MDF panels are a popular and attractive material that is perfect for interior decoration of almost any room. With the help of such cladding, you can transform the atmosphere, making it more presentable and aesthetic. Today we’ll take a closer look at how to fix MDF panels.

Features

MDF panels are the demanded finishing material, which is made from woodworking waste. Many consumers mistakenly confuse them with chipboard or fiberboard. And these are completely different materials, since MDF is more durable, reliable and environmentally friendly, since no additional chemicals are used in its manufacturing process.

As an adhesive in MDF, a component such as lignin, which is present in the composition of wood, acts. It is released as a result of exposure to high temperatures.

MDF sheets have a characteristic texture reminiscent of felt, which consists not of wool, but of wood fibers. As a rule, MDF panels are attached to various bases on ordinary liquid nails and other high-quality compounds. Thanks to a large selection of adhesive products, consumers can choose a mixture that will fit the panels in color.

Modern MDF panels are distinguished by the fact that they can be installed independently, without involving specialists. Even an inexperienced home master can easily do such work. The main thing is to adhere to simple instructions, as well as purchase high-quality tools / materials.

Pros and cons

MDF panels have their advantages and disadvantages.

To begin with, let’s take a closer look at how good these finishing materials are.

- MDF panels are environmentally friendly and absolutely safe finishing material. The composition does not contain harmful chemicals and toxic adhesive components. Thanks to this quality, such materials can be safely used in any room.

- High-quality MDF panels are quite easy to attach to the walls, as they keep their original shape perfectly. They are very tough, which positively affects their strength characteristics.

- This finish is durable and wear-resistant. MDF panels are not easy to damage or break.

- MDF panels are materials on which mold and fungus do not start.

- Such finishing materials are not afraid of dampness and moisture. This is because there is a special laminated film or plastic on the surface of the panels.

- Such wall cladding is practical. On MDF panels dust and dirt do not accumulate. If dirty spots appear on the surface of the finish, they can be wiped with a damp cloth.

- These finishing materials can be sawn and cut seamlessly, if necessary. In addition, original curved shapes can be formed from MDF panels.

- With the help of such panels, you can make the room warmer, since they have good heat-insulating properties.

- It should be noted the beautiful appearance of such a finish. With the help of MDF panels, you can make the interior richer and more solid.

- This finish can be mounted both in private suburban and wooden houses, and in city apartments.

- The design of the walls with such panels is relatively inexpensive, especially when compared with the lining of natural wood.

Of course, MDF panels are not ideal finishing materials. They have their own weaknesses.

- If these canvases have poorly finished edges, they can absorb dampness and moisture, and then swell and deform. Correct such defects is unlikely to succeed. That is why in the decoration of the bathroom and kitchen such coatings are not recommended.

- MDF panels are quite durable, but they can still be damaged. For example, with a strong punch, such a material may crack, since it does not have sufficient elasticity.

- If condensate can collect on the floors, then MDF panels cannot be installed on them, since they do not have increased moisture resistance.

- MDF panels are flammable materials. It is recommended to hide wiring elements and various cables in separate boxes. You can apply an additional insulating layer of mineral wool.

- The range of such finishing materials can hardly be called rich. The choice of shades and textures of MDF panels is very modest.

Panel Views

There are several varieties of MDF panels. Each of them has its own distinctive characteristics.

Fully pressed

Such panels are the most common. They are canvases having a perfectly smooth surface on both sides. Such panels are made by pressing wood pulp under high pressure and in conditions of high temperature conditions.

Laminated

The second most popular are laminated panels. They are produced in the same way as all-pressed, but at the final stage their front side is covered with the thinnest polymer film. The result is a complete protection of the base from mechanical damage and other adverse factors.

On such panels, a film of different colors may be present. That is why laminated panels are the most diverse in terms of choice. Such coatings look attractive and aesthetically pleasing on the walls. They can be used in environments of various styles.

Moisture resistant

Such MDF sheets are made from dense and durable materials. In the production of such products, only high-quality and environmentally friendly materials, for example, natural wood, are used. It has been pressed for a long time at high temperatures. Conventional MDF panels cannot boast sufficient moisture-resistant characteristics, so they are not recommended for installation in rooms such as a bathroom or kitchen. An exception to this rule are only these moisture resistant sheets, which are perfectly acceptable for decorating such areas.

Veneered

These panels differ in that they have an attractive wood texture. To repeat the natural raw materials, a thin veneer consisting of natural wood is laid on the surface of the rough sheets. The thickness of this element, as a rule, is not more than 3 mm. Most often veneered panels imitate oak, ash and other noble wood species. Such finishing materials are very popular because they look rich and are quite durable.

Glossy

Similar types of panels have glossy surfaces. They are made by laminating the front of the sheets with a transparent polymer-based film. Such materials have a beautiful glossy sheen.

Painted

Such MDF panels are rightfully recognized as the most common. They are created in this way:

- a special coloring composition is transferred to the rough basis;

- It aligns all the differences on the panel;

- special paint forms a glossy or matte shade.

Scope of application

Wall paneling is inexpensive and aesthetically pleasing. Of course, if you want to give the room a more luxurious look, then you better turn to expensive options made of natural wood. MDF panels are rarely used in the design of a living room in a private house. As a rule, they are used for facing an accent wall, for example, behind a soft corner or a TV. Such materials are more common in reputable offices. In addition, MDF sheets are used in the decoration of office premises or spacious corridors.

As for ordinary city apartments, here MDF panels can be met even in a toilet or bathroom. Of course, for such spaces you can use exclusively moisture-resistant material. Otherwise, the sheets will swell and deform, forever losing their visual appeal.

Cloths MDF permissible sheathe bal-Konny block or loggia. With such a finish, such spaces can acquire a more “lively” look, especially if supplemented with suitable lighting fixtures and a pair of chairs / armchairs. Of course, for such conditions it is better to purchase more reliable and wear-resistant materials. If your BAL-KON is open and not glazed, then instead of MDF panels it is better to use another cladding.

Video: Than Sawing MDF Panels At Home

Similar materials look good in a room or bedroom. As in the case of private houses, here most often MDF panels are laid on accent walls, for example, behind a bed or sofa.

Often, such finishing materials are used in the lining of the hallway. Designers recommend in these conditions to install lighter panels so that the space does not seem too cramped and "oppressive." Some owners combine wood and masonry materials in the hallway. In a single tandem, such a design solution looks very beautiful. MDF panels often finish not only the walls in the room, but also the ceilings. In addition, from these popular materials, you can build a beautiful edging of a door or window opening, an elegant arch, slopes and even sheathe them with a door, attaching a beautiful trim to them.

MDF panels look very beautiful in the attic. In such rooms, these materials can be used to finish the walls and ceiling.

MDF panels are also used in other areas:

- in the manufacture of billboards and signs;

- from them produce mobile homes and mobile structures;

- MDF panels are suitable for creating shelves, cabinets and racks;

- cases of musical instruments are made from these materials;

- MDF sheets are used in the manufacture of speakers, radio receiver housings, gearboxes.

Instruments

Before proceeding directly to the finishing work, it is necessary to prepare all the necessary tools.

For wall cladding with MDF panels you will need:

- jigsaw;

- construction level (laser or bubble) and plumb;

- roulette;

- metal ruler;

- special building corner;

- pencil or marker;

- electric drill;

- screwdriver;

- simple screwdriver;

- pliers;

- hammer.

It is also necessary to stock up on fasteners (dowels, kleimers, screws).

Preparatory work

If you stock up on all the necessary tools, then you can begin the preparatory work. The walls on which you intend to install the MDF sheets must be perfectly dry.

It is impossible to start facing if:

- on the ceiling there are moist or wet areas;

- there is frost on the surface of the base;

- traces of the formation of fungus or mold are visible on the walls;

- the top layer of the floor is destroyed.

If there are no such defects on wall ceilings, then they can be safely prepared for future cladding.

- Remove any old trim from the walls, because bacteria may begin to multiply on it in the future. With the adhesive installation method, they will interfere with the high-quality adhesion of materials, and the panels will lie on the wall unreliably.

- Remove the whitewash layer. Many experts argue that this work is not mandatory, however, if you need to apply a primer on the base, the old whitewash will interfere with its absorption, so it is better to remove it from the wall.

- Mold and fungus on ceilings are a common problem. Fighting her is not easy. To do this, you can treat damaged areas with special solutions. Some companies produce such funds in the form of a spray.

It is worth noting here that you can completely get rid of the fungus only after removing the entire mycelium, therefore the only way out is to completely clean off the old plaster and thoroughly soak the exposed area with appropriate solutions.

- After this, it is necessary to cover up all the cracks that are on the base. To do this, you need to prepare a high-quality putty mixture (acrylic or gypsum is more suitable).

- Previously, the seams need to be expanded. They must be cleaned of the remnants of the previous solution.

- These areas should be impregnated with a primer.

- When the soil is completely dry, it is necessary to spread a mixture into the floor, which will cover all the voids.

It is recommended that the substrates be treated with primers so that the materials adhere better to each other and hold more reliably.

Mounting

Installation of MDF panels can be done in a frame and glue way.

To the frame

Let’s consider step by step how to install panels on the frame.

- First you need to make the crate of the walls. It happens metal or wooden (from a bar with a certain section).

- If the frame is made of wood, it is better to choose a beam with a square section and a side length of 3 cm. In addition, these parts should have a moisture level of less than 15%.

- Wooden frames must be treated with an antiseptic.

- Now you need to find out the dimensions of the walls with a tape measure. At the same time, the length of the bars should be slightly less than the calculated indicators.

- With the horizontal position of the panels, the crate should be vertical and vice versa.

- Transfer all measurements to wooden elements. Next, you need to cut the bars in accordance with the applied measurements. Position the hacksaw perpendicular to the wood to avoid crooked ends.

- Now the slats need to be fixed on the walls with dowels, if the foundation is brick or concrete. If it consists of a tree, then self-tapping screws should be used.

- After this, it is necessary to lay the insulation in the gaps between the parts of the crate.

- To fix the finishing paintings, you need to use a clamp for MDF panels and self-tapping screws (3×20 mm). They need to be installed in grooves, or use special nails with a thin hat.

- At the end of the finishing work, you need to connect the outer slats and the inner corners to each other.

Metal frames are no different in design from wooden. First, wall profiles are installed (around the perimeter). Then the main parts are mounted at a distance of 40-50 cm from each other. All profiles are fixed on the walls with self-tapping screws. After that, you can proceed to the installation of the finish coating.

On glue

Glue mounting can also be done with your own hands. With this method of installing MDF panels, the base should be perfectly flat.

- The walls can be coated with a deep penetration primer, so that the base is more reliable and acquires additional adhesion.

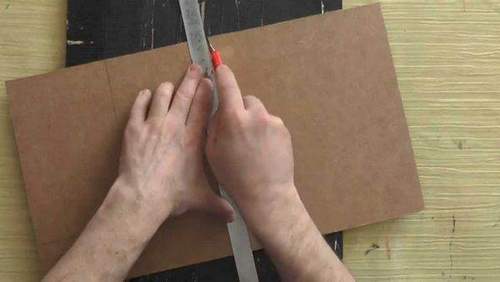

- After this, the MDF panels should be cut with a jigsaw or hacksaw into parts of the desired size.

- Then you need to knead the required amount of glue. It is applied to the back of the skin. The mixture is recommended to be applied portionwise. The places covered with glue should be as large as possible.

- The start panel must be laid from the bottom of the floor.

- Next, each panel should be pressed against the wall and held for some time in this state. Continue the work until you put all the MDF boards on the floor.

- All elements should be joined together carefully so that there are no large noticeable gaps between them.

- At the end of such work, the connecting strap is fastened, and the angles are also set. They are fixed to the surface using liquid nails.

Often, the installation of MDF sheets is carried out on a drywall basis. This inexpensive material is also used in the construction of the frame, and is installed directly on the floor to align it.

Drywall work should be carried out as carefully as possible, as it is fragile and can be easily damaged. Repairing broken material is usually not possible.

Tips & Tricks

It is quite possible to install MDF panels at home without the involvement of specialists. To do this, you just need to stock up on quality tools and materials, and also follow the instructions.

Perhaps some tips and tricks from experienced finishers will come in handy in your work.

- At the preparatory stage, remove the plaster from the ceiling to the base. This will reveal hidden wall defects, as well as reduce the cost of fasteners.

- If you are installing a metal frame, it is best to use a small angle grinder or circular saw. With a jigsaw for metal work can significantly drag out.

- Wooden frames are simpler. It’s easier to work with them. They do not need a large number of hardware. In addition, such structures absorb moisture, and then give it at the level of MDF boards. The main thing is to immediately treat the frame with an antiseptic, and it will last as long as possible.

- Trim trim materials carefully. During such work, you can accidentally damage the front side if you “capture” an extra section of the part. Therefore, it is necessary to take into account how the teeth are located on the jigsaw.

- If you use a metal frame, it is recommended to fix the clamps using small self-tapping screws with small caps. Such a mount will not interfere with further work.

- Keep in mind that the diagonal way of laying MDF panels is more expensive.

- It will be easier to work if you draw or photograph the resulting crate, indicating all the coordinates of the intersection of bars and profiles.

- To close corners, fittings such as MDF corners are ideal. Inside these elements, it will be possible to hide the screws that fix the extreme panels. Attach similar parts to glue or liquid nails.

- To trim the slopes, use the remaining pieces of the MDF panels. Similar elements are attached along and across. So, if the slopes are narrow, then the pieces are attached across, and if they are wide, then they should be fastened as the owner wishes.

Beautiful examples

Finishing floors with MDF panels can make the interior more lively and original. Such materials can be used in ensembles of various styles. For example, it can be a modern setting with a multi-level stretch ceiling, hanging cabinets, LED lighting and a leather soft corner.

MDF panels look great in bedrooms. For example, using materials of a neutral brown hue, you can design a wall behind a double bed. In such an environment, a floor trimmed with a parquet board or laminate in the color of the panels on the ceiling will look harmonious. In order for the general image of the interior not to merge, you should beat it with colorful wall paintings and contrasting decor items, for example, a white fluffy rug.

If you want to install MDF panels in the kitchen, then you should purchase moisture-resistant options, since in such conditions ordinary coatings can quickly become worthless. Against the background of the walls trimmed with panels under the tree, almost all types of headset and equipment will organically look. It can be both objects with wooden textures, and high-tech parts with chrome and shiny surfaces.