Lawn mower stalls

When purchasing a lawn mower, you need to be prepared for the fact that, as in all other similar tools, breakdowns may also appear in it, which will require repair.

But you should not immediately run to the service center and pay big money to the masters, convincing you of the presence of a severe malfunction in the device.

The trimmer loves cleanliness. It is necessary Keep the air filter and fuel clean. Gasoline bought at a gas station is better to stand for 2 days and pass through the simplest filter. a piece of bike matter.

We check the electrical equipment as follows:

We unscrew the candle, examine the gap between the electrodes. We set the correct gap between the electrodes in the “Dedovsk” way. Take the razor blade, break it in half and insert a homemade probe between the electrodes. If the blades fit tightly, then the gap is perfect.

We put the cap of the high-voltage wire on the candle and lean the candle against the metal surface of the engine. We pull the starter several times. If the spark hits one point well, then the gap is adjusted correctly. If not, the spark is weak or “wandering”, then it is necessary to re-adjust the gap between the electrodes.

Why the Chinese lawn mower is NOT developing momentum?

The trimmer does NOT gain momentum, a very frequent problem and of course does not always have the usual solution.

In no case should you store gasoline in a plastic container from under water. When mixing the fuel mixture, a static charge builds up, you can “catch” the spark.

Therefore, at gas stations it is not allowed to fill gasoline in plastic cans, only in metal ones. Before pouring gasoline into a metal canister, it is better to put it on the ground, so static is removed from the case.

But there are situations when simple manipulation of the lawn mower does NOT help. The engine will still not start. In this case, it is used to check the power supply and ignition system, guided by the rule “the engine does not work if there is nothing to burn or nothing to set on fire”.

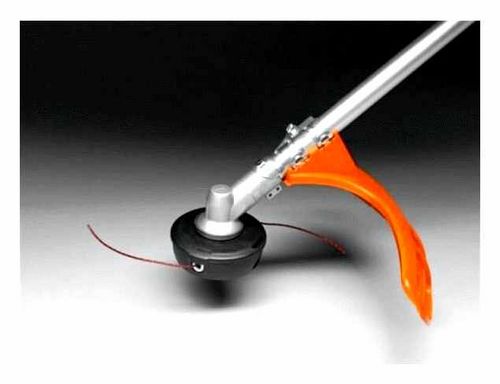

If he puts a cable instead of a fishing line, without the possibility of releasing it, securely fixing the two ends of the cable and cutting them off by welding (a drop of metal melting keeps the cable from opening). Such a tool “knocks down” the grass at a time. Cuts off shoots up to about a finger thick. Not as afraid of stones as a disc. There is, however, a problem: when worn, pieces of cable threads break off, and these twisted wires remain in place of the Mowing. If stepped on, you can get hurt.

But the pieces of the cable left on the field are half the trouble. The line, breaking off, weakens the dynamic shocks on the transmission and the engine, the cable does NOT give such an opportunity. The result is rapid wear on lawn mowers.

You also need to remember that a piece of the cable, spun by centrifugal force when the trimmer head rotates, flies like a bullet. Imagine what would happen if it hits the leg or someone’s eye?

Using a cable, wire, or multicore cable instead of a fishing line leads to quick breakage of the trimmer. In addition, it is a direct violation of safety regulations.!

Experienced users recommend buying a line with a “star” profile. Compared to a round one, it mows much better, stalks as thick as a finger, a fishing line with a diameter of 3 mm chops into an easy one, and is less consumed.

In any braid there is a knife on the protective cover, which cuts off the excess fishing line after winding, and the cable should NOT be cut. If part of the cable breaks off, then the result is an imbalance, increased vibration. Bottom line: the shaft drive bearings break. FS 70

It is a more advanced model with more power and more multitasking. An anti-vibration system is provided to significantly reduce the impact of a running engine on the handle.

Causes and repairs

I want to share my experience in restoring the required power of the trimmer with a gasoline engine.

Sometime in early June, I began to notice that my trimmer model GT22GES (manufactured by “ECHO”) began to lose its former power.

In the process of work, when mowing grass, even with a slight increase in the load (the grass is higher and thicker), the speed dropped and the efficiency of work was no longer what it was before.

Previously, the trimmer did NOT notice such obstacles at all. With a sharp push on the “trigger” without load, the revolutions increased slowly, as if reluctantly.

I took the User Manual for the trimmer, found the section “Faults and their elimination” in it. I chose a suitable malfunction in the table, which is described something like this: “The engine accelerates poorly or dies out”.

Potential causes include clogged air filter, fuel filter, clogged fuel tank drain, spark plug, carburetor, clogged cooling system, clogged exhaust port or muffler.

As it turned out, the list of possible causes is extensive. where to start?

First, I visually looked at the air filter, drain hole, air radiator, all this turned out to be in good condition.

Then I decided to look from the end of the list, that is, to check the exhaust system. exhaust channel and muffler.

To do this, he removed the spark plug tip, unscrewed 3 screws and removed the plastic protective cover of the muffler (in the drawing in the manual under No. 15). Then, having unscrewed two long screws, carefully removed the muffler, so as not to damage the two gaskets that are present there.

The premonition did not deceive me. The exhaust channel of the engine cylinder (through which the exhaust gases come out of the cylinder) was 30. 40 percent clogged with carbon deposits.

So this is what turned out to be the reason for the frustration of my trimmer!

This is what the exhaust channel looks like

Carefully, so as not to damage the surface of the piston and prevent foreign products from entering the cylinder (in other words, the very carbon), I completely cleaned the exhaust channel from carbon deposits, carefully blew the channel with a pump.

I used a knife as a tool (but only at the edge of the canal), and in the depth of the canal, a wooden and plastic spatula of suitable sizes.

The muffler turned out to be pretty clean both inside and out.

After assembly, he started the trimmer, warmed it up a little and tried to mow. the engine started up like new, the power increased noticeably, it doesn’t cut the grass, but cuts (3 mm line).

It’s nice that the device began to work perfectly and doubly pleased that he himself was able to find the malfunction and fix it.

It is likely that such a problem may arise in other models of trimmers, because they all have approximately the same design and all trimmers have an exhaust channel and a silencer.

Why does the lawn mower stall after starting?

After starting, the engine may stall if the carburetor is incorrectly tuned or misaligned. By what signs can you understand that the reason really lies in this? It is very simple, by vibration, which will be clearly felt when the mower is operating. You can adjust the fuel supply yourself by doing everything that is written in the operating instructions for the tool.

The engine may stall due to a clogged fuel valve. The cause is eliminated by cleaning it. If the lawn mower starts up and then suddenly stalls, then the fuel supply to the carburetor is difficult. Loosen the carburetor valves to ensure the free flow of fuel to it in the right amount.

Excessive air leaks can also cause the engine to stall. Turn up the engine speed so that air bubbles escape faster from the fuel system of the unit. Also, be sure to check the integrity of the fuel intake hose. If you find mechanical damage (cracks, punctures, etc.), replace the part.

10 best electric trimmers

Feature in the rating

Many owners of private houses and summer cottages carefully look after their personal plot. When the active growth of grass begins, there is a need for a special technique. The modern market offers a choice of lawn mowers, lawn mowers, electric trimmers. The latter compare favorably with.

Petrol trimmers help to clean up the suburban area. If electric mows are suitable only for “cosmetic” lawn mowing, then lawn mowers are used for an all-encompassing

Choosing a gasoline trimmer for a summer residence. Overview of petrol trimmers.

The best design contributes to the highest tool performance, cutting width.

What to do if Trimmer

Is NOT gaining momentum

?

If you have once purchased a trimmer that runs on gasoline, then you probably had to deal with the problem of turning on the trimmer, as well as with such a problem as the trimmer is NOT gaining momentum.

That is why this article was created.

So, what to do if the trimmer, which has been working for you for more than a year, suddenly just stops picking up speed, and the engine simply stalls? In this case, you and I should consider a number of problems associated with stopping the motor.

The motor can stall under various circumstances. Sometimes a prerequisite for improper operation of the trimmer, running on petrol, is a clogged air filter.

It is the filter that is one of the most important reasons why the gasoline trimmer may stop working.

.

Various debris very often gets into it, dust particles get there, which also clog the filter, so it needs to be cleaned and washed every month, and maybe more often, it all depends on what power the petrol trimmer has, as well as how much often you use this device.

Immediately after winding up

-

Many garden equipment owners face the problem of stopping the trimmer engine after starting it. Gasoline tool repairmen are sure that the matter lies in the fuel system, or more precisely, in the carburetor. As a result of a violation of its settings, an uneven fuel supply occurs and, as a result, increased vibration and a stop of the internal combustion engine.

Trimmer ignition module

Another reason why the trimmer starts and stalls immediately is a clogged fuel valve. To restore the circulation of gasoline in the fuel system, it is enough to dismantle the valve and eliminate contamination.

Trimmer stalls: causes and troubleshooting was last modified: July 22nd, 2018 by

The unit may stall immediately after starting if the carburetor is misaligned or incorrectly adjusted. this causes an uneven fuel supply. The result of this is that the device vibrates distinctly. For troubleshooting, the carburetor is reconfigured, following the instructions for the mechanism.

Also, the engine stops when the fuel supply valve becomes clogged. In such cases, it is sufficient to simply clean it. If the lawn mower first started working, but then immediately stalled, then the fuel may enter the carburetor unit with some difficulty. Weakening the valve helps to resolve the issue, which ensures free circulation of the mixture in the system.

A stop can also be caused by air leaks in the presence of mechanical damage to the hose (holes, cracks) that takes the fuel. In this case, you should add revolutions to the bit in order to quickly expel air bubbles from the system.

Gas meter (motorcycle mower) carburetor repair does not work DOES NOT develop speed. Power loss

In this case, the lawn mower will stall at idle speed. Lawn mower is NOT developing momentum, the reason | funnydog.Tv. Misalignment or incorrect carburetor adjustment can lead to a dilemma with the power system.

The misalignment can be caused by vibrations that occur during the operation of the lawn mower.

Incorrect adjustment of lawn mowers can be corrected simply by adjusting it in accordance with the requirements indicated in the annotation for use.

Apart from that, from time to time gasoline trimmers may stall due to the fact that the valve located in the gas tank cap is simply clogged or stuck.

To find out, try to use a scythe, loosened the gas cap.

If the device operates properly in this mode, clean the valve.

over, the lawn mower can stall due to the disgusting flow of fuel into the carburetor.

Why then does the device start, you ask?

Cause

this consists in the fact that at first the fuel gradually runs into the carburetor and it is enough to work at increased power.

But then it is produced and at high speeds the engine starts to stall.

As for the carburetor, the problem may also be that its body is very tight.

The premise that the lawnmower stalls at high rpm

on gas, there may also be air leaks.

We are talking about the likely presence of a place through which air can pass during the heating of the motor.

In addition to everything else, be sure to check the fuel inlet hose. The trimmer does NOT develop speed. One of the reasons. The problem may lie in the fact that it is weak or cracked altogether.

These are the main reasons why a lawn mower may stall.

Problems with starting the engine

It is very important to correctly determine the cause of the failure, because otherwise we simply cannot eliminate it. If there are no extraneous sounds when trying to adjust the chainsaw (knocking down, grinding, etc.)

It often turns out that there are actually no problems. For example, if it is wrong to start the chainsaw and pull the plug for a long time, the engine just pours and starts very hard.

To properly start the chain saw motor, set the lever or switch to the flap position. Then you need to pump the mixture into the carburetor, if a fuel pump is available. Pull out the starter handle until the resistance of the motor is no longer noticeable, and vigorously pull out the amplitude, taking your hand to the side. After two. Three such movements, the engine must first start, and then decay. If this does not happen, then it is necessary to move the lever to the half-throttle position or simply to the working position, and then continue the operation of the chainsaw in this mode. Many semi-gas chainsaws are locked automatically when pulling the air damper

Some models have key ignition, it is important to make sure it is on

If the engine does NOT start, the first thing to do is. Unscrew and check the spark plug. There are times when the plant fills the burner with fuel during the cold season. Then you also need to Unscrew the candle, Dry the combustion chamber with one plant, clean the spark plug, screw it in and restart. It is advisable to check for a spark immediately. On a twisted candle, we put on a cap with a high voltage wire, we put it on the cylinder and we pull the starter. Visually Observe the blue sparkle treat. OK. We roll the candle into place and fire it up. If there is no spark, change the spark plug and try again. Again, there is. Check the connection of the high voltage wire to the spark plug, coil and ignition system.

In general, the state of the spark plug can be used to determine the type of fault.

- Dry.

Most likely, the fuel mixture will not enter the cylinder. This is not an ignition system, so the plug is screwed in and checked. - Wet, heavily splashed with fuel.

Excessive fuel mixture is caused by a violation of the starting rules as described above, or by incorrect setting of the carburetor. - Coated with black carbon.

This could indicate the use of poor quality oil, an incorrect carburetor setting, or an incorrectly calculated gasoline to oil ratio. The candle should be washed, cleaned of carbon deposits with a sharp object (awl or needle), wipe the electrodes with a cloth and put in place.

When checking the spark plug, you must Pay attention to the gap between the electrodes: the normal is considered from 0.5 to 0.65 mm. Damaged or worn gasket should be replaced

A properly adjusted carburetor chainsaw ensures full power efficiency at the most economical fuel consumption.

The need for tuning the carburetor chainsaw is infrequent, since the adjustment is initially made by the manufacturer to achieve optimal operation. The adjusting screws are designed to more accurately adjust the carburetor chainsaw, if necessary.

When and why is it needed?

Among the reasons for the failure to fix the adjusting screws, the following are most common:

- Strong vibration or damage to the protective cap. It rarely happens, but it still happens.

- Serious engine (piston) wear. Of course, in this case, it is better to take care of the repair of the chainsaw, but at the same time adjusting the carburetor can improve its functionality for some time.

- Litter in the carburetor due to poor quality gasoline or scale formation. In this case, in addition to adjusting the carburetor, it can be avoided.

The Stihl trimmer does NOT accelerate. During the engine run-in period (this is approximately the trimmer operation on 2-3 tanks), the amount of oil can be increased. For example, mix it with gasoline in a 30: 1 ratio.

A small amount of oil mixed with gasoline leads to increased wear of the cylinder-piston group. An excess of oil in the mixture, although not so fatal, is also harmful. Coking of the piston rings, rapid formation of carbon deposits in the combustion chamber, and a drop in engine power may occur. In addition, the muffler mesh screen is coked. Therefore, some users (after the end of the warranty period for the trimmer) recommend dismantling it.

Gasoline Used in lawn mowers. AI 92. The brand of gasoline is precisely prescribed in the operating instructions. You should NOT try to “force” the engine, pour 95th gasoline into it. This can cause overheating, erratic trimmer operation and breakage.

It is not recommended to leave fuel in the trimmer tank during extended shutdowns. It is better to end the working day with the entire mixture completely exhausted. If this is not done, then, since the gasoline will evaporate from the engine overnight, and a thin film of oil will remain, the carburetor jets may become clogged. This will cause difficulty the next time you start the engine.

It is also necessary to observe safety precautions when storing fuel. Many people pour gasoline into a plastic water bottle. Is it worth doing this?

User’s manual

Particular attention should be paid to how to correctly carry out the first start-up and break-in of a gasoline mower. Competent actions will maximize the life of the trimmer and reduce the cost of maintenance and repair

Before starting the device for the first time, you will need to carry out several preparatory steps. Their list includes a visual assessment of the condition of the gearbox and the preparation of a high-quality fuel mixture, taking into account what kind of oil needs to be filled in accordance with the instructions and recommendations of the manufacturer.

It is on the composition of the fuel that experts and experienced owners of gasoline trimmers recommend focusing attention. In situations with two-stroke engines, unlike four-stroke engines, the components will be gasoline and oil

The proportions are indicated in the corresponding instructions attached to the technique, or on the labels of fuels and lubricants. The annotations indicate, among other things, the type of fuel and engine oil recommended by the developers.

After all the trimmer assemblies have been inspected and the fuel has been properly prepared, you can proceed directly to starting it and then running in the internal combustion engine. This process includes the following steps:

- The lawnmower must be placed horizontally on the most level surface;

- The lever controlling the air damper is moved to the closed position;

- Using a primer, fuel is pumped to the carburetor (a few movements are enough);

- The ignition is switched on with the appropriate switch;

- The starting cord should be pulled out as smoothly as possible until resistance is felt;

- The device is started by several abrupt pulls of the cord;

- After the engine has started, open the air supply.

In some situations, the trimmer may not start or stall right after starting. In such cases, it is necessary to slightly open the air supply to the carburetor and try again. After a positive result, let the motor run for at least 5 minutes in idle mode.

Using the lever, the air supply should be set in such a way that the line spool or knives remain stationary. After the engine has completely warmed up, the throttle is opened by moving the mentioned lever to the position marked with the ON icon, and the throttle regulator is pressed halfway for 20-30 seconds. In the next step, the trigger is released and the trimmer will idle for approximately 40 seconds. Such manipulations are repeated for 10-15 minutes, after which it is necessary to take a 20-minute break.

By repeating the above steps, further running-in of the internal combustion engine of a gasoline mower is carried out. The next stage is gearbox running-in, for which you will need to select the Corresponding area with soft grass. The latter is mowed for 5-10 minutes with periodic podgazovki (1/2. 2/3 of the maximum speed). This cycle is repeated several times at intervals of 20-25 minutes.

Sooner or later, trimmer owners have to deal with the need to change the line. This is an integral part of the operation of such a technique. There are several ways to update the cutter in question. The simplest option includes the following manipulations:

- Remove the head from the trimmer and thoroughly clean it;

- Unwind the required length of the fishing line (2-3 meters recommended) and bite it off with pliers;

- Bend the line so that one end is 15 cm longer than the other;

- Place the folds on the spike, located between the grooves of the coil;

- Wind the fishing line in two directions at the same time, temporarily Fix it in the grooves (the direction of winding is indicated by the arrow)

- Thread the ends through special holes in the lid;

- Insert the spool of new line into place and snap into place.

Often, when using Stihl lawn mowers, it may be necessary to adjust the carburetor. If you have the appropriate knowledge and skills, you can do it yourself. At the preparatory stage, you will need to thoroughly rinse the air filter. It should be noted that it is highly recommended to do this every ten hours of mower operation.

Adjustment is carried out by three screws, one of which is responsible for fuel supply. It is twisted until the GIS starts to stall. Then the screw should be unscrewed by a quarter of a turn (if the motor has stalled, then by 1/2). After starting the trimmer, continue to unscrew the same screw until the GIS starts to work stably at increased speeds.

Tips for choosing

In accordance with current statistics, it is gasoline mower models that are in greatest demand. This is largely due to their mobility and functionality. However, when choosing a specific model of equipment, a number of other parameters must be taken into account. In such situations, it is useful to compare lawn mowers with other types of trimmers.

Electrical devices are connected to a household mains with a voltage of 220 V. Such machines DO NOT pollute the air due to the absence of exhaust gases. Equally important are the minimum noise level and the relatively low weight. At the same time, the area to be treated is significantly limited by the length of the carriers used.

Cordless models are by far the least common grass trimmer. The electric motor of these mowers is powered NOT from the mains, but from the battery, which ensures maximum mobility. However, the operating time of the equipment is limited by the battery charge and averages 35-45 minutes. Another important point is the relatively high cost of battery models.

When choosing a specific model of a gasoline trimmer, it is necessary to take into account its technical characteristics. So, low-power devices are equipped with reels with fishing line

On more resourceful and powerful models, knives and cutters can be used as cutting elements.