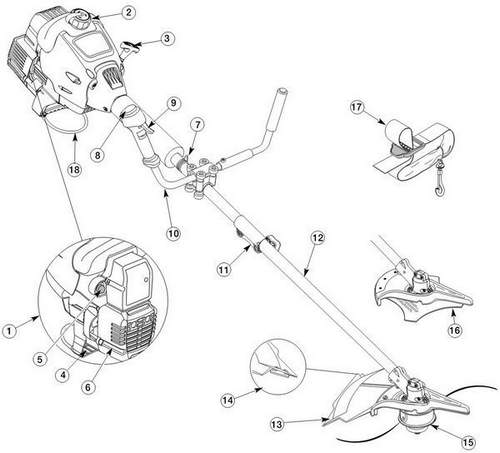

MTD 2-Stroke Trimmer (AST Prime 790 Series) & Pull). Trimmer Assembly

Assembly

Installation and adjustment of the control handle.

- Position the control handle between the upper and middle parts of the mount (see Fig. 1).

- Holding all three parts of the mount together, insert four (4) screws into the holes in the upper and middle parts of the mount.

Note: The holes in the upper and lower parts of the mount will only be aligned when the product is properly assembled. - Position the top and middle mounts, as well as the control handle, above the boom. The bottom of the mount is located on the bottom of the boom.

- Hold hex nuts in the grooves of the bottom of the mount with your fingers. Bolt the nuts with a Phillips screwdriver (not supplied). To adjust the position of the control handle, do not tighten the fastening screws.

- While holding the product in the working position (see. Fig. 20), set the control handle to the position providing maximum comfort during work.

- Tighten the screws that secure the control handle until it is securely locked.

INSTALLATION AND ADJUSTMENT OF THE SHOULDER BELT.

- Pass the end of the belt through the central slot of the buckle (see. Fig. 3).

- Insert the end of the belt into the second slot of the buckle.

- Hook the collar to secure the shoulder strap (see. Fig. 4) located on the bar. Adjust the length of the belt.

USING THE EZ-LINK ™ SYSTEM.

Note. For ease of removal and installation of additional nozzles, place the product on a flat surface. Detach lower boom with working

body or with an additional nozzle.

- Loosen the clamping handle (see fig. 7) by unscrewing it counterclockwise.

- Press the lock button (see Fig. 7) and hold it in this state.

- Holding the upper bar with one hand, disconnect the lower bar with the working body or with an additional nozzle (see. Fig. 8).

Installation of the lower bar with a working body or with an additional nozzle.

- Loosen the clamping handle (see fig. 7) by unscrewing it counterclockwise.

- Align the lower bar with the upper bar (see fig. 8). In this case, the locking button should lock (snap) in the hole of the coupling.

Note. To facilitate installation, align the locking button with the locking button guide (see. Fig. 7) of the coupling. - Tighten the clamping handle by twisting it clockwise (see Fig. 9). Before operation, always check the tightness of the clamping handle of the coupling.

Removing and installing protective cover.

When using the product with a cutting knife, the protective cover must be removed. Use a slotted screwdriver to remove the protective cover. Remove the three (3) screws securing the protective cover to the caliper (see. Fig. 10). Save the removed parts for future reference. Install the protective cover when using the product with a reel with trimmer fishing line. To install the protective cover, attach it to the caliper using three (3) screws. Tighten the screws securely using a slotted screwdriver (see fig. 10).

REMOVING THE COIL FROM THE TRIMMER FOREST AND INSTALLING THE CUTTING KNIFE.

Warning: For ease of removal and installation of the cutting knife or reel with the trimmer line, place the product on a flat surface. Removing the reel with trimmer fishing line. Note. Install the cutting knife in the protective cover first.

Video: Attaching a Protective Cover to a Trimmer

- Align the hole in the shaft hub with the hole in the gear cup (see fig. 11).

- Insert the locking rod into the hole of the gearbox cup (see fig. 12).

- While holding the stopper rod, unscrew the reel with the trimmer line by turning it clockwise (see Fig. 13). Save the reel for future reference.

Installing a cutting knife. - Remove the protective cover from the product (see section "Removing and installing protective cover")

- Install the cutting knife on the shaft hub (see fig. 14).

- Center the cutting knife on the shaft hub (see fig. 14).

- Make sure that the cutting knife is centered and lies flat on the shaft hub.

- Align the hole in the shaft hub with the hole in the gear cup (see fig. 11).

- Install the lock washer and nut on the shaft (see fig. 14). Be sure to install the cutting knife correctly.

- While holding the locking rod with one hand, tighten the nut with a wrench, turning it counterclockwise (see Fig. 15). When using a torque wrench, the tightening torque should be: 37-38 Nm. / 325-335 in-lb / 27-28 ft. lb.

If there is no torque wrench, use a 5/8 adjustable spanner (wrench). Tighten the nut until the retaining washer is firmly pressed against the cutting knife, and then additionally pull the nut counter-clockwise to U4-U2 (see Fig. 15). - Take out a lock core.

- Remove the cutting knife from the protective cover.

REMOVING THE CUTTING KNIFE AND INSTALLING THE COIL WITH TRIMMER FISHING LINE.

Removing the cutting knife.

- Install the cutting knife in the protective cover.

- Align the hole in the shaft hub with the hole in the gear cup (see fig. 11).

- Insert the locking rod into the hole of the gearbox cup (see fig. 12).

- While holding the locking rod with one hand, unscrew the nut securing the knife, turning it clockwise using a 5/8 adjustable (wrench) wrench (see Fig. 16).

- Remove the nut, washer and cutting knife. Save the cutting knife and nut for future use. Keep the cutting knife out of the reach of children.

Installing a reel with trimmer fishing line. - Align the hole in the shaft hub with the hole in the gear cup. Insert the locking rod into the hole of the gearbox cup (see fig. 11). Install the locking washer on the shaft with the flat side to the shaft hub (see Fig. 13). Screw the reel with the trimmer line onto the shaft by turning it counterclockwise. Tighten the reel by hand.

Note. For correct operation of the reel with trimmer fishing line, it is necessary to correctly install a locking washer on the shaft. - Take out a lock core.

- Install the protective cover, (see section "Removing and installing protective cover")

USE OF GASOLINE AND OIL.

Recommended oil type.

It is recommended to use high-quality oil designed for 2-stroke air-cooled engines that meets the classification according to API ТС, TSC-3 (with marking "For garden equipment with a 2-stroke engine") When preparing the fuel mixture, use a 40: 1 gasoline / oil ratio (2.5%). Do not use oil for outboard motors, motorcycles, etc.

Recommended type of gasoline.

Warning. Under certain conditions, gasoline is extremely flammable and explosive.

- Refuel the product with fuel mixture only in well-ventilated areas and with the engine turned off. Do not smoke when refueling; keep all sources of fire away from the fuel tank or gas tank.

- Do not overfill the fuel tank with fuel mixture (fuel mixture should not be visible in the inlet pipe). After filling the fuel tank, make sure that the fuel cap is closed and tightened securely.

- Do not spill fuel mixture while filling the fuel tank. Spilled fuel mixture or its vapors may ignite. If the fuel mixture has been spilled, wipe the surface dry before starting the engine.

- Take measures to prevent prolonged exposure to vapors on the skin of the body or from inhalation.

Always use clean, fresh, unleaded gasoline (stored for no more than 60 days).

Refueling

- Unscrew the fuel cap.

- Pour clean, fresh fuel mixture into the tank. Do not overfill.

- Tighten the cap on the neck of the fuel tank.

- Move the product from a gas station or gas canister approximately 10 meters before starting the engine.

The use of gasoline and oil.

An old and / or improperly prepared fuel mixture is the main reason for the unstable operation of the engine, as well as its failure. Be sure to use a clean, fresh fuel mixture. Strictly follow the recommendations of the instruction manual when choosing the ratio of gasoline / oil. When preparing the fuel mixture, use a 40: 1 gasoline / oil ratio (2.5%). Use a special container to mix gasoline with oil. Do not mix gasoline with oil directly in the product’s fuel tank.