Installation of sockets in a concrete wall: drilling holes

If you have already decided where you will have sockets, you can start mounting work, which consist of several stages.

Before installing the socket in concrete, marking is made, then a hole in the wall is made and a gypsum solution is prepared.

Step 1. marking on the wall

The sequence of marking works is as follows:

- Measure the distance from the floor to the expected place of the unfortunate installations with a roulette;

- If the flooring is not yet laid, then it is necessary to add another 5 cm;

- Using the construction level, draw two lines: horizontal and vertical with a intersection point at the place where the box will be installed;

- attach the glass to the wall and circle it with a pencil.

If two or more sockets are installed, then at first a horizontal fishing line for a trimmer is carried out with the help of the construction level. It should be located at that distance from the floor at which sockets will be placed.

Find the center of the first box and draw a vertical fishing line for a trimmer through it. Then postpone exactly 71 mm and conduct a second vertical. The center of the second glass will be in this place. The marking of the following sockets is made similarly.

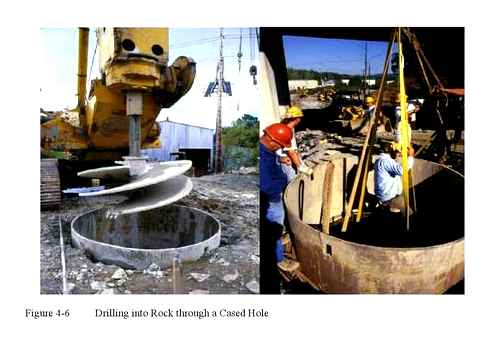

Step 2. piercing the holes in concrete

You can make holes in a brick or concrete wall in several ways. The simplest of them. with the help of a crown by concrete with winning teeth, which she, crashing into the wall, makes a circle of the desired size.

In the center of the crown there is a drill from winning to make a central hole.

Since standard sockets have an external diameter of 67-68 mm, a crown with a diameter of 70 mm is suitable for work. The nozzle is put on a peorator or drill, installed on a marked fishing line for a trimmer and a hole is made.

Then the nozzle is pulled out, and the entire concrete layer remaining there is knocked out of the hole and a hammer.

If there is no crown on concrete, then you can make a hole with a drill with a winning drill. First, the central hole is drilled to the entire depth of the nozzle, and then holes are made in the same drill along the circle line.

The larger there are, the easier it will be to hide the hole of the desired diameter and depth with a chisel with a hammer or a peorator.

Another way is to make a square hole with an angular grinder with a nozzle in the form of a diamond disk. First, the central lines are cut through, and then. along the entire perimeter of the socket. The process as always ends with a hammer chisel.

Step 3. installing the box in the wall

After the hole is made, it needs to be cleaned well and inserted into it for fitting. It should freely enter the width, and the depth should remain about 5 mm for the solution.

If everything turned out as it should, then it is now necessary from the upper or lower part of the hole (depending on the location of the electrical wiring room) to make the passage for laying the wire.

The socket also needs to be prepared. We turn it over the bottom of it, where there are slots for wires and cut one of them with a knife. We put the wire there and insert the box into the wall for verification.

To fix the glass, we prepare a solution of gypsum or alabaster, which must have a consistency of sour cream. It is worth considering that the solution of these materials hardens very quickly, and you have no more than three to four minutes to complete the process of the unit installations. In five minutes, the mixture will already be unsuitable.

Two minutes before laying the box in the wall the hole is wetted with water. After the liquid is absorbed, a layer of gypsum is applied to its walls with a spatula. The wire is spreading into the glass, the back of it is also smeared with solution, and the socket is inserted into the hole.

Adjust the position of the box so that its edge is flush with the wall, and the screws are located horizontally.

Step 4. combining several sockets

How the marking of two or more sockets is performed, it was described above. Holes are made in the same ways as for a single box. The only difference is the need to combine holes among themselves. This can be done with a chisel or corner grinder.

Before the installation work, the sockets need to be connected with each other with the help of a side fastener element. Installation in the wall is carried out similarly to the installation of a single glass.

An important point that you need to pay attention to when attaching the box block is a strict exposure of the sockets horizontally during their fixation in the wall with a gypsum mortar. It is necessary to produce this part of the installation only with the help of the construction level

Frequent errors

Common errors made during the installation of sockets:

- Installation of sockets until the finishing of the walls, which makes it difficult to subsequent alignment of the surfaces. When installing parts with distortion, you will have to remove the mounted boxes, and then close the parts again. An additional layer of plaster reduces the likelihood of contact of the crown and reinforcement when drilling.

- Installation of socket mechanisms into walls without transitional elements. A similar installation method is strictly prohibited, since it does not provide insulation of the wall material from power cables.

- Skewing the block of sockets horizontally and an erroneous determination of the distance between the centers of the mounting boxes. Incorrect positioning leads to the formation of cracks between the surface of the wall and the decorative frame of the module of the sockets.

- It is forbidden to use mounting foam for fixing the sockets, since the material does not meet the requirements of fire safety. I exist non.combustible foam class B1, but the strength of the material is inferior to gypsum or alabast mixtures.

How to install a socket in a wall?

Any installation always begins with markings, so before installing the socket in the wall, you need to correctly mark its location. We measure the desired distance from the floor: sockets are usually placed at an altitude of 30-40cm, switches-90-100cm, although there are exceptions. We draw a cross with a pencil and begin to drill.

How to make a hole for a socket in drywall?

If it is planned to install a socket on a wall of drywall, then take a coronal saw with a diameter of 68 mm and drill a hole. Then we insert the socket into the wall and fix it. To do this, we twist the screws, and they, in turn, press the socket to the drywall sheet with the help of the paws. Sometimes in the resulting hole is removed the chamfer to deepen the socket a little. If this is not done, then the outlet can stand up to the wall not close.

How to make a hole for a socket into a wall of gypsolite, brick and concrete?

To drill a hole in a full.shaped brick or gypsolite wall, you need a special crown by concrete. It is inserted into the peorator and is drilled. In this case, it is desirable to use the combined mode of detonation and drilling. You can drill a hole in the wall of drywall or brick using the simplest peorator.

The technology for drilling holes for the socket in the concrete wall is also performed as in Hypsolite or brick. However, for this you will need a peorator more reasonable.

What to do if there is no crown?

How to install a socket in a wall without this crown? Very simple! We circle the socket with a pencil and begin to make holes along the contour using a peorator. Then we insert a peak or shoulder blade into the peorator and begin to connect the holes. Thus, the recesses we need is depressed. We take the tender and try on: it should be flush with the wall or can be slightly drowned. If you bulge, you still need to hide. When the recess is ready, we fasten the socket to the wall with a dowel and self.tapping screw.

It is not difficult to cut a hole for the socket and in drywall without special devices. To do this, along the marked circle, a small drill of holes is made, and then a hole is drank using a file from a hacksaw on the metal.

How to get a wire into a socket?

Before installing the socket in the wall, it is necessary to make a hole for the wire in it. The holes are already scheduled on the panel body, so you just need to cut out the excess with a knife or carefully break out. You need to cut it from the side from which the wire will come. Then everything is simple: we start the wire so that it is exhibited 15-20 cm.

How to smear the socket in the wall?

A hole that is always a little larger in the wall than the socket itself. Therefore, after installation, around it you need to light. In addition, to fix the socket in the recess, you will also need something. For this, any dry mixture on a gypsum basis is suitable. I prefer to use alabastr for a number of reasons. In many construction shops, it is sold in small packages-1-3 kg. Costs 20. 40. Nothing by today’s standards. The full time of hardening is about ten to twenty minutes, which allows you to soon use a socket or switch.

How to put the sockets exactly?

The technique of fixing the socket in the recess using alabastra is very simple. Having prepared a mixture of water and alabastra, we apply it inside the recess, and then you need to press the socket there too. Further, using the level, rules or metal corner, we align the plane of the socket with the plane of the wall.

For proper work with concrete or other processed material, you need to choose the corresponding type of tool. When choosing a crown, you need to take into account the following conditions:

Cool

Crowns for sockets with carbide nozzles (surfaces) are used most often. They are cheaper than other crowns and are used for drilling under ordinary conditions, in everyday life for personal use.

Such a crown is created by applying a durable alloy on the cutting surface of the instrument of attack. A feature of such drills is that attacks fly out during drilling when entering the reinforcement. Therefore, for concrete areas with reinforcement, they are not suitable.

Diamond

The strength of such a crown is similar to a diamond circle. it also cuts concrete also well. Such a product is most effective for drilling concrete, reinforced concrete. A high.quality tool of this type has a high price, but this is justified by durability, saving labor and time. Such a crown is ideal for performing a large volume of work.

The cutting surface of the specified tool has spraying from technical diamonds and is able to cut out the reinforcement. It is suitable for work in very complex areas. When working with it, it is still recommended to avoid sites with metal. this will extend its ability to work.

Carbido-Wolfram

Carbido-wolframic spraying crows is used to drill ceramic tiles except concrete, stone and brick. This type of tool is very convenient for working with various materials at the same time: it does not need to be changed and can be moved immediately, for example, from drilling concrete to the creation of holes in ceramic tiles, and then to work with brick or stone.

The carbido-wolframic crown has a hexagonal shank, it serves to drill a conventional drill. Its power should be 800 watts or more. The only significant drawback is that this type of crown fails when it hits reinforcing rods or metal elements.

Rating of the best sockets for drywall

C3E2 for hollow walls

An excellent product at an affordable price that is sold in many construction stores. Made of durable materials that show high resistance to various influences. Waste for 240 months.

GUSI C3E3 NG

High.quality box made of non.combustible materials. Differs with a pleasant color, as well as a good degree of security. The person will have to cut out the cable channel on his own.

Schneider Electric D65

Reliable model of European production, which is suitable for drywall walls. The case is made of high.quality plastic, which does not deteriorate from prolonged exposure. For convenience, there are openings for wiring.

GUSI Electric C3e3

A more expensive option that will provide a person with reliability and strength for the entire period of operation. The case is made of polypropylene. Method of installation. secretive.

Safety precautions

Concrete drilling is a traumatic type of construction work, so it is important to follow the safety rules. The requirements for individual protection of a person are as follows:

- Use plastic glasses, because there is a great risk of rebound from the wall of crushed stone particles included in the cement. The mask is put on for the same purpose, so as not to damage open areas of the skin on the face.

- Put on a respirator or mask-“petal”. Concrete carvings are accompanied by the release of a large amount of dust. Small particles of cement settled on the mucous membranes, leading to a throat, difficulty in breathing. To protect the skin from dust, put on a protective suit or old unnecessary clothes and a headdress.

- It is recommended to use cotton gloves. They will protect their hands from possible burns and small scratches, will allow more confidently to keep the device without accidental slipping.

It is also important before drilling holes to study the plan in the room so as not to hurt the wiring and gas pipes. If there is no such scheme, the walls are checked with special devices. When it is impossible to do this, they refuse to work on concrete.

During the making holes in the wall, people are taken outside the radius of 3 m from the working area. If a socket is done at a height, then drilling is carried out on stable forests. The use of a penetrator without a strong base under the feet of a worker is prohibited.

When using electrical tools are held tight with two hands. The revolutions are increased gradually, not bringing to maximum values.

Non.compliance with the listed safety rules is fraught with breakdown of equipment in the very light case. Often workers receive serious injuries or a fatal outcome occurs when the concrete carvings for concrete carving incorrectly occur.

Devices for drilling

The opening device in concrete is selected based on the parameters of the concrete wall. There are such options:

- The thickness of the concrete ceiling does not exceed 300 mm. In this case, it is enough to use only a drill with a SDS-Plus cartridge. The preferred tool power is over 350 watts, the diameter of the drill clamped in the cartridge is 10 mm and above.

- The monolithic wall erected from the cement of the M400 and the highest brands can be cut out only by the SDS-MAX system with a shank diameter of 2 cm.

- For reinforced concrete structures, a heavier technique is optimal. a peorator.

- If necessary, drill a hole in the wall more than half a meter thickly used (rarely used in domestic conditions due to difficulties with connecting to a single and dual-phase network).

Thus, for drilling holes for the socket, the peorator is most often used. It is used independently, or in combination with a crown for a socket.

A hole using a crown

Crowned Building by concrete. consumables used together with the peorator for drilling holes. Consists of 4 elements:

- Pin with a flange for mounting on the device.

- The crown itself (has the appearance of a pipe with a diameter of up to 8 cm) with a thread.

- Drill for centering.

- Screw.

- winning (the cheapest and short.lived);

- tungsten carbide (universal use, quickly wear out without the possibility of recovery, but are inexpensive);

- metal with diamond spraying (cuts reinforcement, drilles the hole in 3-5 minutes of work).

- Withstand up to 10 cycles of work (cut up to 10 holes). they cost an average of 500;

- maintain performance even after 100-150 disperse in concrete. their

The following actions are performed for the manufacture of the hole:

- The pedorator drill is combined with the marking center on the wall, blend concrete for the required thickness.

- Put on the apparatus a collected crown. The centering drill is inserted into the finished hole, the device is included.

- The crown enters the wall two.thirds. this is how an even hole turns out.

Crown and drill combination

The crown even with winning teeth in the diameter of the cylinder is not always able to cut out the concrete wall. Therefore, they often use the combined method of drilling: with a coronet drill, they finish the work begun by the drill. In order to carry out work on reinforced concrete or strengthened surfaces, take the following steps:

- Mark the center of the new power point and approximate radius.

- The pedorator drill the center of the future outlet is drilled, and also make holes in diameter with a step of 2-3 mm.

- If it is necessary to perform the work as carefully and evenly as possible, the marking is made by the crown itself, turning it on for 7-10 seconds in drilling mode.

- Then they work out the wall around the circle with a drill, making an average of 20 holes. If the holes are drilled less, then during operation, the jolly movements of the penetrator are possible. the device is advised to keep it stronger.

Drilling by a pedorator

If there are no crows for the penetrator, and the work must be performed immediately, resort to an alternative drilling method:

- Design the center and circle of the future outlet.

- The holes are drilled with a drill in the middle and in diameter with a small step.

- Then, with the same drill, the recesses in concrete are drilled inside the already outlined circle for the socket. To knock concrete from the inside is allowed and with a chisel.

The process is very expensive in time and the efforts to be used in exceptional cases. The method also does not guarantee decorativeness: the knocked out circle will have uneven edges and unequal depths.

The use of corner grinders

Another unpopular method is the thread of the hole under the socket with a corner grinder. For work, the appropriate disk is used to work on concrete surfaces. They start work like this:

- The circuit of the outlet is marked, but not in the form of a circle, as in other methods, but in the form of a square with sides 8 cm.

- Turn on the corner grinder and make cuts of the desired depth.

- With the help of a hammer and a chisel, the concrete from the resulting contour is extracted.

The radius of the disk of the corner grinder is usually less than the necessary depth of the hole, so the wall is worked out with a chisel not only within the cuts, but also in deep.

This option is considered the most dangerous of the presented, because incorrect movements of the device lead to breakdown of the disk. The consequence of such an incident is often accidents.

Corner grinder is carried out only at right angles to the wall, without changing the position of the cutting parts during operation. In addition, when carving, the device occurs more harmful cement dust than from the peorator.

Making holes on the concrete wall

This stage is the most difficult and painstaking, especially if the concrete wall is durable and is difficult to drill. There are several ways to drill holes under the outlet depending on the presence of the corresponding tool.

- Using a special crown for concrete carvings. In this case, a hole is drilled in the center of the marking to enter the central axis of the crown. Thus, the crown will come in easier. The hole is drilled with a crown, and the remaining pieces of concrete are knocked out by a chisel.

- Using a drill with a drill on concrete. In this situation, 10-12 holes are drilled around the marking circumference, after which the resulting circle is knocked out using a hammer and a chisel (or other convenient ways).

- Mixed way. The first step, several holes around the circle are drilled, and then this design is drilled to the end using the crown by concrete. The remainder is knocked out by the chisel. It will be easier to work in this way, since the crown move will be easier and softer. This method is most relevant for strong concrete walls.

Do not strongly focus on a clear rounded hole. It’s okay if the place for installation is a little square, because the rest of the space in any case will be covered with a special solution for a strong and reliable fixation of the socket.

It is important to note that when installing a block of several outlets, it is necessary to drill grooves between them for laying wiring, which will interconnect all elements.

Installation of a socket

One of the simplest stages is the installation of sockets in concrete. This process is simple, but it must be remembered that the upper edges of the plastic socket should be flush with the surface of the concrete wall. It is unacceptable for him to stick out or fall at some distance.

Before installing the mechanism, you need to prepare a hole. To do this, prepare a gypsum or cement solution and apply to the inside of the hole. The layer should not be applied very thick, but only so that the socket is securely fixed in the hole. All the necessary wiring is threaded into the socket and is displayed out. After that, it is mounted in a concrete wall and is regulated by flush with a plane.

The remains of a cement or gypsum solution that will get out of the socket during installation it is advisable not to remove immediately, but after a partial drying (4-5 minutes) for a more reliable and strong fixation of the structure. We trim the residues of the solution with a spatula, and also soak all the remaining bumps and voids between the frame and the wall. The process of complete drying of the solution will take from 1 to 24 hours, depending on the type of solution and its number.

Requirements for sockets

A single set of rules describing the installation of boxes for the hidden installation of electrical outlets does not exist. The rules for the installation of electrical installations require compliance with the general requirements of fire and electrical safety. In this sense, the installation of the box under the outlet is no different from the installation of the distribution box. There are building norms and rules (SNiP), which determine the geometry of the placement of sockets in the room. Well, no one canceled common sense.

We will try to combine all the conditions under which the installation of the sockets will not cause problems during the operation of electrical equipment.

- The material of the boxes should be strong enough to withstand the force with which the fork is removed from the outlet. In addition, the case itself should not pull out from the wall with the outlet. To do this, on the sockets designed for installation for building mixtures (as a rule, it is gypsum or alabaster), there are ribs, grooves and hooks cast on the outer surface. Technological holes for the establishment of wiring also work as fixing elements.

- A pasty solution falls into these gaps, after drying the body can be pulled out only by destroying part of the wall or breaking the plastic.

- The vast majority of sockets are made from various types of plastics. On the one hand, it is cheap, on the other, plastic is a dielectric, and is not destroyed under the influence of moisture.

- On the inside of the boxes should be shaped ribs for fastening sockets.Many people remember Soviet buildings in which sockets fell out of the wall with the slightest effort. Previously, sockets were made of metal. Not only is it unsafe, the spacer guides on the outlet could not catch on the smooth surface.

- In addition, the sockets are equipped with landing holes for screw mounting.

- The plastic from which the sockets are made should not maintain combustion. From the point of view of the wall (concrete or brick), this requirement is pointless. But from a clumsy outlet, wallpaper on the wall can ignite, or standing next to furniture.

HOW TO install threaded rod with adhesive anchor into concrete. SafeSet method

Optional, but useful requirements. the ability to connect several sockets among themselves to standard clamps. This allows you to collect a design of any length.

We proceed to the direct installation of the sockets

Before starting work, it is advisable to have a complete set of consumables. Power cable, the required number of sockets (with a small margin “for scrap”), construction mixtures, glue PVA glue. Power tool with which you plan to cut holes.

Marking

Regardless of whether the power cable is laid in advance, or you will post the walls under it simultaneously with the drilling of niches for sockets, the installation of the sockets begins with thorough marking.

Guess where electrical appliances will be placed. Perhaps tomorrow you will want to make a rearrangement in the apartment. Therefore, sockets are installed according to the following principle:

- For universal use. at an altitude of 30 cm from the clean floor (meaning height from the staged finishing coating).

- For large household appliances (washing machine, refrigerator) at an altitude of 1 meter.

- If the blocks of sockets are mounted above the countertops or nightstands. at least 10 cm from the surface.

- A special case is the installation of outlets for the TV suspended on the wall. This is an individual project.

- But the distance between the centers of the sockets is a constant (applies to a group installation, in a row). This value for installing standard outlets is 71 mm.

It is also necessary to take into account the horizontal location. From the corners, ceiling, floor, door boxes. distance of at least 15 cm. From heating radiators no closer than 50 cm. Of course, it is impossible to place sockets over heating devices (with the exception of the “warm floor” system) and above the kitchen slabs. The rules for the installation of electrical installations and SNiP prohibit the installation of sockets and laying wires on the walls that directly go out into the street.

We make holes

There are three main ways. Advantages or disadvantages between them do not exist. It all depends on the presence of your tool and nozzles. There is no fundamental difference between the installation of sockets in a brick or concrete wall, so the technology is similar.

-

Crown on stone (concrete, brick). Classic and fastest option for drilling a wall under a round box.The diameter of such a nozzle is usually 70 or 75 mm. Given the outer size of the sockets (61–65 mm), it is better to use a larger crown. Firstly, it is easier to fill a solution with a solution than to squeeze the box into a tight hole. Secondly, you have a small supply in case of a mark in the markup.Then, adhering to strictly central marking, we drill holes to a depth exceeding the length of the socket by 10-15 mm. You will not succeed in the finished holes, most likely the installation site will look like this: it’s okay, the core is easily knocked out by a chisel or a nobleman.

Advice! What to do if the reinforcement came across the crown on the way? (Concerns only concrete walls).

It is not difficult to identify metal under the crown. You are definitely not mistaken: the deepening stops, a characteristic knock and vibration appear.

The most correct advice is to change the installation site of the outlet. The reinforcement has a step of 15-30 mm, if the placement is not so fundamentally. move the hole 3-5 cm. Before this, try to determine which armaturin you got into: vertical or horizontal. This will help to avoid further mistakes.

If it is impossible to move the outlet block, you will have to remove a piece of reinforcement. To do this, knock out the “glass” of concrete to see the metal. Break the hidden place around the reinforcement a couple of centimeters. A wire with a diameter of 5-6 mm, you can kill a chisel.

Thicker armaturin will have to drill.

Tip: Do not be afraid to violate the integrity of the wall around the holes. I certainly want everything to look beautiful even at the preparatory stage: holes, as in the picture, a perfectly even row. You just spend extra time, all the irregularities will hide and close the finish surface.

By the way, if you carry out the installation of sockets in a brick wall, drilling will not be a difficult task. The material is soft, easily drilled even without a peorator: a conventional drill with a winning drill.

If you make a niche in red brick, try to get between cement layers. Less destruction (concrete is broken out in pieces), and easier to choose a hole.

The only condition under which this method is indispensable is to work with a reinforced concrete wall of special strength. You just take off the expensive crown, and the wheels on the corner grinder are a penny.

Together with the strokes for the power cable, we just cut out rectangular or square holes with a margin around the sockets.

It looks unconditionally rude. On more or less processed walls, the hand does not rise to such blasphemy. And if the finish is still far away, this is the fastest and most effective way. Also suitable for brick walls.

The final result is ready.made holes for sockets with summarized strobes. Clean the niches with a brush or construction vacuum cleaner, and be sure to primer.

Installation of boxes

In accordance with the marking, try on the collected blocks. Installation of sockets is carried out regardless of the quality of the holes. If the box rests against an incorrectly drilled niche. it must be expanded. Marking. our everything! Do not be lazy at this stage, even if you do not want to pick up the chisel and pitch again.

Experienced installers fix the sockets on some guide, fix the perfect location, and then soak the boxes with alabastr.

If you just put the sockets in a liquid solution, they can shift until completely dry. We’ll have to fuck everything again.

Drilling reinforced concrete. About the sockets

Say Yuri Pashayev, head of the sales department of the company “ATACE TRUAL”:

After we drill a diamond crown, we will show you one of our last developments. diamond sockets. Here is one of the diamond sockets that we make. They are 3 types. As a rule, all manufacturers make these diameters, there are only 3 of them. diameter 68, diameter 72 and diameter 82. These are 3 standard. Basically, now for modern circuit breakers and outlets, of course, the socket is used here is the same-68th diameter. For switches and outlets of the old.sample (sloppy), 72 diameter is used, you need a little more. And the 82nd diameter is used for hidden rewinding boxes to connect the cable in the wall. This is diameter 82.

What is the cardinal difference between a diamond socket and probably all known sockets with winning incisors, inserts that are used on powerful SDS Max peorators, the work is done with penetration, with a blow.

First. Winning sockets. they are quite effective in uninhabited material, t.e. brick, block, something else. But if you are faced with at least some reinforcement, the chance that you will somehow get this effectively, drill, strives for zero. As a rule, it is customary to work with diamond sockets. The work of these sockets is carried out exclusively in drilling mode, there should be no shocks here, occur. And in the process of manufacturing, designing this product, we focused on the simplest use of. We did not make Accent for some mega-resources, we wanted an ordinary person or operator, a worker, taking a completely ordinary peorator in the region of 800-900 watts, the most common, put our tool and in a few minutes-2, 3, maybe to be, 4 minutes. quickly coped with this hole, to a depth of 6 cm. this is enough to install the plastic casing of the socket and then insert the outlet.

After we show dry drilling technology, we will move on to the demonstration of this particular tool.

All of our sockets are delivered without fail with very detailed. please look, let it go by hand. step.by.step instructions.

We had a case, a person calls me and says: “Listen, something your soccer does not drill.»I begin to ask in more detail what and how it was. He tells me: “Well, he inserted the central drill, made himself a centr clip, wrapped a socket, continued to drill.”I say:” Wait, and you pulled out a drill?”He says:” What, you need?”I say:” We must.”And only after he pulled the center drill, he continued to effectively drill.

Someone somehow out of habit, by mistake, in carelessness or out of ignorance, and quite often, forget to switch from the pederation mode and continue to drill. After that, we decided to create the most detailed instructions so that any person can be far from using this tool, could familiarize himself and act step by step. Very detailed instruction, which, in principle, levels (protects) completely from any errors in the process of using this tool.

Another nuance. In the manufacture of a socket, we focused on household peorators with a capacity of 900 W. There were cases when people put on more powerful peorators, someone wrapped it on a corner grinder-there is a way to wrap it on the shaft of a corner grinder. The speed is crazy, just almost a minute and 6 cm is ready. But, all the same, our tool is designed for more running.level surveyors of the household level. If you use a more powerful peorator or other turns, the resource is significantly reduced, it is very reduced. And when using a household peorater, you calmly send 20-25 can be 30 holes in concrete. And the most important thing when designing these segments, there is a specialized series of segments, it is only one, namely for the sockets. It is specialized, it cuts out a reinforced mesh on an ordinary small as a rule.

Now, colleagues, we proceed to the demonstration of a diamond socket in work. Maybe someone can try?

The first operation. we drill the center hole in a certain place. Next, install a diamond socket. Everything is quite simple. They got. And the following: we need to do, let’s say, a call of an entry. To subsequently remove the center drill and calmly continue drilling. It is enough to do a few mm drilling. Removed the center drill. it is important. and continued to drill.

If the crown is clogged, it needs to be pulled out and shake off. After we drilled, Kern is knocked out very simply. with the same drill or other drill.

The selection of products and recommendations for the installation of sockets

Wall material is the first thing to consider when choosing a socket. On this basis, existing types of products can be divided into two categories: for full.bodied walls and for thin partitions.

Full.bodied walls include the bases made of solid materials. Among them are aerated concrete, brick, concrete and reinforced concrete. For such materials, sockets are used without additional fixers. To fix the product in the wall, a construction mixture (alabaster or gypsum) is used).

Such glasses provide installation holes for wires. They are placed in the bottom or in the walls. Before installing the socket in the concrete wall, you just need to break the jumpers and squeeze out the plug to free up the hole.

In installation glasses, special openings for wires are provided

A Beginner’s Guide to Attaching Things to Concrete and Brick

Thin partitions are made from composite materials. These include plastic slabs, drywall and plywood sheets, wood-based wood and pr. For such surfaces, mounting boxes are used, equipped with metal.mounted paws of metal or plastic. They are pressed, reliably fixing the glass in a hollow wall. The paws are held inside the box with screws that regulate their position.

For the installation of triple sockets, glasses are used, in the lateral part of which there is a special mechanism for fasteners. Products of this type can be combined into entire blocks, fastening them by groove joints by.

What are the requirements to meet the glasses under the outlet

The material from which the box is made should have a sufficient margin of strength. High.quality products can withstand the effort that is attached in order to remove the fork from the outlet. In this case, the mounting box should remain in the wall, and not pull out after it. To ensure these conditions, manufacturers equip glasses with special grooves, ribs and hooks. All these elements are located on the outside. This rule applies to glasses that are fixed in the wall by building mixtures.

Technological holes perform two functions: provide access to the wires to the outlet and enhance the degree of fixation of the box inside the wall. After installing the socket in the concrete, pulling out the glass will no longer be possible. Will have to break plastic or destroy the wall area around it.

Installation glasses must be reliably fixed inside the seats

As a material for the manufacture of most boxes, plastic is used. Several types of raw materials are used in production. There are also metal sockets for wood. But it is still worth giving preference to plastic. This material, unlike metal, has dielectric properties. In addition, the purchase of a plastic socket will cost cheaper.

Important! Before buying a glass, you need to make sure that there are ribs necessary for fixing the outlet. Manufacturers form them on the inside of the products.

Metal sockets have another drawback. From the inside they have a perfectly smooth surface. The fasteners on the outlets simply have nowhere to catch on, so electrical installation devices may fall out.

Plastic glasses should not maintain combustion. This requirement is of particular importance if it is planned to install a socket in drywall and other composite partitions. With brick and concrete walls, the risk of fire is much lower. However, a closure in the outlet can provoke a fire of wallpaper or furniture located nearby.

The place inside the socket is enough to place the required wires

Installation distances between sockets and other standards for the device of electrical installations

Before installing a socket in the wall, you need to choose the optimal place for its placement. According to the standard, the installation distance between the centers of glasses is 71 mm. This value is used in cases where it is necessary to organize several sockets at once in one place. Electric power plants belong to the category of sources with increased danger, so points for their installation are selected taking into account safety requirements.

Basic rules for placing electrical installations:

- between the gas pipe and the outlet. at least 0.5 m;

- It is advisable to install electrical installations from the side where the handle is on the door and at a height of not more than 1 m from the floor;

- In the bathroom, the installation of sockets with an indentation of at least 0.6 m from the bath, shower and washbasin is allowed to eliminate spraying;

- The distance from the floor depends on the purpose of the outlet. If the electrical installation is necessary to connect large household appliances, its installation is carried out at an altitude of 1 m from the coating. This rule applies to dishwashers and washing machines, electric stoves, refrigerators. For universal purpose outlets, 0.3 m high is enough;

When planning sockets, it is necessary to adhere to the requirements for their placement

- in the kitchen, where small equipment is located on the table, blocks of sockets for it are installed at a height of 0.1 m above the level of the working surface;

- The parameters for sockets for a wall TV in the kitchen are selected individually;

- The proper installation of the socket also provides for the standards for placing boxes horizontally. Between the outlet and the door frame should be at least 0.15 m. The same applies to the floor, corners and ceiling of the room;

- The electrical installation is mounted with an indent of at least 0.5 m from the heating radiator.

Important! It is strictly forbidden to install sockets over gas and electric slabs, as well as heating devices. The exception is the “warm floor” system. Installation of electrical installations in the premises of saunas and baths is not allowed. In addition, standards are prohibited from using walls that go outside to organize wiring and placement of sockets.

Tool for the installation of sockets: what crowns are needed for concrete and brick

The choice of crown depends on the technology of installation and the material of the walls with which you will have to work.

The crown for drilling holes is selected based on the wall material

For household purposes, several options are used:

- Carbide crowns. cutting edges are covered with attacks from winning or other solid alloys. Suitable for dry drilling in a stress way.

- Carbide-wolframic crowns-designed for work with concrete, brick, stone. Can be used to install sockets for tiles or shell.

- Diamond crowns. cutting edges are covered with diamond spraying. Suitable for drilling walls made of durable concrete in an unstressed way (wet and dry).

The shank of the crown must definitely approach the cartridge of the tool, which will be used for drilling.

The shape of the shank and type of fastening distinguish between such types of crowns:

- with hexagonal tip;

- with a trihedral shank;

- SDS Plus and SDS (suitable for most drills and domestic surveys, their diameter. 10 mm);

- SDS TOP (for semi.professional peorators, diameter. 14 mm);

- SDS Max (for professional.purpose peorators, diameter. 18 mm).

With your own hands, the next set of tools and consumables will be required to install the sockets in a concrete wall:

- Electric Peotor with a cartridge corresponding to the SDS Max or SDS Plus standard;

- BURN according to concrete (length more than 6 cm, diameter within 5-8 mm);

- a hammer and a chisel (an alternative is suitable for a steel blade for a penetrator);

- Crown for concrete of the corresponding size with a shank under the cartridge of the penetrator (SDS Max or SDS Plus);

- respirator and protective glasses;

- a container for the preparation of a gypsum mixture;

- putty knife;

- gypsum powder;

- Mixer nozzles for a drill to mix components of the solution.

note! You can start installing sockets with your own hands only after the wiring is completely organized in the room. In some cases, an additional cable is allowed to lay. However, for the formation of a stroke, an angular grinder with a diamond disk is used for its installation, which leads to the release of fine dust into the room.

The crown can be used as a nozzle for a drill or a peorator

Winner and carbide-wolframa crowns for brick and concrete sockets

The decisive factor when choosing a crown is not only the drilling method and wall material. The value of the holes, their number and budget capabilities of the buyer, is also important.

Carbide-wolframic and winning nozzles are characterized by the most affordable price. Their resource is designed for a small number of holes. Such crowns are suitable for beginners who want to perform installation work with their own hands. The diameter of the holes for the outlet must correspond to the size of the plastic glass. Given this requirement, a crown with an identical size is selected.

Fear: diameter, depth and other parameters of the products for hidden installation

Installation of sockets inside the wall. Review of standard parameters and recommended sizes when working with concrete and drywall.

A solid alloy of cobalt, tungsten and carbon is applied to the cutting edges of the winning crowns. Such an attack is durable, so the nozzle can be used for drilling brick and concrete walls in a stroke method. But it will not withstand contact with steel reinforcement.

Carbid-wolframic nozzles do a great job with drilling brick, concrete and ceramic tiles. These crowns greatly simplify the work when it is required to install the socket in the wall, which is already faced with tiles. Carbid-wolframic nozzles are designed for power tools (peorator, drill), the power of which is at least 800 watts. In this case, an unstressed way of drilling should be used.

Useful advice! When the crown falls on the reinforcement, the baptism is removed from the cutting edges. Therefore, it is advisable to have a nozzle with diamond spraying of a similar size at hand to apply it if it is required.

How to choose a diamond crown by concrete for sockets

Diamond baby, which is applied over the cutting edges of the crown, effectively copes with the drilling of solid materials such as granite, concrete, stone, reinforced concrete concrete. She is not afraid of reinforcement.

In terms of stiffness, there are three types of spraying on diamond crowns for sockets:

- “T” (solid). for working with high.mass concrete, is used at low speeds.

- “C” (medium rigidity). for drilling reinforced concrete;

- “M” (soft). for working with strong concrete.

Crowns with diamond spraying are used for dry and wet drilling. In the second case, the cutting device is periodically cooled during the operation using the liquid. Dry drilling crowns are used in domestic conditions. They are suitable for working with concrete and brick walls. In this case, an unstressed way of drilling is used using a drill or a peorator.

Drilling holes by dry drilling

Advantages of crowns for the dry method:

- the possibility of drilling reinforced walls;

- high speed of hole formation;

- large working resource;

- minimum dust;

- low noise exposure;

- In the process of drilling, the walls retain their integrity.

Types and characteristics of sockets

Modern sockets both in appearance and in the method of installation are significantly different from those that were placed in the houses of the Soviet era.

If earlier they were simply grinned into the wall without the possibility of replacement, today to install them and, if necessary, change the outlet, is not particularly difficult.

And all this thanks to a socket, which, in fact, is a box that reliably holds a socket in its bowels and at the same time ensures its fire safety.

The sockets are of different shapes and sizes, differ in manufacturing materials and the installation method, so before buying, you need to deal with their views.

Feaster. Installation device designed for reliable fixing of the hidden wiring electrical installation products

Regardless of whether the installation of a single or group of sockets is carried out, before their installation, the walls are carried out

When dripping into a brick or concrete wall, these mounting boxes or glasses are fixed with alabastr

Fastening the socket in the partitions and false walls of drywall is carried out using adjustable spacer legs

Almost all building materials and slab options used in the black wall sheathing are suitable for installing sockets in them

In the line of products for hidden wiring, you can find options for arranging log and timber buildings

During operation, a “loosened” mechanism is easier to pull up in a socket. With its use, the installation is installed faster and more accurately

Choosing a socket on the walls of the walls

The main selection criterion is the material of the walls in which the installation of sockets will be installed.

On this basis, there is the following classification of boxes:

- structures designed for installation in walls made of solid materials: concrete, reinforced concrete, aerated concrete, brick;

- Walls for walls from composite materials: drywall, plastic slabs, wood-piece stove, plywood and others.

In the first case, the socket is a round glass on which there are no additional elements. It is fixed in the wall using a construction solution.

In its walls or bottom there are mounting holes for supplying wiring. When installing a socket, it is enough to remove the jumpers and squeeze the plug.

Bearing workers with side docking units allow you to quickly and simply install two or more outlets at once

For installation of several rosettes located a number of sockets, you can use glasses, the side of which is the mounting mechanism. The sockets join each other using special grooves and are combined into blocks.

In the boxes for drywall there are special clamping plastic or metal paws designed to fix the elements in the hollow walls. Clamps are mounted on screws that rotate, regulate their position.

When turning the screw, the paw is raising or lowering. Rotation clockwise brings the clamping element to the wall, and fixes the glass in drywall

What form is the products manufactured?

The most widespread are the bandits of the round shape. It is very easy for them to make a hole in the wall using a variety of devices.

Round glasses can be used both for the installation of a single outlet or switch, and united them into groups, attaching to each other through the docking units.

Square boxes are not used so often, but have certain advantages. Their volume is much larger, so you can hide many wires in them.

Often they are used to install the elements of the Smart House system. There are single and group sockets of square shape, designed to install up to five outlets.

Oval boxes are also found on sale, which, as well as square, have a large internal space. They are convenient in that you can immediately connect a double outlet in them. All the products described above are mounted in the walls and are used to carry out hidden wiring.

There is another type of installation boxes that cost somewhat apart-plastic linings or differently multiboxes designed for open installation for skirting boards. They are designed for one or more outlets and usually have a square shape.

External sockets have two modifications. structures with installation to the middle of the baseboard or to the floor. Since multibateboxes are mounted on top of the baseboard, their distinctive feature is aesthetic attractiveness and original design.

The size of the installation boxes

An important parameter of the sockets is their size, which are selected based on specific installation conditions. The size fork in diameter is 60-70 mm, in depth-25-80 mm.

Standard designs have external dimensions of 45 x 68 mm, it should be borne in mind that the internal depth in this case will be 40, and the diameter is 65 mm.

With a group installation of several round sockets, one of them, having an increased depth, can serve as a distribution box in addition to its main purpose

Items of increased sizes, the depth of which is about 80 mm, it is advisable to use when there is no distribution box in the wiring, and its functions are performed by the socket itself. As for square products, then, as a rule, they have a size of 70×70 or 60×60 mm.

Material material of installation boxes

The most popular are the sockets made of non.combustible plastic. They can be installed in concrete walls and structures from composite materials.

Basic rules for installing sockets

Before installing a socket, you need to choose the place of its installation. But since the socket is source of increased danger, special requirements prescribed in the “Rules of the Electrical Installations” (PUE) are presented in some rooms.

- From an electric outlet to the pipe along which the gas passes, there should be a distance of at least 50 cm; can be installed at a distance of at least 60 cm from a spray source (washbasin, shower, bath);

- The installation of switches is recommended to be carried out on the side where the door handle is located, while the distance from the device to the floor should be up to 100 cm;

- You can not install sockets in saunas, baths, rooms where washing is produced.

There are no special rules for other premises. Placing sockets should be placed in such a way that their use is convenient for all family members.

It is also necessary to be guided by safety requirements, and installing devices taking into account the location of electrical devices in the house so that their cords are taken to outlets without the use of extension cords.

You may also be interested in information about the nuances of the installation of an outlet for washing or sockets for an electric stove.

Recommended places for installing sockets and switches in the room in terms of practicality and convenience

Features of installation in high.strength concrete with reinforcement

Hole punching in the wall using diamond drilling installation

If the sockets are installed in panels made of high.quality reinforced concrete, special equipment should be used. the installation of diamond drilling. The reason is that the bourgeois of the pedorator is powerless against the reinforcement, and the drill on the metal will dull concrete. A corner grinder with a diamond disk, which has equally effectively saws both of these materials can be a way out. After performing the slots, the concrete is broken, the reinforcement is cut off.

How to install a double socket

For the installation of two outlets in one frame, the installation of two sockets is required. Let us consider in detail how this type of installation is performed.

The docking is performed with the help of a connector (butterfly).

From the side of the sockets there are special grooves in which they are inserted.

Thus, you can collect a garland of 2, 3, 4. 5, 6, and so on by the sockets.

For our example, we need only two. We make markings. We measure the distance from the floor.

Using the level at the desired height, we draw a flat horizontal strip.

Next, we apply the sockets fastened by the connector to the strip and mark the center of each on it.

Now, using one of the three methods described above, we make two holes of the hole.

The difference from the installation of a single socket is that after making the hole, you need to connect two holes among themselves. This is done so that the connector is fitting in the holes of the two sockets. Perfect these compounds with a corner grinder.

After the manufacture of holes, as well as in the example of the installation of a single socket, we lower it into one of the two wire holes obtained in the gate.

The rest of the installation is carried out similarly to a single socket.

The last moment, which is worth paying attention to, is a strict approach to setting them horizontally when fixed with gypsum. It is necessary to plant on a gypsum solution only with a level, the larger the number of sockets in the chain, the stricter this requirement.

Installation of various electrical wiring elements in the most detailed and colorfully described here.