What to make of the boat motor. Homemade boat motor. How to make an electric outboard boat motor with your own hands

A boat motor can be made from many mechanisms that are gathering dust in the shed or garage and are not used for their intended purpose.

It often happens that the equipment fails, and to fix it you need to spend more than half the cost of a new device. It is much easier in this case to buy a new device, and put the old one aside and use it as source of spare parts and various bolts and nuts. It is from such devices that a boat motor can be made.

If there are no such devices available, you can inexpensively buy such a mechanism on the secondary market. The main thing in such devices is to have a functioning engine.

A boat motor from a grass trimmer

Minimally changing the design of the grass trimmer you can arrange an excellent pulling unit for a boat of any design. The engine and transmission in such a device is already there, it is enough to make a mount for the boat, and instead of a reel with a fishing line or a disk to install a propeller.

Before making a boat motor from a grass trimmer, it should be understood that the power of such devices is very low, and it is unlikely to move against a strong current.

Grass trimmer as a boat motor is ideal when used on a lake or pond.

The disadvantages of using this device should include a high level of noise. Besides, at low speed you will have to breathe absolutely all products of “life activity” of this system.

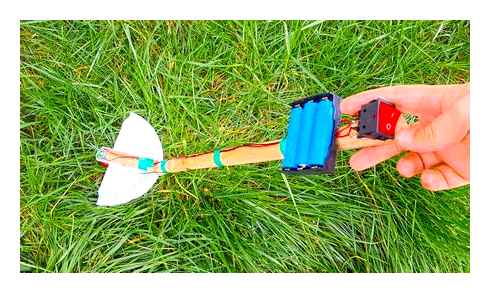

Boat motor from a screwdriver

Electric-powered boat motors have excellent performance in terms of noise production and environmental friendliness. You can make a motor for a boat from a screwdriver, but the power of the device should not be less than 300 watts. A flexible shaft from a grass trimmer can be used to transmit torque to the propeller, which is located underwater.

A small aluminum propeller from a car fan is used as a propeller, and to ensure a long operating time of such a device car batteries with a capacity of 60 Ah are used.

The disadvantages of these designs are the need to carry a fully charged car battery with you. Mass of such part is more than 20 kg. The disadvantages include the limited power of such a motor, after discharging the battery it will be necessary to manually drive the boat again.

A boat motor from a power tiller

The most powerful of self-made boat motors is a device made from a power tiller. Technics for the processing of the homestead plot is equipped with sturdy and durable four-stroke internal combustion engines, which, when installed on the watercraft,

Allow it to reach a decent speed both upstream and downstream. Such engines have considerable weight and are not usually used on PVC boats.

The easiest way to install a boat motor of this design is to make minimal modifications to the basic structure. It is enough to attach a single-axle tractor to the boat’s hull and install aluminum blades instead of cutters. The blades must be in one plane with the shaft, which in this case is located perpendicular to the movement of the watercraft The blades are in the form of rectangular plates, which the lower half should be lowered into the water, and the upper part should move freely through the air. This arrangement of the propeller will allow you to travel at high speed, even in places where the depth is less than half a meter. A boat engine made from a powerboat with a fast current is excellent.

Other options

You can make a homemade motor not only using grass trimmers and screwdrivers as the basis. If there is a desire to design a boat motor yourself and has a significant reserve of time and money, then as a power unit you can use any technical device equipped with an internal combustion engine or driven by an electric motor.

Many masters put the motorcycle engines on the boat. In this case it is possible to regulate the speed of the propeller with the help of gearbox switching. Powerful 12-volt motors, which are used in various mechanisms, can be successfully used as boat engines.

Features of a homemade engine

When converting a motor, it is worth taking into account that they were developed to perform different functions. The grass trimmer functions at high revolutions and a small torque, and the boat motor must do the opposite. Therefore, the remodeling of the device requires special tools and even a drawing.

The engine from the trimmer for grass is more convenient and easier to construct, because it has a number of necessary components of the mechanisms:

- a very economical engine;

- Built-in unpainted fuel tank, allowing you to easily control the amount of fuel;

- The presence of a starter and gas in the device;

- Boom, equipped with a rigid shaft.

It remains only to buy the missing parts or make them yourself and you can proceed to the manufacture of an engine for the boat.

The grass trimmer operates at high revolutions and low torque, and the boat motor must do the opposite

What you can do

There are several possible options for refinement of the grass trimmer under the motor for the swimmer.

A very simple method, but requires additional financial costs.

You will need to buy the following parts:

- Clamp to secure the device to the boat transom.

- Propeller. You can buy a pre-packaged kit online, as stores may not have this product. In the package includes a special drive, made of stainless steel, as well as universal adapters for flexible shaft trimmer for the grass, which allows not to bother with the fact that they fit to your model or not lawnmower.

Sometimes a clamp may be included in the set, so before you buy it check what’s included in the kit.

The drawing of the attachment to the trimmer is shown in the instructions. For installation it will take about half an hour.

You’ll need an angle reducer from an angle grinder, a screw that can be cut from a sheet of stainless steel, and gaskets and bearings for the fasteners. This method allows to get the maximum speed, despite the small pitch of the propeller. In the field, the device requires additional adjustment, which is done with pliers.

This method is performed as much as possible with your own hands. Let’s consider it in more detail on the example of a lawnmower with a two-stroke motor of 25 cm3. The 700 W unit weighs 4.5 kg and has a bent leg. Grass trimmer with this power allows the boat to move at a speed of about 5-7 km/h. For alteration you will need an angle reducer from an angle grinder, a screw, which can be cut from a sheet of stainless steel, as well as seals and bearings for the fasteners

What will be needed

To make it, you will need materials, as well as tools:

- Grass trimmer.

- Duralumin with a thickness of 2 mm. It is needed for the propeller.

- Clamp or any other device for attaching the device to the boat.

- Welding machine.

- Fixing elements.

- Additional tools for work.

All necessary elements can be bought or made by yourself. A blueprint may be needed to design a homemade propeller, but not for the drive. The size of the propeller directly depends on the power of the drive, as well as the weight of the watercraft. For example, a propeller with dimensions of 10×3 cm is able to move a vehicle weighing about 120 kg.

Instructions for making

To make a boat engine from an ordinary grass trimmer you will need to do the following steps:

For running-in of the homemade engine, we need a tank of gasoline (0.5 l.) with oil in the ratio of 1:40. One tank of gasoline can cover about 10 km of territory. The speed of the watercraft with such a motor is in the range of 5.6. 7.9 km / hour, depending on the load of the boat.

- It is much easier to convert a grass trimmer with a straight shaft.If the rod has a curved shape, it will need to be completely changed, because the steel cable will not be able to transmit the necessary torque. To change the bent shaft you need to use a duralumin tube, press a sleeve made of bronze into it and mount it in an appropriately fitted holder.

- The propeller should be created according to the drawing of duralumin.Its dimensions can always be adjusted if necessary.

- Mounting the screw should be done in place of the trimmer head.Be sure to make a ring attachment to protect the cylinders.

- On the Internet you can order ready-made kits and save time on creating the elements yourself.The kit has all the necessary adapters to the shaft and drive, sometimes the kit even includes a clamp.

- The unit can be operated using the starter handle, but it is very often inconvenient to use.It can be easily replaced with a normal bicycle gear shift.

- To fix the engine a clamp is used, and the mount is made on the boat transom.

Having an engine on a boat makes life a lot easier for its owner. However, gasoline engines produce a lot of noise and consume a lot of resources. The alternative to this type of motive power. electric motors. These are quiet units that run on cheap electricity and are slightly inferior to gasoline-powered boat engines in efficiency. This version of the engine will cost cheaper, all the more, you can make an electric motor on the boat with your own hands.

In the name “electric motor” lies the essence of the device it refers to. Electric motor for boats means the unit that drives the watercraft through the movement of the blades. Its action is based on physical laws. The peculiarity of electric motors is the resource they consume to perform their functions.

Today, fuel-powered boat motors are common all over the world. Electric motor for the boat, unlike similar units, works by consuming electricity, not gasoline. Among some boat owners there is a common opinion about low efficiency of such devices. But it’s wrong. If properly designed, an electric motor can provide enough traction force to move the watercraft at normal speed.

A boat motor from a chainsaw

Boat owners are familiar with the problem of needing to get to their destination quickly or without physical effort. With a motor you can do it much faster than rowing by yourself. It is quite realistic to buy a suitable unit in the market, especially since there are a huge number of offers now. But the obstacle can be the high cost of factory boat engines. Therefore, boat owners try to get out of the situation, using homemade devices, converted from chainsaws.

The idea of using a chainsaw engine instead of a motor on a boat became real with the appearance on the market of garden tools with enough power to get the boat on the water fairly quickly. The advantage of this attachment is its low cost, the possibility of using a second-hand motor and the decent speed the boat will be able to develop.

Block: 2/10 | Characters: 873

Remaking the device

It is worth saying that such a tool as a chainsaw is successfully used in many cases in which you need to manually make a motor for something. In order to implement the conceived, you only have to make small changes in the design. When making a boat motor from a chainsaw, the number of changes made will be minimal, and therefore the device will be able to perform its main function.

But you have to choose: either a great saw or a good motor, but with little power. The main factor here will be the price. If you compare a purchased product with about the same characteristics as a motor from a chainsaw, the cost of the second version is almost three times lower.

Block: 2/12 | Number of characters: 715

Working principle

Grass trimmer has a higher blade speed, which allows you to move through the water with higher speed, which will allow you to start fishing faster than with a motor. Everyone has seen how a grass trimmer works. how it cuts the lawn and regular grass, but here, its blades are turned the other way and at the same time, performs the function of the most economical motor.

And the most important thing is that absolutely everyone can operate it. the most important thing to understand is that the higher to the surface of the water are the blades themselves, the faster the speed of turnover and thus. higher speed.

But if the grass trimmer is lower, the speed will be lower. But the most important disadvantage of trimmer compared to conventional boat motors is that they are very loud, and they should not be used at full power, if you do not want to scare the fish.

Blitz Tips

Using the trimmer for grass, as a boat motor, the operator must constantly monitor the state of the engine, and give him time to cool down.

In addition, to extend the life of the boat motor from the grass trimmer will help:

- inspection of all available fasteners in the device. before each start of the motor it is necessary to carefully inspect the fasteners, which hold the elements of the engine from the grass trimmer;

- filling the engine from the grass trimmer only with the gasoline and oil that was used to operate the brushcutter;

- timely cleaning and replacement of the engine air and fuel filter

- regular check and timely replacement of the fuel pump

- inspection and, if necessary, replacement of the spark plug.

To extend the life of the grass trimmer boat engine, regular venting of its regular cylinder will also help. To do this, you should unscrew the spark plug about every 2 months, and rarely pull the starter rope 4-5 times. After the procedure, the candle can be screwed back into place and continue operating the engine.

Finishing assembling

Another important point will be the assembly of the swivel assembly for the homemade boat motor. In order to successfully complete this stage, you will need a metal tube, the diameter of which will be slightly larger than the diameter of the shaft. Also a piece should have an angle welded to fix the rail. You will also need the guide itself, a hollow hexagon, a metal rod with the right diameter. The last necessary part is a metal workpiece, cut from a material with a rectangular cross section, and also having holes in the ends for fixing the rod.

Another important step is to carry out the adaptation of the gearbox shaft to the existing screw. It is best to remove this small element from an old motor, making it with your own hands is problematic.

After the screw and the shaft of the gearbox have been connected by means of a stud, you can proceed to the final step. Transmission oil is poured into the gearbox, the installed shaft and cover are fixed with sealant.

Model with protected gearbox

Boat motors with a protected gearbox are nowadays quite popular. In order to assemble them yourself, you need to pick up a motor of at least 3 kW. The starter is suitable as a manual starter. First of all, the motor clamp is cut out. Only then can the fuel system be installed. Thermostat can be mounted on the rocker if desired.

The next step is to fit the gearbox. The rocker arm can be padded to prevent jerking during operation. The pushrods are installed on the pallet, and this will require the use of a welding machine. It is important to secure the top rod under the clamp. In order that the pressure does not deform the pallet, many experts advise installing additional supports.

Prepared a set of nozzles

Now sell special attachments for converting the grass trimmer into a boat motor. This attachment includes everything you need to attach the gas cable to the engine. On the boom mounted control knob and pushbutton switch. The throttle grip is made with a gear shift option and has a ratchet that locks the desired position.

The kit includes a device for mounting the device on the boat. The attachment on the grass trimmer can be assembled easily, it has a simple design. To reassemble, attach the throttle cable to the motor and then secure the muffler cable. The attachment costs about 5 thousand in a specialized store. rubles.

Motor for a boat with their own hands

You can perform a homemade boat motor from a grass trimmer. First you should prepare materials and tools:

- 3L grass trimmer.с.;

- 2 mm thick steel plate for the propeller;

- welder;

- mounts;

- screw clamp to mount the motor on the side of the boat;

- Angle grinder;

- drill.

Before working, you need to create drawings showing all the dimensions, the parts and assemblies required for the work, as well as the scheme and order of installation.

You need to figure out the size of the propeller, which depends on the power and weight of the boat with cargo. It is necessary to take into account that a propeller with dimensions of 3×10 cm, mounted on an ICE, can carry a boat with passengers with a total weight of up to 120 kg.

Stages of work to make a motor from a gasoline mower:

- To make a motor for a boat, you must first remake the bent shaft.

- Then make a propeller.

- Replace the plastic motor cover with a switch.

- Attach the shaft to the motor from the mower.

Redoing the bent shaft

First you need to remake the bent shaft. To do this, you need to take a nut with a height of 2 cm in the form of a cylinder with a notch inside. Unscrewed nuts and bolts must be kept because they have non-standard threads. Then remake the rod with a rigid shaft. Pull out the flexible shaft from the rod by removing the nut.

The end of the rod has no bearings, the sleeve replaces them, so it must be cut out. Remove the tread. Since the metal tube is bent, it is difficult to align it, so it will not be used. It should be replaced by a dural tube of the same diameter or smaller than the bushing.

A bronze bushing is inserted into the tube. To do this, bore the tube slightly. Then gently tap the bushing into the groove with a hammer. It is not advisable to use force in order to prevent the sleeve from being damaged. The tread is cut to the proper diameter and fitted to the rod. If the tube has a large diameter and it is difficult to put it in the opening of the ICE head, you should grind it to the necessary size.

Instead of a flexible shaft, take a steel bar and connect it to the motor shaft. Then a screw is screwed into the shaft and secured with a nut. Then you need to fix the rod with the inner shaft to the motor with the adapters. They need to be made in a lathe workshop. Different mower models may have special features that need to be taken into account.

Using the gearbox from the angle grinder

The gearbox from an angle grinder is often used to make a haymower-based boat engine. It needs to be reworked. The shaft with the gear must be replaced with a longer one, which will match the rod. The end of the shaft is made similar to the extracted short shaft so that the same bearings can be used.

In the places where the bearing is installed, mount the gasket, which will protect the bevel gear from water. The gearbox housing is screwed together with sealant. Pour grease into the gearbox to cover the gears.

Making the propeller

To create the screw you need a 100 mm long and 30 mm wide strip of duralumin. If you put the screw on the table, from it to the blade should be 10 mm. The angle of the propeller blades should be adjusted with pliers. Before this, perform annealing of dural. You can make propellers with 2 or 3 blades, different sizes. The dimensions of the propeller should be selected individually.

Motor for a boat with your own hands

You can make a homemade boat motor from a grass trimmer. First you should prepare the materials and tools:

- Grass trimmer with a capacity of 3 liters.с.;

- 2 mm thick steel plate for the propeller;

- welding machine;

- fasteners;

- clamp for installing the motor on the side of the boat;

- angle grinder;

- drill.

Before the work, you need to create drawings with all the dimensions, necessary parts and assemblies for the work, as well as the scheme and order of installation.

You need to figure out the size of the propeller, which depends on the power and weight of the boat with cargo. It should be taken into account that a propeller with dimensions 3×10 cm, mounted on the engine, can carry a boat with passengers with a total weight of up to 120 kg.

Stages of work to make a motor from a gasoline mower:

- To make a motor for a boat, you must first redo the bent shaft.

- Then make a screw.

- Replace the plastic motor cover with the switch.

- Attach the shaft to the motor from the mower.

Redoing the bent shaft

First you need to rebuild the bent shaft. To do this you need a 2 cm high cylinder shaped nut with a slit inside. Keep the nuts and bolts that have been unscrewed, because their threads are not standardized. Then redo the rod with a rigid shaft. Pull the flexible shaft out of the rod by removing the nut.

The end of the shaft has no bearings, but is replaced by a sleeve, so cut it out. Remove the tread. Since the metal tube is bent, it is difficult to align it, so it will not be used. Instead of it, find a dural tube of the same diameter, or smaller than the diameter of the sleeve.

Place the bronze bushing in the pipe. To do this you need to slightly bore the tube. Then carefully press the bushing through the groove with a hammer. At the same time, it is not recommended to exert force so that the bushing does not deteriorate. The tread is cut to the desired diameter and put in the rod. If the tube has a large diameter and it is difficult to put it in the hole of the head of the internal combustion engine, you should grind it to the necessary size.

Use a steel bar instead of a flexible shaft and connect it to the motor shaft. Then a screw is screwed on the shaft and secured with a nut. Then fix the rod with the inner shaft to the motor by means of adapters. They need to be made in a lathe workshop. Different mower models may have special features that need to be taken into account.

Using the gearbox from an angle grinder

To create a boat engine on the basis of a haymaker often use a gearbox from an angle grinder. It must be reworked. The shaft with the gear must be replaced with a longer one, which will fit the rod. The shaft end is made similar to the removed short shaft so that the same bearings can be used.

In the places where the bearing is installed, mount a gland, which will protect the bevel gear from water. The gear housing is twisted with sealant. In the gearbox is poured grease to cover the gears.

Making a propeller

To build the propeller you need a dural strip 100 mm long and 30 mm wide. If you put the propeller on the table, there should be 10 mm from the propeller to the blade. Adjust the angle of the propeller blades with the pliers. Before that, the dural is annealed. You can make propellers with 2 or 3 blades of different sizes. The dimensions of the propeller have to be selected individually.

How to make a boat motor with your own hands from a trimmer for grass?

To create a boat motor from a lawnmower, a tool with a straight boom will do. If the grass trimmer’s boom is curved. you have to work on improving it.

The modification is made according to the following algorithm:

-

First remove the standard nut (marked with number 2 in the drawing below). Do not throw it away or lose it, since it is impossible to replace the factory parts with ordinary nuts.

If it is not possible to buy a ready-made set for the remodeling, which was mentioned earlier, the adjusting handle can be taken from a sports bike handle.

You can also make a screw yourself from a piece of duralumin using the drawing below:

The pitch is the distance from the blade to the horizontal surface. Adjust the tilt angle with the pliers. To do this, the workpiece is preheated.

For filling the motor from the grass trimmer on the boat use only high-quality fuel and lubricants. Dilute petrol with oil in an appropriate proportion. Do not subject the engine to high loads for the first 10 kilometers. this will be the running-in period. Depending on the capacity of the engine, a boat with such a motor can develop a speed of 5 to 8 km / h.

Below is a video, which demonstrates the work of such a unit:

What are self-made engines for boats made of?

Some products will do, even defective ones, but only if they have a working motor. Even if you buy a new gasoline mower or an electric screwdriver, it will be much cheaper than a new boat motor, the only thing left is to modify the product a little. The financial issue turns out to be the main in solving this problem, otherwise every boat would have a motor.

- To make a boat motor with an electric motor you will need to buy an electric screwdriver or an electric drill on rechargeable batteries. It is possible that someone has a damaged electric screwdriver or drill lying around in the shed or garage. An electric screwdriver is preferred because its output speed is not as high.

- Naturally, the batteries that are installed on electric devices are not powerful enough to move around the pond for a long time. In this case a 12 V car battery will do. Naturally, you need to buy devices for the same operating voltage. An electric motor of 300 W is enough power to move the boat around the pond with a load.

- It is also necessary to solve the problem of reducing the speed of the electric device. In this case you need a gearbox. This is especially true when using an electric drill.

- You will also have to make or buy a drive shaft and propeller. The advantage of an electric boat motor is that it is silent. In addition, the repair of such a motor will cost much cheaper than the repair of a classic boat motor.

- Gasoline engines are much more powerful, so they can significantly increase the catching area. In addition, their power does not drop, as with electric motors, and the battery has a significant weight and takes usable space. You can use power units from brush cutters, tillers, chainsaws, etc. д. You should choose according to your finances, the size of your boat, and what kind of gear you have.

- Grass trimmers are best suited for such purposes, as they require minimal modifications. It is enough to replace the device where the line for the trimmer is attached and install a propeller, as the motor is already ready and it can be used.

- Other power devices require more serious modifications, because a gearbox, shaft and propeller will be needed. In addition, they need to be connected together.

On a side note! Some fishermen use a motor cultivator, removing the cutters and installing primitive propeller blades in their place.

In addition to making the motor, you should think about how to fix it to the boat. The thing is that not every boat has a transom and not every boat is suitable for installation of a motor. It is especially difficult to install such a device on a rubber inflatable boat.

Boat motor from an electric screwdriver

Screwdrivers are best suited for making motors for the boat. You should choose a device with operating voltage of 12 V, so you can install a car battery with a capacity of 45-55 ampere-hours. It’s elementary to modify the device.

Lifting gear

The purpose of the lifting mechanism is to move the motor in different planes, both horizontal and vertical, in order not only to operate the watercraft, but also to be able to lift the motor out of the water. The simplest design is the clamping system that attaches the electric screwdriver to the hoist. The hoist must be rigidly attached to the boat, especially if the boat is rubber. There should be rings on the clamps, through which the tube passes, and inside the tube there is a shaft made of a steel rod of suitable diameter. To make it slide easily, bearings are installed inside the tube.

Gear and propeller

An electric screwdriver has a high rotation speed, but you don’t need it for the homemade electric motor for the boat, that’s why you need a reducer. Gearbox from an angle grinder is the most suitable option. To mount the gearbox, the upper part of its shaft is simply clamped in the chuck of an electric screwdriver.

You will also need a propeller, which is better to make of stainless steel, 2.5-3.0 mm thick. Do not use aluminum or plastic.

- First of all, a square billet is cut, with dimensions of 30×30 cm.

- In the center of the workpiece is marked out a square of 5×5 cm and diagonal lines are drawn through the corners. Along these lines it is necessary to cut the workpiece to a small square.

- The 4 resulting blades are rounded and turned at an angle of 30 degrees.

- In the center of the product need to drill a hole for mounting on the gearbox.

- After that, the propeller is set in its place and fastened securely.

Motor for a boat with my own hands

You can make a homemade boat motor from a grass trimmer. First you need to prepare the materials and tools:

- 3L grass trimmer.с.;

- 2 mm thick steel plate for the propeller;

- welding machine;

- mounts;

- A clamp for mounting the engine on the side of the boat;

- angle grinder;

- drill.

Before the work, you need to create drawings with all the dimensions, parts and assemblies required for the work, as well as the scheme and order of installation.

It is necessary to find out the size of the propeller, which depends on the power and weight of the boat with the load. It should be taken into account that a propeller with dimensions of 3×10 cm, mounted on the engine, can carry a boat with passengers with a total weight of up to 120 kg.

Stages of work to make a motor from a gasoline mower:

- To make a motor for a boat, you must first redo the bent shaft.

- Then make a propeller.

- Replace the plastic engine cover with a switch.

- Attach the shaft to the engine from the mower.

rebuilding the bent shaft

First we need to modify the curved shaft. To do this, you need to take a nut 2 cm high in the form of a cylinder with a notch inside. Keep the nuts and bolts that were unscrewed because their threads are not standardized. Then redo the rod with the rigid shaft. Pull the flexible shaft out of the rod by removing the nut.

The end of the rod has no bearings and is replaced by a sleeve, so it must be cut out. Remove the tread. Since the metal pipe is bent, it is difficult to straighten it, so it will not be used. It should be replaced by a dural tube of the same diameter or smaller than the diameter of the sleeve.

Place the bronze sleeve in the pipe. To do this, bore the tube slightly. Then carefully press the bushing into the groove with a hammer. It is not recommended that you force the bushing so that it doesn’t become damaged. The tread should be cut to the right diameter and fitted to the rod. If the tube has a large diameter and it is difficult to put it in the hole of the ICE head, you should grind it to the required size.

Take a steel bar instead of a flexible shaft and connect it to the motor shaft. Then a screw is screwed onto the shaft and secured with a nut. Then you need to fix the rod with the inner shaft to the engine by means of adapters. These must be made in a lathe workshop. Different mower models may have peculiarities that must be taken into account.

Using the gearbox from an angle grinder

To create a motor for a boat on the basis of a haymaker, the gearbox from an angle grinder is often used. It needs to be modified. The shaft with pinion must be replaced with a longer one, which will correspond to the rod. The end of the shaft is made in the same way as the removed short shaft, so that the same bearings can be used.

In the places where the bearing is installed, an oil seal is mounted, which will protect the angle reducer from water ingress. The gear case is screwed together with sealant. The gearbox is filled with grease to coat the gears.

Making the propeller

To create the propeller you need a 100 mm long and 30 mm wide strip of dural. If you put the propeller on the table, there should be 10 mm from the propeller to the blade. The angle of the propeller blades should be adjusted with the pliers. Before this perform annealing dural. You can make propellers with 2 or 3 blades, different sizes. Propeller size should be selected individually.

Hunting and Fishing Community Blog About the boat motor

Good day brothers anglers! Found this miracle on the Internet! The design is not complicated, but there are a lot of questions. Can someone use this and can share their experiences. And another question: is it necessary to register this device in the RB as a boat motor. Thank you all!

Комментарии и мнения владельцев 41

So, a foot from the wind with a propeller plus a four-stroke engine with five horsepower and you’ll be happy!

And at what speeds does it have power? On the propeller to 2500 at rated should get. What to reduce? What is its torque characteristic?? The closer to a diesel motor, the better. In general, I think this is bullshit.

I support those who are against this miracle motor.It is better to be patient and buy a normal, at least 5 hp, or better yet 15 hp (if the boat will allow)

I work in the service of a garden. I used to haul Chinese boat motors in the summer, but the noise was so loud. Met this device, a good thing, though air cooling is not a problem, if you look at the summer in the city maintenance workers are running around with trimmers all day mowing and nothing boils and the motors do not break. This motor has 3.8 force, if someone in the garden has a simple gasoline trimmer you can buy a simple boot and operate the same way (I found the boot at a price of 8 500rub.) it will be enough on the small rivers. you should not expect anything more. contacted the service and talked to a mechanic who services these motors. Surprisingly, I have not heard any bad reviews from him. The price of this motor is 11 500 rubles. Now my acquaintance is going to buy this motor and we will test it in practice. Good luck to all

I have a STIHL chainsaw attachment for the ice drill.Use it sometimes at the end of the winter. You know, I’m satisfied)))! When I first joined the water-powered hobby, I also considered buying a similar device for the boat motor and reviewed a bunch of options, but in the end, I still took a scooter on 2.5 л.с. And then, the race to “armaments” has done its work.After 3 years, already a Yamaha 15, and a bigger boat ). If you decide to buy it, I’ll send you your reports.).

Wasted money because the engine is air cooled. Sails this thing slow. And in the heat, 32 in the sun, moments will boil over. I would rather have a used motor or a new one from china. I got a HDX 4 HP

Wasted money. Buy a normal motor.

Made pretty good quality, starts up without a problem. Economical, convenient “automatic transmission”. Of the disadvantages. roars so that temporarily lost hearing in one ear. Making it quieter is not possible. The speed on my boat is about 8 km/hour. Strongly noises gearbox, or clutch mechanism as it heats up, when it collapses I do not know, drove 10-20 km. There’s a live photo here: www.drive2.You should not start with a 5 horse minimum

Oh, man! class! I liked it with the flipper. And the Комментарии и мнения владельцев on there are a bunch of bullshit

found this miracle on the paddle faster however, gasoline only pulls gasoline ))))

I’ve just heard of men getting one of these for a STIHL chainsaw.But it’s not my thing

It’s noisy all the fish inspectors are gonna come running!

I myself have dealt with a similar issue, so neither this nor the 2.5 horsepower, start with 5 horses at least

I saw a guy on a PVC boat with this, he passed me in five meters, I almost deafened and the fish after him went somewhere.

No, it’s not worth it, a friend of mine had one, it’s too loud and it doesn’t drive a damn thing!Koresh sold it in a week and bought himself a Chinese Yamarin motor.

The engine is from a lawn mower. I have a lawn mower like this for grass 3.3hp.according to the passport. a light rubber band might be a good idea. But there’s something cooler !(

) Watch it carefully, it took me three days to come to my senses.

I read the commentary on the video. It’s even more fun.

you can think of so many variants, cut off a cow’s leg and you can swim as long as you have a reflex))

Engine from a lawnmower. I have a mower for grass 3.3 hp.according to the datasheet. on a lightweight rubber, it’s probably safe to put. but there’s a better one !(

) to watch carefully, I couldn’t get it up for three days.

It’s a lawn mower engine. I have a grass scythe 3.3 hp.by passport. you could probably put it on a light rubber band. but there’s a cooler thing !(

) watch carefully I couldn’t come to my senses for three days.

Thanks!I didn’t expect such a cool idea, our ingenuity we are unbeatable!I haven’t laughed so hard in a long time!

The engine is from a lawn mower. I have such a scythe for grass 3.3 hp.from the passport. on a light rubber band, it’s probably a good idea. but there’s a cooler thing !(

) watch carefully I could not come to my senses for three days.

The engine is from a lawn mower. I have this grass trimmer 3.3hp.according to the passport. I have a lightweight rubber. but there’s something cooler !(

) I couldn’t get out of it for three days.

The engine from the lawnmower. I have a grass mower like this 3.3hp.according to the passport. on a lightweight rubber band is probably a good bet. But there’s a cooler thing !(

) watch carefully I could not come to my senses for three days.

Website gardentool.under gasoline grass trimmers.

I once saw a man floating on a rubber band. Funny. It should be used only as a helicopter!