Than and how to cut foams at home: review of methods and stages

Engaged in assembling kitchen stools, I thought why not make sitting soft. But in order to create such a kind of upholstery, I faced the question of how to cut foams very exactly at home. Indeed, for the finish covering of the seat, you need to be able to correctly cut the fragment in accordance with the size. In this post I will tell in detail about the process.

Furniture manufacturers use special machines. You can cut polyurethane foam of any thickness, with a perfectly flat seam and accurately observing the size.

Naturally, these options are not entirely suitable for home: especially when you need to cut a couple of sheets to restore furniture and never do it again.

In such cases, it is recommended to use the so.called “loaf” (with zazubins on the blade). Its shape and length allows you to make an even section of thick polyurethane foam. It will have to be cut for a long time, but as a “one.time action” the method is quite suitable.

Please note: in no case do not listen to the advice of the “craftsmen” and do not cut the foam rubber with a wire (tungsten or nichrome). Heating foams leads to the release of phosgen. toxic gas. It is extremely dangerous to inhale it in a closed room.

Drawing up a project

For example, we have determined that a double.sized shredder with a low rotor rotation frequency is suitable for production tasks.

His project necessarily includes:

- engine selection by power;

- calculation of the gear ratio of the gearbox and the choice of the factory model;

- determination of the diameter and length of the rotors (according to the size of the loading window);

- calculation of shafts for strength;

- The choice of bearing supports.

For this you will need the textbook “Parts of cars” for universities. You will also have to look into GOSTs according to threaded connections, reference books on gearboxes, bearings, couplings and other assembly units.

This must be taken into account when you assign the dimensions of the groove.

A GUIDE TO UPHOLSTERY FOAM | UPHOLSTERY FOAM AND HOW TO USE IT | FaceliftInteriors

After calculations, it is necessary to make a layout of nodes on a millimeter paper or in an AutoCAD type editor, determine the dimensions of corps parts and beds.

This task must be approached responsibly so as not to miss anything. Sometimes the protruding head of the “unaccounted” bolt leads to the fact that the car has to be redone. After that, a detail is made. the drawing of each part separately.

How to cut foam rubber?

There is no need to buy a specialized saw for polyurethane foam, which is used in stores or in small industries to cut a sheet of foam at home.

It is enough to use a sharp knife, you can take a knife with a zazubins with which a loaf is cut. Thanks to its shape and length, the material is even. If there is no such knife, then any other well.sharpened knife is suitable. If you have a construction knife with a advanced blade, then it is also suitable for cutting foam.

The secret of the even edge of the material is a knife tilt during cutting, if you need to make a flat fishing line for a trimmer. Когда требуется фигурная резка поролона, угол наклона следует увеличить. This will avoid beads at the edges.

Stages of cutting foam

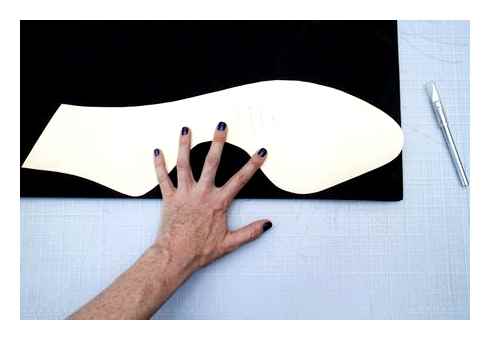

To cut the canvas PPU does not require expensive tools or special conditions. In order to cut the canvas at home, it is necessary to stock up on a sheet of cardboard and plywood, a ruler or curly pattern (if the fishing line is uneven), a marker or construction tape, as well as a sharp knife. The whole process consists of simple stages:

- You need to choose a flat surface where you will cut the foam.

- Put the plywood and cardboard on the surface of the floor or table so as not to damage it with a knife while cutting the material.

- Using a line with a marker or construction tape, note a fishing line for a trimmer of the alleged cut. Scotch tape is suitable for a flat line, and for a figure. a marker.

- The ruler can be held by the material while cutting the sheet into parts. Do not press too much on the ruler, as this can lead to deformation of the canvas, and the edge in the site of the cut will turn out to be uneven.

- You can use two slats made of wood, when it comes to cutting on a flat line. Between the strips should be left for the cut. This will fix the sheet.

- Cut the canvas with a strong and smooth movement of the knife. If the first time it does not work out to cut a thick material, then it is necessary to repeat the procedure by inserting the knife exactly into the fishing line for the trimmer of the already made section. You can first make a cut to half the thickness, and then continue cutting until the end.

- Figure cutting of thick material with a knife is more difficult, so you need to keep the knife at a large angle on yourself, and lead a knife more carefully.

To make the incision even, you need to buy high quality foam. Our store presents material from the best manufacturers. The assortment has sheets of different thicknesses and density. To choose and buy a suitable foam for your task, call our store by phone indicated on the site.

Stages of cutting foam

When all the materials are prepared, you can proceed to the cutting process:

- First you need to put on the table or floor plywood and cardboard so that they protect the working surface from scratches.

- Then, using the ruler, draw a fishing line for a cutting trimmer with a marker.

- You can use the line during cutting of the material if it is long.

- The blade of the construction knife must be set in the thickness of the material. The knife should be kept diagonally (with a slope to yourself) and make an incision on one side of the canvas.

- After that, insert a knife into the resulting section and confidently draw them along the already outlined line. In this case, it is necessary to hold the edges of the material on both sides so that the fishing line for the trimmer is flat, and do not break the fabric in those places where the knife did not cut it until the end.

- To cut the thick material, you need to push the cut area, draw a blade along the already intended line again. You will hear the sound of the contact of the metal with a cardboard, which will confirm that the material is completely cut, throughout the thickness.

- For curly cutting, PPU needs to draw a fishing line for a trimmer on the pattern on the material, and increase the angle of inclination of the knife to yourself.

The result depends on the quality of the knife and PPU. It should be durable and sharp. If the knife is poor.quality or stupid, then the edges of the canvas will be uneven. To buy durable foam rubber, contact our store by phone indicated on the site.

How to cut foams

Hello everyone, just recently I had a problem, how to cut off the foam rubber evenly, and at home. For all the time of passion for carpentry, I have never encountered foam rubber, it is understandable, I usually work with woods.

Since cut off foam? And what you need to do. The first thing that came to my mind was some kind of expensive machine that it is simply not realistic to buy, since I once cut a foam, but for a very long time, and I didn’t really succeed.

At work, in the next workshop, they are engaged in upholstered furniture, and somehow, at lunchtime, I met a guy who is engaged in this Street. During the conversation, I found out that in order to cut off foam, they use the knife, and they have no expensive equipment for this. We talked and he told me how to cut off foam gently at home.

To cut off foam rubber will need the following

- A sharp knife, best is the chancellery or for cutting linoleum

- A felt.tip pen or a marker with a thin rod

- Cardboard or something else for the base

- Good ruler

So, how to cut off foam rubber, first using a marker, make the cut line on foam. If these are straight lines, it is better to use the ruler, if you should have a cut under the radius, it is better to use some kind of pattern, template or other device in order to draw exactly the radius.

Next, to cut off foam, it will be necessary to prepare the base. As a basis, many advise you to use a plywood or a wood-piece plate. I would not advise you, because when you cut a foam rubberle with a knife, the tip of the knife will dull about this plywood. Therefore, for the ground, I advise you to use cardboard. By the way, I forgot to say why the base is needed, the base serves so that the floor or another base does not spoil, on which you are going to cut off the foam rubber, well, and as you understood for protecting the tip of the knife.

Well, the last point how to cut off foam, this is the process of cutting. To do this, take a very sharp knife. Your kitchen knife is clearly not suitable here, since his blade is thicker. Therefore, I advise you to use a stationery knife, or a construction knife, like those that cut linoleum. It is very important that the blade and the tip are sharp, otherwise you can’t get a foam rubber.

Well, then go to work, spend exactly along the line with a knife, preferably without using the stop, since the emphasis will be pressed on foam, thereby creating a load in it, and the knife will be poorly cut. If you doubt your abilities, then it is better to practice a little on another piece of foam rubber so as not to spoil the workpiece.

Anyway, foam rubber is usually cut in order to sheathe up her upholstered furniture. Therefore, you can not do perfectly evenly, and you can’t get 100% exactly cut off exactly. The fabric will still be on top of the foam, which will smooth out all the irregularities and errors of the cut.

Here I am an article, it may be useful for those who have thought about cutting off foam at home with your own hands. I will be glad to Комментарии и мнения владельцев, tell us what you think about it, and if there is experience, share it.

Often you can find advice that foam rubber should be cut with a heated nichrome wire connected to a voltage of 12 V, as well as a heated soldering iron.

How to cut smoothly thick foam at home?

However, at home, this is not recommended, since foam rubber distinguishes harmful substances into the air, which, even in small doses, are highly toxic and affect the respiratory and nervous systems of a person. We will not risk health, especially since foam rubber is well cut by an ordinary knife.

Mark a piece of foam rubber with a marker or felt.tip pen, while putting small marks. Combine the tags together in a ruler (you can use a flat bar).

Under the place of the future cut, put a piece of boards, plywood, wood-boring plate or just dense cardboard. This will protect the floor from damage during cutting.

Cutting foam is recommended without a ruler. Spit with a strong and accurate movement with a knife according to the marking you made. At the same time, hold the knife vertically.

If the foam rubber does not cut through to the end, spread the cut part with your fingers and cut the foam to the end with the second reeza.

If the cutting is obtained, this means that the knife blade has become dull. Break the tip of the blade or replace it with a new.

Curved cuts are made according to exactly the same technology. Mark the pattern, then cut the foam along the line, making sure that the knife does not fill up, but is located vertically. The quality of the cut will not be perfect, but it will be quite fit if you need to cut out a pillow for upholstered furniture, which will then be covered with fabric.

Pre.soaked thin foam is much easier to cut with scissors.

How to cut foams?

It would seem that the question? Take it and cut. There are no problems with a material up to 5 cm thick.

Than cutting exactly thick foam?

But how to make an even section of a 10-centimeter or even thicker foam?

In the vastness of Internet forums, advisers are actively offering pretty bold ways. For example, heated tungsten or nichrome wire. over, the craftsmen are advised by connecting the wire to electricity with a voltage of 12 V. Choose, they say, the temperature so that it does not burn, but cut. Here right here. Stop! Porolon-Optom store.RU considers it his duty to warn that this method of cutting polyurethane foam materials, and especially at home, is dangerous to human health. The chemical reaction between heated wire and foam rubber is accompanied. With normal contact of foam rubber with fire, this will not happen, the material is not fuel and environmentally safe. But chemical experiments of self.taught that have not read the textbook on chemistry should not become an example to follow.

How foam is produced?

There are two main methods of manufacturing this material:

Large enterprises use continuous technology. But for a small company it is more profitable to use the periodic method. Its main advantage is the lower cost of the purchase of equipment. To use this method of manufacturing foams, special knowledge is not needed. Almost all equipment manufacturers will teach you all the wisdom of its use. And the staff can be trained in the workshop.

Foamen is a material with unique properties. Its production does not cause difficulties. Especially if you purchase a ready-made minister for foaming and pouring polyurethane into forms. When comparing with other types of production business, the manufacture of foam rubber does not cause large investment.

According to the estimates of the industry analysts, today the market is saturated with PPU manufacturers by about 70%. 75%. “Lack” of the material is covered by foreign brands. The quality of which there are no complaints. But the cost of the material exceeds analogues by 1.5. 2 times. And in some regions and more than the number of times.

Foam manufacturers use various types of equipment. If we talk about the disadvantages of this business, then the main thing is the acquisition of several types of various equipment. At each stage, a certain type of equipment is used. You can save a little if you buy an automated fishing line for a PPU trimmer. Investments will be quickly justified, especially if you already have channels for sales of such products.

The foam production algorithm is as follows:

- Creation of raw materials from special ingredients.

- Bringing to uniformity and spill in prepared forms.

- Tracking the reaction of foaming and formation of solid crust.

- Ensuring cooling of the material with a gradual decrease in temperature.

- Cutting the material on sheets or figures of a given shape.

- Material transfer to the finished product warehouse.

An important component of the production of quality material is the observance of the correct dosages of the components. The creation of the raw material mass occurs in a special bunker, where raw materials are delivered in automatic. It is meres and is brought to uniformity.

In the production of mass for the manufacture of foam rubber, it is important to properly observe the proportions. An error even in one gram can affect the quality of the material

Therefore, in the manufacture of the mixture, electronic scales are used that have a small error. A specially trained technologist should monitor the process.

There are several technological features of the production of such material. The production of foams in from the plant to the plant may slightly change. The only important point is polyizoctions and polyol. It must be unchanged. Otherwise, the material will lose its qualities and properties.

An important nuance that should be taken into account is the allocation in the air, in the production of this material, dangerous compounds

Therefore, it is extremely important to observe safety and labor protection. The factory requires high.quality ventilation and a gas output of vapors from the personnel work area

The environmental component is no less important. Gas formed with a chemical reaction of foaming raw materials for the production of foam rubber should not fall into the environment. Therefore, in addition to spending on the purchase of equipment, the owners of such an enterprise should provide their production by treatment facilities.

DIY foam cutting | Interesting facts with photos and videos

At home, cutting foam, knife, thread and other improvised devices can be performed.

- Foaming blank that needs to be cut.

- Lining (on the flooring or table, you should not lay out the material, because they will be damaged when cutting). It is recommended to use plywood sheets with a cardboard on their lining material.

- Construction knife. The best option is for cutting linoleum. Such knives have several removable blades in the kit, so it will be possible to quickly change them when foam rubber.

- Ruler. You can also use the pattern if you need to perform figure cutting of the material with high cutting accuracy.

- A felt.tip pen or marker (for applying a mowing cut line).

Cutting process

- We free up the place, remove all the things that may interfere.

- We place a sheet of foam rubber. Celebrate the fishing line for the cutting trimmer using a ruler and marker.

- We take a knife with a blade of the desired length (over the width of the foam) and carefully make an incision on one side.

- We tilt the plane of the blade to us to make an even section.

- If the blade clings to foam rubber, then it is dull. Then it must be changed, otherwise there is an opportunity to spoil the material.

- In the case when you could not cut the thick sheet of foam rubber, do not worry. Spread your hands fishing line for a cutting trimmer, put a knife and draw again.

In order to do figure cutting, it is worth acting absolutely the same. Only as much as possible increase the angle of inclination of the knife to you, so that the mowing fishing line of the bend is even.

To cut the material such as foam rubber, purchase everything you need and be patient.

Cutting instructions

If you follow the instructions in everything, your foam rubber will be delivered perfectly. So, let’s go:

- Since we still decided to cut the foam rubber on the lining, and not on linoleum or parquet, first we put it. First plywood, then a sheet of cardboard.

- Lay the foam layer on top that we want to cut. We make sure that the fishing line for the trimmer of the future section is on the lining.

- We take a ruler and, in accordance with the specified dimensions, draw a fishing line for a trimmer along which the future incision will pass.

- We remove the ruler. If we cut along the ruler and pressing it at the same time, then the section will turn out even, but the edge will be as pressed as in the case of scissors. If you decide to cut it on a ruler, then in no case do not press on it.

- We take the knife, set the blade to the desired length and make a small incision on top of one side. Many people wonder how to cut thick foams, so that even from the edge, in the place of the original section, it was even. In fact, there is no difference in what thickness the foam itself. The main thing after the first cut is inserted into the original fishing line for the trimmer of the cut and make the first full cut, grabbing both the edges of the cut foam on both sides of the knife with a free hand. Then the cut will be perfect.

- In many articles, advisers recommend that the knife must be kept vertically. Rewrite each other without understanding. Do not listen to idiotic advice. The knife, on the contrary, must be kept leaning towards yourself. This plane of the knife blade should always be in a vertical position in relation to the ground. It can not be filled up either to the right or to the left, otherwise the edge on the cut will come out trapezoidal.

- Surely the first Reza of the foam rubber will not explore to the end. Patience. It’s OK. Put the edges of the cut, insert the knife and make another even cut. Ultimately, the tip of the knife will grind the cardboard, and the task will be completed.

Good advice on how to cut foams, so that the edge is perfect. If you feel that the knife began to make peculiar hooks during the wiring, it means that in some place the blade was dull and, without cutting out, begins to tear the foam rubber, forming a strip of foam grouse. In this case, you should immediately change the blade to a new. It is best to do this without waiting for this to happen. Made five to six wiring, changed the blade. They can then be used again for any other purposes, but for cutting foams they will already be unequal. Simple cutting of foams with a knife is clearly given in this video.

So how to cut? Here are what tools are needed for cutting foam:

- We use cardboard or plywood for lining to save the surface of the table or floor where this operation will be performed;

- a building knife with adjacent blades;

- ruler or template;

- cutting marker.

Cutting process

In order to do figure cutting, it is worth acting absolutely the same. Only as much as possible increase the angle of inclination of the knife to you so that the bending lines are even.

To cut the material such as foam rubber, purchase everything you need and be patient.

How to cut foams?

It would seem that the question? Take it and cut. There are no problems with a material up to 5 cm thick.

But how to make an even section of a 10-centimeter or even thicker foam?

In the vastness of Internet forums, advisers are actively offering pretty bold ways. For example, heated tungsten or nichrome wire. over, the craftsmen are advised by connecting the wire to electricity with a voltage of 12 V. Choose, they say, the temperature so that it does not burn, but cut. Here right here. Stop! Porolon-Optom store.RU considers it his duty to warn that this method of cutting polyurethane foam materials, and especially at home, is dangerous to human health. The chemical reaction between heated wire and foam rubber is accompanied. With normal contact of foam rubber with fire, this will not happen, the material is not fuel and environmentally safe. But chemical experiments of self.taught that have not read the textbook on chemistry should not become an example to follow.

There are special knives for cutting foam. The secret of obtaining a flat cut in such porous materials as spongy rubber or polyurethane foam, in very thin and sharp blades and special movements that these blades make. In electrical goods stores, you can purchase an electronics for cutting foam. Devices look usually like this.

On an industrial scale, these are already entire electric machines. Here you can, as they say, write out the most bizarre forms and lines. To fix the sheet or cube of foam rubber in industrial installations, vacuum is used.

The machines most often have a strip knife for cutting foam.

A very thin blade and a special location of the zabrinki, as well as a stable continuous force that can be obtained from the machine, allow you to get an even smooth cut.

However, master-taught masters are not behind. On one of the forums for the so.called dummies, the luminaries demonstrate a wonderful alternative to the electronics for foam.

A device of two aluminum rails and a sharply sharpened knife can save the situation when it comes to one or two pieces of foam rubber, which must be cut out at home. True, the knife will not need the usual, with a serrey sharpening. This is a special, wavy type of sharpening, which is often used by hunters. However, and culinary knives for cutting hot loaves have a similar look. Such a artisanal invention is not at all scary to try to do it independently, at least it will not threaten health problems. And who knows, maybe you will become the next innovator who will show the world the next hypostasis of the most popular material of the 21st century?

If you want to save your time and effort and get foam crumbs or a cut of foam rubber, you can contact us by phone 7 (495) 978-33-44. Always in stock at affordable prices!

How to cut foams at home?

Phased plan:

- Make a felt.tip pen, by which you need to make a cut, and connect them along the ruler. If you need smooth crooked lines, then draw them on the pattern

- Under the place where you will make a cut, put a board, thick cardboard or plywood

- Cut the foam on the intended line strongly and slowly. Attention! The knife during cutting should be located vertically

- If the foam suddenly did not completely cut through, we advise you to push the cut and cut.

If irregularities and burrs begin to appear in the process of cutting, change the blade.

Preparation of tools in cutting foam

In order for the edges of the material to be as similar as possible to what they get in production, it is necessary to prepare consumables and suitable tools. If specialized instructions

- The material that needs to be cut.

- A stand for the material so that the knife does not cut, or does not leave scratches on the surface of the knife or stand. As a stand, you can use for yourself and your loved ones.

- The knife can be taken kitchen if there is no construction (a knife for cutting linoleum is suitable).

- A ruler if you need a straight line for a trimmer cut, or a template with a pattern, if a figurative is cut. Using a ruler and a template with a handle or pencil, cut lines are applied.

- A marker to apply a fishing line for a trimmer or draw a figure by which it is planned to cut good pieces of foam rubber.

When the preliminary preparation is completed, you can proceed directly to the process of cutting foam.

Stages of cutting foam at home

To get a neat and even cut on a sheet of thick foam, it is necessary to perform a sequential algorithm of actions:

- Put a sheet of material on plywood or cardboard.

- Take a ruler or patterns on which a marker is applied to a fishing line for a trimmer.

- Take a large kitchen knife, sharply sharpened, you can use a construction or stationery knife.

- Perform the first small incision on one side.

- After the first incision, insert the knife into the material along the cutting line, and make a full movement along the entire thickness of the foam rubber, capturing its edge.

- Gradually spreading the edges of the material

The knife must be kept towards yourself. It is necessary that the blade moves vertically in relation to the sheet lying on the horizontal surface. So that the edge of the cut does not turn out to be trapezoidal, the knife should not be filled up to the sides.

If you have to cut along the curly line, then the angle of inclination of the knife to itself needs to be maximally increased so that the resulting edges are even.

Dismantling the riser

It is necessary to follow the rules when separating the vertical sewage pipe:

- Management services are notified, permit for repair work is issued;

- Users of the riser living above along the floor are notified;

- Repair operations are carried out.

The presence of a compensator allows you to shift the product in one direction or another up to 10 cm. It must be remembered that the vertical design has a certain mass. Therefore, it needs to be fixed.

The joints of the joints are processed with machine oil. When performing rotational-setting movements, the part is removed from the overall structure. The absence of a compensator forces to resort to radical methods. to cut the fan pipe.

PVC plastic sewer pipes are processed by most locksmith tools:

Mechanized device. angular grinder, saber saw.

When carrying out work, it is required to pay attention to the presence of a number of other communications elements:

The compounds of sewer pipes that have served 10 years or more can “grab”, “grow” to each other. Help in such cases a number of recommendations;

- Processing the junction of the WD-40 lubricant;

- wrap sandpaper around the pipe; make rotational movements through it. hands will not slip, circular effort will increase;

- If the product is scrapped, then it is necessary to make a through hole across the part; By inserting a tube or a metal rod, we get a lever;

- Apply a “barbaric” dismantling method. cut the pipe into pieces, break into pieces.

Methods for separation of PVC pipes used to arrange an external highway, exactly the same. But, it is necessary to determine the place of damage and perform excavation work.

How and what methods of unlocking pipes. choose the owner of the housing or invited specialists. The main thing is to determine the feasibility of a particular way of dismantling faulty details.

How to Make a Contoured Cushion with Foam Ridge

Well, something, and there was a lot of cast iron in the Soviet Union! All technologies were developed taking into account this material. So in the laying of sewage, Chugun is still very popular. Of course, cast iron has many very significant advantages. it withstands heavy loads, which allows you to collect risers on many floors, it is durable, can fulfill its function in raw or cold rooms for decades, the paint lies well on the cast.iron pipe, that is, it can be beautifully entered In design. In a word, a sewer pipe made of cast iron is a thorough, durable thing. But in this thoroughness lies its main drawback. To disassemble, if necessary, part of such a pipeline is very difficult. And this is sometimes an acute need. For example, you needed an additional discharge or the existing discharge has become unusable. What to do?

Best. when a professional is performed, a master of his craft. In this case, you can be sure of the quality and efficiency of the work done. But this option is not always possible. Often plumbing should wait for weeks, and their prices, to put it mildly, are inflated. It happens that this “master” has no experience in such works. Not all those who wears the plumbing of the plumbing are such, are such.

Manufacturing of the machine site

The machine site will consist of a countertop (desktop) and four legs. We make them from plywood 12 mm thick. The size of the countertop according to the drawing of the master is 30×31 cm.

We saw off the workpieces of the required size, after which we process them on a grinding machine or using a grinder. The edges of the countertop should be slightly twisted so that they do not catch the workpiece.

We attach the legs to the countertop on a scythe. To do this, the author dries at an angle of two holes with a diameter of 4 mm, then a 10 mm drill will need to expand the holes along the screw hat.

We also recommend reading an article-review: how to make a conductor with a fixer for compounds with a slanting screw. Such a device in the workshop will definitely not be superfluous.

Next, mark and drill the fasteners to connect the legs with each other using plywood segments. We mark the attachment points of the legs, retreating a certain distance from the edge of the site.