An angle grinder is an angle grinder (angle grinder), which is a power tool used for cutting stone and metal, as well as for treating various surfaces. Despite the fact that this device is rarely used, sometimes it is simply impossible to do without it.

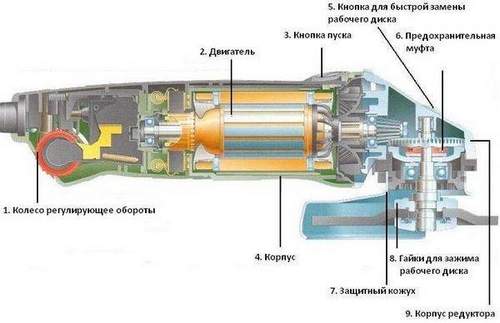

Figure 1. Angle grinder device.

In the modern market of construction power tools, an angle grinder is represented by various brands that differ from each other both in technical characteristics and in terms of use. Therefore, the choice of angle grinder must be carried out taking into account some factors, which somewhat complicates the matter. Next, we will consider how to choose the right angle grinder.

Device and principle of operation angle grinder

At different manufacturers, the layout of this device may differ slightly, but the principle of its operation remains the same (Fig. 1). The main components of an angle grinder are:

- Two-piece housing

- electric motor of a certain power;

- reducer designed to rotate the disk;

- Electronics, which include: a system of support for constant revolutions under load, a soft start system, a start button, etc.

With the help of electricity, the engine of the apparatus is operated. Through a special gear, the rotation of the engine is transmitted to a steel shaft to which a grinding or cutting wheel is attached. High quality cutting work depends on the number of revolutions of the disk in 1 min.

Types of angle grinders

Angle grinders are professional and for home use.

The angle grinder, like the rest of the construction tool, is divided into household (for home use) and professional. Units of the first type have some differences from those intended for use in large-scale construction work. Household angle grinders have less power and dimensions, and their additional functions are somewhat simplified compared to professional devices. In this regard, their performance is much lower, due to the need to stop the work of an angle grinder for its cooling after a certain period of time. Because of this, a professional tool can cost an order of magnitude more expensive than a household one.

The main features of a professional-angle angle grinder include:

- high power value (more than 1.5 kW);

- high wear resistance of component parts, which significantly increases the operational life of the apparatus;

- low probability of overheating;

- heavy weight, which is associated with the presence of additional nodes and a high-strength frame;

- additional functions with which the operation of the device is greatly simplified.

Usually, an angle grinder is sold in a case with protective equipment and various nozzles.

All angle grinders are also divided into one-handed and two-handed. The first type has a power that usually does not exceed 1500 watts. Such devices are conveniently used both for grinding and for cutting purposes. Some one-handed models have a speed adjustment function, which is more important for those who carry out grinding work. This device in terms of price and quality is excellent for household needs. The main advantages include mobility, low cost and ease of operation.

The power of a two-handed angle grinder lies in the range of 2000-2700 W, which allows cutting concrete, brick, hardened steel, etc. without any problems. Two-handed models are superior to one-handed ones in almost all respects, and therefore they are heavier and more expensive. Such devices are preferably used for professional purposes.

The main characteristics of grinders

Answering the question of how to choose the right angle grinder, it is worth considering some characteristics of this tool, which determine its functionality and practicality. Of these characteristics, it should be distinguished:

- Diameter of nozzle used.

- Power.

- Rotational speed.

- Temporary resource of work.

- Availability of additional features.

Video: Choice Angle Grinder 125 Variable Speed

The diameter of the nozzle is one of the main criteria when choosing an angle grinder. The thickness of the material that can be cut depends on this parameter. Circles for an angle grinder can have a diameter of 115 to 230 mm. The maximum diameter depends on the power of the device: a more powerful unit allows you to work with a larger nozzle.

In many angle grinders there is a speed controller.

115 mm angle grinder is suitable for the lightest work. Cutting with such a nozzle will be inconvenient, therefore it is used for grinding work. The next largest diameter is a 125 mm circle. Such an angle grinder has small dimensions and weight, as well as good performance. It will be convenient to grind and cut with such a tool. However, she will not be able to master too thick parts. This is the best choice for domestic needs.

150 and 180 mm angle grinders can already be used in construction work. With such nozzles, you can cut a brick and a thick pipe, although in the first case, the material must be cut on both sides.

Nozzles at 230 mm are the maximum possible. With their help, without much effort, you can cut a brick, pipe, tile, etc., but they are not suitable for grinding work. In this case, a lot of weight and power will not play into your hands. Such devices are recommended to be purchased for capital repairs and construction works.

Power. The power range of grinders is very large: from 0.6 to 2.7 kW. Devices with a 115 mm disk are produced with a power of 0.6-1.0 kW. angle grinder with a disk of 125 mm can have a power of 0.75-1.5 kW. In most cases, low-power products have a small number of additional functions and are not intended for long-term use.

angle grinder with a circle of 180-230 mm belong to tools with high power (1.5-2.7 kW). For cutting massive elements of stone, concrete and steel, the power of the unit must be at least 2 kW. But for grinding and cutting small parts made of plastic, sheet metal and wood, 0.7-1.0 kW is enough.

The larger this value, the longer it will work under load.

Power must be selected taking into account the duration, complexity of work and the diameter of the disk to be used.

angle grinders are divided by power, nozzle diameters and rotation speed.

For example, to grind a weld, you can use an angle grinder with a power of at least 1000 watts.

The rotation speed shows how many revolutions per minute the spindle makes the angle grinder and the nozzle used. This value can range from 2800 to 11000 rpm. over, the smaller the disk, the greater the speed you can use. For example, at a speed of 11000 rpm you can work with nozzles with a diameter of 115 mm, and at a speed of 6000 rpm. with a diameter of 200-230 mm. Exceeding the permissible speed can lead to destruction of the nozzle and damage the device.

Almost all modern models have a speed control function. Adjustment is carried out using a special controller, which allows you to reduce or increase the speed of rotation of the spindle.

Additional functions of grinders

Additional functions are different, the cost of the tool depends on their availability. These include:

Disk sets from 125 to 230 mm.

- smooth inclusion, allowing the angle grinder to slowly gain momentum, this significantly increases its service life, since when you turn on there is no sharp jump in speed;

- anti-jamming protection function: if jamming occurs, the power tool will automatically turn off;

- adjusting the position of the handle is quite useful for lefties;

- the speed control function allows you to set the optimal spindle speed for cutting or grinding various materials, which helps to save electricity and consumables;

- protection against secondary operation is needed in case of power failure, when the angle grinder is simply forgotten to turn off;

- maintaining a constant number of revolutions becomes indispensable in labor-intensive work;

- vibration damping function during operation is useful for powerful devices, which can improve comfort during operation of the tool;

- the ability to quickly change the disk.

Models and Manufacturers

It’s quite difficult to navigate and choose the right option in today’s abundance of models. The only thing that can be recommended is not to buy cheap Chinese fakes.

Domestic angle grinders (for example, Interskol company) are slightly inferior to world famous brands (Bosh, Kress, Metabo, Makita), but at the same time they are much superior to their Chinese counterparts. Therefore, when choosing a particular model, special attention should be paid to proven and well-established firms.

Recommendations for working with angle grinder

An angle grinder is a rather dangerous power tool, therefore, to avoid various injuries, some recommendations should be followed:

When working with an angle grinder, you should protect your face and hands.

- Work in a protective plastic shield, otherwise metal filings can damage your eyes.

- Hands should be protected by tight leather gloves.

- There should not be paper, rags, or flammable substances near the workplace, because sparks can set them on fire, resulting in a fire.

- It is necessary to avoid situations where the cutting disc can jam in the material being cut, as this will lead to the tearing of the angle grinder from the hands and damage to the disc.

- It is not necessary to use a disk of larger diameter during operation than is allowed by the design of the device.

- Metal scouring can only be carried out with an abrasive wheel with a thickness of more than 6 mm.

If, when choosing an angle grinder, the operating conditions are fully taken into account and all operational characteristics are correctly selected, then you can be sure that such a device will work much longer than the warranty period.