Tile cutting methods: how and how to cut tiles and porcelain tiles?

If you decide to independently start laying ceramic tiles, the process of cutting it cannot be avoided. You will need certain skills and a set of tools. However, if you carefully consider the optimal arrangement of the tile, the number of cut tiles can be minimized. Basic rule: so that the masonry looks worthy, do not use too narrow stripes. The joints in the corners should be made of fairly wide strips (at least half of the tile).

Cut the tiles correctly. with the receipt of a perfectly even cut. Having bought several tiles more, you can practice cutting them yourself. And soon the result will please you. There are several ways of accurate tile cutting.

How to cut tiles? Tile cutting tools

The most common tool for cutting tiles among builders and those who make repairs on their own is a small manual tile cutter. Its width corresponds to the size of one tile. The cutting wheel of a large diameter leaves a deep groove in the tile, so that the tile is easily and evenly blushed at the cut site.

Manual tile cutter: the optimal tool for cutting tiles (both in price, and in speed of work, and in quality of the result)

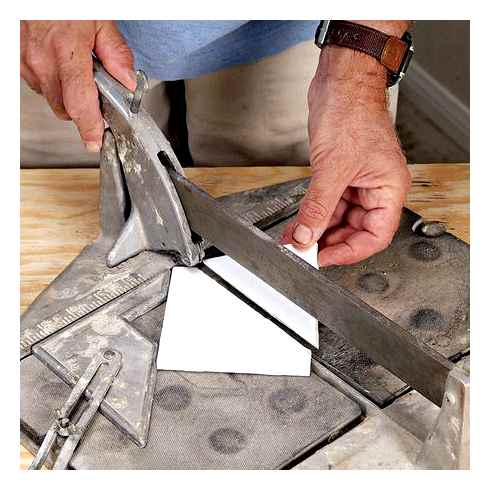

In order to carefully cut the tiles, you must first draw a fishing line for a trimmer for a tile, then hill horizontally in the device and fix it with a ruler. It is necessary to cut off the movement, raising the handle. Then it remains only slightly pressed in the place of fault.

With the help of manual tile cutter, you can cut a thin wall tile and thick sexual tiles qualitatively. The cost of such a tool is slightly lower than electric: the cheapest costs about 40. But in a high.quality device with a hard frame and support, the price reaches 300. Plastic tile cutter is quite suitable for a wall tile, and for heavy sexual tiles you need to choose a metal case.

With the help of manual tile cutter, it is difficult to make a curved cutout, but this is subject to professionals and this. Of course, you need to train and work out the skill. How to use manual tile cutter and how to use a figure cutting of tiles with it, watch the video.

Basics of design and technological capabilities

Teling cutter is a generalized name of building tools for a straight, curved or completely figured cutting of tiles. The classification of the variety of these tools is based on the type of drive movement. So, tile cutters can be:

Manual tiles consists of the base. a bed, a carriage with a roller and a handle. It resembles on the principle of action ordinary glass cutter. cutting tiles are cutting with a cutting video. At that moment she was clamped in the building according to the principle of pliers. After receiving the cut of the glaze, the tiles are broken down along it. To obtain a more even and neat cut, guides are used, which are exhibited by the tile clamping field. Иногда ручной плиткорез настольного исполнения может использоваться для получения круглых отверстий.

Electric tile cutter. a device equipped with an electric drive that rotates a diamond cutting disc. The principle of operation of this version of the tile cutter is similar to the circular saw. ceramic tiles are moved along the guide to obtain even and neat cut. One of the varieties of mechanized tile cutter is the strip, equipped with a diamond tape. For cooling tiles, water is supplied to the cutting area, which also rinses the cutting products.

In order to correctly cut ceramic tiles, you need to know how to use a tile cutter.

Manual tile cutter

Stable, sufficiently heavy weight and stiffness along the base axis of a stamped bed, which serves as a support for the tool itself, on which tiles for cutting is laid, has a rubberized surface of the base, excluding the possibility of slipping during the cutting process. The weakness of the stanchous body will lead to the occurrence of vibration during the split of the tile, which will lead to the culling of the consumable and damage to the tool itself.

The bed is firmly connected to two metal guides, in which the carriage is fixed. the main working element, the components of which are:

- Handle-bucket. A strong handle gives a more powerful lever, which is especially valuable when working with porcelain tiles.

- Carular shift cutting wheel. The surface of the cutting roller should be properly round, without flaws, burrs and potholes. When the roller is blown, the quality of the cutting is significantly falls. the sharpening of the cutting roller is impossible, the dull must be replaced.

- Holding the blank from random shift during pressing the foot.

The guides and the lever are made of strong steel and silumin, which have the characteristics necessary for the attached pressure: strength and rigidity. Additional elements are made of high.quality plastic.

Some models have a scale for choosing the size of the tiles, the size of the size is fixed with “lambs” screws (it can be very convenient to use the tools with a mirror double scale). The presence of a rotary line in professional models of tile cutters allows you to perform cuts of tiles at an arbitrary angle for figure processing of the workpiece.

A tile cutter can be fixed on any even stable surface using bolt compounds for the convenience of work and get additional stiffness when working with tiles of a sufficiently thick width. for this, technological holes are provided on the platform of the bed.

Classification of manual tiles

To cut the tiles in small quantities, you can use a manual tool. Cutting tiles in large volumes is much more convenient, using electric drive devices.

Based on the design features, the following varieties of manual tile cutters are distinguished:

- Roller. The simplest device in which a carbide roller is used as a cutting element.

- Mechanical. The tool is equipped with a hard carriage, thanks to which you can cut with particular accuracy.

- On bearings. The softness of the course during cutting is determined by the presence of bearings on which the bushings are installed.

The tile can be cut out with both a manual tool and an electric tile cutter, corner grinder, nippers, glass cutter. This can even be done with a jigsaw, but it is better to use specially designed devices for this, t. to. They allow you to achieve the desired cut quality.

The main rules on how to use a tile cutter

First, we will study the material part. There are many varieties of this tool. They are created for different types and sizes of the tiles, and most importantly, for various volumes of work.

Electric desktop tile cutter.

- This tool is similar to a circular saw, fixed on certain guides. Under it, a cutting table with special locks is laid out.

- The tile is fixed at the required angle, and you just walk along it with a circular. Of course, some cutting discs are used (most often with diamond spraying).

- The speed of rotation is quite serious, thanks to this, the cut is even and almost without chips. On certain models, liquid cooling is used. Even the coating tile looks in the part of the cut is quite presentable.

- Allows you to cut with an accuracy of a millimeter. Using this tool, you can cut off a strip of a couple of millimeters (you can’t do so mechanical tile cutters). Another difference is that with a disk tile cutter you can cut a groove.

- Two main disadvantages: huge price and restrictions on the size of the workpiece. Can be used at home, although this tile cutter for special construction teams.

Read also: Disks for longitudinal sawing of wood for circular

Electric stationary tool.

In fact, this is an unit for cutting tiles.

- The functions are almost the same as that of a desktop unit. Only functions and quality of work is better. The cutting table is calculated on the tile of any size, including floor porcelain tiles for huge areas. A better engine that helps to make a cut is put on tiles of any thickness.

- In addition to the inaccessible price, this machine will take up a lot of space. Therefore, it is used only by construction organizations at large facilities.

- Remember! With all its advantages, electric disk tiles is created only for linear cutting. Cut a curved fishing line for a trimmer, or make a hole. it will not work.

Mechanical manual machine.

- If you carry out repairs in the house (of course. yourself), or build a stone house, you can’t do without this tool. It can be rented, but the low cost makes this tile tile affordable for purchase.

- We will analyze this technique in more detail. It is difficult to work with manual tiles, despite the simplicity of the design. Actually and the glass can not become immediately. you will need a skill.

- The most important rule is not to be afraid to crush the tile during the passage of the video. Most of the destroyed blanks, the result of a poorly drawn furrow.

Tile cutting with a hand machine.

Do not believe that you will be offered a complete instruction like a funny treatise: “How to score a nail with a qualitatively”. Having studied the technology of hand cutting tiles, you can start working with the least percentage of marriage.

How to cut tiles with manual tile cutter?

Before you start using a manual tile, it is necessary to carry out a number of preparatory work that have a direct impact on the final result.

Preparation of tools for work

- Inspection of the product for any damage. View the video. there should be no curvature, Zazubrin. Otherwise you have to replace it with a new.

- Pay attention, cleaning the device, not forgetting to wipe the guides and the surface of the bed.

- All nuts and bolts need to be pulled up.

- Lubricate the carriage with oil if problems are observed with its movement.

Marking

To work at this stage, you will need a pencil/marker, with which you need to apply a fishing line for a fault trimmer. In the future, the tool will need to be fixed so that the cutting element is located exactly above the drawn line.

Tile cutting technology

So, how to cut tiles with a tile cutter correctly? To obtain an even cut, follow the technology:

- For 1-1.5 hours, cover the tile with a wet cloth or soak in water. Thus, it will be possible to make ceramics more malleable and avoid its crushing.

- Tile fixation. There are models of tile cutters that have seizures. take care of the immobility of the dick. If there is no such element, you need to support the material with one hand. The cutting element should be exactly over the future fault. If the dick is large, you can put something under its edges so that it does not stagger.

- The cutter should be at the very beginning, on the edge of the tile (where the fishing line for the trimmer is drawn).

- In the process of cutting, make efforts so that later it is easier to break the dick into two parts.

Attention! If the furrow turned out to be shallow, you do not need to be repeatedly passed with a tile cutter. Otherwise, it is likely that the edges will begin to crumble and turn out to be inaccurate.

Fault

After cutting carefully, slowly, click on the lever. The tile should break through exactly along the line.

Tile cutting technology

It is advisable to practice a beginner master on a bat or defective tile.

A furrow of sufficient depths must be cut in one pass. With a second attempt, it is impossible to set the video exactly in the same position, you get two furrows and the tile will break crookedly.

Whether to wet the tile

Soaking the tiles in front of a sharp in warm water is a useful procedure: the material softens and therefore crumbles less, the cut is smoother.

Smooting time is 40-50 minutes. No longer needed. the tile will deteriorate.

Porcelain tile is not subjected to smearing. only tiles.

If the tiles are large, and there was no large container at hand, it is wrapped with wet rags.

How can you cut the tile if not Tiles cutter

How to cut tiles with a tile cutter with a manual or other way, you can watch on the video. But what to do if there is no special tool? What can you do, how to cut the tile without tile cutter ?

Coating processing for even and not only cut is also performed by the following tools:

The latter can be performed with a fairly wide scale. For this, a variety of discs are available: steel (with segments or continuous), with spraying (more often than others, diamond), simple detachment (for gross work). Smooth, diagonal, curved and curly lines, as well as holes with a size of a diameter of the circle are formed.

How to cut tiles without Tiles cutter

Working glass cutter. forceps and other similar mechanisms are simple:

- The product is laid on the edge of the countertop;

- The tile with force is carried out with a cut;

- The cut part is slightly hit with a hand.

The method is suitable for thicknesses up to 5-6 mm. Deep cut is made by a diamond type of video.

A drill is possible to cut after preliminary refinement. it is grinded until an acute form is obtained. The finished “pencil” the surface is deeply cut through, the excess part is broken off.

It is known how to cut the tile with a tile cutter. But few know and possess more specialized equipment. So, the installation of hydro.carbraise. is involved in the workshops. Works water supply under high pressure. A controlled stream with a diameter of up to 0.3 mm erodes the structure itself and allows you to get any trajectory.

Tools

High.quality surface cladding with ceramic tiles often involves the use of a tile cutter, which will help adjust the tile to the desired size. Teling cutter is the easiest and high.quality way of cutting tiles: the operations are silent and exclude the appearance of dust, and most importantly, do not require professional training, so they can be performed even by an inexperienced user at home.

- Tile cutting as a component of facing work

- Tile cutting tiles with electric

- How to cut tiles with a tile cutter with a manual stationary

- How to cut a roller tile

- How to use a tile-cutting tank

- Cutting curly edges and oblique lines

Tile cutting as a component of facing work

Laying ceramic tiles to the surface of the floor or wall only in rare cases is complete without its cut, much more often the master is ready to hold a tile cutter, which he can use at any time of facing work.

So, our article is specifically for those who are currently engaged in or only plans to clad surfaces with ceramic tiles, but has not yet decided on the choice of the most suitable tile cutter model and does not own the technology of proper cutting.

It is known that the glazed ceramic tile is made of burned clay, covered with a layer of glaze on top. The technology for the production of ceramic tiles is very simple: clay give a certain shape and dry to fix the volume. After applying the glaze, the product is burned in the furnace, due to which it acquires special strength, durability and beautiful aesthetic appearance. In the finished form, as you yourself know, the tile is not susceptible to deformation and bend, although it is very fragile and easily pricks.

All these properties and characteristics of the tiles become the head of the choice of a certain method of cutting. Let us dwell in more detail on the main methods of cutting ceramic tiles and talk about how to use a tile cutter at home to perform small volumes of work.

Tile cutting tiles with electric

There is no doubt that an electric tile cut with a diamond disk is the highest quality and high.performance way of cutting tiles, stone and porcelain tiles of any hardness, shape and even thickness, and its use guarantees a completely straight and clean section with slightly rounded and smooth edges, unlike acute which are formed as a result of using simple tile cutter. Armed with an electric tile cutter, additionally equipped with nippers, you will get the opportunity to manufacture figured cuts of impeccable quality and pieces of tiles less than 5 mm.

Another indisputable advantage of equipment of this type is the cleanliness of the working process by equipping the tool with a pallet with water, where the dust and the smallest particles of tiles come at the time of the operation.

Regardless of the features of the design of the electric tile cutter, the cutting technology is the same: traditionally, the machine consists of a platform attached to it with a disk with a diamond coating and a pallet of water, which is supplied to the knife during operation, thereby wetting it abundantly wetted. Due to this, the amount of dust released is noticeably reduced, the life of the diamond disk increases, and the tile itself does not crack.

The speed of the cut of the tile is comparable to the speed of cut the logs with a regular saw, but in this case you have to move the tile under the disk, and not the knife for the tile.

The pressure force on the tile determines the density of the tiles and the material from which the knife blade is made. It should be remembered that at the moment when the knife blade barely touches the processed tile, the pressure should be minimal, as the blade moves through the tile, it increases and reduces again to the end of the operation. During cutting, the tile should be well fixed on the table, this will help to avoid vibration and reliably protect the blade from jamming in the central section of the tile.

It should be noted that experts advise changing water in the pallet as often as possible, since, together with the tile crumb, it is supplied to the knife, and this can lead to a serious breakdown of the blade.

A win.win option would be pressing the hands of the tiles on both sides at the same time, since if the tile leans to one side, then the edges of the cut will turn out uneven and with fragments, or the disk will be completely tightened with the tile, then throwing it to the side.

Since work with electric tile cutting is fraught with danger, it is recommended to wear protective glasses and headphones from strong noise accompaniment.

The saw disk in a wet cutting is able to withstand a thousand harsh. The blade periodically clogged with ceramic particles requires cleaning. To do this, it is enough to cut the worn sandy form for brick or perform cuts in grinding stone for ceramic tiles. You can choose another way. remove the blade, expand it and rotate in the opposite direction. And only if the wear of the blade is great, you can replace it.

The question of the advisability of buying professional electric tile cutter, practice and experience for working on it are extremely important, each user decides individually. At the same time, I would like to note that it is very effective for large volumes of work, and its only drawback is the high price.

How to cut tiles with a tile cutter with a manual stationary

Manual stationary tile cutting cutting is the most common tool for high.quality cutting of tiles and porcelain tiles in the circle of professionals and those who decided to carry out repairing with their own hands.

The package of manual tile cutter, the photo of which is presented below, includes a bed, a carriage with a cutting wheel and, of course, the handle.

Many people wonder: “How to use manual tile cutter?””

So, the technology of working on such a tool is impossibly simple: initially with a pencil on the surface of the tiles, marking the future section is performed. Then the tiles are placed on the surface of the bed so that the marking coincides with the direction of moving the cutting wheel, and the incision is carried out under a slight pressure. At this moment, it is important to feel the pressure of pressure so as not to crush the tile and at the same time make a groove of the cut of such a depth that would be sufficient for the subsequent break on this incision.

How to cut tiles with a manual tile cutter

Before learning how to cut tiles or porcelain tiles, you need to get acquainted with the rules of use, the choice of a suitable manual tool. You need to find out the nuances, listen to the advice of professionals.

To use manual tile cutter, it is recommended to take into account the following:

- The tool is always chosen taking into account the volume of work. If you need to cut several tiles, it is more profitable to buy cheap Chinese tile cutter. Anyway, he is the rest of the time in the barn or it is not a pity to just throw it away. Когда предполагается большой объем работ или использование инструмента в будущем, предпочтение отдают профессиональной модели.

- A hand tool is selected so that the length of the working area is larger. Otherwise, at a time it will not work to make an incision. Here you need to think for the future. For example, if it is supposed to cut floor tiles, then the tiles are bought with a large margin of length, since such finishing material occurs impressive sizes.

- Before cutting, the masters drip a drop of cleaned machine oil onto the video. Due to the reduction of friction, the quality of the cut will improve.

- During cutting, the lever with the carriage is moved smoothly without jerks.

- The roller should have no backlash. If such a drawback is observed, the knot is changed.

Smooth movement of the cutter improves the quality of the cutting, specialists use a secret that simplifies the manual cutting procedure. 1-1.5 hours before the start of work, they moisten the tile. The material softens, it becomes more obedient during the fault.

Often, inexperienced people have a question in the direction of the cut: from themselves or to themselves. There is no particular difference here. Experts cut the tiles in any direction. Everyone chooses a convenient way for themselves.

How to work with a tile.based tile with a manual tile

The very cutting principle does not differ for all types of tiles made of different material. However, there are small nuances. From porcelain tiles and ceramics is fragility. Here it is important to correctly calculate the force on the lever. If it is weak, the video will sober up a small groove. It will be difficult to turn the tile or it will burst in a completely different place. You can’t press too much too. From excessive effort, tiles are able to crack under the cutter.

How to Use a Manual Tile Cutter

For tiles and ceramics, you need to choose the right force of pressing the lever

With excessively strong pressure, the cutter in the tile will make a too deep groove. Chips will go on the tile along the decorative layer. Then they will have to be polished.

Cuts and ceramics do only one. Repeatedly with accuracy, it will not work to carry out a cutter. Two cuts or wagging lines are formed on the workpiece. A break will be sloppy with a crumbling edge.

If the force is selected correctly, the tile will easily turn into two parts. The edge in any case is polished with a file or corner grinder.

Safety measures when working with tools

A hand tool is less dangerous than an electric counterpart. Dust, sharp solid particles of the processed material do not fly from under it. The need to use glasses, respirator is no longer. Many masters do not even use gloves. However, it is impossible to completely neglect security measures.

Some types of tiles have a glossy coating. When cutting and breaking tiles, this layer crumbles, flies away with small sharp particles. Working with such materials, it will not hurt to wear glasses and gloves.

When working with a hand tool, they do not always use personal protective equipment, but this is not recommended for their own safety

Before using a manual roller tile cutter, check its performance. It is better to ruin a piece of unnecessary tiles than a new workpiece. Before cutting, the workplace is prepared. Nothing should interfere under hand. The table is freed from extra items. Prepare a place where to put the necessary and unnecessary blanks.

Manual cutter is considered safe due to the lack of rotating mechanisms at high speed. A person performs all movements himself. However, the danger of injury exists. Often, during cutting, they hold the workpiece so that it does not move. You need to find its correct location, where the cutting is lacking during cutting.

How to cut tiles with manual tile cutter?

Before you start using a manual tile, it is necessary to carry out a number of preparatory work that have a direct impact on the final result.

Preparation of tools for work

- Inspection of the product for any damage. View the video. there should be no curvature, Zazubrin. Otherwise you have to replace it with a new.

- Pay attention, cleaning the device, not forgetting to wipe the guides and the surface of the bed.

- All nuts and bolts need to be pulled up.

- Lubricate the carriage with oil if problems are observed with its movement.

Marking

To work at this stage, you will need a pencil/marker, with which you need to apply a fishing line for a fault trimmer. In the future, the tool will need to be fixed so that the cutting element is located exactly above the drawn line.

Tile cutting technology

So, how to cut tiles with a tile cutter correctly? To obtain an even cut, follow the technology:

- For 1-1.5 hours, cover the tile with a wet cloth or soak in water. Thus, it will be possible to make ceramics more malleable and avoid its crushing.

- Tile fixation. There are models of tile cutters that have seizures. take care of the immobility of the dick. If there is no such element, you need to support the material with one hand. The cutting element should be exactly over the future fault. If the dick is large, you can put something under its edges so that it does not stagger.

- The cutter should be at the very beginning, on the edge of the tile (where the fishing line for the trimmer is drawn).

- In the process of cutting, make efforts so that later it is easier to break the dick into two parts.

Fault

After cutting carefully, slowly, click on the lever. The tile should break through exactly along the line.

Safety precautions

It is required to know how to safely carry out the cutting of tiles with your own hands, how to avoid possible injuries. There are a number of requirements that must be observed:

- Inspect the tile cut through performance and breakdowns.

- Check the carriage. She should move smoothly, without jerking.

- The guides should be even and smooth, without damage.

- The cutting disk should have a flat surface, without burrs and potholes. He must rotate on the axis freely, not creaking and not stuck.

For safety reasons, you need to use protective plastic glasses and fabric gloves.

Tile cutting methods

The method of cutting depends on the material and the complexity of the cutout, consider the most common methods.

Cramping Ceramics with corner grinding

Corner grinder (angular grinder) is able to cut off any tile, the main problem is that the tool is quite complicated in circulation and is injured. In the process, a large amount of dust is formed, and small pieces of tiles can break off and fly away. When cutting a corner grinding of a fishing line for a cutting trimmer, it has a torn edge and a large number of chips appear on it, so this tool should not cut a cladding that requires delicate processing. In the presence of manual tile cutter it is better to use it.

When cutting the tiles with corner grinders, you should definitely use personal protective equipment: gloves, respirator, glasses.

Expanding an electrician

Electrician is used for small volumes of work and, if it is necessary to create curved cutouts. For cutting tiles, an abrasive saw is required. Let us give recommendations for cutting tiles with an electrician.

How to dry cut porcelain tiles with a manual tile cutter

- The tool should be able to adjust speed, do not set the maximum parameter. A neat result can be achieved by working at low or medium.speeds.

- The sole can leave scratches on the front side of the tiles, when sawing the tiles, you need to turn the back side up. It is also recommended to seal the sole of the tool with masking tape to damage the tile less.

- In a closed room, it is advisable to use a tool with a pipe. The pipe allows you to connect a construction vacuum cleaner, which eliminates a large amount of dust.

- When sawing tiles, you should not put pressure on the tool or otherwise force the process. The jigsaw must be promoted along the line smoothly and without effort.

Electrolobsik copes with wall tiles of medium thickness. Cutting floor tiles or porcelain tiles with this device is quite difficult. If you need to cut thick tiles, it is better to give preference to another tool.

Any glass cutter is suitable for cutting ceramic tiles. The principle of operation is not different from the glass. Marking is applied to the tile, then in one motion you need to carry out a straight line for a trimmer. The section must be done with one press in the entire site and the first time, because then it will be very difficult to get into the first furrow.

Когда леска для триммера проведена плитку надламывают об край стола или об цилиндрический предмет (гвоздь, наконечник отвертки). For the first option of breaking, the tiles are chopped from the edge of the table and pressed on the hanging part. If you break about the cylinder, the item is laid under the fishing line for the cutting trimmer, then you need to press on two edges of the tile.

If a small slice is made 2. 3 cm, then part of the tile can be broken off by pliers.

This cutting method is suitable only for direct cutting, it is almost impossible to make glass cutter. Also, the tool is poorly suitable for textured surfaces, as it will get stuck all the time.

Before using the glass cutter, you need to take spoiled tiles and practice draw the lines first on it.

Manual tiles (mechanical)

In most sources, this tile cutting device is called manual, although in fact it would be more correct to call this device mechanical. Manual tiles acts according to the principle of glass cutter, while its design is specially designed for convenient and accurate cutting of the tile. The cutting element is a diamond video that is fixed on a movable element, a carriage. The carriage moves along two guide rails. Compared with the use of glass cutter, make a straight cut is much easier.

Manual tiles has a special emphasis for cutting off the cut part of the tile. The lever structure facilitates the pressure on the press. Depending on the model, the tile cutters differ in the presence of various design features in them.

- Dry move, lubrication or video on bearings.

- The presence of a device for figure cut.

- Changing size for different types of tiles.

When working with manual tiles, it is important to observe a certain sequence of actions.

- At the first stage, you need to make markings, on the front side you need to apply a fishing line for a cutting trimmer.

- The tile is laid on a tile cut, so that the fishing line for a trimmer coincides with the protrusions on the bed.

- The cutting element is installed at the beginning of the marking line, then with a slight press on the lever we stretch the carriage.

- After that, pressing the cutting line in the middle of the line, we break the tile.

Electric tile cutter

In the presence of the word “tile cutter” in the name of similarity with the previous tool is not so much. In fact, an electric tile cutter is called a water saw. The device has more similarity with a circular saw than with a manual tile cutter. The device is equipped with a diamond disk, which is able to cut almost any tile: thick floor porcelain tiles, tiles with textured coating, facing materials for facades, etc.

The main advantage of this tool is that it can provide rapid cutting of any amount of tiles with any complexity of cutting. Also, when working with such a tool, such a amount of dust does not appear as when working with other electrical appliances.

One of the main problems in cutting stone and ceramic products is to heat the cutting disk. For example, when working with a corner grinding, the disk can overheat and fly apart, which can apply injury to the operator. The water cooling system on electrical tile cutters reduces heating.

Figure thread

Figure cutting is performed if the tile should bypass communications or plumbing equipment (shells, toilets, outlets, etc.). Here are tools that are suitable for figure cut.

- Drill with a nozzle of ballerinkeli crown is used to cut out circular holes.

- Manual or electric jigsaw can be used for curly cutting tiles with a small thickness.

- Electric tile cutter depending on the design.

- Kusachki allow you to fail from the edge of the tiles small pieces of ceramics.

- The cutters with a cutter have a cutter and nippers, first make an incision, and then turn the tool and clamp the tile along the cutting line until it breaks.

- Corner grinder can be performed a curly cut, but this must be done if there are certain skills, it is also important to observe safety precautions.