Tools and Parts

Tools

(1) 7/16″ combination wrench (1) 9/16″ combination wrench (1) 3/4″ combination wrench (1) 11/16″ combination wrench (1) 9/16″ socket (1) 12″ socket drive extension (1) ratchet drive (1) shop hammer (1) mechanical punch (drift) (1) needle nose pliers or spring tool

NOTE: A lift or work table is not required but very helpful.

Introduction

Step 1

Using a 1/2″ socket, 12″ extension and ratchet, loosen the drive belt keeper located to the left of the transaxle.

Step 4

Using a 9/16″ socket, 12″ extension and ratchet, remove four bolts from underside of mower which hold the transaxle in place.

NOTE: The belt tensioning idler spring partially covers bolt #2 and must be pushed to one side in order to remove the bolt.

Step 5a

Remove the seat assembly by doing the following.

a. Using a 1/2″ wrench, remove the seat rod nut located on the right (left) side of the mower.

Step 5b

NOTE: Use special care during reassembly to insure that the connection plug is placed between the seat base and the seat frame. This prevents the cable from being pinched or caught up in the moving parts of the transaxle.

Step 5c and 5d

c. Remove the seat rod by pulling it toward the right (left) side of the seat.

Step 6a

NOTE: On models built prior to July 17, 1996, remove the clips from both the left and right side of the brake shaft. See Figure 19 for the location of the two clips.

Step 6c

NOTE: The one piece brake shaft was used on mowers built prior to 17 July 1996 and is a solid shaft rather than a tube as is used on later applications.

Step 8a

8a. If the mower has a one piece shaft and slide the cross shaft to the left side of the chassis and allow it to drop downward out of the way.

Step 8b

NOTE: Field experience has shown that it is not necessary to remove the fenders on models built prior to 17 July 1996, although earlier instructions suggested their removal.

Step 9

Using a 9/16″ socket and ratchet, disconnect the ball joints from the transaxle (ball joints will stay attached to the drive levers in the chassis).

Step 10

Push the transaxle toward the front of the chassis and remove the primary chains from the drive sprockets.

Step 11

- SHOP WITH CONFIDENCE

- 35 YEARS EXPERIENCE

- 365 DAY RETURN POLICY

- FREE TECH SUPPORT

- WE SHIP ANYWHERE

- MILLIONS OF PARTS

- Need help finding the correct repair parts?

“thanks thousand the tanks has arrived. A reliable seller”

“Thank you so much. It’s rare to find good service like this. I appreciate it.”

“I will keep your company book-marked and order from you first in the future! Your kind of service is exceptional!”

“It’s nice to do business with good people like you.”

“Many thanks for the prompt parts order. I waited over 4 months for my local repair shop to get the part and they ended up with the wrong one. Next time I will do it myself.”

Dixon Zero Turn Mower Problems And Troubleshooting Tips

Dixon zero-turn mowers are worldwide popular for conventional specifications. Like other brands of mowers, you can face some complications that are normal for any high-end lawnmowers.

If you can manage the compilation, you will experience the best performance from the Dixon zero turn mower. Here we will talk about those Dixon zero turn mower problems with the best possible solutions for the specific issues.

Let’s have a glance at tips and tricks to make your Dixon zero-turn mower.

Problems And Solutions Of Dixon Zero Turn Mower

Let’s point out some common problems so that you can troubleshoot the issue yourself. We have decorated this segment in such a way where you will go through the problems, causes, and solutions.

Dixon Zero Turn Mower Won’t Start

After months of use, it is a universal problem for every zero turn mower no matter from which brand you have purchased. And the frustrating point is that you will not get any clue why the mower is not starting.

But don’t be nervous here we are. Here are some possible reasons why you’re Dixon zero turn mower is not starting.

The carbon wears on the spark plug and gradually it will limit your engine to start and generate power.

Inspect the spark plug if the engine doesn’t start.

Replacing the spark plug is the best solution. Because trying to fix a spark plug is a waste of time. But if you observe that the spark plug has a little carbon mark you should wipe it with cotton, and we hope it may work.

Routine cleaning is urgent for the mower’s carburetor. If you do not clean the debris of the carburetor, surely it will restrict the engine from starting.

When you observe dust on the carburetor, clean it to achieve the best performance from the Dixon zero turn mower. Clean the carburetor with recommended carburetor cleaner only!

Fuel filter helps to provide clean fuel to the engine and for doing the job day by day, the filter becomes clogged.

If the filter becomes clogged, it will be unable to make the flow of fuel to the engine. As a result, the engine won’t start or will make a lot of problems while starting.

We recommend you check the fuel filter and replace it if the filter is full of dust. And learn when to replace from the manual of the manufacturers so that you can change it when needed.

The ignition coil helps the spark plug and deliver the necessary voltage while the engine is in process.

If there is any problem with the ignition coil it will be unable to distribute the necessary voltage to the plug as a result the engine will not start.

To detect, you need to use an ignition tester to test if the ignition coil is working or not. If there is any problem found, it needs to be replaced.

Mower Starts But You Face Sluggish Problem

So follow the previous solutions such as checking the carburetor, fuel cap, or defective plug if you face the problem.

For Dixon zero turn mowers gas leakage problems are not so common but you may face them after a long time of usage.

Check the carburetor bowl gasket. Displacing the gasket is the main reason for gas leakage. If you find any leakage here changes the gasket before starting the engine.

Already we have discussed the common problems related to the engine.

Other Problems And Solutions To Those Problems

As the mower has a hydrostatic transmission system to give a better experience, the problems in the hydrostatic system require frequent maintenance such as changing the hydro fluid regularly.

The air is the main problem of the hydro transmission system, if it gets any leaks the air can ruin the system. It has a risk of a sudden jam if there is any failure in the hydrostatic transmission system.

There is no shortcut for the problems, only routine checking and maintenance is the solution to the problems.

If you face the problem where your Dixon zero turn mower is not moving backward or forward but still the engine is on, you should check the belt.

A broken belt is the most likely reason for the problem. If there are any problems with their belt, replace it.

If the battery cannot hold the charge, then you can assume that one or more battery cells are dead. Replacing the defective battery is the best solution.

If your mower proceeds black smoke maybe the carburetor is getting more fuel than needed. And if the choke is stuck, the engine will not get enough air as a result it will produce a lot of smoke.

You will encounter the steering problem sooner or later. So, watch this video to fix the problem.

Effective Tips To Solve The Problems Of Dixon Zero Turn Mower

If the blades don’t move or are unable to mow, check the blades and remove any grease clogs and clean the blades.

If the blades do not sharpen enough change with new blades to get the actual performance.

There are some other problems such as uneven mowing and sound in the engine. Checking the blades and air grommet pipe can solve the issue most of the time.

You may need to call the service center if you are unable to find out the problems

PTO Clutch (Power take of clutch) engages or disengages the blades to the engine. So if the PTO clutch does not get power it can’t move the blades to mow.

So after heavy use, the PTO clutch can be defective, and it is not repairable so you must need to change it.

The possible reason for not engaging the clutch is the damage of the PTO switch. It provides power to the clutch.

So if there is any problem with the switch the clutch doesn’t get enough power. Before replacing the PTO clutch, check the PTO switch once.

Final Thoughts

Dixon zero turn mower problems are the most common problems like other zero-turn mowers. All the time you do not need to contact the service point if you follow some instructions and do regular maintenance.

Most of the time the problems have easy solutions. The above problems are the most common problems and the solutions the best for those problems.

Den Hicks

Traveler, food lover, interior designer, and blogger. I love gardening a lot! I designed my home myself with the help of my beloved wife. You are welcome!

Problems with Carburetor

You must clean the lawnmower carburetor as soon as possible.

Failure to clean the carburetor will almost certainly prohibit the engine from starting.

Clean the carburetor if you find dust on it for the optimum performance from Dixon zero speed mowers.

Only use the approved carburetor cleaner to clean the carburetor.

Clogged Fuel Filter

The fuel filter ensures that the engine receives clean gasoline, and it becomes clogged during regular operation.

If the filter becomes clogged, it will no longer be able to feed fuel to the engine. As a result, the machine will not start or will create several problems during startup.

We recommend that you inspect the gasoline filter and replace it if it is clogged with dust. Also, consult the manufacturer’s instructions to determine when it should be replaced so that you can return it if necessary.

Mower Remains Sluggish

Another major issue with zero-speed lawnmowers is that they do not start! This statement means that it will run slowly or unexpectedly stop while in use. A clogged fuel cap could be the root of the problem.

You may have observed the tiny valves that allow steam to enter the gas cap. This supplement is also essential for regulating the oil-vapor balance.

However, if blockages form in your fuel tanks, air cannot access the fuel apertures, resulting in cavitation, and the mower may start but then stop.

Another reason can be a defective spark plug. Carbon buildup, which causes wear on engines and rods, can also harm spark plugs over time. Furthermore, a weaker electrode can cause your mower to bounce up but then remain sluggish.

Leakage of Gas from Mower

The last and most prevalent issue with a zero-speed lawnmower is a gas leak, which might occur from time to time. One of the possible causes of such an incidence is a worn carburetor seal.

If you find a leak in your carburetor, the most likely cause is a flat or missing carburetor gasket. And when this happens, the carburetor starts to lose gas.

Furthermore, faulty float installation can be a significant source of gas leakage from the unit. Many float attachment mechanisms in the carburetor may be incorrect or improper.

The float unit also has an entrance or needle via which fuel enters and exits the bowl, opened and closed. As a result, if the gasoline connection or the fuel assembly itself is destroyed.

The carburetor will continue to fill with fuel, eventually overflowing and leaking.

Conclusion

We hope you liked our guide on zero turn mower problems that are defined in detail above. We suggest you check on the mower’s fuel tank; try to fill fresh fuel before an operation to achieve efficient working.

over, look for a fuel stabilizer so that no residue builds up again inside the mower, letting it get interrupted during your work. Also, if the fuel filter is the actual cause, you can easily replace it using simple steps.

How to Adjust Cones on a Dixon Lawn Mower

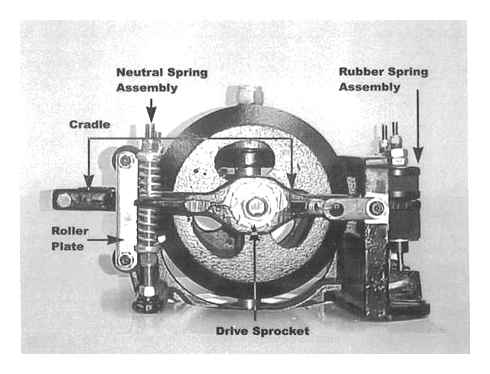

Dixon Corporation is a manufacturer of zero-turn riding mowers and tractor mowers for residential and commercial uses. According to the Dixon-ZTR website, the company has been utilizing zero turn technology on its mowers since 1974. Cones are a part of the transmission assembly and help to control torque and steering. Adjusting the cones, specifically, adjusting the distance of the cones from the discups, can create more precise steering control of the mower.

Loosen, but do not remove, the locking nuts on the Allen head pivot bolts at the rear of the transmission using your 11/16-inch open end wrench.

Back off, but do not remove, the outside locking nuts on the torque rods slightly, using your 1/2-inch open end or box end wrench.

Undo the old gap setting between the discup and cones by turning the Allen head pivot bolt and the inside torque rod nut until the discup cradle moves in toward the cone. Turn the torque rod nut twice for every one turn of the pivot bolt, as the threads are much finer. Continue loosening the bolts until the discup just makes contact with the cone but are not jammed up against one another.

Square the discup so it rests perpendicular to the back frame of the transmission. Loosen either the front or back discup, whichever is more inboard holding the Dixon special tool or a square to know when you’ve reached perpendicular. Adjust until the discup is square and just barely touching end up Release the front or rear that is more inboard than the other and adjust the outboard one in until the discup is square and it is still just barely locked on the cone.

Create a new neutral gap by barely loosening the adjustment bolts so the cups and cones have a.020 to.025 gap between them on both sides of the assembly.

Set the rod lock to neutral by making the space between the bottom rod lock and the lower spring nut a uniform distance of roughly five threads. Rotate the upper spring nut until the gap distance is evenly divided between the upper and lower cones.

Adjust the control rods so the lever stubs are positioned vertically or slightly rearward and the two steering control levers are even. Push the machine forward with the engine off to confirm that there is no sound from the cones abrading the cups. Get rid of any abrading by adjusting the neutral spring nuts. Tighten down all of the nuts to hold the adjustments you just made.

Test the mower by turning it on and driving in a straight line over relatively flat terrain, the mower drives relatively straight when both levers are within 1-inch of touching each other.

Lot # : 1024SE. Dixon ZTR 502 Zero Turn Riding Lawn Mower

Auction Terms Conditions ONLINE AUCTION TERMS AND CONDITIONS REFER TO LOT 1 FOR AUCTION CLOSE TIME. BIDDING ACTIVITY WILL EXTEND, 3 MINUTES, PER LOT, IF THERE IS BIDDING ACTIVITY IN THAT LOT IN THE LAST 3 MINUTES. ALL ITEMS SOLD “AS IS, WHERE IS” WITH NO WARRANTY. ALL SALES ARE FINAL. THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, STATUTORY OR OTHERWISE, AS TO THE MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE OF ANY GOODS OFFERED IN THIS SALE. THE ITEMS ARE AVAILABLE TO THE PUBLIC FOR INSPECTION PRIOR TO THE START OF THE AUCTION CLOSING. SMITH AUCTIONS LLC (OFFICERS, MEMBERS, AGENTS EMPLOYEES) MAY ATTEMPT TO DESCRIBE THE MERCHANDISE IN ADVERTINSING, ON THE INTERNET BUT MAKES NO REPRESENTATIONS. IN NO EVENT SHALL SMITH AUCTIONS LLC (OFFICERS, MEMBERS, AGENTS EMPLOYEES) BE HELD RESPONSIBLE FOR HAVING MADE OR IMPLIED AND WARRANTY OF MERCHANTABLILITY OR FITNESS FOR A PARTICULAR PURPOSE. SMITH AUCTIONS LLC (OFFICERS, MEMBERS, AGENTS EMPLOYEES) WILL NEITHER BE HELD RESPONSIBE FOR ACCIDENTS, NOR ERRORS, DELETIONS OR OMISSIONS. NO CREDIT OR ADJUSTMENTS WILL BE ALLOWED IN ANY FORM OR AMOUNT. THE BUYER RELIES EXCUSIVELY ON HIS/HER PRE-AUCTION INSPECTION AND EACH LOT IS SOLD WITH ALL FAULT AND DEFECTS THEREIN. THE BUYER SHALL TAKE FULL RESPONSIBILITY AND ASSUME ALL RISK OF SAID EQUIPMENT AND OR ITEMS FROM THE TIME THE AUCTION COMPANY ACCEPTS THE FINAL BID FROM THE BUYER. PLEASE INSPECT BEFORE YOU BID AND BUY. BUYERS OUTSIDE THE CONTINENTAL 48 STATES MUST PAY WITH CASH OR WIRE TRANSFER (ADDITIONAL 10.00 FEE WILL BE ADDED TO INVOICE) TERMS OF THE SALE ARE, CASH, GOOD CHECK, MASTER CARD, DISCOVER OR VISA. ALL ITEMS MUST BE PAID FOR WITH IN 5 DAYS OF AUCTION END, WITH NO EXCEPTIONS. 5.5 % SALES TAX, WHERE APLLICABLE. 10% BUYER’S FEE NOT TO EXCEED 300.00 (PER ITEM) 4% BUYERS PREMIUM 4% DISCOUNT FOR CASH OR CHECK PAYMENTS (LATE PAYMENTS NOT SUBJECT TO DISCOUNT) 25.00 PROCESSING FEE ON ALL TITLED VEHICLES, TITLE LICENSE FEES EXTRA AFTER BUYER PLACES A BID, IT CANNOT BE RETRACTED. AFTER A BID IS MADE, SAID BID IN THE SOLE DISCRETION OF SMITH AUCTIONS LLC MAY BE ACCEPTED AND CREATE A LEGALLY BINDING CONTRACT. BUYER SPECIFICALLY AKNOWLEDGES SMITH AUCTIONS LLC’S POLICY ON BID RETRATION SUPERSEDES ANY CONTRARY PROVISIONS OF WIS. STAT. §402.328 SALE BY AUCTION OR OTHER APPLICABLE LAW. ANY INDIVIDUAL FOUND TAMPERING WITH ITEMS ON THIS AUCTION WILL BE PROSECUTED TO THE FULLEST EXTENT OF THE LAW. BUYER WILL INDEMNIFY AND HOLD SMITH AUCTIONS LLC (AND OUR AFFILIATES AND SUBSIDIARIES, AND OUR AND THEIR RESPECTIVE OFFICERS, MEMEBERS, AGENTS AND EMPLOYEES) HARMLESS FROM ANY CLAIM OR DEMAND, INCLUDING REASONABLE LEGAL FEES, MADE BY ANY THIRD PARTY DUE TO OR ARISING OUT OF YOUR BREACH OF THIS AGREEMENT, YOUR IMPROPER USE OF SMITH AUCTIONS LLC SERVICES OR YOUR BREACH OF ANY LAW OR THE RIGHTS OF A THIRD PARTY. YOU AGREE THAT THE LAWS OF THE STATE OF WISCONSIN WILL GOVERN THE TERMS AND CONDITIONS BETWEEN YOU AND SMITH AUCTIONS LLC, EXCEPT AS OTHERWISE STATED IN THE TERMS AND CONDITIONS. YOU AGREE THAT ANY CLAIM OR DISPUTE THAT HAS ARISEN OR MAY ARISE BETWEEN YOU AND SMITH AUCTIONS LLC MUST BE RESOLVED EXCLUSIVELY BY ST. CROIX COUNTY CIRCUIT COURT IN THE STATE OF WISCONSIN. DISPUTES CONCERNING FEDERAL LAW WILL BE RESOLVED IN THE WESTERN DISTRICT OF WISCONSIN. YOU AND SMITH AUCTIONS LLC AGREE TO SUBMIT TO THE PERSONAL JURISDICTION OF THE COURTS LOCATED WITHIN ST. CROIX COUNTY WISCONSIN FOR THE PURPOSE OF LITIGATING ALL SUCH CLAIMS OR DISPUTES. IF ANY PROVISION OF THESE TERMS AND CONDITIONS ARE HELD TO BE INVALID, VOID OR FOR ANY REASON UNENFORCEABLE, SUCH PROVISION SHALL BE STRUCK OUT AND SHALL NOT AFFECT THE VALIDITY AND ENFORCEABILITY OF THE REMAINING PROVISIONS. IF BUYER FAILS TO PAY IN FULL, BUYER (A) AUTHORIZES OWNER AND/OR AUCTION COMPANY TO RESELL SUCH PROPERTY AT ANY TIME AT PUBLIC OR PRIVATE SALE, (B) AGREES TO INDEMNIFY OWNER AND/OR AUCTION COMPANY AGAINST ALL LOSS OR DAMAGE UPON SALE, TOGETHER WITH COST AND EXPENSES THEREOF, INCLUDING ATTORNEYS FEES ALLOWED BY LAW, IF ANY AND (C) AGREES TO PAY AUCTION COMPANY INTEREST OF 1.5% PER MONTH ON UNPAID BALANCE. BUYER ACCEPTS FULL RESPONSIBILITY FOR ALL PURCHASES MADE AND HOLDS THE COMPANY FREE FROM ANY LIABILITIES INCLUDING THEFT OF ITEMS. THE BIDDER IS BOUND BY THESE TERMS. STORAGE FEES COMMENCE ON THE SIXTH (6TH) DAY AFTER AN ITEM HAS BEEN PURCHASED. STORAGE FEES ARE 20 PER DAY. ITEMS ARE CONSIDERED ABANDONED IF NOT PICKED UP WITHIN FIFTEEN (15) DAYS OF PURCHASE. IF AN ITEM IS ABANDONED, BUYER IS STILL RESPONSIBLE FOR MAXIMUM STORAGE FEES OF 200 AND ANY OTHER DAMAGES INCURRED BY SMITH AUCTIONS LLC AS SET FORTH IN THESE TERMS AND CONDITIONS. ONLINE GUN AUCTION TERMS ALL TRANSFERS WILL BE CONDUCTED BY MIDWEST GUN SALES 20.00 TRANSFER FEE PER FIREARM. NO TRANSFERS ON BARRELS OR UPPERS. LONG GUN BUYERS MUST BE AT LEAST 18 YEARS OLD. HANDGUN BUYERS MUST BE AT LEAST 21 YEARS OLD. ALL FIREARM SALES ARE SUBJECT TO ALL FEDERAL AND STATE FIREARM REGULATIONS ALL OUT OF STATE BUYER REGULATIONS APPLY OUT OF STATE FIREARM PURCHASES MUST HAVE FIREARM SHIPPED TO LICENSED FFL DEALER IN THE STATE THEY HAVE RESIDENCY IN ALL FIREARMS NOT PICKED UP IN PERSON AT SMITH AUCTIONS LLC MUST BE SHIPPED TO A LICENSED FFL DEALER. ALL SHIPPING TRANSFER FEES AND CHARGES MUST BE PAID BY THE PURCHASER SHIPPING OF FIREARMS WILL BE HANDLED BY MIDWEST GUN SALES, BUYERS RESPONSIBLE FOR ALL SHIPPING CHARGES FIREARMS UP FOR BIDS HAVE NOT BEEN INSPECTED BY A GUNSMITHALL SALES ARE FINAL NO REFUNDS OR EXCHANGES. RECOMMENDED TO INSPECT BEFORE BIDDING FIREARMS WILL NOT BE SOLD TO BIDDERS THAT DO NOT COMPLY WITH ALL REQUIREMENTS FIREARMS WILL NOT BE SOLD OUTSIDE THE U.S.A. WE NO LONGER SHIP FIREARMS TO CA, NY OR CT CR LICENSES NOT ACCEPTED, ALL FIREARMS TRANSFERS SUBJECT TO FEDERAL/STATE BACKGROUND CHECK ALL ITEMS MUST BE PAID FOR BY NOON OF THE FIRST SATURDAY FOLLOWING THE CLOSE OF THE AUCTION WITH NO EXCEPTIONS, IF YOU CANNOT MAKE THAT DEADLINE YOUR CREDIT CARD WILL BE BILLED FOR YOUR PURCHASES. IF YOU FAIL TO PAY FOR ITEMS, SMITH AUCTIONS LLC RESERVES THE RIGHT TO CONTACT LAW ENFORCEMENT REGARDING FAILURE TO PAY AND MAY PURSUE ALL CIVIL PENALTIES ALLOWED BY LAW WHICH MAY INCLUDE: FORWARDING THE MATTER TO OR OUR ATTORNEYS FOR COLLECTION, COURT COSTS, STORAGE FEES, AND ANY OTHER COSTS INCURRED BY SMITH AUCTIONS LLC.- Terms Of Use

Today

Nowadays, zero-turn lawn mowers are still one of the best and most popular machines for maintaining your lawn. They’re most often used for large, flat lawns, and more than thirty-six manufacturers offer their own versions of the design.

Ready to see which version fits you best? Contact us at Four Brothers Outdoor Power for more information, or to see our zero-turn lawn mower inventory for yourself. We proudly serve the people of Garland, Canton, and Greenville, Texas—let us serve you today!