The main types of breakdowns and methods of their elimination

Before starting work on the diagnosis of malfunctions and their elimination, it is necessary to prepare the necessary tools.

Сборка двигателя бензопилы штиль stihl ms 180 Assembling the engine chainsaw calm stihl ms 180

General view of the Stihl MS 180 chainsaw with the main units

Due to the fact that the chainsaw is a relatively simple unit, the list of accessories includes the following items:

- a set of flat and Phillips screwdrivers;

- open-end locksmith keys;

- candle key;

- set of socket heads with a knob

- Stihl Multifunctional Tool.

Multifunctional tool calm

In order to qualitatively eliminate the emerging breakdowns and restore operational indicators, it is necessary to establish as accurately as possible the malfunction preceding the unit failure. Following from the fact that the chainsaw is equipped with an internal combustion engine (ICE), the main causes of breakdowns should be primarily looked for in the power unit.

Before starting work, it is necessary to turn off the engine, allow it to cool down and exclude the possible start of the chainsaw. It is recommended to wear cotton gloves to protect your fingers.

The most common faults when repairing a chainsaw calm 180 include:

- the engine does not start;

- the operation of the motor is intermittent, with a short operation of the chainsaw, it spontaneously stalls;

- oil leaks near the chain lubrication mechanism;

- engine does not develop full power.

Frequent breakdowns of the transmission part of the saw include rupture of the chain links. You can independently restore its integrity by riveting links or replacing with a new one.

Despite the relative simplicity of the design and the absence of complex mechanisms, experts recommend searching for faults in a specific order. First of all, the presence of a mixture in the fuel tank is checked, and if everything is in order with the liquid level, it is necessary to proceed to inspect the chainsaw starting unit. If this mechanism is also in normal condition, you need to check the performance of the spark plug.

After the performed manipulations to diagnose the spark plug (determining the presence or absence of carbon deposits, the correct gap between the electrodes, the state of the sealing ring), we turn our attention to the carburetor. Small sawdust, dust and soil particles often clog the fuel system.

If cleaning the carburetor of the stihl 180 chainsaw did not help to restore the previous performance of the unit, the reason probably lies in the cylinder-piston group (CPG). The power unit belongs to the most complex mechanism of the tool, the diagnosis of which requires almost complete disassembly.

Chainsaw malfunctions and repair calm

Do-it-yourself diagnostics and repair of the Stihl 180 chainsaw

Despite the many varieties of modern building materials, wood remains the most demanded. In this regard, chainsaws are in great demand among fellers, owners of their own houses and summer residents.

Among the huge variability of the model range, the most popular among both amateurs and experienced foresters for many years has been the calm 180 chainsaw, which is distinguished by its simple maintenance, repair and operation. The Stihl company was founded more than 9 centuries ago and began production of gasoline chain saws back in 1926. Thanks to many innovations, simplicity and durability, the tools of this manufacturer are in demand on the world market of woodworking equipment.

Failures in the lubrication system of the chainsaw 180: causes and repairs

In the process of sawing wood, the cutting part of the tool is subjected to high loads. In order to reduce frictional forces and subsequent wear of the chain, the chainsaw is equipped with a lubrication system that gradually supplies oil to the tire. The rapid loss of cutting properties by the teeth and the absence of traces of lubricant may indicate its leakage or clogging of the pipes.

Stihl 180 chain lubrication principle

First of all, when diagnosing the chain lubrication system for the ms 180 chainsaw, we pay attention to the oil supply hoses and their fixation points. Damaged connections cannot be repaired and must therefore be replaced. The oil channels can be cleaned with compressed air. For these purposes, we use a compressor or an ordinary car hand pump.

Due to its ease of operation and repair, the chainsaw of this model has gained wide recognition among professionals and amateurs in the field of woodworking.

How to disassemble and assemble a Stihl chainsaw

Before disassembling the individual elements of the Stihl chainsaw, you need to do preparatory work: remove the side lattice cover on the body, the chain and the guide bar. Next, clean the entire body of dirt, oil-gasoline deposits, adhering sawdust. If somewhere there are many oil smudges and mechanical cleaning fails to remove them qualitatively, you should use kerosene, gasoline or VD-40.

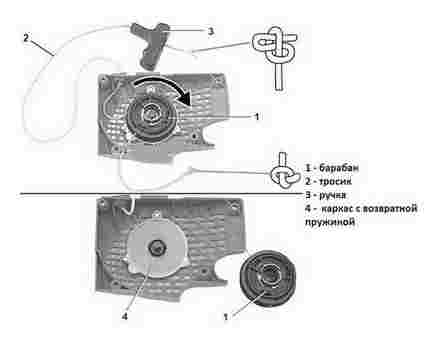

Remove the starter

When the upper cover of the Stihl chainsaw is dismantled, you need to unscrew the 4 mounting screws of the starter. Then the cover of the oil tank and fuel tank will be accessible. The starter does not hold anything in place, it is easy to dismantle.

51488 / YR-CS4500S – 45 cc Chainsaw bar and chain assembly / disassembly

When the starter is removed, you need to clean the opened internal cavity with gasoline or VD-40, which usually contains a lot of small resinous sawdust pressed with oil smudges. Before using solvents, if the layer of this thick substance is very thick, clean it with wood chips.

Engine runs intermittently

You can start to identify the malfunctions of the Stihl 180 chainsaw yourself if the warranty period has expired. Sometimes the engine runs intermittently, which can be caused by the failure of the cylinder piston group. You can repair it yourself. To remove the cylinder from the tank, it is necessary to unscrew the bolts on its head. The master should check the piston; there should be no chips, scratches or scuffs on it. If they could be found, then the piston must be replaced.

Piston rings and piston ensure optimum pressure in the combustion chamber. The rings must fit snugly over the piston body. If the piston inserted into the cylinder has a free swing when swinging, then this indicates its wear. To fix the problem, it is necessary to bore the cylinder and install repair parts. But the easiest way would be to replace the CPG kit.

Chainsaw assembly Calm 180

Assembling the stihl ms 180 saw back is quite simple, the main thing is to adhere to the following algorithm:

- Install the piston on the connecting rod, the arrow on the piston should point in the direction of the Stihl 180 chainsaw, and the side of the crankshaft, which is intended for installing the flywheel, is located to the left of the piston;

- Carefully insert the piston back into the cylinder, the place for mounting the coil should be on the side where the flywheel is installed on the crankshaft;

- Install the bearings, oil seals, circlip on the shaft and lower the entire assembly into the seat in the cylinder;

- Next, degrease the installation site of the crankcase and the crankcase itself, then grease with sealant and, setting in place, tighten 4 fastening screws;

To assemble the Stihl 180 saw after the engine is assembled, the reverse sequence of disassembly must be followed. It is important to treat the process carefully and do not forget to install the rods on the carburetor, and connect the ignition wire.

Below you can see a disassembly of the calm 180 in the video, it was made for inexperienced users, it shows the whole process in detail.

Dismantling the chainsaw calm 180 and its assembly, if you have a certain experience, is quite simple, the main thing is to thoroughly clean the saw before work and not to rush. In order that small parts are not lost, you need to use containers in which, in the process, you should lay out the parts.

Removing the starter

At the next stage, the upper case cover is removed and the 4 starter mounting screws are loosened, after which it is necessary to remove the oil tank and fuel barrel covers. The starter is removed quite simply and there should be no problems.

After removing the starter, the opened inner cavity of the chainsaw must be cleaned, since usually there is a large amount of compressed small sawdust on the body under the starter.

Removing the handle

The direct disassembly of the calm 180 begins with the removal of the handle, which is attached to the body of the chainsaw using three rubber shock absorbers. To remove, it is necessary to remove the plastic plugs from the inner cavity of the shock absorbers, then, using a powerful screwdriver, first squeeze out the upper shock absorber, then the one closer to the rear handle.

At the back of the handle there is a throttle trigger, which is connected to the carburetor through a wire rod, in order to disconnect the throttle trigger from the throttle trigger, it is necessary to unscrew two screws and disassemble the handle.

When the handle remains on one shock absorber, it is necessary to unscrew the body of the chainsaw from the inside of the handle and bend it to the side, remove the body from the last rubber band.

Stihl MS 180 is a reliable and undemanding tool, alas, when it requires repair, as well as no matter what equipment. Next, let’s see how the chainsaw is disassembled calm ms 180, which is necessary if the passage of a half engine repair.

Repair of any equipment should begin with a preliminary work step, and the calm 180 saw is no exception. At the preliminary step, before the calm 180 is disassembled, the side cover, chain and tire must be removed from the chainsaw. Next, using a compressor and a brush, you need to clean the chainsaw from dirt, sawdust, oil drips and the rest.

When cleaning the saw, special attention should be paid to the place where the chain saw drive sprocket is located, since this is the dirtiest area.

Concrete disassembly of calm 180 begins with removing the handle, which is attached to the body of the chainsaw using 3 rubber shock absorbers. To remove, you need to remove the plastic plugs from the inner cavity of the shock absorbers, then, using a strong screwdriver, first squeeze the upper shock absorber, later the one that is closer to the rear handle.

At the back of the handle there is a gas trigger, which is connected to the carburetor through a wire rod, in order to be able to disconnect the rod from the gas trigger, you need to unscrew two screws and disassemble the handle.

When the handle remains on one shock absorber, you need to unscrew the body of the chainsaw from the inside of the handle and bend it to the side, remove the body from the last rubber band.

Next, the upper housing cover is removed and the 4 screws for fastening the starter are unscrewed, then the oil tank and fuel barrel covers must be removed. The starter is removed quite easily and problems should not appear.

Dismantling the chainsaw calm

Carburetor, muffler and ignition coil

To remove the carburetor, you must have a head 8 and an extension, with which it is convenient to unscrew the nuts securing the carburetor and air filter. Before dismantling the carburetor, it is necessary to disconnect the ignition wire and the choke rod from the engine control lever and remove the lever, only after that the air filter and carburetor are removed.

The Stihl 180 muffler is attached with two nuts, by unscrewing which you need to pull it towards you, it can be easily removed.

The coil is mounted on two screws, to remove you just need to unscrew them.

Removing and disassembling the engine

The engine is held in place by 4 screws installed on the bottom of the Stihl 180 chainsaw. To remove them, unscrew them, then carefully remove the engine from the seat and the rubber pipe of the carburetor.

To disassemble the engine, 4 crankcase screws are unscrewed, and it is removed, then you can remove the crankshaft assembly with oil seals, bearings and piston rings.

Removing bearings and seals usually does not require additional tools, but if the bearings were pressed onto the shaft with force, then a special puller will be needed for dismantling.

To remove the piston from the connecting rod, you will need to remove the retaining ring from the seat using a thin screwdriver, then the piston pin is squeezed out from the opposite side, after which the piston is retracted to the side.

Preparatory stage

The repair of any equipment should begin with the preparatory work, and the calm saw 180 is no exception. At the preparatory stage, before the calm 180 chainsaw is disassembled, it is necessary to remove the side cover, chain and tire from the chainsaw. Further, using a compressor and a brush, you need to clean the chainsaw from dirt, sawdust, oil drips and other things.

When cleaning the saw, pay special attention to the place where the chain saw drive sprocket is located, since this is the most polluted area.

In places with a large accumulation of oil, can be washed with clean gasoline.