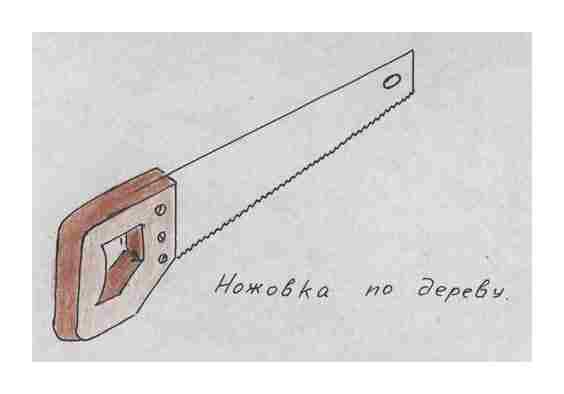

Hacksaw for wood and metal

In our case, hacksaws (saws) for wood and metal are used.

Hacksaws for wood differ into fine-toothed, large-toothed and medium-toothed. And also by the size of the set of teeth.

Classic tooth shape. triangular. There are, but much less often, and with a curly tooth.

Hacksaws for wood

When it is necessary to saw through a thick board or timber, then take a hacksaw with a large tooth and a large, up to 5 millimeters tooth divorce.

The more accurately you need to saw off the tree, the smaller the hacksaw tooth and the width of its distribution should be.

Wood hacksaws are distinguished by purpose. for sawing across wood and for sawing along the grain of wood. The first. more common.

The purpose of describing the most common hacksaws is to understand what you need from their universal types, therefore we omit the stories about bow saws, two-handed saws, narrow and wide hacksaws, with a backing, awards and jigsaws.

A universal hacksaw can be considered one that can be used in most cases of construction. That is, a length of about 0.4.0.5 meters, for cross cutting and with an average size of a triangular tooth with a divorce of about 1.5.2 millimeters.

On sale now you can find hacksaws that are not much different from each other in shape and about two dozen different manufacturers of the same size.

The price range is unpredictable. The most expensive ones can differ in price by ten times from the cheapest ones. What is not written in annotations! And ultra-strong, and with diamond spraying, and with high-frequency hardening, and made by nanotechnology, etc., etc.

Buy not expensive, because after you accidentally walk over the nails, they will cut about the same. So at least save money.

Most hacksaws, despite the warning that they cannot be sharpened, can be perfectly sharpened with a triangular file. It is better if someone who can sharpen a hacksaw for you, and you can do it yourself, as a last resort. Bears ride bicycles, and humans are much smarter than them!

As for the breeding of the hacksaw teeth, it is somewhat more complicated. Requires special wiring. It is a plate with a handle. The plate has slots of various dimensions. But the best. This is a wiring-clamp with adjustable parameters. Personally, I inherited this one and was brought from Germany in 1945, and I have never met any analogues on sale here.

FITTER LESSON NO. 18. HACKSAW BLADE

Our kulibins usually spread the teeth of a hacksaw with an ax. Insert a point between the teeth and turn it with a hatchet. The main thing is to do it evenly along the entire length of the hacksaw.

And why are the teeth bred? Yes, because if you do not do this, then the hacksaw panel will jam when sawing, and you will not be able to move it forward or backward.

Hacksaw for metal

When building wooden structures with your own hands, in addition to a hacksaw for wood, it is sometimes necessary to have a hacksaw for metal.

For example, the end of the nail sticks out of the board in the most conspicuous place and cannot be covered with anything. If you bend it, you will still be able to see it. And with a hacksaw for metal, you can saw off a protruding edge in seconds. Sometimes, in an inconvenient place where it is impossible to stick a hacksaw, this is done with one hacksaw blade.

There are many varieties of hacksaws for metal, ranging from slots to jigsaws. But they are smaller and, accordingly, more fragile than the classic locksmith. It is suitable for our universal work. In stock, the heels of blades with medium and large teeth will not interfere with it. The main requirement is that the blades are well hardened. Very often there are substandard ones. You run two times on a steel rod with such a blade and the teeth immediately jam.

Classic hacksaw for metal

Often, the blades break due to either a strong or too weak tightening in a hacksaw. Choose a middle ground.

By the way, the handles of some wood hacksaws are made so that their edges are made at an angle of 45 and 90 degrees. This is very convenient when there is no square at hand. Attach a hacksaw to the board, draw a line with a pencil and the indicated angles are transferred to the surface!

Ask a question to Semyonich (author of materials)

Our site is regularly updated with interesting and unique materials and articles on the topic of lumber, building materials and works, the author’s opinion and knowledge of a real shabashnik with more than 15 years of experience is given. There is a section. funny stories of shabashniki. If you would like to receive information about this, subscribe to the newsletter of our website. Non-transfer of your address to third parties is guaranteed.

Ax

In terms of its importance, the ax occupies one of the first places among the carpenter’s tools. Nice ax. this is the key to your good work. What can they do?

Chop, chop, hew, plan, spread the teeth of hacksaws, and much more, up to cutting a loaf, if there is no knife! It is noticed that when you work with an ax, even onlookers are not suitable, not to mention other bad people. I wonder why?

A good ax should be made of hardened steel, sharpened, and weighed against your physical capabilities. It is clear that, ideally, you need to have two or more axes, one for rough work, the second for finishing, the third for miniature, etc. But you can still limit yourself to one.

It is extremely rare to buy a good ax on the first try. When buying, try to consider everything very carefully. Lurid in shape and rough in forging are best set aside. Self-respecting manufacturers stamp their brand name on the blade. The angle of the blade should be about 20 degrees.

Cut metal easily! DIY Power hacksaw

The metal should not have delamination, chips, or inclusions. One of the signs of a good ax may be the following: pass a piece of rope through the hole and, holding the ax on it, hit it with a metal object. A great ax will sound like a church bell. And if the sound is dull or worse, rattling, then look for the ax elsewhere.

It’s good when for the first time an experienced specialist sharpens an ax with an electric grinder. It is important here that the angle remains the same at about 20 degrees and there is a possibility of water cooling, otherwise break the temperature regime of processing and the blade will become fragile.

After that, the blade is adjusted with bars, first coarse, then fine-grained.

If at the beginning you can sharpen towards the blade, then at the end of sharpening it is better to move with a bar in the opposite direction.

For fine work, the ax can be adjusted, that is, it can be brought to the ideal with Goya paste, thread and leather belts, but this is rarely done, since the point does not stay sharp for a long time during the cutting process.

However, all these skills come with time and experience.

The tree for the ax is used the same as for the handles of hammers, that is, birch, aspen. It is preferable to use the so-called twisted wood, with fibers that are not straight. Then there is less likelihood of chipping the ax. Juniper (it does not dry out, being once dried, but sometimes prone to chipping) or mountain ash of such a cross-section, as for an ax, is not always possible to find.

To prevent the ax from jumping off the ax, as in the case of hammers, use wooden and metal wedges, lowering it into the water. Sometimes a mounting plate bent at an angle of 90 degrees is additionally used. It is pushed into the hole of the ax, then the ax is inserted and fixed with a pair of self-tapping screws through the holes.

Attaching the ax with a plate

Apartment renovation and Moscow region

A wide range of renovations.

Professional craftsmen.

Varieties of tools

Currently, there are three types of tools for metal carving:

Homemade. The most popular and inexpensive option, which is well suited for simple household chores (cutting seams, grooves) and stands out for a high level of convenience during use. Quite often, such tools are complemented by wooden handles, which are placed longitudinally to the canvas.

Professional hacksaws. They are used for long-term work and obtaining accurate cuts, thanks to them there is an opportunity to cut metal to non-standard sizes. Supplemented with a comfortable rubberized handle.

Hacksaw handle. It is characterized by a special shape in the form of a staple, it is used for processing hard-to-reach areas. Well suited for cuts on the inside.

If you wish, you can see the photo of the presented options for hacksaws for metal.

Material and canvas

Among the common options for the material that is used to make hacksaws, there are aluminum, asbestos, bronze, hard rubber, brass, copper, plastic, cast iron and steel.

The blade for a hacksaw for metal is selected taking into account the size and volume of the workpieces. On average, the length of the canvas is from 300 to 700 millimeters. There must be even teeth on the blade.

When bending, the saw surface should return to its original state. If there are cracks or even the slightest traces of rust on the canvas, then you should refuse to buy such a hacksaw.

In most cases, hacksaw blades are made thin and narrow. If you follow the rules noted in GOST, then there are two types of hacksaw blades for metal:

- A. the teeth are located on one side of the file;

- B. teeth are located on both sides of the blade.

Shape and pitch of teeth

The shape of the teeth can vary depending on the inclination of the cutting element placed in front. Using the pitch of the teeth, you can determine the hardness and thickness of the material that will be processed.

Measure the number of teeth per millimeter of the file. During operation, the tool uses 2-3 teeth in parallel. The hacksaw teeth are directed away from the saw.

Hacksaw for metal where the teeth are directed

A hacksaw for metal is a tool that every man should have, since there is a huge variety of chores, in particular construction, where you cannot do without it.

But due to the huge variety of this kind of hacksaws, people may have difficulties with the selection of quality products.

Brief content of the article:

- Design features

- Varieties of tools

- Tool selection criteria

- Shape and pitch of teeth

- Material and canvas

- A pen

- Photo of hacksaws for metal

Design features

Mini-hacksaws and ordinary hacksaws for metal are characterized by a rather simple design: a narrow file is stretched between the two ends of the U-type staple. A file equipped with teeth acts as a working area, and working with this tool will be effective only if you use both hands.

The fastening system is of two types: thread (initially the web is pulled, and then with the help of a nut and profit they fix it), a lever (installation and shooting of the web is carried out using a special lever).

Tools with a lever are more expensive due to their versatility, quick installation and removal of the blade.

The great advantage of hacksaws for metal is that they do not require recharge from the electrical network.

Tool selection criteria

You can choose a good tool only if you take into account a number of criteria.

A pen

It is worth refusing to purchase a tool with a hollow handle, since even with the slightest pressure, there is a high probability of breakage.

It is preferable to pick up the instrument and hold it. The handle should be completely covered by the hand, you need to control so that the fingers do not cross, thereby interfering with each other.

If you follow all the rules presented, then a hacksaw for metal will last for many years, the main thing is to replace the blades in a timely manner and correctly select the check between the teeth. Thrifty owners even leave old hacksaw blades, and then use them to make many of the tools necessary in everyday life.

What should be the design

The structure of the hacksaw is quite clear. in the middle of the two ends of the bracket, which resembles the letter “C”, a hacksaw blade with fine teeth is stretched, which is the working part. For fastening, use either a nut with a wing, or a special small lever.

The second option, due to its versatility and ease of installation, is much more expensive than the first. The difference between electric appliances with a hacksaw for metal, and hand hacksaws is that they do not need electricity for use, they are easy to operate and maintain due to their low weight.

For the convenience of working in hard-to-reach places, use a hacksaw-handle. This mini hacksaw for metal is used to work with broken canvases. It takes up less space, but is no less efficient.

Hacksaw for metal where the teeth are directed

Every owner knows that a hacksaw is one of the most relevant tools in everyday life. It is not always convenient to use electrical appliances, especially in the country or in those places where there is no electricity. In this case, a hacksaw for metal will be an indispensable assistant and will cope with any task.

A lot of difficult work will be up to you, regardless of what material you will work with. wood, plastic or metal.

Brief content of the article:

Hacksaw for metal

The peculiarity of this species is in extremely small denticles. The canvas is stretched onto the frame from both sides, and the tension force is independently adjusted.

Pay attention to blade length and tooth pitch. The length is determined by how large the piece needs to be cut. On average, it fluctuates between 300 and 700 millimeters.

The distance between the teeth must be chosen, depending on what materials the work will be carried out. For example, a blade for a hacksaw for metal is selected based on the density of the material. for soft metal, a tooth pitch of 1.5 mm is selected, and a pitch of 2-3 mm for hard ones. Teeth with pitch of 3.5 mm and 5 mm respectively for soft and hard woods.

Choosing a blade for a hacksaw

Do not forget to pay attention to the teeth on the canvas, it should not have any cracks, chips or corrosion. The more teeth there are per inch, the easier it is to use and the faster the sawing process. According to the standards, the number of teeth per inch can be 18, 24 or 32 pieces.

GOST hacksaw for metal divides such a tool into 3 types:

- Single, with a distance between the pins of 250 mm, the total blade length is not more than 265 mm;

- Single, with a distance between the pins of 300 mm, the total length of the blade is not more than 315 mm;

- Double, with a distance between the pins of 300 mm, the total length of the blade is not more than 315 mm.

Varieties of hacksaws

Choosing a hacksaw or a saw, the consumer is often faced with a wide variety of models on the market and it can be difficult to figure it out on his own.

Knowing what types they are divided into, depending on the purpose of this tool, the task is simplified.

The use of a hacksaw for metal

Such a blade is quite versatile, due to the small teeth, you can cut not only metal, but also many other materials, for example, plastic, plexiglass or wood materials.

It should be flexible enough and not wobbly to allow for a correct cut. Over time, the operation of the tool dulls it and it will be necessary to replace the blade itself.

Concrete and plasterboard hacksaws

By design, it resembles a saw for wood, but in this case its thickness is significantly greater and, accordingly, the teeth;

Hacksaws for wood

Such a tool is used for sawing any wood products. The type and thickness of the canvas is selected depending on the structure of the tree. For example, a device with a wide blade is used for a straight rough cut, with a narrow blade for cutting wooden blanks;

METAL CUTTING

The essence and purpose of cutting. Hand hacksaw cutting

Cutting (cutting). an operation to separate parts from bar or sheet metal. Cutting differs from felling in that impact forces are replaced by loads. It is performed in two ways: with the removal of chips and without removal. For cutting with removal of shavings, the following are used: hand saw, cut-off hacksaw machines, metal saws, metal-cutting machines (turning, milling, grinding), autogenous gas cutting, anode-mechanical cutting, etc. Cutting without removing shavings is carried out with manual, lever and mechanical shears, nippers, pipe cutters, press-shears, parallel (guillotine) shears, dies, etc. Cutting is hand and machine.

A manual hacksaw is used to cut sheets, strip, round and profile metal, cut grooves, trim and cut out workpieces along the contour, etc.

Hand-held locksaw (fig. 7.1) consists of a machine (frame) 5, a handle 6 and hacksaw blade 3. The canvas is inserted with its ends into the slots of the movable 2 and motionless four heads, after which they are fixed with pins and tightened with a screw with a wing nut one. Hacksaw frames are made in one piece (Fig. 7.1, a) and sliding (Fig. 7.1, b). The former are used to fix hacksaw blades of one specific length, the latter allow you to fix hacksaw blades of different lengths.

Hacksaw blade is a narrow steel hardened plate with teeth on one or two edges and two holes along the edges (Fig.7.2, and). The length of a hand hacksaw blade is equal to the distance between the centers of its two holes. According to GOST 6645-86, the following main dimensions of the hacksaw blade can be distinguished: length I, width L, height B, step R teeth. The most commonly used hacksaw blades for hand hacksaws length I, equal to 250 or 300 mm, height B, equal to 13 or 16 mm, width / r, equal to 0.65 and 0.8 mm, respectively.

Fig. 7.1. Hand locksaw hacksaws: and. efficient (one. wing nut; 2. movable head;

- 3. hacksaw blade; four. fixed head; five. frame;

- 6. handle); b. sliding

Each tooth of a hacksaw blade is wedge-shaped (fig. 7.2, b) and the following geometry: clearance angle a, taper angle (3, rake angle y, cutting angle 5. For the geometry of the hacksaw blade, the following equalities are fulfilled:

When cutting, a comma-shaped chip is placed between two adjacent teeth until the point of the tooth comes out of the cut. The size of the chip space depends on the value of the clearance angle a, the front angle y and the pitch R. For cutting metals of different hardness, the following angles are taken: y = 0.12 0. a = 35.40 °, P = 43. 60 °. For cutting harder materials, blades are used, in which the angle of sharpening P is greater, for cutting soft materials, less.

Step P teeth of a hacksaw blade. the distance between two adjacent teeth (fig. 7.2, b). The choice of a hacksaw blade with the appropriate pitch depends on the properties of the metal being cut. For cutting cast iron, mild steel, a blade with a step of 1.2 is used. 1.5 mm profiled steel

Fig. 7.2. Saw blade:

and. the device of the canvas; b. the geometry of the tooth of the blade; in. wiring along the canvas; r. spread on the tooth; to. cutting width

rolled products and pipes, non-ferrous metals. 1.25, thin-walled pipes, thin shaped rolled products, soft and ductile metals and alloys (brass, copper). 1.0, for sheet steel. with a pitch of 0.8 mm.

To avoid jamming the hacksaw blade in the metal, the teeth are set apart. There are two wiring methods: 1) on the canvas (wavy wiring) (fig. 7.2, in), when the web is bent to form waves in increments of 8R; 2) by the tooth (fig. 7.2, d). only the teeth are set apart in different directions and the blade is not affected. The spread on the canvas is used for canvases with a pitch of up to 0.8 mm, the spread on the tooth is used for canvases with a pitch of more than 0.8 mm.

Cloths are made of steel grades U10A, P9, Kh6VF with hardness Sh1S 61.64.

Before proceeding with metal cutting, it is necessary to choose a hacksaw blade taking into account the hardness, shape and size of the metal being cut. The blade of the hacksaw must be installed in the slots of the heads of the hacksaw so that the teeth are directed with the tip from the handle (see Fig. 7.1, and). In this case, the end of the web is first inserted into the fixed head until the holes coincide and the position is fixed by installing a pin in them. Then the second end of the web is inserted into the slot of the movable head and secured with a second pin. Tighten the canvas by rotating the wing nut (Fig. 7.3, and). It should be borne in mind that a tightly stretched web with a slight skew can break, and a weakly stretched one bends during the cutting process and breaks.

Fig. 7.3. Techniques for working with a hacksaw: and. tension of the hacksaw blade; b. position of the right hand; in. position of the left hand; r. plunge into rolled products of rectangular cross-section; d. plunge into a round bar; e. cutting a thin sheet

Then the workpiece is marked out and securely fixed in a vice. The height of the vise should correspond to the height of the worker (Fig. 7.4, and). When cutting, it is necessary to stand half-way to the vice, i.e.

at an angle of 45 ° to the longitudinal axis of the vise (Fig. 7.4, b). The distance between the vise and the body of the worker must be

- 200.300 mm. Stand in front of the vice must be straight, free and steady. The left leg is put forward and the body is supported on it. Place your feet so that they form an angle.

- 60.70 °. The worker’s posture is considered correct if a right angle is formed between the shoulder and elbow parts of the right arm bent at the elbow with a hacksaw installed on the jaws of the vice (Figure 7.4, and).

Fig. 7.4. Position when working with a hacksaw: and. cases and hacksaws; b. legs (feet)

The hacksaw handle is wrapped around the four fingers of the right hand, while the end of the handle should rest against the middle of the palm, and the thumb is placed along the handle (see Fig. 7.3, b). With the left hand, take the hacksaw frame so that the thumb is inside the frame, and the rest grab the tension screw of the movable head (see Fig. 7.3, in). To facilitate plunging, the hacksaw is tilted towards the rear edge of the workpiece (see Fig. 7.3, d) or put a metal stop at the place of the cut and abut the hacksaw blade against it (see Fig. 7.3, e). In some cases, in the place of the future cut, a shallow cut is made with a triangular file for better direction of the hacksaw. When cutting, it is necessary to coordinate the efforts of the right and left hands. The movement of the hacksaw must be strictly horizontal. Press on the hacksaw with both hands, but make the greatest effort with the left hand, and with the right hand perform the reciprocating movements of the hacksaw.

The cutting process consists of two steps: the worker, when the hacksaw moves forward from the worker, and the idle, when the hacksaw moves back towards the worker. When idling, the hacksaw is not pressed, but pulled towards you. During the working stroke, press the hacksaw with both hands, providing cutting force.

When working with a hacksaw, the following rules must be observed:

- the entire canvas should be involved in the work;

- you should work with a hacksaw slowly, without jerks, smoothly;

- the rhythm of the hacksaw is 30.40 double strokes per minute when cutting hard steel, 40.50 when cutting medium hard steel and 50. 60 double strokes per minute for cutting mild steel and non-ferrous alloys;

- short workpieces are cut along the widest side;

- before the end of the cut, the pressure on the hacksaw is weakened, since with strong pressure the hacksaw blade can break and cause injury to the worker;

- the canvas must be periodically lubricated with mineral oil or graphite grease;

- a new blade should cut softer steels and alloys, with a dull blade. harder;

- pressure on the hacksaw depends on the hardness of the metal and the size of the cut part (hard metals require more pressure than soft, narrow parts. less pressure);

- the workpiece must be securely fixed in a vice;

- if the blade has “taken away” away from the marking risks, it is necessary to turn the workpiece and start cutting in a new place.

Workpieces of different profiles and cross-sections are cut with a locksaw hacksaw. In this case, it is necessary to take into account some of the features of cutting these blanks.

- 1. Strip material is cut along a narrow plane if its thickness provides simultaneous operation of at least three teeth. Therefore, thin strip material is cut in the following ways: a) along a wide edge; b) along a narrow edge, holding the workpiece between two wooden blocks (see Fig. 7.3, e); c) along a narrow edge, collecting several identical blanks together (package). These methods of cutting narrow workpieces exclude chipping of the blade teeth.

- 2. Round, square, hexagonal rods are cut with the hacksaw in a horizontal position, but so that the blade does not meet sharp corners when moving. Such rods are usually notched on two or four sides.

- 3. When cutting wide enough surfaces, tilt the hacksaw alternately to the back and front edges of the workpiece. In this case, the cutting does not take place over the entire cutting width and the work is facilitated.

- 4. For long or deep cuts, when it is not possible to complete the cut due to the fact that the hacksaw frame rests against the end of the workpiece and interferes with further cutting (Fig. 7.5, and), it is necessary to turn the canvas in the frame by 90 ° (Fig.7.5, b).

Fig. 7.5. Cutting with a hacksaw for deep cuts: and. the frame rests against the workpiece; b. cutting with blade turns by 90 °; in. work in a closed loop

When cutting blanks with a closed rectilinear contour (Figure 7.5, c), cutting is also performed with the blade turning 90 °. Before cutting, holes are drilled in the workpiece at the intersection of future cuts with a diameter equal to the width of the blade, and, passing the blade through the holes, fix it in the frame and cut along the markings.

When cutting workpieces with a curved contour, jigsaw saws are used (Figure 7.6, and).

Fig. 7.6. Cutting techniques: and. a jigsaw saw; b. cutting the pipe with a hacksaw; in. slotting

- 7. Cutting the pipe is carried out according to the marking, holding it in a parallel vice. Thin-walled and cleanly machined pipes on the outer surface are cut by clamping them in a vice between two wooden blocks (Fig.7.6, b). When cutting, turn the pipe periodically. It is necessary to cut with very light pressure and at the same time do not deflect the hacksaw blade away from the marking risks. If the hacksaw “takes” away from the marking risks, then the pipe must be turned and cut in a new place.

- 8. Before proceeding with the cutting of the metal of the shaped section, for example, an angle profile, it is necessary to use a square and a scribe to apply marking marks at the cut points on both shelves (when cutting the channel, the risk should be applied to its wall as well). After that, the metal to be cut is clamped in a vice so that the risks of both shelves are visible, and a small cut is made with a triangular file along the risk from the corner of the profile base. Having installed the hacksaw blade in the cut, they begin to cut the profile, holding the hacksaw in an inclined position, and then level it and cut it horizontally. When cutting blanks of different profiles with a hacksaw, it is necessary to monitor its direction all the time, not allowing to deviate from the marking risks.

A hacksaw can be used to make slots in the screw heads (fig.7.6, in). Wide slots (slots) are made with two canvases folded together.

Scheme of work with a hand hacksaw

A hacksaw for metal does not require special skills and knowledge in operation. Basic rules of work:

- It should be remembered the importance of the correct position of the performer’s body in relation to the cutting sites. At the beginning of work, the arm is bent at the elbow at 90 degrees, and the feet are slightly turned to increase stability.

- Before fixing the canvas in the frame, it is pushed apart along the width of the canvas. After installation, it is fixed with nuts that provide the required web tension. High-quality fixation of the web allows you to exclude various kinds of vibrations. In this case, the main thing is not to overdo it, because too strong fixation can cause the canvas to break. The degree of fixation can be adjusted initially with nuts.

- Hold the hacksaw with both hands while cutting. Movements when working with a hacksaw should be calm and uniform, preferably without sudden jerks. When moving the hacksaw forward, the tool should be pressed against the part more firmly, and when returning to the initial state, the pressure should be relaxed.

- Before cutting the material, experts recommend fixing it in a special vice. This helps to reduce the risk of blade breakage and further damage to the part.

Manual hacksaw for metal. Faithful assistant to the home master

A hacksaw for metal is a construction tool that every thrifty owner has. It is difficult to imagine performing any simple chores without using this device. A hacksaw can be actively used in working with various types of materials, therefore it is often called a universal tool. Now the choice of hacksaws is quite extensive and, as a rule, there are no difficulties when choosing such a device. The main thing, when making a purchase, take into account certain characteristics and parameters of hacksaws.

In the construction markets, hacksaws are presented in two main varieties. manual and electric. The hand-held hacksaw can be used anywhere as it is very light and mobile. Most importantly, the instrument’s advantage lies in its low market value. The only drawback is the expenditure of additional time and great physical strength in work.

Types and areas of application of the tool

The main purpose of a hacksaw is cutting metal products, cutting seams, grooves, cutting workpieces along outlined contours, etc. In addition, a hacksaw allows you to cut not only metal, but also, for example, foam plastic, ceramic products, plastic, organic glass and even wood.

In general, hacksaws for metal are conventionally divided into three types:

- home models are the most common and affordable option, which is optimal for performing simple tasks around the house and is particularly comfortable to use. Often, these hacksaws are equipped with additional tensioning screw mechanisms combined with a wooden handle located longitudinally to the canvas;

- professional hacksaws. suitable for longer work and getting accurate cuts. Hacksaws of this level are equipped with a comfortable rubberized handle and make it possible to install the blades at an angle for making non-standard cuts;

- hacksaw-handle. has a special shape in the form of a bracket for working in hard-to-reach places. The rigging in such hacksaws is cantilevered and fixed only on one side. The hacksaw handle design allows you to install even broken saw blades and is perfect for internal cuts.

Design features of a hacksaw for metal

The design of the device is quite simple. A hacksaw for metal has the form of a C-shaped arc, between the two edges of which the canvas is fixed (stretched). The tool consists of a removable blade and a special holding frame. The key part of the hacksaw and its main working element is the blade with teeth.

Each hacksaw element has its own characteristics and features:

- Handle. plays a major role in work, especially with regard to comfort when holding for a long time. The best among all types of handles are considered two-component, which are equipped with special rubber inserts. The handle can be placed on the side or on top of the hacksaw. The upper handle position (models without a bulky frame) will be needed when working in hard-to-reach places or for performing painstaking types of work.

- Frame. with the help of it the canvas is attached. The frame can be made from a variety of materials. If it is necessary to cut hard workpieces, the frame can be made of high strength composites. The frame design depends on the working conditions. So when cutting metal in poorly accessible places, a hacksaw is used with an adjustment of the angle of inclination of the canvases or a short frame. The frame can be solid or sliding. Preference is usually given to sliding frames, since in their device there is the possibility of attaching hacksaw blades.

- The blade is a thin strip of hardened steel. It is the most fragile and thinnest part of the hacksaw. Therefore, when working, it is necessary to be extremely careful and attentive, paying special attention to the details for the fasteners. Carelessness can lead to breakage of an already fragile blade. Wedge-shaped teeth (cutters) are applied to the edge of the blades. When choosing a hacksaw, an important indicator should be taken into account. the presence of hardening of the blade teeth. This can significantly extend the life of the saw and increase its productivity when processing hard materials with a high degree of rigidity. When processing hard metal products, blades with small teeth are used, and for soft ones. with large teeth. Hacksaw blades are available in different materials. It is better to choose bimetallic (painted in any color) or hardened blades (made of nickel-plated stainless steel with teeth. a dark color indicates the degree of their hardening). The blades are fixed in the frame in such a way that its teeth are located in the direction of the opposite side of the handle.

The design features of the tool mainly affect only the ease of use of the hacksaw. The cutting speed and the quality of the cuts made depends mainly on the hacksaw blades.

Choosing the right one

The quality indicators of the instrument are determined according to the following criteria:

Hand saws

The use of a hacksaw for metal

A hacksaw for metal is a tool used to cut pipes and profile metal. The simplest product consists of a hacksaw blade and a machine. The hacksaw machine, in turn, consists of a frame, to which a handle is attached to fix the hacksaw blade. On the other side there is a groove for adjusting the angle of inclination of the web and adjusting the degree of tension. The tensioning device on one side is equipped with a groove for inserting and fixing the web, on the other. a thumbscrew that tightens the web.

A hacksaw for metal of 300 mm or similar differs in the types of blades, which, in turn, have different lengths, widths, thicknesses, distance between the teeth, as well as different heights. For different types of work, different types of canvases are selected. The dimensions (steel grade, length, tooth width) are usually indicated on the packaging of the hacksaw blades. Each consumer buys a hacksaw blade with a blade that will be used to cut a specific material (Steel, copper, aluminum, bronze).

No matter how simple and not complicated tool the metal tool looks like, the price of some models can vary several times, it all depends on the quality of materials and the overall quality of workmanship.

How to work with a hacksaw for metal?

Before starting work, it is necessary to firmly secure the material that will be cut, you need to clamp it with a vise. This will protect the master from injury, will not break the canvas, and will not spoil the workpiece or part. If the workpiece is too thin, it can be secured in a vice by placing wooden spacers between it and the jaws of the vice. After that, it is imperative to inspect the hacksaw, check the condition of the blade, its wear and tightness, the condition of the saw frame of the hacksaw.

On the one hand, the web is inserted into the fixing groove with the handle, and on the other. into the adjusting device, fixing it with pins. The teeth of the blade should go from the handle, that is, during work they should be directed away from the master. A hacksaw is a simple tool, and you need to follow a few simple rules to make it easy to use.

A hacksaw for metal will be an excellent helper in your work if you use it correctly. The hand saw should be conveniently positioned in the hand so that the worker has a correct grip with his hands. The position of the worker’s legs should ensure a stable body position when cutting with a hacksaw. The cutting process provides a uniform and smooth, without jerking, forward movement of the tool, but only with the correct installation of the saw blade. It is necessary to move the hacksaw on the metal carefully, evenly, without jerking in different directions, otherwise such actions will break the canvas. If the blade nevertheless breaks, then it must be replaced, and the work continues, walking with a new blade along the cut already made, without applying significant efforts to the hacksaw.