how to fasten polycarbonate on a greenhouse

Polycarbonate greenhouse allows you to grow fresh crops all year round. It guarantees reliable protection from the sun and any bad weather conditions. That is why many summer residents are decided to install a greenhouse made of polycarbonate on their own. It is quite possible to implement this, adhering to the technology.

During the construction work, you will have to perform the cutting of polycarbonate sheets. This procedure needs to be carried out slowly and carefully. How correctly the cuts will be carried out, the quality of the design in the future depends.

Polycarbonate. quite suppressed and thin material. Work with it can be performed with a clerical knife or sharp scissors.

Inexperienced builders are better off to help knowledgeable people. But you can do these work with your own hands if you follow the technology and follow several simple rules. First you need to prepare the desired tools: a hacksaw for wood, saw or circular.

Basic rules for working with polycarbonate:

- You can not damage the protective film on the material;

- The sawdust created in the process is advised to remove the tinker with compressed air;

- It is necessary to create a cutting plan for a minimum amount of polycarbonate in the process;

- Cutting must be carried out along the voids to reduce the risk of sheet breakdown.

Polycarbonate is used for arched greenhouses. First you need to do the cutting of the roof of the building. After that, you need to cut the sheets on the door and windows. Only after that you can cut the material on the walls.

The ends of polycarbonate sheets must be closed with sealant. The outer layer should be part with the protective coating. It is it that will protect plants from the negative effects of the sun.

Which side to attach polycarbonate to the greenhouse

Polycarbonate is widely used in the greenhouse business and in personal buildings of greenhouses. It is light, durable and its installation can be done on your own. But it is important to know which side to fix the sheets on the greenhouse.

Tips on how to determine the right side when attaching the material:

- The color of the protective film and the inner layer may differ;

- The instructions may indicate the tips of the manufacturer, as it will indicate the protective surface;

- The seller or other specialist will be able to help.

The protective coating is located only on one side of the material. But it is not always possible to correctly determine what. But it is necessary to understand, because the quality of the construction and protection of plants from UV radiation depends on this.

The easiest option to determine the right side is to distinguish the colors of the coating. Usually the protective film is painted. The inner layer remains transparent.

Many manufacturers make special designations of the front side. To do this, you need to familiarize yourself with the instructions.

The protective film can be distinguished by color or other signs. You can also purchase a polycarbonate with double protection on both sides. Such a purchase will cost more, but it will be stronger.

The necessary side can easily be determined by the specialist. They may become a seller or a person who is installing polycarbonate. The necessary sides can be easily confused. So that this does not happen, it is necessary to do the work especially carefully.

How to close the ends of the polycarbonate on the greenhouse. the garden and the garden

The reliability of greenhouses and other objects from cellular polycarbonate is ensured not only by the correct construction technology and quality material, but also by protecting the latter from negative environmental factors. For this purpose, various components are used, including a percussion tape for cellular polycarbonate.

Oeinated tape for cellular polycarbonate

What is the sealing of cellular polycarbonate for

SEC, t. e. Cellular polycarbonate is a very popular building material from which greenhouses, visors, awnings and much more are erected. Its structure looks as follows: there are several (from two or more) layers of polycarbonate, and between them are several rows of rectangular or triangular cells.

SPK itself is a waterproof material, but during operation the ends of the sheets often remain open and in no way protected from the external environment. In such cases, water, garbage and dust almost instantly enter the cells of cellular polycarbonate. At the same time, blowing or washing them without dismantling the sheet from the frame of the greenhouse or a canopy is almost impossible.

At first glance, there is no problem in this. SPK does not pass through itself water, does not corrode (if there is a stabilized coating and the correct location of the sheet during the installation) and is not afraid of dust or garbage. However, in reality, the situation is completely different.

Getting inside cells of cellular polycarbonate, moisture settles on their walls in the form of condensate. At the same time, light transmission of the material falls by a third, and in some cases even half of its nominal value. For greenhouses, this is critical, because the less sunlight passes through the skin, the worse agricultural crops will grow.

Condensate in a sheet of cellular polycarbonate

note! In addition to deterioration of light transmission, SEC with condensate in cells has higher thermal conductivity values. This means that in the case of frosts, the greenhouse with the “wet” inside the sheathing will freeze much faster. Is it good for plants? Naturally, no.

It can aggravate the situation through unprotected ends into the cells of the SEC of dust and fine garbage. Together with condensate, they form dark dirt, which creates many inner spots and leads to clouding a sheet of cellular polycarbonate. From an aesthetic point of view, a canopy or greenhouse with such defects looks terrible. you can see this by looking at the image below.

An example of what mud entering the unprotected cells of cellular polycarbonate can lead to which

Together with dust and moisture, many microorganisms and fungal disputes also fall into the SEC.

As a result, polycarbonate will not just become dirty and cloudy, it will “bloom”, which will affect its light permeability, thermal conductivity and appearance even more.

It will be almost impossible to clean such a sheet, even having removed the greenhouse from the frame, it remains only to replace the sheathing element with a new. And this is a loss of time and money.

Using an oen.colored tape, you can avoid the deplorable consequences of the external environment on the structure made of polycarbonate

The fungus, which appeared in the cells of the cellular polycarbonate, will make it not only muddy and ugly, but also less durable. over time, microorganisms will destroy the structure of the SPK sheet sheet.

The best way to cope with these problems is to avoid them. And this will help you with sealing and oral tape for cellular polycarbonate.

What is the ribbon

Now the time has come to find out what the oenic tape is made of and how it is used. In general terms, it is a flexible and adhesive tape with many small holes. They allow you to come out of condensate pairs from the SPK cells outside, but at the same time they do not pass moisture and dust inside.

The ribbon for cellular polycarbonate is also known as antipyle or anti.condensate.

Policarbonate ribbon for 4-8 mm

The outdated samples of tapes as the basis had an aluminum foil, and the infantry layer was made from non.woven polypropylene or its analogue. The result of the work of such samples often did not correspond to expectations. the tape either missed not only condensation, but also external moisture, or, conversely, did not allow extra couples to leave the cells of the SPK.

In addition, obsolete samples had many problems with strength and reliability. the base of aluminum foil was easily torn both during installation and during subsequent operation. Due to the lack of elasticity and the difference in linear expansion coefficients, with an increase in temperature, the polycarbonate sheet “pulled” the oenic tape at the end.

When the threshold of strength was exceeded, a gap occurred.

An oral tape with an aluminum base

But time passed, the technology did not stand still, and the engineers of companies specializing in the production of components for the SEC took into account the experience of operating the perilation tapes. In the latest models, the above deficiencies are mostly eliminated.

The basis of the modern anti.condensation tape is made of a rather elastic polymer, which has a linear expansion coefficient, close to that of mobile polycarbonate. Therefore, with the expansion or narrowing of the end of the sheet SEC, its integrity is not violated. Modern samples of anti-spial ribbons can lengthen in width without gaps by 10-15%.

As a parallel layer in quality samples, a water.repellent non.woven canvas is used. The size of the pores is 40-45 μm, because most particles of dust or drops of water are not able to penetrate. But at the same time, the SEC cells can “breathe”, because condensate vapors freely go through such holes. The result is a kind of unilateral filter.

Cutting PVC roof panels the easy way, no cracks, perfect cuts, Palruf, Suntuf, Suntop, Palram

note! It is not recommended to use the oenic tape in places where metal welding is regularly carried out, its cutting or grinding is. the small particles formed can penetrate through the pores. In such cases, it is more effective to use continuous sealing tapes.

To combat bacteria, pollen and spores of fungi, a non.woven canvas of modern infantry ribbons is treated with biocide. a substance that suppresses activity and kills all microorganisms (regardless of their species).

We select the sheets correctly

All the advantages of polycarbonate that were listed above can only be attributed to a quality polymer. Therefore, buying material for the greenhouse, it is very important to avoid fakes. The seller who will sell it to you must have the relevant documents. In addition, the main parameters of the sheet should be checked. They should be as follows:

To check the strength of the material, you can squeeze its edges, if the quality of the material leaves much to be desired, it will appear cracks. But the quality material is not scary even squeezing with pliers. He is easily bended with an arc. In this case, there are no crunch and breakdowns. Do not forget about the need to check the material for transparency. There will be no extraneous inclusions in quality material, the color of all sections of the sheet will be homogeneous. If you press the palm to the sheet, then on the other hand it should be clearly seen by its veins.

For a greenhouse coating, you need to purchase the plates of the material that has an UF film applied by varnishing. Information about this will be in the passport of the material.

Such work as fixing polycarbonate to a metal or wooden frame must be performed in stages:

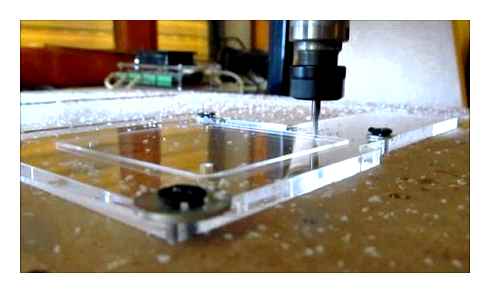

Cutting panels

The installation process of polymer sheets should begin with their cutting. Cellular polycarbonate up to 10 mm thick can be cut with a simple knife or hacksaw. In order for the work to go faster and accurately use the power tool.

Cutting the material, you need to hold the sheet well, excluding its vibration. Having finished with this stage of work, it is necessary to clean the internal cavities of the material of the chips.

Drilling sheets

It is necessary to drill holes between the rib of stiffness with an ordinary drill, no closer than four centimeters to the edge of the polymer panel.

Protection of the ends

It is necessary to tightly close the ends of polycarbonate, in order to avoid moisture and dirt from entering. The upper ends are sealed with a special ribbon made of aluminum, the lower ones with a ribbon with penetration, for moisture release.

sealing can be achieved using aluminum or polycarbonate profile. Moisture is diverted through small holes made in the profile.

Location

All details must be taken into account when designing a structure. The panels need to be attached in such a position that moisture can freely drain outward.

In the open air, you need to use polycarbonate with a layer that protects against sunlight on the outer side of the sheet. The film is applied to this side.

In order not to confuse with which side to attach polycarbonate, the film should not be removed until the end of the installation. Bend the sheets strictly on the permissible radius.

Point mount

Polycarbonate panels are attached to the frame using screws and washers. Point mount provides tightness in drilled places.

Thanks to the washers, heat is preserved and the possibility of crushing polymer material is prevented.

Point mounts are made at a distance of about 35cm from each other. When installing polycarbonate, one should not forget that:

- It cannot be firmly fixed on the frame;

- No need to resort to improvised means (nails, rivets, etc.) instead of special mounting elements;

- no need to tighten the screws excessively.

The mounting of the panels to wooden structures is carried out in the same way as for metal.

How to cut the material sheets correctly?

Here are the basic rules that need to be guided by:

- It is important that during cutting a protective film, which is already on the sheets, remains on the plates of the intact.

- Sawdust that will appear in large quantities will correctly periodically blow out of the channels, better compressed air.

- You need to cut so that there are as few unnecessary waste as possible. for this you need to pre.draw on paper, and consider several possible schemes, choose the most economical option.

- It is most convenient to cut along the voids of polycarbonate sheets, working in this way, you can reduce the risk of breaking a sheet.

Stages of cutting and cutting sheets for the greenhouse

Most often from polycarbonate create arched greenhouse greenhouses. Specialists with experience in building greenhouses from polycarbonate advise acting in stages, starting from the roof. Roulette should measure the size of the arc, draw it with a marker and cut a roll. Then you need to measure the doors, cut two rectangles at once. Then you can do figure cutting of the side parts then.

The ends of all pieces of material must not be forgotten by a high.quality sealing tape (from above), a ribbon of the ribbon for this purpose is suitable for this purpose. During installation, the sheets are important to place the side that contains a protective film and marking, because just from this side a layer is applied to the polycarbonate sheets that protects it from a dangerous UV radiation.

How to cut polycarbonate on the ends of the greenhouse. step.by.step actions

So spring has come and it’s time to build a greenhouse. And it’s time to take care of the upcoming crop. To do this, prepare the material for the future greenhouse structure. Modern greenhouses are built from polycarbonate. From our article you will receive information on how to cut a polycarbonate to the ends of the greenhouse, also what types of greenhouses are best used in the summer cottage.

Internet resources selling home goods are full of offers of purchases of ready-made greenhouses from polycarbonate. The older generation remembers homemade greenhouse buildings covered with polyethylene. Modern greenhouses are built from polycarbonate, which, in addition to strength, have thermal insulation. Light, which is important for the photosynthesis of the plant, passes completely, and harmful radiations are dispersed. The only drawback of polycarbonate is lightness. This fact should be taken into account when loading on the material.

Stages of building a greenhouse

Of course, you can buy a finished design. But it costs more than independently made. Wooden beams will probably be found in the country after construction, and polycarbonate sheets can be purchased in specialized stores. Suppose you have prepared building material, then, for starters, you need to thoroughly approach the process so that your greenhouse does not fall apart from the first gust of wind. Technologically, this process looks as follows:

- Preparation of the site. To do this, remove the upper soil layer and do drainage;

- lay out concrete or wooden beams around the perimeter;.align the level of the foundation;

- Along the perimeter of the foundation, we attach wooden risers with dowels;

- Polycarbonate sheet cut into the ends. We try to ensure that the cuts are even, otherwise our greenhouse will not only be “unpresentable”, but also moisture will fall through unevenly attached surfaces. How to correctly cut a polycarbonate for greenhouses can be found in the instructions that are attached to the product;

- make designations with a pencil in order for the sheet to “go” to the frame. Cut polycarbonate in the shape of the frame with a clerical knife.

Fix the sheets to the frame with the help of self.tapping screws. Prevent moisture, an attached ribbon at the top can.

Installation of ready.made greenhouses

With a shortage of time, you can buy ready.made details of the greenhouse building of the brands “Maria” and “Yuvis”. By their functionality, they are designed to plant vegetable crops. Unlike homemade greenhouse buildings, the installation of the Maria greenhouse is very simple. Some manufacturers in the instructions indicate the optional presence of the foundation for the greenhouse. But for the strength of the structure, it is better to install a greenhouse on the base.

Structural dimensions: 3 meters width and 4. long, height two meters. These changes in dimensions occur only in length and are multiple of two meters. 4 meters, 6 meters, etc.D. The width of all greenhouses is 3 meters, at a height of 2.1 meters. The main action for installation is the correctly selected polycarbonate sheet in size. How to correctly cut a polycarbonate for a greenhouse Maria described in the instructions for the product. A knife is used for cutting. Fixed to the ends of the polycarbonate sheet up to 50 mm. From the edge.

For greenhouses like “Yuvis”, you can choose a platform without a foundation. The kit has everything you need for installation: a metal profile, sheets of polycarbonate, dowels and screws. It is not always easy to cut off polycarbonate and attach to the end. About how to cut a polycarbonate for the yuvis greenhouse, is described in detail below in step.by.step actions:

- You need to put a polycarbonate sheet upside down.

- Press the sheet to the ends with improvised objects.

- We fix the sheet with a screw.

- Gently trim the edge of polycarbonate with a boot knife.

In order for the greenhouse structures to be operated as long as possible, lubricate the metal compounds with with with with with with with with spinning products. Polycarbonate does not require special care. In order for the greenhouse to look neat, you need to wipe the dust with a damp cloth. Do not use chemical reagents, clean the surface with a knife or metal net. This can damage the surface of polycarbonate.

We hope that our tips will help you decide on the choice of a greenhouse structure and building.

If you are looking for a reliable and durable polycarbonate greenhouse, then pay attention to the Kremlin greenhouses. Read about their features in our article.

In order for vegetables in the greenhouse to grow healthy, it is sometimes necessary to ventilate it, in our article you will learn how to make a window in a polymer greenhouse without much effort.

Features of the cutting of polycarbonate for ends

The ends of the greenhouse are considered the most difficult in the process of cutting, since there are many different elements in them, and each incorrect cut can spoil all the work. Events are recommended to be carried out sequentially, carefully guided by the basic rules.

Subsequence

Clear observance of the sheet cutting algorithm guarantees efficiency, lightness and quality of work.

Preparation of the work site. Before proceeding with the execution of cutting, they carefully clean the place of outsiders, extra objects. Dry twigs, small pebbles or boards can damage the integrity of polycarbonate sheets and lead to the formation of chips, cracks, dents, which is almost impossible to get rid of. For ease of work, the surface is covered with a sheet of plywood or wood stove.

Blueprints. Before cutting plastic, pre.drawings are made by cutting.

The scheme may look as follows:

Polycarbonate is installed on the working surface, while the protective film is not removed until the end of the work. By means of a marking felt.tip pen and a paper marking line are transferred to plastic panels. On both sides of the markings under the sheets, they have boards-support boards, 4 cm high, and a width of 10 cm. At the same time, the length of the subpoenes should be slightly longer than the polycarbonate sheet itself.

Cut of panels. To make neat cuts along the intended drawing lines, use: for a flat line. a grinding corner grinder, for circles. an electrician. All small inaccuracies, uneven edges that arose during the cutting process are adjusted with the help of a clerical knife.

After cutting the sheets from their surface, it is necessary to remove all the garbage and sawdust, and the ends should be treated with a sealing peolet, which prevents the accumulation of empty mud, dust or moisture inside empty cells.

The direction of the polycarbonate canvas

As noted above, cutting the canvases into the ends is carried out in two directions:

In order not to make a mistake with the direction, you need to pay attention to the protective film glued on the inside, which has the appropriate marking. On the outer side of the canvas there is a special coating from ultraviolet stream. The sheets are cut quite easily, according to the cell pipe, which acts as an excellent limiter for the blade.

They do not cut the canvas across and diagonally, since there is a high probability of cracks, and besides, quite great efforts will be needed for cutting. Plastic is cut across in two stages: first they cut the upper layer, and then finally divided the sheet into two parts.

The calculation of the material

The calculation of the number of materials is an important stage in covering coverage. When installing paintings, it is advisable that all joints fall on the supporting components of the greenhouse, and this rule should be observed both for gable structures and for arched. Experts also advise paying attention to the interval between stiffness ribs. The length of ready.made polycarbonate sheets can fluctuate, depending on the manufacturer.

The best option for arched devices is 10–12 m. For pitched structures, by the type of “house”, it is better to choose a web of medium length so that it is more convenient to work with them when cutting. The amount of material required will depend on the size of the entire greenhouse. There are special online calculators on the Internet, with which you can quickly calculate the volume of materials required for assembling structures of different types: rectangular, semicircular, arched, etc.P.

Cutting polycarbonate sheets for lining a home greenhouse requires certain efforts, knowledge and accuracy from the master. To do all the work efficiently, you need to choose the right canvas corresponding to certain characteristics, prepare the drawing and necessary tools, carefully study the cutting algorithm and use the services of the assistant.

Electric jigsaw

This tool is very often used to cut polycarbonate. When working with a jigsaw, experts recommend adhering to certain rules and then it will become the best tool for cutting monolithic polycarbonate:

- When sawing thin sheets, they must be laid on each other, lining cardboard from below;

- use a file with small teeth;

- When cutting one sheet, the risk of cracking appears. In this case, the teeth of the files should be perfectly sharpened, and the master must carefully monitor that the structure of the fibers of the material is not violated.

Secrets of professionals

Let us listen to the advice of experienced masters, giving specific recommendations for cutting both monolithic and cellular material:

- It is necessary to carefully prepare the place by cleaning it from any items. Cleanliness is not only the key to health, but also the condition for the absence of scratches or cracks on the material.

- Have a marker at hand and a rather long metal ruler. They are necessary for marking and direction when cutting the material.

- When working with cellular polycarbonate, sharp movements should be avoided and have a honeycomb as a guideline itself.

- Do not forget about safety measures and work with glasses to protect your eyes from the smallest particles.

- Following the old good proverb: “Seven times, cut off the old.time, once, once cut it off!

Manufacturers

The same type of polycarbonate brands of different manufacturers can differ significantly in basic technical parameters. This is due to the characteristics of production and the quality of the products manufactured. Among the manufacturers of polycarbonate for greenhouses, which is better? The most popular are the following brands:

- Carboglass. a manufacturer of fairly high.quality products, gives a guarantee of up to 15 years of operation without reducing the main characteristics. The cost of its products is much higher than the average level.

- Novattro. also domestic manufacturer. According to the reviews of its products of decent quality, which is confirmed by a guarantee of 14 years. The average price range.

- SunNex. a trademark under which Plastilux produces its product. Very popular in the domestic market. Warranty 8 years. The average price range.

- Vizor. Czech brand common in the quality of polycarbonate mediocre, which was reflected in warranty. only 5 years. But the cost is almost half as much as leading domestic brands.

- Italon. Chinese manufacturer. The cost of its products is very moderate, as well as the quality. Warranty 5 years. The nomenclature of products is very limited, both in color solutions and in the thickness range.

Cutting polycarbonate corner grind

The next in popularity after the knife is the tool grinder, better known as the “corner grinder”. It is well suited for sawing large sheets of polycarbonate on straight lines. If you need to make a cut with rounded elements, for example, cut off the end wall of the arched greenhouse, then it is better to use a knife or an electric jigsaw.

angle grinder

How To Cut Polycarbonate Sheets, Cutting Twinwall Polycarbonate, Home D.I.Y

For cutting polycarbonate, use cutting circles for metal, and preferably those that are designed to work with aluminum. This is due to the fact that when using them, the temperature in the cutting zone will be less than when using a circle of steel. Accordingly, the risk of melting the edges of the polycarbonate sheet will also be less. The use of “corner grinders” at low speeds will help make the chances of melting even less (and at the same time reduce the likelihood of burrs).

A cut circle with a diameter of 125 mm in aluminum

For safety reasons, use an angular grinding machine with a casing. In addition, in no case do not use the cut.out circles of the inappropriate basic and planting diameters or saw wheels from the circular saw. this is dangerous!

Prepare the sheet and the site for work as described in the instructions of one of the previous sections of the article. When working with a corner grinding machine, mount supports and stage from the boards on the right and left of the cut line. Do not remove the protective film from the sheet.

The sheet should be located on the support

Test the “corner grinder” on segments or unnecessary parts of polycarbonate. So you train and get little experience with similar material and corner grinding machine. After that, it will be much easier and safer to perform the cutting of the main sheet.

Marking before cutting is mandatory

Turn on the angular grinding machine, let it dial the desired number of revolutions and bring the cut round to the end of the sheet along the cut line.

Start the cutting process. Slowly move the cutting circle of the “corner grinding” forward along the cut line. Control the situation and do not rush, otherwise there is a risk of leaving a large burrs. When cutting cellular polycarbonate along the ribs of the stringity of the fishing line for the trimmer of the cutting, it should be located so that the cutting circle of the “corner grinder” does not crash into the walls of the cells. Work in goggles so that plastic chips do not get into the eyes.

The start of cutting polycarbonate using an angular grinding machine

At the end of the cutting process, turn off the angular grinding machine and de.energize it. As a rule, the sheet is cut off immediately and completely, additional work using a knife is not required.

The completion of the cutting process

If you are cutting cellular polycarbonate, then after completing the process, remove plastic chips and dust from cells. To do this, use a stream of compressed air, vacuum cleaner or fan.

Came the edge of the cellular polycarbonate sheet with a construction tape.

In a similar way, you can cut cutting using a circular saw. Choose saw wheels with small cloves designed to work for metal or plastic. Immediately before the start of the disk insert, let it gain the right number of revolutions. The supporting plate of the tool that needs to be pressed to the sheet will help you increase the accuracy of cutting.

Cut cellular polycarbonate into a greenhouse: how to cut the material

Polycarbonate, as a material, is a colorless, moderately solid plastic of a polymer type, this is used in production in the form of granules.

The properties of this polymer allow it to be used quite widely, including for economic purposes. Many owners of household plots are happy to make it greenhouses in their summer cottages.

About how to cut and cut cellular polycarbonate correctly, is described in detail in this material.

In its structure, the material can have a design consisting of two, three or even four layers, each layer is filled with stiffeners. with jumpers.

The properties of this material are exceptional, thanks to its cellular structure, it is quite light, durable, almost transparent optically, moderately plastic, frost.resistant. It is also a powerful dielectric, quite durable.

Successful cutting of material is possible due to its high strength and plasticity, even very thin and light plates can be cut.

High strength makes it possible to create an extrusion method of a plate with extremely thin walls, up to 0.3 mm, with a very small weight. Due to the resulting voids, the weight and costs are reduced, and the original cellular structure gives structures extraordinary lightness and airiness.

What are the errors when cutting?

The excellent properties of this material make it the most suitable for the construction of greenhouses. Greenhouses in areas are made to grow garden, garden crops with the help of their microclimate. Home greenhouses are most often made from a profile pipe made of steel.

Such structures are placed directly on the ground, without the foundation, while the design itself is built from the plates of cellular polycarbonate. But in order for the structure to turn out to be durable and functional, it is very important to be able to correctly cut the material, as well as to cut it correctly.

Photos of greenhouses from this material are attached to this article.

Here are mistakes that inexperienced people most often make:

- Incorrect orientation, for dubious saving of sheets. especially when cutting for broken and spherical roofs. correctly orient the panels only in the direction of bending or ramp;

- It is forbidden to fix the sheets “through”, because immediately, or gradually, leaks will occur in these places;

- It is important to correctly choose the material of the desired thickness, because too thick polycarbonate is more difficult to cut, and it is more expensive-when choosing, you need to follow the recommendations of experienced specialists, as well as the manufacturer;

- A big mistake. non.compliance with the tolerances that are necessary for thermal expansion;

- Another big mistake. non.compliance with the conditions for fastening the edges of the sheets of material.

During the construction of the greenhouse, you must need to carry out cutting and cutting polycarbonate for the structure. I sow the procedure must be extremely careful and slowly.

The successful installation of the structure will depend on how true the cutting will be carried out, as well as its trouble.free “work” in the future. Beginners are recommended to consult a knowledgeable specialist.

But even an inexperienced master will be able to cope with sharp polycarbonate if he carefully reads this article and watch a video that shows all the stages of working with this material.

To work with the sheets, you will need the most standard equipment: a hacksaw for wood, a manual or circular saw. Many masters for working with thin material use a regular durable stationery knife, or even high.quality tailor scissors.

Here are the basic rules that need to be guided by:

- It is important that during cutting a protective film, which is already on the sheets, remains on the plates of the intact.

- Sawdust that will appear in large quantities will correctly periodically blow out of the channels, better compressed air.

- You need to cut so that there are as few unnecessary waste as possible. for this you need to pre.draw on paper, and consider several possible schemes, choose the most economical option.

- It is most convenient to cut along the voids of polycarbonate sheets, working in this way, you can reduce the risk of breaking a sheet.

Stages of cutting and cutting sheets for the greenhouse

Most often from polycarbonate create arched greenhouse greenhouses. Specialists with experience in building greenhouses from polycarbonate advise acting in stages, starting from the roof. Roulette should measure the size of the arc, draw it with a marker and cut a roll. Then you need to measure the doors, cut two rectangles at once. Then you can do figure cutting of the side parts then.

How to cut a polycarbonate for a greenhouse

So spring has come and it is time to build a greenhouse.

And it’s time to take care of the future crop. To do this, prepare the material for the future of the greenhouse structure. Modern greenhouses are built from polycarbonate.

From our article you will receive information on how to cut a polycarbonate to the ends of the greenhouse, also what types of greenhouses are most perfect to use on a summer cottage.

Timidalex writes: Yes, without a cigarette I would not collect.

Artem Zabolotsky writes: Yes, apparently did with the smokers)))

Phone repair writes: There are hands, quit smoking a man

Internet resources selling home goods are full of offers of purchases of ready-made greenhouses from polycarbonate. The older generation remembers homemade greenhouse buildings covered with polyethylene. Modern greenhouses are built from polycarbonate, which, in addition to strength, have thermal insulation.

Light, which is important for the photosynthesis of the plant, passes completely, and harmful radiations are dispersed. The only drawback of polycarbonate is lightness. This fact should be taken into account when loading on the material.

Reviews:

Radik Chamidullin writes: Ilya thanks for the video course ! what temperature was at the time the video is removing, what temperature can be used with polycarbonate. Thanks.

Radik Chamidullin writes: Ilya thanks for the video course ! what temperature was at the time the video is removing, what temperature can be used with polycarbonate. Thanks.

High strength makes it possible to create an extrusion method of a plate with extremely thin walls, right up to 0.3 mm, with a very small weight.

Due to the resulting voids, the weight and costs are reduced, and the original cellular structure gives structures extraordinary lightness and airiness.

The excellent properties of this material make it the most suitable for the construction of greenhouses. Greenhouses in areas are made so that with their help microclimate grow garden, garden crops. In most cases, home greenhouses are made from a profile pipe made of steel.

Such structures are placed directly on the ground, without the foundation, with all this, the design itself is built from the plates of cellular polycarbonate. But in order for the structure to turn out to be durable and functional, it is very important to be able to correctly cut the material, also to cut it correctly. Photos of greenhouses from this material are attached to this article.

Training

Marking and cutting a polycarbonate sheet begins with the preparation of the workplace. It is important that perfect cleanliness is observed on the working surface, since the surface of the canvas can damage and scratch even a tiny pebble. Next, be guided by simple rules:

- Do not take a protective film from the sheets ahead of time. On it by a marker or felt.tip pen, the marking lines are easily applied. The film will protect the surface during operation from mechanical influences.

- Having put the sheet on the work surface, transfer the size of the necessary part according to the drawing by the marker.

- After applying the markup, make sure again the correctness of its application and with the help of your chosen tool, start a cut of the sheet.

- When cutting the power tool, the panel must be securely fixed to avoid vibration. Before starting the cutting of polycarbonate, the workplace should be prepared

Cutting process

Polycarbonate also differs in that it is very convenient and easy to work with it. Even a beginner at home can cope with this material. We offer some tips that will help correctly and without loss to cope with the harsh:

- When performing straight small sections of the canvas 4-6 mm thick, an acute construction knife is suitable. The cut along even long lines is better to perform a corner grinder. Rounded parts are cut by an electrician.

- When working with power tools, be sure to use personal protective equipment. Put on glasses that protect your eyes from fine dust. Rubber gloves will protect against accidental shock.

- If necessary, apply marking on large sheets of polycarbonate, pave long boards on top that go beyond the sheet. You can move around them like a bridge without causing damage in the form of dents.

- After the end of the work, remove the protective film, blow the electric pump with all the processed seams on the received details to get rid of dust, and close them with special protective profiles. Do not remove the film from polycarbonate sheets during cutting

A construction knife

To trim cellular polycarbonate up to 6 mm thick at home, you can use a construction knife. The only and main condition is that the tool should be sharp, high quality and have enough spare blades.

- Put the knife tip at the starting point, and by clicking on it, make a cut. Along the marking line, perform a small incision slowly and as accurately as possible.

- According to the cut, the knife is carried out again, gently introducing the material inside, and cutting it. In this case, the blade should be strictly perpendicular to the plane of the sheet.

Work requires special attention without haste and fuss.

Corner grinders are convenient to saw large polycarbonate sheets in length. We recommend using cutting circles for metal (better for working with aluminum). On the desktop, install several wooden supports along the edges, put the sheet on them.

Corner grinder is perfect for sawing sheets of polycarbonate of large length

- Before you start cutting, try the work of the tool on a small unnecessary pruning of polycarbonate. Such a “rehearsal” will be especially needed for beginners.

- Do not forget about personal protective equipment.

- Turn on the machine, putting on a minimum rotation speed, and combine the cut.out circle with the place of cutting on the edge of the sheet.

- Slowly and confidently start moving the circle forward along the intended line. During cutting, do not be distracted and constantly control the combination of the cutting line with marking.

- Having completed the cut, turn off the corner grinder. Peel the edges of the cellular polycarbonate with sandpaper, then blow out a vacuum cleaner for cleaning from dust. Remove the protective film by sealed the ends with tape.

Electric

The jigsaw will cope perfectly, cutting both straight lines and other complex configurations. The main task is to choose the right file for cutting:

- For cutting cellular polycarbonate, it is better to purchase a file with straight teeth. It is capable of crushing the material less and makes the cut as even as possible.

- Choose files with frequent and small teeth. For cutting cellular polycarbonate, files with TR marking (from 9 or more teeth per 1 inch) are suitable).

- Give preference to the canvas that is high.quality and is suitable for work with metal.plastic.

Swap of polycarbonate sheets using an electrician requires experience, you should practice on small sheets of the material

The basic rules when working with an electrician are as follows (we advise you to practice the remains of the material before work):

- The desktop is ready to work, the corresponding canvas is inserted and securely fixed in the jigsaw. For convenience, make a small notch on the polycarbonate canvas with a knife.

- Turn on the tool, wait for it when it picks up, and bring the blade to the notch, slowly directing the machine forward. By clicking on the tool, make sure that the polycarbonate sheet does not bend.

- When working with large sheets of material, it is better to use the services of an assistant. He will hold polycarbonate, not allowing the sheet to vibrate. Work with long canvases can be divided into two stages: first go around to the middle, and then repeat the movement towards the opposite side.

- After finishing work with an electrician, do all the actions that are described above when working with a corner grinder.

If you have already gained some experience with this electrical appliance, you can cut several thin sheets at once on one pattern. Just put a cardboard of the corresponding size under them and cut all layers at the same time.

Beginners should thoroughly practice before starting work with a hacksaw for cutting polycarbonate. Without experience, sheets, as a rule, crack along the cut line and lead to large losses of the material. It is important to correctly and correctly fix the sheet without allowing excessive voltage and vibration.

Drinking polycarbonate sheets with a hacksaw is a very difficult task, as it has a number of nuances

The laser refers to professional tools and only a highly qualified specialist can work with it. Laser cutting is usually used on an industrial scale, since the purchase of equipment is quite costly.

Once again we want to remind you that when working with power tools, be sure to follow all safety rules. The health and life of the employee sometimes depend on this, sometimes.