnace to burn the combustible mixture. If the spark plug is primed, the carburettor is defective or a cold engine does not start correctly. Purge the engine, the procedure is performed with the ignition off and away from the open flame. To ensure the ignition of fuel at the time of start-up, clean the mechanism:

- unscrew the spark plug, wipe dry, dry for half an hour;

- Remove heavy carbon deposits with an emery board;

- Adjust the gap between the contacts;

- Turn the tool upside down and drain the gasoline;

- The starter motor is jerked several times in this position (to remove any fuel residue);

- Reassemble in reverse order.

Why does idling cut out?

The first and most common reason for this malfunction is improper carburetor adjustment. You can adjust the idle speed yourself with the STIHL adjustment screwdriver that comes with the machine. The adjustment hole is on the right side of the STIHL 180 on the handle and is marked with “-” and ” “.

If a STIHL chain saw does not hold rpms and stops idling, it is usually more or less 90% certain that there is a fault in the fuel pump system, normally an air leak in the crankcase through the oil seal or, more often, through the crankshaft oil seal. Air intake reduces or completely stops pulse, which is supplied to chainsaw fuel pump by special channels. The STIHL STIHL 180 chain saw does not receive the correct amount of fuel and stops when idling.

To make a diagnosis, you can use a special device called a vacuum gauge.

The second way to test the performance of seals, is to pour gasoline into the crankcase and look at them, if the seals will leak gasoline, then they can not provide the normal pressure in the crankcase, which will make the work at idle impossible. If the bearings of the crankshaft can seize while running at high rpm with leaking seals, it is possible that the bearings of the crankshaft will seize.

Check the STIHL 180’s crankcase and oil seals for leaks as follows:

- Removing the top cover.

- Dismantle the air filter housing and carburetor.

- The chainsaw handle can be removed.

- Unscrew and remove the starter motor.

- On the side opposite to the starter remove the side cover and the drive sprocket.

- A piston stopper is installed in the spark plug hole, or a piece of string from an old starter with knots tied to it is stuffed into the cylinder.

- Unscrew the handwheel and the clutch and remove the parts. Please note that the chainsaw clutch has a left-hand thread and should be unscrewed in a clockwise direction.

- Remove the oil pump pinion.

After taking the STIHL MS 180 chain saw apart you can see the seals, fill the sump with gasoline and check for leaks. Fill the crankcase through the fuel window in the cylinder. To do so, move the piston upward as much as possible. If leaks are found, the leaking gaskets must be replaced or the sealing of the pan must be renewed. To assemble the STIHL 180 you need to follow the reverse sequence.

Leaking carburetor and clogged nozzle

Sometimes, when the screws fixing the carburetor cover loosened or gaskets came into disrepair, the chainsaw can also show loss of power, to rule out the possibility of this malfunction, you must check the integrity of the gaskets and the tightening of the screws on the carburetor covers. To do this, you need to remove it from the engine (the algorithm described above) and disassemble. Replace the gaskets with new ones from the repair kit for the STIHL MC 180 carburettor.

If a complete check of the fuel supply and exhaust system has been carried out and no results are achieved. It is necessary to check the main fuel valve-nozzle. To check it, it is necessary to knock it out of the carburetor body. All work should follow the following algorithm:

- The carburetor is removed from the chainsaw.

- Unscrew the four screws fastening the cover with a compensator, and then the cover can be removed.

- The carburetor is placed on a wooden pad, then using a bolt with a diameter of no more than eight millimeters and a length of 50, knocked into the inner cavity of the carburetor.

- Next, you need to find a small hose, the inner diameter of which corresponds or slightly less than the outer diameter of the nozzle and put it on the nozzle.

- The next step is to blow inside the hose. If it blows in one direction only, the nozzle is fine. If it blows in both directions or not at all, replace the valve.

All the actions described above should help in the elimination of the fault related to the fact that the chainsaw does not pick up speed, otherwise it will help to carry out a full diagnosis in the service center of the manufacturer.

Leaks in the carburetor and clogged injector

Sometimes, when the screws fixing the carburetor cover loosened or gaskets came into disrepair, the loss of power can also be observed on the chainsaw, to exclude the possibility of this malfunction, it is necessary to check the integrity of the gaskets and the tightening of the screws on the carburetor covers. To do this, you need to remove it from the engine (the algorithm described above) and disassemble. Replace the seals with new ones from the repair kit for the STIHL MC 180 carburettor.

In the case when a complete check of the fuel supply and exhaust system is carried out, and there are no results. It is necessary to check the main fuel valve nozzle. To check it, it is necessary to knock it out of the carburetor body. All work should proceed according to the following algorithm:

- The carburetor is removed from the chainsaw.

- Unscrew the four screws fixing the cover with the compensator, and then the cover can be removed.

- The carburetor is installed on a wooden pad, and then using a bolt no more than eight millimeters in diameter and a length of 50, is knocked into the inner cavity of the carburetor.

- Next, you need to pick up a small hose, the inner diameter of which corresponds or slightly less than the outer diameter of the nozzle and put it on the nozzle.

- The next step is to blow inside the hose. If it blows only in one side the nozzle is serviceable, if it blows in both directions or does not blow at all the valve should be replaced.

All actions described above, should help in elimination of malfunction connected with that the chainsaw does not pick up speed, otherwise, carrying out of full diagnostics in the service center of the manufacturer will help.

STIHL 180 chain saw STIHL STARTS AND STOPS Cause

A chainsaw has long been more than a luxury. it’s an essential item for anyone with a garden or a home. However, just like no other equipment, this tool tends to fail, in spite of the uncomplicated device.

The systemization of the main defects means:

- Complete absence of engine starting

- The engine starts and stalls

- Unbalanced operation of the tool

- Stops when there is no load

- loss of power.

If the chainsaw does not start at all, the reason you will like more in the following:

- Production defect

- No fuel

- Trouble with starting

- No spark from spark plugs

- Bad fuel mixture

- Clogged carburetor

- Problems with the high-voltage cable

- Lack of compression.

Why the chainsaw starts and stops, what to do under such circumstances? It is necessary to look carefully at the prerequisites for this.

Chainsaw starts and stops: cause, video

If your chain saw stops right after you start it may be because there is a problem with some part of the machine.

Why the chainsaw does not start and stops

If the equipment does not start well “when cold” the problem may be a lack of compression, i.e.е. the rings are worn out from long use and need to be replaced. It is very difficult to start without warming up because there is a problem with the muffler or a bad contact between the spark plug and the cable.

READ STIHL chain saw does not rev up

Also causes for poor starting may be a worn or damaged gasket, rubber collar in the booster pump of the carburetor, which causes additional air flow, resulting in a higher rpm.

Troubleshooting

The operation of the equipment must be correct, with periodic inspection of the constituent elements to prevent breakage. To correct malfunctions you should check all parts of the equipment for proper functioning.

If your chain saw starts and stops, you can do this yourself. If it is a shortage of fuel or incorrectly mixed fuel, you need to correct it. As a preventative measure, you should always drain any remaining fuel when the chainsaw is not in use.

Check the spark plugs periodically. You should remove the soot that clogs the junction gap, and check the tips for fuel. Another reason for trouble with spark plugs can be that they are wet with gasoline. To do this, take them off, wipe them with a rag and leave them to dry. Faulty spark plugs are replaced.

STIHL chain saw starts and stops because.

If there is no spark between the spark plug and the high-voltage wire, but if they are well connected, the ignition unit must be replaced.

READ STIHL chain saw does not rev up under load

A clogged muffler is a common cause of failure, in which chain saw

starts and shuts off immediately. To fix the problem, you need to dismantle the muffler, clean it from carbon deposits with sandpaper or a special chemical solution. If the model of the chainsaw is not dismantled, the system is filled with chemicals and stay there for several hours, then it is blown out.

The carburetor needs to be adjusted if the chainsaw

Stops when idling. Fine tuning your chain saw is a relatively time-consuming process. But, on some models there are elements for its adjustment, it is enough to turn the bolt a half-turn to increase the revolutions of the chainsaw, the problems will be eliminated. If jets, nozzles, passages and filters are clogged, the carburetor needs to be disassembled and cleaned. At wear of seals, gaskets, collars, it is necessary to replace them, preventing “air drainage”.

If there is a problem with the fuel or air filter, the fuel pump should be changed or the air filter should be cleaned.

If the breather plug is clogged, clean it with a regular needle.

If the chain saw starts and then stops right away, the chain may be malfunctioning. To eliminate problems, check the presence of oil in the lubricating tank of the chain, as well as the oil drain tube for breaks or clogs.

STIHL 180 starts and stops with reason.

Inspect the piston assembly and if necessary replace the cylinder or piston. Cylinder can be bored to fit a new piston. If the piston and cylinder are normal, look for piston ring defects and the need for replacement.

Among other things, it is necessary to monitor the service life of the parts specified in the product data sheet, which include the drive sprocket, the bar, the chain, part of the anti-vibration system, to replace them in time.

If the tool is idle for a long time, it is worth checking the condition of the fuel line. If the tube is cracked, you will have to replace it with a new one.

STIHL chain saw stops on throttle

Why the gasoline saw goes out when I push the gas: causes and solutions

It is not uncommon for chainsaw owners to have to deal with their breakdowns, and it doesn’t matter what model of this type of equipment, because the nature of the failures is almost the same for all. Well, it’s a chainsaw stalled and what next? Undoubtedly, you can include the equipment to specialized services, which will repair your “iron friend” for a fee. But as they say: why pay more??

In the end, you can personally take the tool apart and have it repaired, since the breakdown may be minor, and you’ll have to pay a lot to do it. But of course, in order to bring the tool back to life, you must be able to understand the causes of failure and how to fix it. So let’s learn! In this article, you will be able to find answers to questions about situations where the tool simply throws itself after a direct touch of the gas. So, let’s get started.

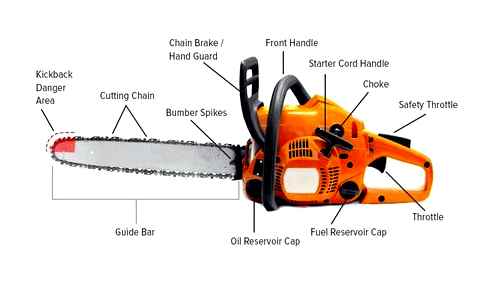

The main elements of a chainsaw

Before we start to get into the problems with the breakdown and repair tools, let’s first figure out where the chain comes from. First of all, I would like to note that this tool belongs to the category of equipment, the work of which depends directly on.

It is also important that chainsaws are equipped with an engine with one cylinder, and whose work is done on a fuel such as gasoline. It is worth noting that despite the similarities with other tools, it does not have a gearbox. And it is replaced by a kind of chain single-speed gearbox, through which the movement of the chain (saw) itself is made.

In fact, the chainsaw is a fairly simple design, but this does not prevent it from being reliable, practical and capable of fully providing immediate continuous and cyclic operation even in quite difficult conditions. This tool consists of a huge range of certain elements “vital” for proper and productive operation. This carburetor, a device for. A tire with a chain and other elements.

Before you buy a chainsaw, be sure to research all the options and choose the right brand of chainsaw.

To make your choice easier, we’ve made a chainsaw rating for you for reliability.

If you’re on a tight budget, read this article about Russian chainsaw manufacturers.

Characteristic and possible reasons of failure. Fix the problem with your own hands

Chainsaws. Pretty reliable and simple design. Therefore, if you take proper care of them and deal with them based on the manufacturer’s recommendations, they fail, very rarely, and quite quickly, various types of failures are fixed. But if you are faced with such a situation and want to repair your tool yourself without turning to professionals, read the information below.

READ Cutting down a tree near an apartment building

In fact, it is impossible to unambiguously and accurately determine the reason why the tool does not start or kiosks when you press the gas, because many factors affect this. But don’t forget that starting from the fact that a chainsaw is equipped with a simple two-stroke engine, conditions such as lubrication, fuel, spark and air are important for its effective operation.

Therefore, the carburetor is directly involved in preparing the fuel-air mixture, the filter cleans the air of dust, the ignition and spark plug create the spark, and the lubricant. in gasoline.

Therefore, you need to look for the causes of this kind of breakdown in a sequential order, starting with simple ones and gradually moving on to complex ones. And this is an important factor in proper repair, because the person who, without considering this, begins to analyze the carburetor is putting it at risk of. Since this type of device must be repaired or adjusted directly in special workshops (read about carburetor tuning).

-

What’s important is that for the appliance to run smoothly, the fuel needs to be directly handled. Because if the mixture is not made right, most chainsaws just won’t start. Consequently, not every owner will guess the cause of fuel failure. Therefore, to ensure that your tool always works properly, you need to use only high-quality gasoline for the mixture.

STIHL 180. A classic of the genre. Doesn’t rev it up

The video looks at a fairly common chainsaw malfunction

and 100% carburetor tuning method. How to do it

Why does the chainsaw quit on the gas?Chainsaw stalls when pressing on gas

This is one of the problems why the saw stalls when you press

gasoline saw repair And simply use the oil that is made by the manufacturer of your tool. It is also important to prepare this kind of mixture in an amount that you use for one or two weeks, but no more (see. Dose of gasoline and chainsaw oil).

Because otherwise the excess mixture directly in the canister will cause it to lose all of its octane properties, and this will cause significant problems with the tool.

- In addition, the cause of the violation may be a direct filling of the spark plug mixture during the operation of the mechanism. To solve this problem, you need to unscrew and dry the candle, but remember that it cannot be fired in any way. Excess fuel should be drained through the hole (spark plug), wait 20-30 minutes, then put it back in place and try again to start the tool.

- Chainsaws stop when you press the gas because there is no spark. This can happen if there is no good contact between the tip and the wire (high voltage). However, if this connection is working properly, but there is still no spark, then the whole reason. is the ignition unit (electronic). It is important to note that such parts cannot be repaired, so they can be replaced. Checking the spark plugs

READ Husqvarna chainsaw chain tension screw

Don’t forget that by examining the spark plug, you can get important information about the chainsaw’s breakdown. Because if its surface is dry, it is caused by a cylinder that is not directly supplying fuel. Here’s why you should check your entire performance range in stages. If the spark plug is in black carbon, it means that the carburetor is not working properly, that is, it is feeding a lot of fuel or pouring oil directly into the gasoline.

If your STIHL MS 180 chain saw cuts out at idle, fails to pick up power when you step on the gas, or stops cutting off at full throttle, have the fuel system checked and have the sump checked for leaks. You can do it yourself, but you need to have certain skills. If you don’t know much about two-stroke saws, it is better to appeal to professionals, because. к. this technique is quite capricious and any mistakes are costly.

The main causes of chainsaw failure

Although the chainsaw is a very simple machine, it does occasionally have problems which can only be corrected by disassembling it. The following are examples of malfunctions:

- The chainsaw won’t pick up speed;

- The chainsaw stops functioning in the cut;

- The chainsaw starts and stops;

- the chainsaw loses its power;

- Chainsaw stalls when pressed.

Most often the faults are related to the malfunctioning of the motor, as well as problems with other systems and assemblies. Proper handling of this equipment is of great importance. If all the rules of use are followed, problems are highly likely to lie in the most obvious. When searching for the causes of faults, it is advisable to start with checking the simplest part of the chainsaw and end with the most complex.

Causes of stalling at full throttle

Sometimes the chainsaw stalls at full throttle. If it was working well and suddenly stopped doing so, and the starter does not turn, you can suspect that the device is jammed. In this case you can’t do without an overhaul.

When the chainsaw is working well but it loses power little by little and then stops, it is time to think of something else entirely. When this happens, the cylinder is overheated, which can be traced to air leaks under the rubber choke or to a ruptured choke. To eliminate the problem, it is worth changing this element.

Design of chainsaw cylinder piston group

Problems associated with improper operation of the fuel system

The tool stalls if the integrity of the fuel line is compromised or if the fuel mixture ratio is incorrect. Especially often such tube defects occur when the tool has been in the room for a long time, where there have been sharp temperature fluctuations. When refueling the appliance, the manufacturer’s recommendations regarding the ratio of gasoline to oil must be followed precisely.

Oil and gasoline ratios for chain saw

Clogged air filter

The first reason the air filter is clogged is the fine dust that forms when you are sawing wood. Sawing raw wood is especially clogged. Of all the causes of a chainsaw stalling, this is the most common. Some models are an exception. For example, a STIHL chain saw stops for a variety of reasons, but not because the air filter is clogged. Because its carburetor has a compensator that takes in air if the filter fails.

Particles of wood dust get under the housing and are sucked up by the filter installed on the carburetor. Clogged air filter creates an obstruction in the air and causes less air to flow into the carburetor.

In order to clean the air filter, it is necessary to remove the closing cap and separate it from the carburetor.

Before removing the carburetor, brush off the sawdust or blow it out with air. Then remove the filter so that debris does not get into the carburetor. The carburetor should be sealed with a rag for cleaning.

Then the filter should be blown from the inside with compressed air, and then installed in place.

Probable causes of failure

All chainsaws are powered by a single-cylinder internal combustion engine. Such malfunctions as in-cylinder compression failure, fuel mixture ratio change, incorrect ignition operation, poor-quality fuel and lubricants are characteristic of this type of devices. If the chain saw will not start when hot, it is all wrong if the STIHL 180 chain saw starts to run flat on its hinges. The main problems with the power unit are as follows:

- The engine runs steadily at minimum rpm, but stalls when the rpm is increased;

- the start is normal, but the idle speed is unstable, it stops quickly;

- does not start.

Diagram of electronic ignition of a chainsaw.

The abnormal operation at idle can be caused by various reasons. They can be divided into several positions:

- capacity of filters (gasoline and air) is reduced;

- abnormal operation of the ignition system:

- spontaneously changed carburetor settings;

- Faulty gasoline line components;

- clogged exhaust ducts, muffler;

- piston, cylinder, valve defects.

Repair should begin with an external inspection and check the presence of fuel in the tank.