»How to miscellaneous [del]

Correct divorce and sharpening a band saw is half the success!

The most important factor in the success of a sawmill business is which saws are used in production. The size of the saw, the material from which it is made, and the technology by which it is made, matters.

But even the use of saws of the optimum size, produced according to the most modern standards, will not allow you to get the profit you are counting on if these saws are not correctly sharpened and divorced. Improper saw blade sharpening and sharpening lead to defects on the lumber, which means that its cost drops significantly.

Particularly important is the correct sharpening and separation of saws when working on a tape sawmill. Unfortunately, in practice, many people even confuse the sequence of these procedures: first they make a saw, then they grind it. As a result, the saw tooth divorce goes away, and the saw needs to be bred again, or, if this is not done, the quality of the finished product will leave much to be desired.

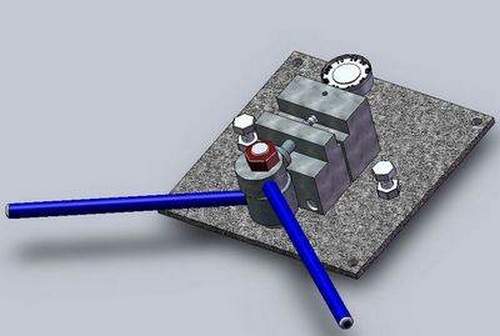

If we talk about machines on which sharpening and sawing are performed, then every detail is really important here. The Emerald Forest company has contributed to the development of high-quality adjustable and sharpening devices.

The adjustable machine has the correct geometry. when installing the saw in the adjustable machine, the tooth root is between the cheeks that clamp the saw. In many other machines, including from a number of well-known manufacturers, this condition is not fulfilled. Therefore, when bending the tooth, both the tooth and the saw body deviate. Technically correct saw blade divisions imply something else: the pusher abuts 1/3 of the tooth and bends only its tip.

In the manufacture of the adjustable machine, two clamping stops are used, which, with light pressure on the handle, press the tooth against the indicator head. The pusher, not reaching the tip of the tooth, shows the actual divorce on the band saw. If it is insufficient, the operator presses the tooth until it is diluted to the required size. We consider it very important to pay attention to one point: a band saw tooth has a property such as metal memory. Because of it, under the influence of inertia, the tooth tends to return to its original position. Therefore, for proper wiring, it is not enough to make one click on each tooth: it is necessary to act on the tooth several times so that it remembers its position. If someone tells you that it is enough to click on each tooth once, know: you are misled.

Two clamping stops with powerful springs used in the machine show the actual tooth tooth bend, which is very convenient: you do not need to unscrew the pusher endlessly and reconnect to find out how the tooth tooth has been retracted.

Another strength of the adjustable machine manufactured by the company is the ease and safety of the operator’s work: tooth extraction does not occur due to the operator pushing the pusher forward, as in a number of analogues, but due to the operator’s own weight and using an eccentric. As a result, the operator does not experience sprains.

So, high-quality adjustable and sharpening machines are what, undoubtedly, should be in the arsenal of each owner of the sawmill. But by themselves, they do not guarantee the quality of lumber, they will not allow the saw to serve for a long time if sawmills with serious technical flaws are used in production.

For example, if the rollers are made with a cone, or they became conical, because the saw has undermined them, then even with the correct sharpening and wiring, the saw begins to look for its place in the log. This will happen because the rollers are tilted. If the pulleys on the sawmill are divorced and are not in the same plane, then the saw is not flared clearly in the middle, but from the sides, and then the voltage goes to the edge of the tape blade. It also reduces the life of the saw.

So the role of the correct wiring and sharpening of the saw, of course, is great, but these factors do not determine 90% of quality sawing, as is commonly believed. It’s just that the saw itself will not be able to cut perfectly evenly and will not fail for a long time if, for example, a hard tension is used on the sawmill.

If you are just starting your business and have not yet had time to get acquainted with all these nuances, we recommend that you contact those who have been working in the market for more than a year. Telephone of the central office of the Emerald Forest company in Novosibirsk: 8 (383) 249-43-21. Contact us and we will advise you on the choice of equipment based on your needs and your budget.

Sawing a band saw

Band Saw Sharpening

Band saws, which are blades with a serrated edge, connected by ends to a continuous tape, have their own inherent advantages. The cut width left by them is less than the cut width from circular saws. When sawing ordinary wood, this feature may not be very important, however, when cutting valuable wood and cutting expensive metal, this is significant.

Band Saw Sharpening

The small width of the cut makes relatively low energy costs for cutting the material. And finally, with a band saw, you can cut the workpiece of almost any thickness, while the geometry of the circular saw imposes restrictions on the thickness of the material cut by it.

However, to take advantage of all these advantages, band saws need to be able to properly prepare for work. The main preparatory operations include sharpening and wiring band saws.

Video: What a Band Saw Scam In Winter

Band saws are made from different materials. depending on what material they are intended for cutting.

Saws for wood are made of tool alloy steel having a hardness of 40-45 HRC. Domestic manufacturers use 9HF, B2F steel (for band saws for metal) and other foreign. their own steels (C75, Uddeholm UHB 15, etc.). When hardening the teeth of such saws with high-frequency currents, they can acquire hardness of up to 64 HRC and higher.

Saws for cutting carbon steel and non-ferrous metals of small thickness are also made of tool steel with obligatory filling of teeth with high-frequency currents. However, more often for cutting metal, bimetallic saws are used, in which the blade is made of spring steel, and the strip on which the teeth are cut, band saws high-speed steel with a high content of tungsten and cobalt. After hardening, it acquires a hardness of up to 65-69 HRC. High speed steel is welded to the base of the saw with an electron beam.

Teeths with greater wear resistance are obtained by fusing them with stellite (an alloy based on chromium and cobalt with tungsten and / or molybdenum additives) or soldering hard alloy plates to them. Such saws are superior in their cutting abilities to bimetallic ones. They are used for cutting fiberglass, tires, cables, reinforced plastics, heat-resistant alloys, graphite, aerated concrete, bricks and other materials that are difficult to process by cutting.

The geometry of the teeth of band saws

Band saw teeth profile

Characteristics of teeth of band saws

Specific cars for a large family of sharpening angles for band saws are determined by manufacturers, based on many factors. In general, one can single out such a dependence. the harder the wood, the smaller the rake angle (γ).

For saws for metal, a different tooth shape is also used, depending on which metal they are intended for cutting. Saws with a constant pitch distinguish two main forms.

Standard, designed for cutting thin-walled metal with short chips with a rake angle (γ) of 0 °.

A tooth with a positive rake angle (γ) used in saws for cutting thick-walled metal with long chips.

For thin-walled material, saws with a relatively small pitch are used (the number of teeth per inch of the nuclear family is from 4 to 18). Saws for cutting thick-walled material do not need a large number of teeth, their number is 1.25-6 teeth per inch.

To eliminate the effect of resonance leading to blade vibrations, some saws are made with a variable pitch, at which the distance between the teeth varies within a separate group. The step size is indicated by the largest and smallest values.

Sawing a band saw

Divorce is the operation of bending the teeth of a saw to one or the other side in order to reduce the friction of the saw blade against the walls of the cut and prevent it from being clamped. In order for the web to move freely in the cut, the width of the latter should be 30-60% greater than the web thickness.

There are several types of wiring, the names of which may differ from different manufacturers. The main types are.

Correct divorce and sharpening a band saw is half the success!

The most important factor in the success of a sawmill business is which saws are used in production. The size of the saw, the material from which it is made, and the technology, matter.

Band Saw Sharpening

Band saws, which are blades with a serrated edge, connected by ends to a continuous tape, have their own inherent advantages. The cut width left by them is less than the cut width from circular saws. When sawing ordinary wood.

Band Saw Sharpening

Band saws, which are blades with a serrated edge, connected by ends to a continuous tape, have their own inherent advantages. The cut width left by them is less than the cut width from circular saws. When sawing ordinary wood.

Subscribe to articles

How to sharpen and breed a saw

Band saws are often sold in unfinished condition. A professional tool must first be diluted and then sharpened. Once every two to three years, the wiring process is repeated. An improperly diluted and poorly sharpened saw can ruin all the work.

How to sharpen and breed the saw correctly? First you need to understand the essence of these processes. After all, the preparation of a hand tool is different from the preparation of an electric one. Hand saws have a completely different tooth shape and working technique.

Why make a saw

Wiring is such a process, as a result of which the teeth of the band saw are bent in different directions. Even teeth bend in one direction, odd. in the other.

Before you breed a band saw, you need to understand why this is necessary. Meaningless processes usually do not bring a good result. It is known that during sawing, the width of the cut should be twice as large as the thickness of the saw blade. If there is already a cut, then the saw will start to get stuck in it. If the wiring is incorrect, the web may bend. As a result, the saw will go crooked, and a smooth cut will not work.

Wiring Methods

Wiring Methods One of the easiest ways to breed saw teeth is with pliers. You just need to take each clove and bend alternately in different directions.

The tooth must be clamped by two-thirds, then the bias will be correct.

As a result of this work, half of the teeth will be bent to the right, and half to the left. Another wiring method is carried out using a special tool.

Sharpening

Sharpening a saw After breeding, the saw must be sharpened. This is done using a special set of simple tools. You can sharpen a band saw using a regular trihedral file. During sharpening, moving the file away from you, it is pressed to the teeth. Moving in the opposite direction, it should be slightly rejected.

If you can sharpen a circular saw only with the help of a whole set of tools, the band saw can be brought into working condition with just one simple trihedral file.

The teeth of the band saw should be pointed from two vertices.

In the working process, you can also grind the teeth using a bar. When the saw is constantly sharpened, the wiring gradually disappears, the cloves are aligned. In order to return the instrument to its working form, the dilution is repeated again. Major wiring and sharpening is not required very often.

Saw Care

It is important for a saw to be able to not only breed and sharpen. You must also be able to store it. When the tool is not in use, it should be placed in a warm and dry place. If moisture gets on the saw, it will rust.

Even processed with special compounds, the saw will not be able to withstand all aggressive factors.

You need to be careful about the tool, and then it will serve for a very long time. A saw usually wrapped in material is stored. You can also provide a case for her. Leaving the tool for winter at BAL-KO is not recommended.

Types of Band Saws

Band saws vary in tooth size. You should also highlight:

Two-handed saws are sharpened and bred in the same way as ordinary single saws. The whole difference of such an instrument is that two people work with it at once.

Using band saws, wood and varieties of this material are most often sawn. The tree does not require too much impact, it is a soft material that is easily sawn and drilled. However, in the process, it is desirable to still secure the logs and boards. During sawing, be careful not to keep your hand too close to the groove of the saw. This could result in serious injury.