Why is the chain of the chainsaw leads to the side. about the construction and not only

Discomfort during operation, decreased performance, increase in fuel consumption, cutting curve, these are all the negative consequences of this phenomenon, but what is the reason?

- Uneven sharpening of teeth;

- The use of a chain that does not correspond to the parameters of the tire or vice versa;

- Increased wear of the sawing headset of the chainsaw.

Discomfort during work, decreasing performance, increasing fuel consumption, curve cut, these are all the bad consequences of this phenomenon, and what is the reason after all?

- Uneven sharpening of teeth;

- The introduction of a chain, not corresponded to the characteristics of the tire or on the contrary;

- Overstated wear of the sawing headset of the chainsaw.

Discomfort during work, decreasing performance, increasing the consumption of fuel, curve cut, this is what to make our client the bad consequences of this phenomenon, what is the reason after all?

Babakers crookedly, what to do? Why does it take a tire on a chain saw to the side when sawing a log? Why saws.

Discomfort at one time of work, decreasing performance, increasing the consumption of fuel, curve cut, this client remains the bad consequences of this phenomenon, what is the reason for all the reason?

Discomfort at one time of work, decreasing performance, increasing the consumption of fuel, curve cut, this is what remains to make our client the bad consequences of this phenomenon, what is the reason after all?

Uneven sharpening of teeth; The introduction of a chain, not corresponded to the characteristics of the tire, as it is also called it.

Shinka is not a brand new chain, and the effect remained the same, t.e. Leads cut. I agree about the “screw” in the fraction of a degree, but such a “screw” looks like a saw.

If our client remains so, in appearance you are described, then the situation is unusual. This is to experience the brain sturm. The tips indicated above are correct, if you are convinced that this will not cause the difficulties of sharpening, mud, then check the subsequent: 1) the tire has a huge groove thickness than a chain shank (tire 1.

5 mm, shank 1.3 mm, another tire 1.6 mm, shank 1.5 mm) 5) the chain is not stretched enough. In the annotation they write that the chain should sag a little. But this is perceived that it is like oil should simply hang freely from the tire. Check the tension of the chain.3) the assumption of the wear of the leading star does not withstand serious criticism, but I will still express it. who knows. Often new chains are torn only because of a worn leading star. Perhaps in your case, it has some kind of exotic damage.

Usually a new chain saws evenly, if the saw leads to any chain, then the case is in the tire, you can try to turn it over. On old saws of the “friendship” type, for this it was necessary to rearrange the tensioner. On imported saws, the tire simply turns over and that’s it, it is symmetrical. The saw will be taken away if the tire has more wear on the one hand more than on the other and the chain is overwhelmed by sawing.

This wear occurs faster, the worse the lubrication of the tire, which are sometimes forgotten by inexperienced sawmen. If the reason is the uneven sharpening of the chain, then you need to learn how to sharpen it with a round file and a device-chain. In this case, you need to grind the teeth more, taking into account the departure. For example, the saw leads to the right, this means that the teeth are slightly higher on the right, you need to flood them, and do not touch the left side. Perhaps only a few teeth are, it is important to find them and.

Ropper saws crookedly what to do? Why takes the tire on a chain saw to the side when sawing a log? Why saws.

Discomfort during work, decreased performance, increase in fuel consumption, crown of the cut, this is what to make our client the negative consequences of this phenomenon, what is the reason?

- Uneven sharpening of teeth;

- The use of a chain that does not correspond to the parameters of the tire as it is also called the opposite;

- Increased wear of the sawing headset of the chainsaw.

- Uneven sharpening of teeth;

- The use of a chain that does not correspond to the parameters of the tire or vice versa;

- Increased wear of the sawing headset of the chainsaw.

The chainsaw does not start

In case of difficulties with the launch of a chainsaw, many immediately sin on the carburetor. In fact, there are several options and any reason for the malfunction can be any:

- Air and/or fuel filters are clogged. The problem is solved by cleaning filters.

- Lack of fuel in the tank. Yes, there is such a reason. some owners forget about such an insignificant detail as a gas station refueling and think that a pair of liters of gasoline will be enough for six months. In addition, fuel in the tank should not be stored for more than 14 days, t.to. gasoline evaporates and is lost octane number.

- Check the pipe from the fuel tank into the carburetor. it could clog or break, so gasoline does not enter the tank.

- No spark on the spark plug. Why there is no spark. there can be many reasons: there is no contact, you need to change the candle or it was flooded. Why floods the candle on a chainsaw is another question. But if this happens, it is required to dry and reinstall, then check the presence of a spark. If the candle has a strong fog, it is recommended to replace it.

- Check the muffler for the presence of soot. If there is a dozen, carefully clean the muffler, but it is still recommended to take the chainsaw to the service center so that the cylinder and the piston are checked there, t.to. Nar-a sure sign of improper operation of the elements of the cylinder-piston group.

- The carburetor clogged. How to properly adjust the chainsaw so that the carburetor worked well, is considered in a separate article.

If none of the above methods helped, then the reason is more serious-the breakdown of one of the nodes of the connecting rod piston group. In this case, it is recommended to take the chainsaw to the service center.

Husqvarna 240 Chainsaw

What the curve of the cut of wood affects

If the chainsaw is in the hands of a beginner, then the curve cut wood can be attributed to the lack of sufficient experience. Another thing is when an uneven cut is obtained with a singer with extensive experience. If only it was not planned, then the cause of the crooked saw is a tool malfunction. Before studying the reasons why this happens, we consider the influence of such a defect. Negatively affects the curve cut on the following factors:

- If the chainsaw is crookedly sawn, in order to try to make an even slice, the sawer needs to apply appropriate physical efforts. This means that he is much tired of work much faster.

- Fuel consumption increases. Explanation of this fact is quite simple. Due to the change in the trajectory of the tire movement along the sawing workpiece, fuel consumption increases.

- Reducing the resource of a leading star, tire and chain. The increasing load contributes to a significant reduction in the life of the working elements of the tool.

- Decrease in performance. The movement of the chain in the spit direction helps to increase its friction against the wall of the sawed material. As a result, the load on the engine increases, and thereby decreases the performance.

- Receiving defective material. If the logs are cut down for the subsequent manufacture of boards and other timber from them, then the curve cut is a sign of marriage of products.

Curvoline sawing of a chainsaw is used in practice, but only when it is planned by a sawmill. If the master wants to get an even slice, but in the end it has a crooked cut, then this indicates the need to diagnose the tool.

The fundamental reasons why the chainsaws and saw an electric saw is crooked and go aside

If the chainsaw saws crookedly, then to the question why this is happening, the corresponding answer immediately begs: due to the tire. This detail of the tool may be one of the reasons, but it is not always the only factor. The following fundamental causes of crooked sawing of the wood of the chainsaw are distinguished:

- Sharpening of the teeth of the chain. With their incorrect or uneven sharpening, curvilinear sawing of wood will occur;

- Incorrect selection of consumables. If the chain, tire and leading star are not selected correctly in the step, then the result of such an unskilled choice will affect the work of the tool;

- wear of the saw set. This applies precisely to the bus, in which one side can simply be erased;

- The chain stretch. This factor also affects the fact that the chainsaw begins to saw crooked.

Such a defect cannot be ignored when the chainsaw saws crookedly. This is preceded by the appropriate reasons, and if they are not eliminated, then in the end this will lead to more serious breakdowns: the wear of the chain, tires, stars, a decrease in the ICE resource and others. To determine the exact cause specifically for your tool, you should do the appropriate diagnostic actions. We will pay a little more attention to each reason, and we will analyze them in detail.

Strong wear of the saw canvas

The tire serves much longer than the chain. However, this does not mean that it can be exploited forever, and not think about replacing it. Usually the guide changes after 2-3 worn chains. Before replacing the guide chainsaw, you need to evaluate its technical condition. If the tire of Chinese.made is installed on the chainsaw, then it can be worn out faster than the chain. That is why if the crooked cut of the wood of the chainsaw is detected, it is necessary to diagnose the tire.

To verify the wear of the tire, it is necessary to remove it and inspect it. Usually wear is manifested by a shortened one of the sides. Sometimes it is extremely extremely difficult to detect, so you need to use a caliper. The difference of several tenths of MM suggests that the tire needs to be replaced. There is still a simple way to check the deployment of the guide using a square. For this, the tire is located on a flat surface, and you need to put a square to the side. If the guide walls are in contact with the square from above and below, then the part is serviceable.

It is interesting!It is possible to increase the service life of the guide chainsaw only by periodic turning it. To do this, be sure to make sure that the tool provides such an opportunity, which will tell the appropriate markings on the headset about.

Accelerated tire wear can occur due to improper functioning of the oil pump. If the lubricant is served with large breaks, then friction increases accordingly, which means that the details wear out faster. If the lubricant works properly, then this increases the service life of not only the headset, but the entire tool.

Uneven sharpening

According to the instructions for sharpening circuits, grinding teeth is supposed to be the same distance, and in the independence on which side they are located. Observing this simple requirement, you can protect yourself from the problems associated with the fact that the chainsaw is led away by sawing.

Unevenly stubborn teeth are the most common problem of crooked saw.

Having tightened the chain with a file, it is not always possible to control the length of the tooth using the technique of counting the number of movements with a file.

This is due to the fact that the wear of the teeth is uneven, some are more damaged and a larger number of movements are required by the file, in order to bring them to normal, which means the size of such teeth will decrease significantly, compared to the rest.

How to avoid improper sharpening

In order to warn the cut curve due to uneven sharpening, it is possible from time to time or with severe damage to use a special sharpening machine for editing the chain. Buy a machine and sharpen yourself or give for sharpening to the workshop.

The fact is that the machine during sharpening is configured on the most worn tooth, which has a smaller size among all. After the sharpening is carried out, all the teeth will have the same size, which will be equal to the tooth, through which tuning was made.

The disadvantage of this method is that the resource of the chain is significantly reduced, t. to. you have to grind hard even damaged teeth. Try to use the chainsaw, monitor the nails and any other metal products that may come across when cutting old boards and other trash.

Malfunctions and how to repair the tire

With your own hands, a detailed scheme and understanding of the main mechanisms of the device will be required to repair the chainsaws with your own hands. The guide tire and its fasteners are vulnerable, consumable parts experiencing the largest load. You can repair the chainsaw tire yourself or by contacting the service center. Damage and breakdowns in this area are indicated by the absence of normal tension, sharp or intermittent chain stroke, the inability to ensure normal lubrication and fastening of the axis of the cut with respect to the aggregate body. Types of breakdowns:

- The rear and front leading links are riveted. The reason is the discrepancy between the step of the star and the links of the chain, weak tension or wear of the star. The problem is solved by replacing or adjusting the mechanisms.

- The presence of broken or non.kissed links indicate a weak tension or a chain break.

- Rounded backs of the spouts occur with excessive length of the chain headset and a lack of oil.

How to hide

Periodic sharpening is a mandatory event necessary for the normal operation of the gas station. Methods of independent sharpening of the chain:

- The use of a file is a simple and common option that allows the event directly at the site of the sawing.

- The use of a special machine. The method is found in personal farming and service centers.

- With a corner grinder. Sharpening will require skills.

A special machine is the most effective method. But with the help of a file you can also achieve good results.

How to choose a tire

Tire choice is a responsible event, the result of which the work of the entire device depends. The installation of an inappropriate element not only leads to the failure of other details, but also unsafe for the operator. In order to competently select the complete, it will require data from the length, size, shape and parameters of the shank.

The size is determined by the types of work that you plan to do with a saw. Small dimensions are suitable for simple manipulations, sawing thin boards. The most powerful installations are useful for harvesting firewood from thick trees trunks.

How to install a tire on a chainsaw

Before removing the tire, it is recommended to check the availability of the necessary components and tools. The tire installation begins with a fast tension system of the circuit, then it is necessary to go to the side and front device. Compliance with the sequence will allow you to correctly assemble the mechanism and ensure the productive operation of the tool.

Why does the jigsaw saw crookedly and how to fix it

In most cases, the process of direct and curly sawing materials requires the ultimate accuracy of the tool. This statement is most fair for the electric jigsaw. Thin saws used in this device can easily change the cutting angle, which can negatively affect the accuracy of the line. The clarity of the faces of the product and the evenness of the cut line depends on the operator’s skills, the serviceability of the device and the file. Next, we will tell you how to get the planned contour with perfectly clear faces and what to do if the jigsaw takes aside.

The tire serves much longer than the chain. However, this does not mean that it can be exploited forever, and not think about replacing it. Usually the guide changes after 2-3 worn chains. Before replacing the guide chainsaw, you need to evaluate its technical condition. If the tire of Chinese.made is installed on the chainsaw, then it can be worn out faster than the chain. That is why if the crooked cut of the wood of the chainsaw is detected, it is necessary to diagnose the tire.

To verify the wear of the tire, it is necessary to remove it and inspect it. Usually wear is manifested by a shortened one of the sides. Sometimes it is extremely extremely difficult to detect, so you need to use a caliper. The difference of several tenths of MM suggests that the tire needs to be replaced. There is still a simple way to check the deployment of the guide using a square. For this, the tire is located on a flat surface, and you need to put a square to the side. If the guide walls are in contact with the square from above and below, then the part is serviceable.

It is interesting! It is possible to increase the service life of the guide chainsaw only by periodic turning it. To do this, be sure to make sure that the tool provides such an opportunity, which will tell the appropriate markings on the headset about.

Accelerated tire wear can occur due to improper functioning of the oil pump. If the lubricant is served with large breaks, then friction increases accordingly, which means that the details wear out faster. If the lubricant works properly, then this increases the service life of not only the headset, but the entire tool.

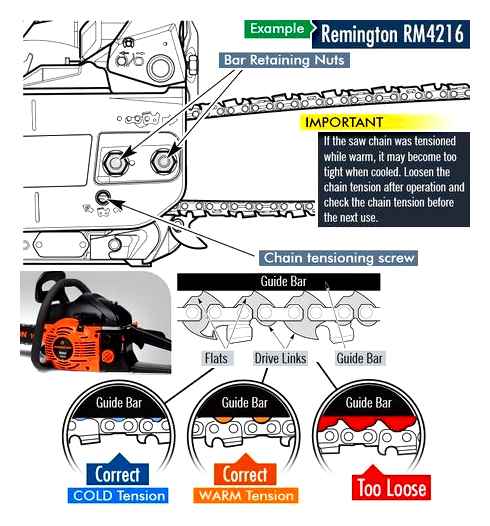

When the chain is weakened and how it is dangerous

Each chainsaw needs to regularly tension the chain. If this rule is not respected, then the consequences can be very traumatic. Most of the sawmills know what is at stake, and how to pull or pull the chain correctly. The correct tension of the cutting headset. when, when trying to pull it from the tire, three shanks are completely visible, as shown in the photo below.

It is interesting! Do not forget that the chain must be pulled only after it has cooled. If you take the tension of the not yet cooled part, then after it cools it will become pulled.

If the chain is weakened or excessively stretched, then this leads to tire wear. And not only the guide, but also the stars, bearing and engine. That is why make yourself a rule to control the tension of the chain before starting the operation of the tool.

How to grind a chain correctly

Intensive operation of the saw, entails the corresponding pace of the wear of cutting teeth, the sharpening frequency of which should be regularly. When working with soft wood, the gap between the sharpening is approximately 8 hours. Hard or frozen wood, wears out the chain faster and reduces the service interval to 3 hours. If, after the active work of the new saw, the question arises why the chain on the chainsaw, when you saw, leads left or right, the teeth should be examined. The sooner the sharpening is performed, the less metal will be removed, which is easier and more economical.

There are several types of specialized devices to sharpen cutting teeth. To understand the technique, it is recommended to start with the basics and master the classic, manual method. The next instruction submitted, transfers the procedure and affects important features of the process. For work, you will need a holder with a round file, the diameter of which is determined by the chain step (table below).

First of all, the chainsaw is fixed in a fixed position. It is better to squeeze the tire in a vice, but you can also with your feet.

For convenience, to see where they started from, a mark is applied to the first sharpened tooth or a rope is tied.

The file is inserted into the holder and snap on both sides. The position of the chain is fixed by the manual brake.

Focusing on the mark on the sovereign, we have a file at an angle of 30 degrees, in relation to the bus. If the chain for longitudinal sawing is pulled, the angle should be 10 ° (less acute).

Forty Cats & Arentis. The Lost Ancient Charm [Monstercat Release]

Install the file in the inside of the tooth so that its end is directed slightly up, and the handle is downward. As a sample, you can navigate the already existing angle of sharpening.

Having determined the position of the tool, we press the file to the tooth and advance a confident movement for the entire available length. When returning to the starting position, it is not necessary to press, but it is better to completely remove it from the chain (sharpening is performed only in the direction of the forward).

To achieve sharpness (with a slight wear), it is enough to repeat the previous point 3 times. If the teeth are strongly erased or tapping from raid on a nail, it may take time many times (you need to look as a state).

Having sharpened the cutter, we proceed to the next, stepping over one on the opposite side. During the process, periodically release the manual brake and scroll the chain to move the lower teeth to a convenient position, up.

Having imprisoned the teeth on one side, we change our position or turn the tool and move on to the opposite.

With frequent sharpening of the chain, the ledge of the cutting part will decrease, approaching the level of the cut limiter. As a result, the depth of immersion in the material and the overall efficiency of work will decrease. A similar problem is solved by uniform grinding of all limiters at each link, an ordinary flat file.

Restoration of a worn.out chainsaw tire

Violation of the accuracy of the cut, occurs due to uneven erasure of the side faces of the groove that controls the movement of the chain. To establish the work of the headset and return it to the previous clarity, it is enough to level the external ends. Such an operation requires maximum accuracy and perform it “on the knee”, you can’t work. First of all, you will need a grinding power tool (corner grinder, sharpening machine or grinder). If the last 2 devices are aimed at accurate operations and the principle of their operation is extremely clear, then regarding the angular grinder may arise.

The second paragraph, you will need a flat and reliable platform on which the processed ends of the tire can be placed, exactly parallel to the plane of abrasive material. There are special stands installed at an angle of 90 ° (or adjustable) on the Greener and the machine machine. When using a corner grinder, it will have to be fixed in a vice through an impromptu clamp, and an even wooden bar can be used as a site. All the nuances of processing the canvas using an angular grinder are demonstrated in the following instructions.

Instead of the handle of the corner grinder, the M10 bolt is screwed, with two nuts, to prevent promoting. Through this design, the tool is clamped in a vice.

It is better to place the site from the back side of the vice, on a retractable beam. A wooden block or several even boards, plywood or wood-based plate is suitable for each other. The main thing is to achieve an exact 90 ° angle between the stand and the grinding surface.

After organizing the workspace, the case remains with the small. Run the corner grinder, put the defective tire on the stand and smoothly draw its edges along the rotating petal disk. Particular attention should be paid to places where wear is most expressed.

Upon completion of grinding and elimination of the defect, we turn the tire and in the identical way we pass the ends from the opposite side. The task is to achieve symmetry of faces, and not make a recess in the plate. Therefore, we do not stop the movement and with equal speed we carry out the tire from the asterisk to the shank.

Without preparing the design (stands and fastening of the corner grinder), the grinding process takes about a minute and requires minimal effort. Upon completion of service, it is better to pass the corners of the faces with a file, removing the burrs and licked protrusions of the metal.

What to do if the chainsaw is taking aside when sawing

Knowing the theoretical moments stated above allows you to determine the paths of prevention and this elimination of the phenomenon:

- Sharpically sharpening saws. Using a special machine.

- Constantly monitor the correct tension of the saw chain. In this case, it is necessary to follow the above recommendations.

- Correct the tire in case of deformation of its sides.

How to edit a deformed tire

If there is no time for editing, then the tire can simply be turned over with the other side. If you have already turned it over, then it is already impossible to avoid editing. To fulfill the editing, you must arm yourself:

First, the tire is removed and the complexity of the problem is checked. For this, the tire is placed on an even table, and a square is assigned to it. This allows you to determine the degree of deformation.

Then the corner grinder is clamped in a vice, and the tire table is raised to the disk level.

With the help of the square, the exact angle of the disk of the corner grinder is set, and the tool is finally clamped.

Having turned on the corner grinder, the tire is treated several times with a corner grinder on both sides.

Then the quality of the work performed is evaluated visually.

The quality of the adjustment is also determined by the square according to the previously described methodology.

It is understandable that after the adjustment of the side of the breeze, the tire was slightly shortened, and the groove on it became less deep. Therefore, you need to make sure that the tailings do not go beyond the aisles of the groove. If the groove is not deep enough, the tire will have to be replaced.

So, now you know what to do if the chainsaw is taking away during the sawing. I hope this information will allow you to easily cope with this defect.

Millions of chainsaws are crookedly sawing from this. Top tire and chain

Over time, a regularly working chainsaw may begin to saw crooked. There are several reasons why this occurs. It is important to identify the problem as soon as possible and eliminate it. If this is not done, some of the tool nodes can be strongly worn out.

Most often, the tool begins to work poorly due to uneven wear of the teeth of the chain. In the process of cutting, the chain may come across obstacles, for example, an unnoticed nail. At this moment, the saw begins to work slower, and the owner, trying to return to the previous pace, presses on it. The teeth blurred on metal or other hard object cease to cut normally, pass along the surface of the wood, without clinging to it. The chain deviates, pressing the tires on the edge, deforming the grooves.

This is how the rib of a curved tire in the context looks like. The chain in grooves with deformed walls cannot be kept directly.

In this case, the shanks wear out. This leads to the fact that the chain is not held in the groove in a normal vertical position, but slightly deviates to the side, meeting even the slightest resistance. The longer the saw in this state work, the stronger the wear of all details will be.

The teeth are sharpened unevenly

If the tool saws one side, then the first thing you need to check the chain. The teeth should not just be sharp, but also properly sharpened. Correct sharpening is when each tooth grows at the same distance with the previous. In this way of sharpening, it is possible to exclude the occurrence of a chain imbalance during sawing. The instructions for the instrument indicate that each tooth when sharpening should grind at the same distance. If this requirement is not fulfilled, then besides the fact that the chainsaw will be taken aside, an increase in the load on the engine is not excluded.

Unevenly stubborn teeth are the most common problem of crooked saw.

How to avoid improper sharpening

In order to warn the cut curve due to uneven sharpening, it is possible from time to time or with severe damage to use a special sharpening machine for editing the chain. Buy a machine and sharpen yourself or give for sharpening to the workshop.

The fact is that the machine during sharpening is configured on the most worn tooth, which has a smaller size among all. After the sharpening is carried out, all the teeth will have the same size, which will be equal to the tooth, through which tuning was made.

The disadvantage of this method is that the resource of the chain is significantly reduced, t. to. you have to grind hard even damaged teeth. Try to use the chainsaw, monitor the nails and any other metal products that may come across when cutting old boards and other trash.

The use of an inappropriate chain

It is no secret that the tire of the chainsaw, like the chain, has several basic characteristics, one of them, this is the width of the groove for installing the chain. The width of the groove can have several main sizes:

Imagine that we take a chain with a landing width of 1.1 and install it on a tire with a groove of 1.3 mm. Initially, having pulled it well, we may not notice the differences, but as soon as the stretch weakens a little, the gap of 0.2 mm will not make it possible to move evenly along the tire, it will lean into one of the sides and we will again get a crooked cut material.

When buying a spare circuit to a chainsaw, call its exact dimensions, not a brand and a chainsaw model. On the same models of chainsaws, different tires can be installed and, accordingly, the chains will also be different.

Check the width of the chain landing, you can use a caliper.

To eliminate the malfunction, if the tire of the chainsaw is not very much damaged and there is no uneven wear on it, it will be necessary to replace only the chain. If wear is already observed on it, it is necessary to install a completely new set.

Violation of the uniformity of sharpening

According to the instructions, the teeth are stuck at the same distance, regardless of the side of the location of the teeth. But in practice, rarely anyone observes this parameter, because the unevenness of the teeth is overwhelmed is the most popular cause of crooked cutting.

Home masters rarely attribute a detail to a professional, preferring to drag the elements with a file. this is incorrect. When calculating the number of movements by a file, there is a risk of different pressure, which is why the teeth will again be worn unevenly. In the process of work, the tire will lead, the cut will turn out to be a crooked.

How to eliminate an uneven sharpening defect

- Buy a brass machine. If you have to work often with a saw, the purchase of a machine is a reasonable attachment. Equipment will increase the life of the chainsaw. The machine is set up according to the most worn element. Automatically selects the shortest tooth, carries sharpening by its size. As a result, all the teeth of the saw will be sharp and the same.

- Give a saw to the workshop. Here the process will be similar, the master will sharpen the tool on the most short tooth.

The process of grinding teeth according to the most short element reduces the resource of equipment.

To increase the period of use of the saw, during work, they monitor the presence of nails, metal brackets. Metiza often come across in old boards, and they lead to rapidly grinding the teeth of the saw.

High degree of wear

The crooked arc of the saw can speak of the unsuitability of the saw headset. Visually check wear on the inspection of the contacting surfaces. Do this:

Looking through the entire groove, they see how worn out the left and right side of the tire in relation to the groove. The standard is uniform wear on both sides, a large curvature in one direction or another is an occasion to replace a defective part.

To grind the tire evenly, it is turned over from time to time. The recommendation is acceptable for models with universal tires. Some types of equipment are indicating the direction of the chain along the tire.

As a prevention, do not forget about the lubrication of equipment, checking the supply nozzle. If it is clogged, the lubricant does not arrive, the wear of the tire increases. Low.quality lubricant, poor oil, uneven supply of the composition will also quickly disable the tire.

If the curvature of the cut appears, the first thing that pay attention to is the sharpening of the teeth and the wear of the tire. Solve the problem by replacing elements or aligning the height of the teeth.