Restoration of books

After trimming the block, the circle of the spine follows. The spine of the stitched block usually thickens slightly (due to the threads). After rounding, this thickening decreases, the finished book acquires a more attractive appearance, the binding covers of it are easier to open. Roots are subjected to roots of thick blocks consisting of more than six prisons.

This operation is performed with a wooden or metal hammer with a flat wide boy. Blok with a previously moistened roof is placed on a metal plate or thick even board.

Rules Range: with a hammer and a grip with the extension of the falses of notebooks

Holding the front edge of the block with his left hand (four fingers should pull the sheets on themselves, and the thumb should be rested against the front tip) and pulling it so that the rook plane is mowed a little, the shock is inflicted on the top of the spine from its middle to the upper and lower cuts, gradually transferred blows closer to the middle part of the spine.

In order not to break the outwater and not to shift the upper notebooks, the blows should be uniform and not very strong. In the same way, the other side of the spine rides in the same way, as a result of which it acquires a correct, oval-conjure form, and the front cut-an oval-wrapped.

The upper lines of the spine on both sides of the block must match the vertical with each other. Sometimes the spine rides after cutting the front field and only after cut it the upper and lower fields.

To give the roots of greater strength and for better opening the book, notebooks resort to bending the folds of the fakes, as a result of which the spine acquires a mushroom shape. To do this, the book block with a spreading rounded spine is slightly clamped in the universal vice between curly binding boards so that the facks of the first and last notebooks protrude over their edges for 2-3 mm.

With a hammer they give the spine the final shape and, turning the screws, clamp the block more tightly. Having wiped the spine with starchy glue, light blows of a hammer or kashirovkp, starting with the extreme notebook of one of the sides of the block, its fold is laid on the end part of the board. Falcers of the subsequent (to the middle of the spine of the block) of notebooks are laid one on another and move on to the processing of the other side of the spine. The spine with stacked folds is glued with thin paper and allowed it to dry, without extracting from a vice.

Finishing of the brand cuts: coloring with a brush, a swab and an application of a convex ornament

So that the book has a more attractive appearance, the cuts of the block are painted. To do this, you can use liquidly diluted colored mascara, gouache, watercolor or tempor. Before the filling, the block is placed between the two boards so that its painted part is at the same level with their edges, and clamped in the press. A brush, a gauze swab or a piece of foam rubber is dipped in paint and with quick movements with uniform pressure apply it to a painted edge of the book. Then, without taking out the press, let them dry.

There are other ways of decorative decoration of books of books. Here is some of them.

The book block, as in the previous case, is placed between two boards and clamped in the press. A thin layer of a tinted flour clayer is applied on a cut and draw some ornament on it with a wooden stick with a wooden stick. Upon drying the Kleuster, the ornament is on the cut. The thickness of the stick and the configuration of the tip that the image is applied is selected depending on the thickness of the block and the planned pattern.

The paint on the cut of the book block can be applied from a spray gun or using a brush. Some binding lovers make stencil rollers, which can be applied (roll) on the cuts of blocks of various ornaments using paints of several colors.

Patterns from colored spots or dots can be applied on a cut of the block with a foam sponge or cloth swab.

Sometimes a convex ornament is applied to the book cuts with a special stamp. According to the front cutting of the book block, it is better to apply it to the rounding of the spine, along the upper and lower. after round. To process the cuts, the block is clamped in a vice. If desired, such a drawing can also be applied with a knife, supraf and other tools. In this case, you should pay attention to the thorough of the decoration of the slotted elements, their cleaning and clarification. Application of a convex or in.depth ornament can give an interesting effect of design.

Having completed the filling of the cuts, they begin further operations for processing the book block.

If conceived, glue the bookmark (liesse). a silk ribbon or braid. One end is lubricated by 30-40 mm glue and glued in the upper part of the spine; Another. they are invested between the sheets of the book and cut off so that it protrudes from the block by 50-80 mm.

Following this, Kaptal is glued. If there is no finished captal, it can be done yourself. To do this, you need to take a colored tape, spread it slightly with glue, fold it in half along and, putting a thin lace in a fold, glue it, wipe it with a bone and dry under the load.

Capal is glued on both sides of the spine so that its scar protrudes above the cuts of the block.

In the old days, Kaptal was not pasted, but weaved on the book itself, sewing it to the notebooks. To make such a cap, you need to take two pieces of twine or stump cord, two needles with thick multi.colored threads seasoned in them (you can twist ordinary sewing colored threads in several layers). The tip of the twine or cord is fastened with the end of the thread. The needle with a thread is inserted into the extreme notebook of one of the cuts of the book block, the thread is extended to the end and, overwhelming the loop around the twine, is inserted outside the next notebook outside.

Then take a needle with a thread of a different color, fasten its end with a cord and, passing it through the third notebook, make a loop like a previous thread, introducing its end to the next notebook. Alternating threads of pronounced colors, braid the entire cord, sewing it either to each or through one or two notebooks (depending on the thickness of the block).

The wicker captal was sometimes attached to the seam close to the cutting of the book or weaved simultaneously with the sewing of the book itself on the cords. In the latter case, the same thread (usually harsh) was used to braid the captal, which was sewn the block.

After drying the pasted cap, the spine is slightly smeared with glue (that when gluing), at the same time strip of newspaper paper cut in size of the spine, but 30-40 mm shorter than it is also slightly smeared with glue and rubbed with the spine with his hand to the spine. A spine of explicit books (more than 800 s.) it is better to glue with paper glued with gauze. This will increase its strength.

Seal

It would seem that it could be easier than printing a book? But there are several important points here. First, you need to choose the right paper. All paper, which is industrialized on the Central Bank, has a clearly expressed direction of the fibers. Only printers are available to the vast majority of readers, which can print on sheets no more than A4 format. Almost all of the paper of this format (I tried about 20 marks) has the direction of the fiber along the long side (short-ko-short-fraudulently bends much worse than long-to-long). Try yourself and immediately understand what you are talking about. We ideally need fibers to be along the short side. Unfortunately, the packaging of ordinary office paper is not marked according to this parameter. Of those 20 marks, all were “inappropriate”. Taken in quotation marks because the result is not very deteriorating, and I believe that if you do not have the necessary paper, then it makes no sense to worry and print on the one that is.

Secondly, pages on book sheets are not in order.

We will make a classic book. This means that in each notebook of the book block we will have 16 pages of A5 format. 4 A4 sheets sealed on both sides and bent in half.

Start by creating a layout. I used OpenOffice Writer (hereinafter. OW). Choose the desired headset and font Kagl, set the fields, numbers pages. I draw attention to the fact that Kegl should be more of the desired. A little later it will become clear why. We save and export to PDF.

Oow does not know how to print pages in random order. That is, if you set pages 16 and 1 numbers, it will first print the first page, and then the sixteenth. But Foxit Reader, which I use to view and work with PDF, does everything as it should. In the printer settings, select the album orientation of the sheet, and in the Foxitreader print settings. two pages on one sheet. Here the increased font size will come in handy, because the real size of the page will decrease.

Page numbers are very convenient to calculate in the editor of tables.

Every two lines indicate the order of printing of the pages of one notebook. First we print one side (8 pages), then we turn the paper and print the second side. You can take the calculator from me.

Subteen more than one notebook can be risky at a time. First you need to understand the features of the paper supply with a specific printer. Yes, and then we work with notebooks. So printing one notebook is our choice.

We collect a book block

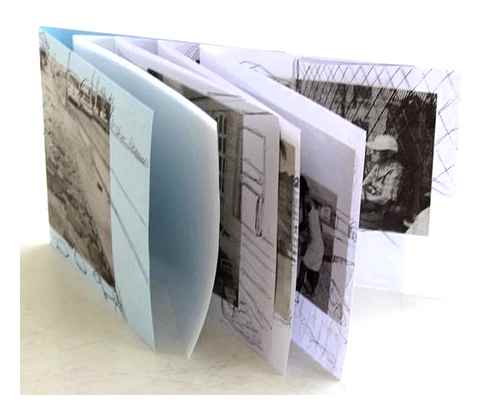

This is what we did:

There are many ways to make binding and stitching a book block, I will talk about those that I use myself.

First you need to bend the notebook in half. Here we would especially come in handy with the right direction of the fibers. You can bend each sheet separately, or you can. a notebook (4 sheets) entirely. I prefer the second option. It seems to me that this is how the notebook turns out to be more integral. The spoon in the previous photo did not stay from lunch. it is very convenient for it to press the fishing line for the trimmer of the bend.

The further step is desirable, but not required. It would be nice to squeeze the bent edge of all notebooks into a special press. But without fanaticism, otherwise there is a risk of mating notebooks.

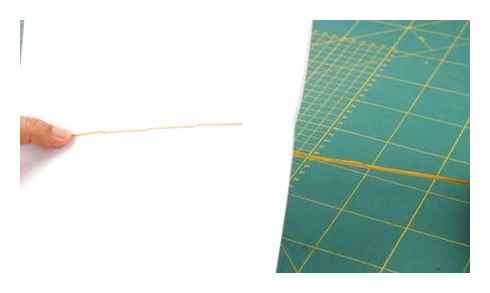

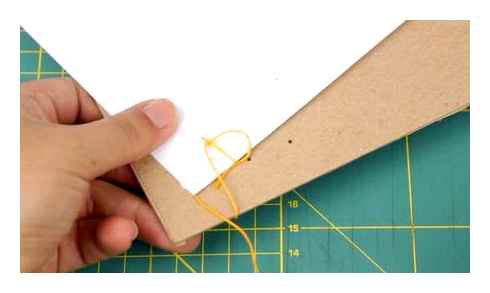

While notebooks under the press, we need to mark the template to pierce holes. We take a piece of cardboard. We denote the edges (210 mm. according to the format of the sheet). To sew a book block, we will use a tape of 5 mm wide. In order for the book block to be very strong, we will sew it on three ribbons. The distances between the holes under the tape take 6-7 mm. And by a hole at a distance of 10 mm from the edge. Everything is clearly visible in the picture.

We mark each notebook on the bend.

Pierce the holes from the inside with an awl. This is what we will succeed.

Burner pieces of tape and glue them at the right distance from each other with tape. We glue on the very edge of the table. This is most convenient.

With which notebook (with the first or last) to start. it does not matter. The main thing is not to confuse their order. The numbers of the pages must be carefully monitored. Otherwise, you have to remake. I want to immediately pay attention to the fact that until the very moment of gluing the book block, we can change everything we want. Here you can take a break, relax a bit. Because the sewing of the block is a very important part of the assembly of the book.

We sew! For sewing, I use the threads for embroidery. They are durable, obedient, multi.colored, quite fat and very easy to find them. Have you ever seen a book sewn with lilac thread? I haven’t seen either. That’s why we take the bright. Individuality is one of the reasons to do all this.

The use of cargo is very desirable. Notebooks will not ride one relative to the other. The ribbons are sheathed outside.

So we almost sewed two notebooks. We fix the thread with an ordinary double knot.

From the third to the last notebook, we fix the thread in this way.

We fasten the last notebook again.

Our book block is almost ready!

We use either such a clamp like mine or ordinary heavy load on top. We fix the block so that the edge performs slightly. We smear PVA with glue (stationery is quite suitable). The glue needs very little, exactly so that it penetrated a little between the notebooks. And clamp under the load so that the notebooks glue. You do not need to tighten hard.

Next, glue the boat. If we used ordinary office paper for printing, then for the overflows we must use dense, from 130 g/m2. Furlers will combine binding and a book block into one whole.

How to cut a book block evenly

Chapter 4. Workplace and tools for relaying work

At home, it is advisable to allocate a special corner for the workplace near the light source, and even better not in the living room. In libraries, for this, a place in the utility room or far from book racks is found so that the dust and evaporation appearing during the processing and gluing of the binding materials do not settle on books. If it is possible to organize a circle of binding business, then the premises for classes must comply with sanitary and hygienic standards and the requirements of production aesthetics, be dry and bright, well ventilated. At the same time, it is better to have two rooms in the calculation of 15 circles and one teacher. one for classes (with an area of 40. 45 m2) and another (with an area of 12-15 m2). for utility work: preparation of adhesives, sharpening tools, storage of material reserves. If only one room is allocated for classes, the place for utility work must be allocated near the window, in the window opening of which the exhaust fan is mounted and fenced off with a glazed partition. The walls of the room for classes are recommended to be painted in light colors of yellow, green, blue shades. It is desirable that the area of the glazed surface (windows) is 1/4 or 1/5 of the floor area. It is better to provide artificial lighting with fluorescent lamps; Minimum lighting at workplaces in artificial lighting. 300 lux. For ventilation of the rooms, the windows should have windows or transmigs. Air temperature should be maintained in the range from 18 to 21 ° C at a moisture content of 40-60%. Place furniture and equipment so that natural light falls on the left side or on the left and front of the working. The table of the head of the mug, a cool board, posters and demonstrated samples should be clearly visible to everyone. Each workplace should be individual. Given that the main binding operations are performed sitting either while standing at the table, and its surface is subjected to physical exertion (pressure, impacts), we need an enhanced and raised tabletop. It can be made from forty.mmile boards, connecting them from the bottom along the end and one longitudinal sides with bars from the same boards (100. 120mm high. ) The front part of the new countertop is covered with plywood or basinax and strengthened on the table cover, which increases its height by 140. 160mm. The edges of the additional countertop should be trimmed with wooden rails, thoroughly cleaned, putty and painted with oil paint. The space formed between the additional and the main countertops can be used to store materials and tools.

In the right front corner of the table cover, a hole is made in the diameter of the adhesives, where it is installed during operation. A penalty for tools is attached to the right side of the front leeal edge of the lid (or to the right end). The general view of such a table, as well as the tool penalty shows on the rice. eighteen.

Chairs, and even better stools should be 100. 150mm. above standard. They are convenient for working sitting and when changing the working position. To store materials, devices, tools, you can use the available cabinets, racks, shelves. Paper and cardboard cutting machines, drive and mechanical presses, etc. P. Equipment (if it is in a circle) should be installed no closer than 2. 2.5m. from desktop and equip them with protective devices. They should be free and safe access. In the workplace of the circle, a place for a showcase with visual aids, layouts stands out. When equipping the utility room, special attention should be paid to the air exchange in it: the sharpeners must be equipped with a dust.free device. To cook the glue, use an electric tile with a closed heating element, placed it in a special metal cabinet, which has an extract (rice. 19). In the room for classes and in the utility room, it is necessary for fire safety purposes to have a sand box, hand-treadmiers of the OKP-10 type. The approximate layout of the premises for binding business is shown in rice. twenty. When creating the corners of the binding business at home or in libraries, you should adhere to recommendations for equipping jobs in circles.

four.2. What tools and devices are needed for relaying work?

Special reinforced worker tools are tested by many generations. They have survived almost unchanged and are widely used in manual work in most countries. They can conditionally be divided into three groups: cutting, auxiliary and finishing. Cutting tools include knives designed for cutting paper, cardboard, cutting of fabrics, pruning of book blocks, shearing (cutting to nullified the edges) of the skin in the manufacture of leather binding lids. Auxiliary tools are bones (ironers), folding line, metal rulers, corners and squares, “racing”, gruel, measurement tools, brushes. Finishing tools are used in the processing of binding covers, covered with technical, textile synthetic fabrics, materials on a non.woven basis, skin, modeling roots, decoration of books of books. These include the same bones (glades), hatching, rolling, ironers, stamps, punch, letters and others. Various devices are greatly facilitated by the operation of the bindter and restorer: clamping devices. binding presses and visa, machines for stitching books, cutting for pruning books (gobel and others.) | special binding boards and t. P. Industry has not yet released such tools and devices, but they are simple in design and it is not difficult to produce on their own or ordering a master.

Restoration of books

The purpose of the block processing. give it the form correct for this book, strengthen and align the spine. It includes the following operations: reducing the thickness of the block in the spine, gluing the spine, rounding, bending the edges of the spine and pasting the spine.

DIY Book Binding / Smooth edge book Trimming

Reducing the thickness of the block. The thickness of the block in the spine after the restoration of sheets and sewing, as a rule, is more than the thickness of the block at the front cut due to threads and restoration paper, which strengthen the sheets of paper in the spine. To reduce the thickness of the block in the spine, the block is placed on the board, leaving the ends of the cords or the laid with free (open). Cardboard and board are placed on the block so that the radicular field remains open and the block is clamped along with the boards in the press. A strip of cardboard is placed on the radicular field, holding it, with a hammer, light short blows are applied on cardboard (Fig. Cardboard protects the block sheets from damage with a hammer. After some time, pull the upper ends of the cords or the siber, firmly holding the lower ones on the board (when the thickness of the cord block or braid is reduced). Cords or braid on the spine must move. They care about this when stitching the block, avoiding sewing cords or braid to the block. If in this way it is not possible to achieve the required reduction in the thickness of the block in the spine, it is coated with liquid glue, putting paraffinic paper under the block to protect the board from the glue and prevent the paper to stick to it, they continue to pour out the block until the glue dries up. Once again pulled cords or braids and leave a block in the press for drying. The spine of the block after such an operation is sophisticated.

Parsing the roots of the block. The spine of the block is glued in order to prevent the displacement of one notebook in relation to another and strengthen the root. Glue is used and applied with a thin layer. The thick layer of glue forms a hard film that breaks and breaks off from the spine.

Before gluing, the block is pushed onto the head and spine, cover the cardboard on both sides, under which the cords or braids are removed and placed on the board so that the spine protrudes slightly beyond the edge of the board.

Holding the cardboard, the brush is applied with a thin even layer of glue from the middle to one, and then to the other end of the block and rub it between the notebooks. Check the correctness of the shape of the block and withstand it under the load until drying, between the sheets of anti.adhesive material a. Another method: a block between the sheets of cardboard, clamps between the boards. The spine protrudes a little over the boards and is in a horizontal position. Gluing the spine is performed as described above. Cardboard can be replaced with anti.adhesion.

Rounding the spine. It is produced in order to reduce the thickness of the block in the spine after its refinement, to give and maintain the correct form of the book. If the circle of the spine is not carried out, the block is self.flared, but in the opposite direction. It is believed that the spine should form an arc after rounding, the radius of which is equal to the thickness of the block.

Rounding the spine is carried out after gluing, when the glue has not yet completely dried. The block is placed on the table with a spine from themselves, opened around the middle and, holding the lower part of the front cut, the upper part is pulled over themselves. The flat end of the hammer is delivered light short blows along the spine from its middle to one, and then to the other end. Blows are inflicted on the first or last notebooks, gradually moving to notebooks in the middle of the block. Rounding the spine on the one hand, turn the book and continue rounds on the other hand. The head of the hammer should be small so as not to damage the cord when round. If the desired result is not fully achieved, the rounding continues with a closed block, pulling the upper notebooks over themselves. Check the correctness of circle. The spine should be even and symmetrical in relation to the middle line. Having finished round, the block between the boards is left until completely dry under the load.

The bending of the edges of the block of the block is carried out in order to dissolve the notebooks, give the spine of the block the mushroom shape, form shoulders equal to the thickness of the cardboard to provide the correct form of the book. This is especially necessary for multi.page publications, in which the thickness of the block in the spine is larger after sewing than that of the front crime

The block after rounding is clamped between the two boards, so that the spine protrudes above the boards at a distance equal to the thickness of the cardboard selected for the binding of the book. Check the correctness of the circle of the block and proceed to the bending of the edges of the spine. Slightly moisturize (not much!) the spine and the pointed end of the hammer apply light blows on extreme notebooks from one side and on the other side of the block, so that the bending of notebooks on both sides of the block is the same. Brokes are cautioned, directing the extreme notebooks to the edges of the boards. The middle notebooks of the block do not touch. At the end of the work, the spine is smeared with glue, they energetically rub the glue into the spine, check the quality of the bend, wipe the excess glue with waste paper or gauze tampon and, if everything is in order, leave the book between the boards until it drys out until it drys out. The correct bending of the edges of the block of the block is shown in rice. 29. The spine of the block should have a symmetrical rounded shape with the same extension of the folds of the extreme notebooks, the folds of the intermediate notebooks of the block should be evenly bent from the middle of the spine.

Playing the spine. The spine is glued with paper or fabric to strengthen and align. The gluing of the spine is especially necessary when the sewing fastening is weak.

To strengthen the spine, a strip of soft cotton fabric is glued to it, and then a strip of paper. The paper should be strong, durable, not containing acids. If the spine has deep furrows between notebooks, they are filled with loose stump. To align irregularities on the spine, it is cleaned with sandpaper. The more strips of paper are glued to the spine, the more even it is, but the book opens more difficult. Therefore, it is not recommended to stick over three strips of paper.

Glue is applied to pre.moistened paper. The paper after applying the glue to it should lie evenly, not twist.

In this form, the paper exactly without folds is firmly glued to the spine.

The roots of blocks sewn on braids or cords are glued with strips of paper between cords or braids. Sometimes in old books sewn on parchment braids, roots were strengthened with fabric or parchment stripes longer than 4-5 cm width width. They simultaneously with parchment braids served to attach the block to binding lids.

Creating a book with a solid binding at home

I have long wanted to print the book on my own and make a hard binding for it.

But in order to make a book with a solid binding, it takes a lot of time, and it is constantly not enough, and it was not necessary to print that. And recently I had a free time and a book that I could not buy anywhere.

David Flenagan’s book JavaScript. Detailed leadership ”(6th edition) turned out to be a strong nut, in all of Ufa I could not find a book, and if you order, it turned out about 2500. I was able to find an electronic version (downloaded from VKontakik), but I have a trouble: I do not like to read books from a tablet, especially technical. Therefore, I decided that I still need to try to print the book.

I want to start the article with the show of what happened. Pages in the book are more than 1000, and since I printed on ordinary sheets, I had to divide the book into two volumes, because ordinary sheets are much thicker than those used in printing houses.

I was inspired by these articles when printing and assembling the book:

Since our book is very thick, we will print by blocks of 8 sheets, then we will bend them in half and get a small brochure (notebook). Then we sew all the notebooks with each other and the voila, the book turns out!

But unfortunately there are many nuances, for example, how to print these brochures so that by combining them, we would get a book. I advise you to redvert the book in PDF (the benefit I already had in PDF format) and take advantage of the free version of Adobe Reader.

First, it is necessary to write a range from which page for what pamphlets will be, for example, I have a brochure of 8 sheets, on one side 2 pages, printed on both sides and there are 32 pages from the book on 8 sheets.

Let me give you an example of how I wrote the ranges:

After we have decided on the ranges, click the seal in Adobe Reader, after which the window will appear, which is shown in the figure from below.

In the settings of the size and processing of the pages, you need to select the type of “brochure”, then select “only the front side” in the brochure range, and finally indicate the sheets: from 2 to 33. Having printed 8 pages, turn the pages and print on the back, indicating the same settings except for the range of the brochure, here you need to select “only the back side”. Thus, the same page range (from 2 to 33) we print twice, first with the setting “only the front side”, then “only the back side”.

Having printed all the brochures, we will eventually get something similar to what is shown in the photo from below.

Now it is necessary to bend the sheets so that there are neat brochures of 8 sheets, a spoon in this will help us. It is convenient to press the folding line for the bending of the folding line with a spoon.

It is necessary to make a press for the book, it will come in handy more than once. In order to make it needed:

With tape you can wrap the boards if you have unprocessed.

We proceed to stitching the book block. For this we need:

- awl;

- cardboard (for the template);

- thick threads;

- large needle;

- PVA glue;

- brush;

- gauze (for pasting the end of the book);

- narrow ribbons for “reinforcing” the end of the book;

- a small wide piece of tape for captals;

- good paper knife.

Before sewing a book block, it is necessary to make holes in each notebook with an awl, I refused from cuts. First we make a template, for this we will mark the places where you need to pierce the holes on the cardboard. The holes should be 6, they should be located in approximately the same as shown in the figure from below. It is necessary to pierce from the inside.

The distance between the openings of 2, 3 and 4, 5 should be wider than your tape for “reinforcement”, consider this in your template. The tape will be located between these holes.

We take our “reinforcing” tapes and glue them with electrical tape to the edge of the table (for fixation), now we proceed to the stitching of the block. So that the notebooks do not drive one relatively different when sewing, it is necessary to use the load, as shown in the figure below.

How exactly it is necessary to sew a book block shown in the picture from below. I repent, I took a photo for this collage from this article. As they say, it is better to see once than hear a hundred times. Take my own photos during stitching, I forgot.

Now it is necessary to cut the uneven edge with a knife for paper, take it seriously, I personally could not do it quite smoothly.

We fix the edge of the book block (the one that we will cut) into our clamp, we take a good knife for paper and change the blade to a new one (break off), everything is ready, proceed to aligning the edge.

Book block processing

Before further processing the book block, you need to prepare the necessary tools special attention should be paid to knives. Unfortunately, they do not go on sale and they will have to do them themselves. For knives, steel from hacksaw canvases for mechanical or manual hacksaw is best suited. Remember that the main tool is the main tool, and on what it is, the quality of all subsequent work depends. At first, two knives will be enough. universal (cutting cardboard, pruning of notebooks and book blocks) and narrow (cutting paper and binding fabrics, cutting on the bend). Ultrazhe. You can, of course, use the workpiece for a shoe knife (sold in the “Tools” store), but the knife in this case will turn out to be less high.quality. The main requirement for a universal knife is stiffness. The blade of the knife should not be bend when the side efforts were added to it. The dimensions and forms of universal knives used in the binding business are shown in rice. 11, a, b, g. The best of them, according to the authors, is the knife shown in the rice. 11, a. In any case, the side of the knife facing the book block processed should be polished and polished. The cutting part is performed in the form of a blade with one.sided sharpening in the form of a chamfer with a width of at least 5-8 mm. The length of the cutting part, as a rule, does not exceed 80 mm. After sharpening the knife, you should make sure that there are no zazubrins and burrs on the cutting edge and polish the left (that is, flat) side of the knife. It is advisable to use flat finely grained abrasive bars of sufficient width. The left plane of the knife is necessarily brought in a wet bar, making circular movements along the bar with light pressure. A properly sharpened knife, the cutting edge (sting) should not be littered on the left side!

Рис. 11. Основные инструменты для переплетных работ: а, б, в,г – ножи; д – растрепка; е – косточка

The quality of sharpening is checked by light glaciers on the left side: the heterogeneity of the glare indicates the presence of blockages, and this, in turn, will certainly lead to marriage when pruning the block. At the end, try with light pressure to be knife on newspaper paper. if the paper is cut, then the knife is sharpened correctly. U and n o z is made from a canvas for manual hacksaw. Its elongated blade (up to 100 mm long) is pulled on both sides. The approximate sizes and the shape of such a knife are shown in rice. 11, c. For safety and ease of work, the manufactured knives try to equip with handles of wood, plastic, leather, chlorwinyl tube or insulating tape. Such knives should work, using a metal line with sides that protect the hand. in case of accidental breakdown of a knife. Such a ruler is best made from steel corner rolling with a width of the shelf of a 30 mm corner, reducing the height of one of the shoulders of the corner to 3-4 mm. Naturally, the working surface of the corner must be polished and polished. It is undesirable to use corners from non.ferrous metal alloys, since when working with them will appear on the surface of the cut.off book block. No matter how carefully work with knives, their blades will dull over time. It is easy enough to notice: more effort is required, burrs on cropped material appear. If you use such a knife and further, it will crush and tear the paper. Therefore, for regular sharpening and editing a knife at hand, the bindter should always be medium. and fine.grained abrasive bars for sharpening and a shortage for editing scabbard. From auxiliary tools, you will need to be (rice. 11, e) and to about the (or fel. With the help of the bone, the sheets of paper are fed up (bend), rub them when gluing, pure the scars, and with the help of a wedge.shaped cut at a wide end, the corners of the binding lids are covered with it Traditionally, the bones are made in the form of a plate of pipe bone of cattle (rice (rice. 11, e). Plate thickness 3-4 mm. One end of the bone is sharp, the other is dumb. All edges of the plate should be rounded, after which the entire surface of the bone is polished and polished is polished. Other materials (solid wood, plexiglass, fluoroplast) are used for manufacturing bones. It is nice to have tools in the arsenal of tools and the dignity (K and I n K) to round the roots of book blocks (kiyanka is made from plastic.Do not forget that when cutting blocks, cardboard, cutting binding materials, you need to put a sheet of plywood or viniplast on the table. Of the measurement and marginal instrument, the desirable are desired. For a pressing of book blocks and ready.made books, ordinary ones are quite suitable for the same in combination with wide (more book blocks) with boards, sheets of wood.steering plates or plywood with a thickness of 15–20 mm. Когда придет опыт в переплетном деле, мастер сам почувствует необходимостъ иметь небольшой универсальный п е р е п л е т н ы й с т а н о к, на котором производятся не только шитье блоков, но и их обрезка и прессовка, а также раскрой binding materials (a sketch of such a machine is shown in rice. 12).

Рис. 12. Универсальный переплетный станок: 1 – нижняя плита; 2 – направляющая стойка; 3 – верхняя (подвижная) плита; 4 – кронштейн; 5 – упорный винт; 6 – линейка для обрезки блока; 7 – зажимный винт; 8 – рукоятка; 9 – вал; 10 – уголок; 11 —фиксатор

And, as a granted one, we need to be a r and, and, a set of K and C to (for gluing narrow stripes and small book blocks, the bristle brushes are quite suitable.-12, better Flat, and for the processing of large surfaces you will need either a round painting hand-brush or flaps with a width of 50–75 mm). Do not forget about glue dishes. Having the listed set of tools and devices, you can start pruning and final decoration of the book block. The most time.consuming operation, therefore, before cutting the book blocks sewn by you, try to practice on the foot of waste paper, for example on old newspapers with the help of a square and a measured ruler, trying to leave large fields at the pages as possible, plan, based on the spine, cutting lines. It is better to start the blocking of the unit with the upper cut (head). To do this, the block is clamped in a clamp or into a binding machine under a movable stove, placing 2-3 sheets of cardboard under it. Pulling the screws of the clamps, they must pay attention to the fact that the block is not skewed or moved to the side. Taking a universal knife in the hand so that the index finger lay on its upper part, press the knife to the ruler, and, holding it at an angle of 30-50 ° to the gornzontal surface, is carried out by the knife blade along the cutting line. Keep in mind, a strong pressure leads to crushing and gaps of pages. The movement of the knife when cutting the block is on itself (rice. 13, a).

Cutting blocks from three sides

If the book blocks consist of notebooks, then pruning of blocks on three sides provides free access to the reader to any page of the book edition, since during this operation all the folds of the block notebooks are cut off, except for the root. Pruning allows you to get even and smooth cuts, t.e. increases the aesthetic indicators of the quality of the book. Pruning must be performed before machining the spine, since the presence of folds in the upper, front and lower edges of the block prevents the relative displacement of notebooks in the process of rounding the spine.

In accordance with the requirements of GOST 5773, 6-7 mm is given for trimming the lower field, the upper one is 4-3 mm (in the amount of 10 mm), and the front is 5 mm or (in formats 60´90/32, 70´90/32, 75´90/32 and 75´90/16) 5.5 mm. Permits to the accuracy of pruning, including mowing, ± 0.1 mm.

Assessment of block pruning quality. Book blocks after trimming are evaluated according to the following quality indicators: 1) accuracy of the publication format; 2) the absence of cosins; 3) the fullness of the cutting of falses, counteners and the edges of the sheets; 4) smoothness and purity of cuts; 5) lack of sticking sheets. The format of the blocks is measured by a metal ruler with an emphasis that fixes the start of the reference. The absence of pruning mowing is controlled by the collision of two blocks attached to each other, turned by the upper and lower cuts in different directions. The remaining indicators of quality are evaluated visually.

Factors affecting the quality of blocks after pruning. The most important indicator of the quality of the blocks after pruning is their size in width, since it determines the width of the expanded binding cover, and in the finished book. the size of the front cows and, indirectly, the density of the insert. When cutting blocks on three.leaf cutting machines, the size of the blocks in height depends mainly on the accuracy of the installation of side knives, since the influence of other factors can be neglected. The accuracy of pruning of the blocks in width mainly affects the force of the block or the foot of the blocks in the process of trimming, the thickness of the block or the height of the foot and the coefficient of their compression.

With an increase Pressure forces blocks and feet of blocks from 3 to 7 kN (from 300 to 700 kgf) accuracy of pruning (reducing the difference in size in the width of the block) increases by about 6 times. With an increase The thickness of the blocks or The heights of the foot and reduction Blocks compression coefficient The accuracy of cutting blocks in width decreases mainly due to the deflection of the upper sheets under the edge of the blade. To withstand the requirements of GOST 5773 for the accuracy of pruning of the blocks with a complete fraud, the coefficient of the compression of the blocks before pruning should be in the range of 0.90-0.96, depending on the thickness of the paper and the block (rice (rice. 6.6).

| Rice. 6.6. Changing the compression coefficient of blocks during processing: one. after sewing; 2. after squeezing; 3. after branding, drying, repeated squeezes; four. after pruning; m. with a small thickness of the block; b. with a large thickness of the block |

Filling of cuts.Filling of cuts is a finishing operation that improves the appearance of the book, therefore it is used in the production of book publications of improved and gift types. The pigmented opaque paint used to fill the cuts to some extent protects the block paper from the action of ultraviolet rays and allows you to hide the multi-purity of paper in some of the block notebooks. For filling the cuts, special paint is used, which is fast-binding which is the Latex of the brand SKS-30shr. At small printing enterprises, the filling of cuts is carried out in a packing and vicious press: after pruning, the blocks are pushed on the upper and front cuts and put in the press a foot of not more than 40 cm with a cut-out, exiled to the outside. Filling of cutting or cutting is carried out with a soft brush or sponge in a clamped state so that the paint does not penetrate between the sheets of the block.

At medium and large printing enterprises, the filling of cuts are made on automatic machines like SF (Kolbus company, Germany), which can be connected to any stiff fishing line for the trimmer of this company.

Gilding of cuts.Until the middle of the XX in. gilding of cuts used for some publications of the gift type was performed manually. According to this technology, the unit after trimming is clamped in the binding grip between the two wedge.shaped mowed planks to ensure the maximum compression of the block sheets at the cut. The sawn.offices are polished with a special sharply sharpened scraper like a wide chisel, moving it from itself, with a slight slope forward. After processing with a scrap, the shafts are polished with a thin sandpaper and wiped with a lump of thin paper moistened with liquid starch clayer. A thin layer of glue prepared from egg protein diluted with water is applied to the prepared surface of the cut immediately before gilding. For gilding, thin leafy gold gold is used, which is cut into strips equal to the width of the cut, with a special knife with a blunt blade lowered on two chamfers and with a rounded end. Cutting sheets is made on a special pillow, with which the strip is transferred to the cut of the block with a flat fan.shaped brush. a “hare foot”. A strip of golden gold is pressed with a cotton swab, and after natural drying the gilded sawdown is polished through a smooth high.kiclander paper, soaked in wax, with a special tool with a “loving tooth”.

At large printing enterprises, a gilding of cutting or wipes is performed on machines in which the following operations are followed: grinding, polishing and cleaning the cut from paper dust; Clutching and drying cutting; adjustment to the tearing of special printing foil. As glue, alcohol sheloc-canine varnish is used. For adjustment by a rubberized roller at a temperature of 180-200 ° C, the anniversary foil of the brand 313-051k is used.

Assessment of the quality of the circle of the spine. The quality of the book blocks after rounding is evaluated by comparison with the reference block and in the following indicators: 1) the symmetry of the profile; 2) the correspondence of the length of the arc of the roots of the thickness of the block; 3) the correspondence of the arrow of the deflection of controlled blocks with the height of the arrow of the reference block; 4) the lack of skew of the block. Symmetry of the profile of the spine can be evaluated using a set of templates made of plexiglass, and comparing with the reference block. The length of the arc of the spine It is measured by a flexible ruler made of millimeter paper, hardened by a polymer film. The nominal value of the length of the core arc Lto determined by the formula

We intertwine the book

Many readers make selections of the literature of interest to them, published in the magazines.

Binding such a selection at home is a useful business, and the lesson is a pleasant.

Before starting binding work, you need to choose glue. the appearance of the book largely depends on it. Of the finished adhesives is a synthetic glue of PVA (polyvinyl acetate emulsion). On sale it happens in a variety of packaging (bottles, tubes, jars).

Glue has all the qualities necessary when working with paper: when dried, it turns into a transparent film, does not have an unpleasant odor, hygienic, non.toxic and easily washed off. True, the speed of drying of the glue brings some inconvenience, especially noticeable for beginners. It is good to use PVA for gluing vipers, gauze, captal, srying the spine.

Beginning binders will be convenient to work with starchy braister.

Prepare it as follows: Dilute 1 teaspoon of starch in 100 ml of cold water and, when stirring, bring to a boil, then cool (you can’t work with a hot clayer).

Carpentry (bone) glue is sold in granules or tiles. The more transparent and lighter this source material, the better the glue welded from it. Place the granules a day before the use of the granules (glue can), completely pour cold water. Cook the swollen glue in a water bath with continuous stirring until it turns into a thick homogeneous mass.

The finished glue should drain from the stick not with an intermittent stream, and not drip with drops or stretch. If the glue thickens, add water, boil liquid glue. The carpentry glue is very quickly “grasped”, so in the work it is used in a hot state.

Prepare a selection for weaving (the thickness of the collection should not exceed 15 cm), clean the remains of the old glue, level the sheets along the upper cut, carefully move the block to the edge of the table. Put a board or cardboard on top and press with a small load. Now smear the spine with glue.

When the glue dries, drill with a thin drill (diameter 2 mm) or pierce five holes with an awl at a distance of 3-4 mm from the spine. Spend the block along the holes with durable threads, as shown in the figure.

Glue the outlets to the stitched block, which are double.folded sheets of thick paper. The direction of the fibers in the v.

Furious boards, located at the beginning and at the end of the book, fasten the binding and block.

There are several ways to determine the longitudinal and transverse directions of paper fibers. Cut from two mutually perpendicular sides of the sheet two equal in length and width of the strip, fold them together and clamp from one end. the strips will disperse. Less curved from them will correspond to the longitudinal direction of the paper.

When the paper ruptures in two mutually perpendicular directions, a more even break will indicate a longitudinal direction of the fibers. If you moisten with water mutually perpendicular wraps of the sheet, then moistened paper in the transverse direction will become wavy, and in the longitudinal deformation will be insignificant.

Direction of paper fibers

Ways to determine the longitudinal and transverse direction of paper fibers: a. two stripes of paper; b. gap; In. wetting.

Cut the outpoints. Along the bend, apply a strip of glue with a width of 7. 8 mm with such a calculation so that the threads glued to the block are closed. Then glue the fabric or gauze strip 20-30 mm shorter than the block to the spine and 40 mm wider than its thickness.

The finished block must be cut. For this work, you need a boot knife sharpened on one side. So that the cut out block looks neat, all its corners should be straight (check on the square). First cut the side edge of the block, then the upper and lower. Keep the knife at an angle of 30. 50 ° to the block, take it to you without pressure, from time to time, pulling it in a small bar. Work on the ruler. It is convenient to use a thick (like a rail) a ruler or a metal angle. For trimming, you can use clamps or a crimping press, which is easy to make yourself. The sight should turn out even, without burrs. And if the burrs still remain, clean them with fine sandpaper.

Book Edge Trimming Without // Adventures in Bookbinding

Homemade press for pruning the book block

The unit is cut, now you can start making a binding cover.

Cut two identical rectangles out of cardboard: the sides of the lid. The height of the side should be 6. 8 mm more than the height of the block, and the width of 2 mm is less than its width. Also cut out of thick paper (drawing watman with a longitudinal direction of the fibers) a rectangle. lagging back, the same height as the height of the side. The width of the lag is equal to the thickness of the block plus 2 mm.

The blanks are made. Now you need to decide what material you want to bind the book. In the School Chancellery stores and in the stores “Make yourself” there are sheets of bumvinyl binding material, and their choice in color and texture is quite wide.

As a cover material, you can use ordinary washing wallpaper or oilcloth on a paper basis, as well as pieces of fabric that will probably be found in any house.

After all, any beautiful fabric is suitable for the binding: cotton, linen, silk, synthetic and even woolen.

The coloring of the material should correspond to the content of the book: the book is serious in content to nothing to weave into motley material.

So, cover material is chosen. Cut a rectangle from it with a height of a height of 30 mm, and a width equal to the width of two sides plus the width is lagging behind, plus 40. 45 mm per hem. Light the cooked rectangle with a thin layer of glue and put on it cardboard sides and lagging back, as shown in the figure. If it is difficult to put the aspects without “fitting”, make markings in advance with a soft pencil.

Restoration of books

Sewed book blocks are removed from the machine. With simultaneous sewing several blocks, they are moved along the cords or braids, which are then cut so that they remain on both sides of the spine of each block 25-30 mm long.

Brash of Fidezets Falch to the roots of an adjacent notebook

If the block has firm boat, then their folds must be immediately glued to the roots of the second and penultimate notebooks. To do this, recludes the first notebook, the exposed fack of the Forsatz from the side of the second notebook is smeared with a thin even layer of glue. The glue should not fall on the bend of the fold, so as not to glue both notebooks. The second facking is glued in the same way. After that, the block is squeezed under a small load.

The tips of the braid, cords or gauze on which the block is sewn is glued to the furious or mucosa. To do this, put the block on the table with a spine to them and disconnect the ends of the cord with the fingers to the roots. Then they bring them under them a “tape” and the back of the knife, slightly, hitting them at the ends of the cord, continue to be disheveled until the cord is dispersed in the form of a fan with a gradual fiber’s thickening by the end.

On an overhead or a slise, just against the cord, they apply a little glue. By pressing the cord in the places of exit from the block, lower the fan to the glue, slightly smear them with a finger, and then grind it with a bone, expanding and dripping the ends of the fan. Usually glue impregnates all fibers and goes to their surface. Therefore, on glued fibers you need to put a small piece of thin paper and press it slightly (when the glue dries, the paper is removed).

After that, the block is turned over, the ends of the cords are disheveled on the other side, slightly pull them, thereby tightening the block, and glue them.

The ends of the braid are glued in the same way, but you do not need to disrupt them, you should only make sure that they lie without wrinkles and folds.

To glue the ends of the gauze, on an overlap or a mlyazer (first from one, and then on the other side of the block), glue is applied (the width of the glue strip is equal to gauze width). Then, slightly pulling the gauze, put it on glue and grind it (you can also apply pieces of paper, which should be removed after the glue dries).

After the glued ends of the cords, braids or gauze dry out, the block is pushed onto the spine and upper tip, put on the edge of the table and smear the spine with glue, rubbing it between the notebooks as deep as possible. If necessary, you can process several blocks at once, folding them with a pile. After gluing, the blocks are put one on the other with roots in opposite directions (so that they do not come into contact with each other) and leave to dry under the load.

If necessary, blocks with a thickness of 15-20 mm can be cut with a binding knife along the ruler (corner) or using a crimping press adapted for cutting paper.

A little more should dwell on the pruning of the book blocks with a disk knife. First, on the square, based on the spine and measured the parallelity of the opposite sides, the cut line is outlined with a pencil. In this case, it is necessary to take into account the location of the text on the pages, preventing the formation after pruning of very narrow fields.

The marked block is placed on the binding board so that its cut part retains 10-15 mm from the edge of the board, and together with it, the clamped press is clamped in the reckless vice.

First, the book is cut through the front field. When installing the block, along with the board, it is necessary to ensure that the line along which the book will be cut off is at the level of the plane of the upper beam. Enough the wrap nuts evenly on both sides and quite tightly, making sure that there are no distortions or shifts of the block, and its sheets do not bend in the spine.

Pruning the book block with a disk knife with the installation of a vice on the floor and their chest fixation

Typically, the vice is put at one end on the floor so that their screws are facing the right hand, and the board on which the book lies was on the left. At the upper end, the vice rests with the chest, thus providing their immobility. The knife is taken in the right hand by the handle at the disk itself. First, you should move the knife disk, pressing it to the upper beam, from the bottom up so that it cuts several sheets with each such movement. To bring the knife to the block must smoothly and with the same effort move it during the entire cut. Subsequently, as this operation is developed, it will be possible to cut the paper when moving the hands with a knife in both directions. It is necessary to ensure that the disk moves all the time in the same plane. As the blade of the disk knife is blown, it is slightly turned and continued to cut another, more acute part.

Pruning the book block with a disk knife mounted in the block

A vice with a book block clamped in them can be strengthened on a table or another strong support. In this case, working with a disc knife is more convenient and easier, especially if the knife is fixed in the block. The knife block is moved with movements from itself (as when working with a shirt), pressing it to the upper plane of the mobile beam of the vice. Bring the knife to the cut block should be smoothly, without jerking. At first, cut the paper only when the block with a knife moves from yourself; In the future, after mastering the process, when moving the pad in both directions. If a universal binding knife is fixed in the block, and not disk, cutting paper is carried out only when moving from itself.