How to cut a cast.iron pipe with your own hands

During the repair, many people try to replace all obsolete communications at once. It turns out that it is most difficult to work with sewer cast iron pipes that need to be dismantled. They used to be connected by cement, sulfur or aluminum. It turns out that the system was carried out for centuries. But then the end of the century came up. And at the same time, complex work begins.

At first glance, it may seem that removing cast.iron pipes is very easy. But here you need to work wisely. After all, having put too much effort, you can damage the riser, which unites several apartments at once. In this case, the anger of the neighbors is inevitable. Costs, time and a lot of work will begin.

Before starting the dismantling of an old cast.iron pipe, you need to familiarize yourself with some rules:

- turn off the water supply in the house;

- remove the hose from the drain tank on the toilet;

- Remove the toilet carefully;

- take out all devices and items from the premises that can interfere with the performance of work;

- cast iron. fragile material. Pipes that are far from the riser can be broken with a hammer;

- removal of pipes that directly approach the riser;

- Cuffs are installed on the bell. First, the bell is cleaned of lubricants.

Dismantling pipes from cast iron

So how to cut cast.iron pipes, let’s try to figure it out. If the pipe from cast iron used to be connected by gray, then the task is not easy. But here there is advice on how to make out cast.iron pipes. Like any other substance, sulfur should be destroyed under the influence of something. And these “something” is open fire. If the sulfur is heated with a soldering lamp, it becomes viscous. So disassemble the pipes is very easy.

Use open fire carefully so as not to make a fire. In addition, when heating pipes from the compounds, sulfur gas will be released. Therefore, you need to apply measures to protect your own health. You can heat the connection for several hours. In order not to suffocate during this time, you need to wear a gas mask. It’s not bad if there is a bucket of water nearby in case something caught fire.

Features of cast.iron pipes

Cast iron pipes in Soviet times were used everywhere. Alternative materials for manufacturing were used on a limited scale, to assemble special sewage lines. The properties of cast.iron pipelines allow the old system to work so far. The advantages of these pipelines:

- strength;

- long service life;

- resistance to temperature differences;

- ability to work with aggressive liquids.

- tendency to corrosion;

- large weight;

- fragility, inability to withstand sharp blows;

- The complexity of the assembly.

The most significant disadvantage is the complex connection procedure, or minting of cast.iron sewer pipes. In combination with a large weight of details that create a significant load on supporting structures, such water disposal lines were difficult to install and maintain. However, the durability and reliability of cast.iron systems is appreciated by specialists. All networks whose condition does not inspire fears are still effectively used to divert wastewater.

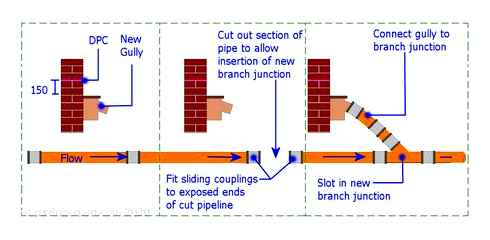

Installation of a new pipe section

When the place for a new pipe is prepared, it is inserted and fixed in the trim of a fan pipe. Depending on which pipe it is planned to be used (plastic or cast-iron), you will need either a pistol for a tube with silicone, or mints, a heel and a solution of cement or asbestos-cement mixture, since the latrine of cast-iron pipes differs from the latrine of plastic pipes in cast-iron columans.

It should be borne in mind that cast.iron pipes are preferable in all respects, therefore a brief instruction is given, which describes the minting precisely for these pipes.

How to cut a cast.iron pipe with your own hands

The most difficult stage in the replacement of the old pipeline is to dismantle the cast.iron pipe, which served its.

Previously, during the construction of communications, pipe from cast iron were used, the connection of which occurred with a cement mortar, gray or aluminum.

Pipelines collected using the last two substances are destroyed with great difficulty, so you need to prepare for long.term dismantling work. And this article will tell you about the technology of their implementation.

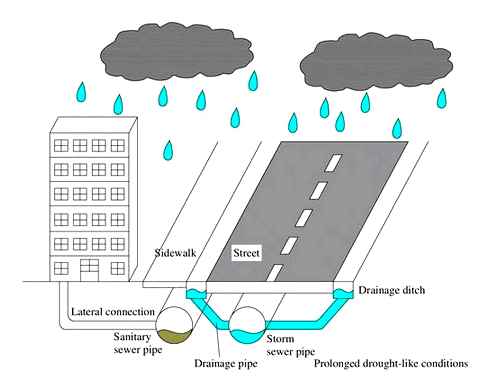

The laying of a new sewage system often begins with the dismantling of the old

General course of work

At first it may seem that the disassembly of obsolete communications is a trifle business, because it is not to build. not to build.

However, here we need just the right, qualified approach, because otherwise it is easy to damage the riser connecting several apartments at once.

And this is a real disaster, the consequence of which will be the need to replace the common riser and, of course, the boundless indignation of the neighbors.

The cast.iron pipe should be dismantled carefully, adhering to such a priority:

- Turning off the supply of water supply to the apartment.

- Disconnecting with the help of a divorce key of the hose supplying water to the flush tank from the toilet.

- Dismantling the toilet (it is necessary to unscrew the bolts attaching it to the floor).

- The release of the bathroom of the bathroom from extraneous things and equipment that may interfere with the replacement of the pipeline (bidet, sink, washing machine, etc. P.).

- Dismantling the old sewage system.

How to cut a cast.iron bed?

Due to the fact that cast iron is characterized by high fragility, the pipes that are at some distance from the riser can easily be broken with a hammer.

Destruction of the joints with a burner

If the joints of a cast.iron pipeline are fastened with gray, this complicates the task of dismantling.

However, we have some tips on how to make out the cast.iron pipes of the sewage system in this case. Like any chemical substance, sulfur is destroyed with certain influences, namely, with prolonged heating with an open flame. High temperatures make it viscous and plastic, so that the removal of the substance from the surface becomes simple.

To dismantle the pipeline connected with sulfur, prepare a hammer and chisel, as well as a gas burner for heating. By the way, the burner can be replaced with a soldering lamp.

When the pipeline is heated with a lamp or burner into the surrounding space, a harmful gas will be released. sulfuries. In addition, open fire is also a danger.

Therefore, measures to protect life, health and environment are required.

Warm heating operations can last several hours so that the combustion products do not harm light, you will need a gas mask, and to prevent accidental fire and other interior elements, a protective screen of metal or asbestos is suitable.

Possible problems

The dismantling of the old pipeline must be carried out to the maximum possible limit, since it is better to cut the cast.iron pipe to the place of transition to its bell. Then the butt of a new plastic pipeline and a cast.iron pipe will take less time and effort. Do not hesitate about how to cut a cast.iron pipe, use a corner grinder.

How to saw a cast.iron pipe if you do not have a corner grinder? Take a hacksaw for metal and get to work, but this, of course, will increase the duration of dismantling operations.

How To Cut And Replace Cast Iron Pipe

If the dismantling attempts were crowned with failure, you should not be upset: transition couplings are sold in stores specially designed to connect cast.iron and polymer pipes.

Sometimes, when cutting plastic pipes, difficulties may occur. Try to saw it around the circumference half, and then exert a slight pressure or produce a slight rotation. the pipe bursts.

If the pipe does not lend itself to extract a riser from the bell, and you no longer know how to pull out a cast.iron pipe, make cuts in a circle along the pipe with an interval of about 20 mm, reaching the bell, and then remove it from the riser.

Before connecting cast.iron pipes and polymeric ones, it is necessary to clean the first from sulfur, using all the same heating. After removing sulfur, the pipes are given the opportunity to cool, as a rule, this is a few hours. At the final stage, the new sewer network is installed. It is best to purchase pipes from modern materials: plastic or metal.plastic.

Cutting cast.iron pipes with pipelines

For cutting cast.iron pipes, there are specialized pipelines. For example, Exact Pipecut is portable electrical pipelines for working with pipes with a diameter of Ø 15. 360

Pipes made of steel, copper, cast iron, stainless steel and plastic can be cut using the Exact Pipecut 170, 200 and 360 pipelines. The use of TST carboreal disk on the pipeline, gives a huge advantage over traditional abrasive circles, the cutting speed is four times higher, the absence of sparks during cutting, cutting without the addition of coolant to the cutting zone. For cutting pipes from cast iron, carbide disks with diamond spraying are used.

How to saw off the pipe with a corner grinder

In work with construction or plumbing tasks, you need to know how to cut off the pipe with a corner grinder. In the articles, consider quick and easy ways, how to cut the pipe with a corner grinder correctly, so that the result is perfect.

Pipe segment at an angle of 45 and 90 degrees

If you need to cut off the pipe at an angle of 45 degrees, which is more often required when laying water supply, heating pipes.

Often, steel, cast.iron pipes are used, which have a cylindrical shape. Rectangular or profile pipes are used in installation work.

However, the pipe should be correctly cut with a corner grinder, then to easily connect. Therefore, you should thoroughly mark the pipe.

Some masters try to mark the place of cutting with a tape measure, but we warn that the result is most likely to be negative. And for a positive result, consider the following recommendation of professionals.

Take a sheet of paper or cardboard, better A4, fold diagonally and wrap around the pipe where an even cut is planned. The edges of the paper should absolutely coincide with each other. And the side of the paper that was closer to the end of the pipe was perpendicular to the axis. Then, in a circle, mark the fishing line for a cutting trimmer.

If you need to cut off evenly at an angle of 90 degrees, then solve the problem quickly with the help of paper again or painting tape. Wrap around the pipe so that the ends coincide. Make a flat marking and drink.

Masters are advised to use a square when cutting a profile pipe. To do this, put the square to the sides, and turn and apply the tags with smooth movements. After action, fix the pipe and cut. Prepare yourself a template that will come in handy in the future and save time. It is better to make an angular grinder, so the incision will be smoother.

In working with a cast.iron pipe, keep in mind that this is a fragile material. Therefore, we will bring a way by which it will be possible to cut such a metal without damage.

Before starting work, make notes for the cut, as in working with steel pipes. Put a wooden beam for support. Pass the corner grinder around the circumference of the pipe, making small cuts. Then take the chisel, insert into the groove and deliver a strong blow with a hammer. Keep in mind that for cutting pipe cuts, cut.based cutting discs are used.

If there is no angular grinder at hand to cut the cast.iron pipe of the sewage system or other destinies, use the hacksaw for metal, chisels or special pipelines.

Cutting the gas pipe is a dangerous effect, so it is best to entrust professionals. But if you are sure, then to cut the metal take a corner grinder, welding, hacksaw, gas welding.

- Before work, redraw the riser with gas supply. Then release the rest of the gas from the pipe. To do this, set fire to the gas in the burners and wait for it to go out.

- After the actions carried out, cut. Using the welding method, the metal base burns when exposed to high temperature. The result is fast and effective. But remember that for trimming or rooting gas pipes again you need experience.

Methods of cutting large diameter pipes

For cutting pipes of large diameter, for example, sewage, there are a number of reliable tools. Next, we consider some of them in detail:

- Corner grinder is an inexpensive and affordable option, but is considered not the safest in working with such materials. Once you decided to use this method, then be careful and use the protective equipment.

- Roller machine (pipeline). such a tool adapted for such manipulations. The device is attached and the removal of the material begins. The force of pressing is regulated using mechanical devices. It is important to note that the machine models differ in shape, so before use, take into account the ratio of size with the pipe.

- Gas cutting is the most popular option for cutting pipes of larger diameter, sheet metal. The incision occurs due to the action of the flames of high intensity, the metal melts and leave the section of the cut with the stream of gas. This method is convenient and effective.

A quick way to cut the pipe along using a corner grinder:

- Pay the main attention to the markup.

- Use a painting thread for such a case that has been distributed during wall marking.

- Before starting work, fix the pipe and in small movements, saw the pipe thoroughly.

- It is better not to rush, but delicately and slowly process parts of the pipe, so the cut.out disk will not jump off the lines of the flake. Remember the safety precautions.

Thin.walled pipes are made of non.ferrous metals: aluminum, copper. Like work should be done delicately, since the high probability of deformation of the material. For cutting, you use fillers, for example, sand. Actions can be carried out using a corner grinder, a special machine.

Summing up, we emphasize that the cutting of metal pipes is complex, but everyone can strengthen the master. Using the advice of professionals, you can easily cope with the cut of pipes of various sizes and materials.

Also do not forget to process the edges of the pipes after cutting with a file or sandpaper. And the most basic thing that should be remembered, starting such actions, is a safety precautionary. Starting to work, put on a special suit (casing), mask or closed glasses.

Hands from sparks should be reliably protected, so use dense gloves.

How to cut the pipe smoothly. common options

The exact trimming of pipes only looks just at first glance. The lesson is quite problematic, especially if you need to perform a cut at a certain angle or a sophisticated configuration. You can do this both with your own hands and using a specialized tool.

Much here depends on the diameter of the product, the thickness of the wall, the material from which the pipe is made and of course the tool itself.

What tools exist

Tool for cutting pipes, like most of the existing tool, can be manual and electric. In both of these niches, in turn, there is a specialized professional and applied amateur tool (find out here how to cut the thread on the pipe at home).

Dismantling of cast.iron sewer pipes

Most of the old buildings have sewer networks of cast.iron, sometimes from steel pipes. Over time, they become unusable, rust and proceed. An unpleasant smell appears in the apartment from these leaks.

At a convenient case, residents change them to metal.plastic or plastic materials. Previously, pipes were connected using cement mortar, twine, sulfur, cabbage. The old pipeline is difficult to dismantle.

To do this, you need to have a great desire, tools and patience.

Tools necessary to remove pipes

To remove old pipes, you need to prepare some tools and materials. Regardless of the methods of connecting the pipes will be needed:

- corner grinder for cutting individual elements of the pipeline;

- cuts and grinding wheels;

- gas burner or soldering lamp for warming up joints;

- hammer and screwdrivers;

- chisel;

- pipe key;

- respirator and glasses for disassembling the flooded sulfur joints;

- Peorator;

- pipeline;

- nail;

- steel wedge or chisel;

- Passatigi;

- Water bucket.

After their preparation, you can start dismantling the system.

How to dismantle a cast.iron sewer

When the sewer system fails, it is necessary to repair or replace the pipes. In this case, it is necessary to calculate the joints. Without this, it is impossible to dismantle the system or its part. Calculation technology is used in each case different. It depends on the materials that were compacted joints. As a seal, used to be used:

The old sewer is more difficult to disassemble. Over the years, rust appears at the joints, deposits. Without experience, it is better to entrust this business to specialists. If it is decided to work with your own hands, you need to determine the degree of its complexity.

To do this, a hammer with a rubber or wooden tip tap joints and determine the method of sealing them. The cement is painted in gray colors, sulfur. in yellow. They try to shake the pipe. If you manage to do this, the seam is made using a cement mixture.

Dismantling of pipes connected by cement and cabin

Cast iron. durable material. Therefore, sewage risers in multi.storey buildings were built from it. He serves for decades, it is good to paint. But durability is a disadvantage when dismantling. Disks for corner grinding is better to use 230 mm in size. You may need a hacksaw for metal with several spare canvases. Work order:

- First you should block water access to the apartment and agree with the neighbors that they also do not use water for some time.

- Free the workplace and disconnect the drain pipe.

- Particular attention is paid to the toilet. It used to be connected by a cast.iron pipe using a cement mortar. It is unlikely that it will be possible to remove such a toilet, you have to break it.

Start calculating with a hammer and chisel. The pipe of the riser needs to be cut in several places. They retreat 2-4 cm from the lower bell and make an incision of a corner grinder.

It will not be possible to completely cut the pipe, so you can use a hacksaw. Attempts to break the unstable area are associated with the risk of cut off part of the bell, and this cannot be done.

A cut is also performed on top, then a piece of the pipe is removed.

The frozen cement mortar is removed with a hammer and a chisel in small pieces. Work is carried out with accuracy to leave the lower bell in safety. If the rush was used during the installation of the riser, you need to get it with pliers and clean the place from cement.

There is a cross at the bottom of the riser. It is removed with a hammer and screwdrivers. You need to knock on the corps of the cross.skinny for some time with a hammer and try to shake it. After that, the tool is inserted into the formed opening, the tee is pulled and removed.

Combining pipes connected by gray

Recognizing the presence of sulfur in the seam. You need to bring the flame of a soldering lamp or gas burner and warm up the seam. If there is sulfur in it, it will begin to melt and publish unpleasant odors.

It is recommended to start work with a long corner. The cross.cut, connected to the riser, is warmed up with a soldering lamp and loosen. Doing work is more convenient together. One person warms up the seam, the other rogs the structure.

We must not forget about the use of protective gloves.

After the structure of the structure and the melting of the substance, it is necessary to pull out the cast.iron pipe from the bell and clean the place of sulfur residues. After completing all the work, they give the pipe to cool.

When performing work, you need to use a respirator or gas mask so as not to breathe in pairs of sulfur. You should use special working clothes. Compliance with safety regulations when working with open fire is mandatory.

Then any pipe is removed without any problems.

How to cut a cast.iron sewer pipe

Dismantling of sewage systems is recommended on weekdays, in the first half of the working day. At this time, most neighbors are at work. Water is turned off, the tool is ready, you can start work.

To work with the riser, you need to mark it. Tags are made at a distance of about a meter from the floor and 10 cm from the ceiling. In these places you need to cut the pipe of the riser. First, a corner grinder is made.

It is not necessary to cut it to the end, it is better to leave the gap, which then breaks. With the help of a staircase, they rise up and make a cut there. Cuts are best done at some angle to each other.

The fallen wedge is removed, the remaining jumper is broken by the blow of the hammer and chisel. At the same time, one person supports the pipe so that it does not fall.

After removing the main part of the riser, the remainder from the bell is removed. If it does not give in, you need to make several longitudinal cuts and shake a piece. He will be removed without problems. If the structure does not succeed in cutting the structure, you will have to invite specialists.

What to do in case of unsuccessful dismantling

Cut cast.iron pipes is better. The work with a hacksaw takes a lot of time and effort. If the dismantling is unsuccessful, do not be upset. You can connect plastic and cast.iron pipes with a special transition coupling.

How to dismantle cast.iron sewers:

Break a cast.iron pipe with a hammer

Removing the remains of sulfur and cooling the tee

As you can see, to figure out how to dismantle a cast.iron sewer is completely easy.

Most importantly, do not forget to remove the remnants of the sulfur from the riser and let it cool.

If the cast.iron system was seriously strong, then you can make cuts around the pipe that needs to be removed. This will facilitate her extraction from the riser. Failed to make out the pipeline?

Angle.grinding machine

It works quickly and comfortably, but not without minuses with a corner grinder. For example, she cuts only in a straight line. An attempt to make a curly cut will lead to a “snack” of a disk, its breakdown, a possible user injury. Therefore, the machine is used for cutting in a straight line. Another minus. the fire hazard of the method (abrasive disk metal = sparking). Before work, you will have to put on glasses, protection on your face and hands.

Cutting more efficiently than a jigsaw around, so more often users choose a noisy corner grinder. When buying a cut.out circle, prefer products on a bakelite bunch, because they are an order of magnitude stronger than ceramic analogues.

Dismantling instructions

Destruction of the joints with a burner

If the joints of a cast.iron pipeline are fastened with gray, this complicates the task of dismantling. However, we have some tips on how to make out the cast.iron pipes of the sewage system in this case. Like any chemical substance, sulfur is destroyed with certain influences, namely, with prolonged heating with an open flame. High temperatures make it viscous and plastic, so that the removal of the substance from the surface becomes simple.

To dismantle the pipeline connected with sulfur, prepare a hammer and chisel, as well as a gas burner for heating. By the way, the burner can be replaced with a soldering lamp.

When the pipeline is heated with a lamp or burner into the surrounding space, a harmful gas will be released. sulfuries. In addition, open fire is also a danger. Therefore, measures to protect life, health and environment are required. Warm heating operations can last several hours so that the combustion products do not harm light, you will need a gas mask, and to prevent accidental fire and other interior elements, a protective screen of metal or asbestos is suitable.

Destroying joints without a burner

If you use the burner, we offer to familiarize yourself with the video presented below.

Dismantling instructions

It is advisable to start dismantling with the analysis of pipes located at a distance from the riser. This is not difficult and problems most likely will not arise if a chisel and a hammer are used, because cast iron is a very fragile metal.

So, consider how to remove the cast.iron sewer pipe:

A hammer break the plots to the cross

- Next, you need to gradually loosen it inside the riser. You can leave a segment of the pipe connected to the cross, then the operations to destroy the crosses will simplify. Some experts, on the contrary, remove cast.iron pipes to the maximum, extremely exposing the compounds.

- Put on protective agents and closing furniture with screens, you should proceed to heating the sulfur. The work will go faster if two people participate in the dismantling: one pays the joints with a soldering lamp or gas burner, and the second with a knife removes the viscous sulfur.

- Когда устранено большее количество серы с мест стыкования, крестовина извлекается из стояка.

Plasma cutting

The method is more likely to be industrial than household ones, so it will not be considered in detail. If the goal is the minimum consumption of material, speed of work, noiselessness, there is no better equipment for cutting cast iron. Plasma will make cuts in the workpieces with a thickness of more than 200 mm, and the sawing material at the end of the work almost does not have to be processed.

The method is used by large enterprises of metallurgy, industry, where there is a need to cut and transport cast iron scrap. Plasma installations are indispensable for volumetric work.

Drilling in conditions of industrial

In conditions of industrial production, if necessary, solving the problem, how to drill cast iron, appropriate machines with a working tool with special working surfaces of the corresponding sharpening are used. Must apply cooling liquids to ensure a given operating temperature.

In addition to drilling cast iron, it is imperative to ask a security issue during such works. It should be taken into account the possibility of the presence of a cavity, voids and similar defects in the array of the processed material. This is more often associated with a large amount of carbon in cast iron and a number of other components.

These sudden defects also lead to the fact that when processing the metal, a large amount of finely dispersed crumb and dust is released. Processing methods depend on the type of cast iron, but there are general rules and safety requirements.

As a result, in the course of work, generally accepted protective measures should be performed. Need to protect the respiratory system. Why is it necessary, in addition to the equipment of the place of work ventilated by the hood, to use a respirator or cotton-gauze “petal” for individual protection.

You should also protect your eyes. Safety requirements provide for the presence of protective screens, the use of protective glasses with closed side edges. Work in special work clothes, mittens and headdress.

Work with a chisel and a hammer

This pair of products will help divide cast iron in an inaccessible place. Dismantling work begins with pipes removed from the riser in places where you do not stick a corner grinder or hacksaw. Since cast iron is a fragile material, it is easily destroyed after point dynamic loads.

A good shock tool has a rubber or polymer nozzle to slightly soften the blow. This is necessary so that the pieces of cast iron do not scatter around, do not get into the riser and do not create a blockage.

The chisel and the hammer work perfectly with the cast iron of the Soviet era, that is, connected by sulfur, aluminum and cement. As you move to the riser of free space for work, as a rule, it becomes larger, so further cast iron can be cut off with a more effective device. As with a corner grinder, when working with a chisel, it is recommended to close the areas of the body into which a cast.iron fragment can fly off.

The performance of the work is extremely small, but sometimes without them in no way.

Recommendations for work

There are a number of small technical and operational subtleties that are important to consider in the process of processing the tree:

- Many, in attempts to make work more comfortable, get rid of the protective casing. But this is categorically impossible to do, since the casing is the only barrier in front of the operator and disk, the destruction of which can lead to injuries.

- A special device will help to increase the reliability of the physical maintenance of the tool. the supporting base. She will make a machine from a manual apparatus.

- To ensure a more tenacious grip, it is recommended to saw a corner grinding of a corner grinder in building gloves with rubberized pads.

- If the model of the angeling machine used is provided with the lock function, it should not be used. Complex situations may require instant disconnection of the device to minimize the damage, and the lock on will not allow this to do this.

General course of work

At first it may seem that the disassembly of obsolete communications is a trifle business, because it is not to build. not to build. However, here we need just the right, qualified approach, because otherwise it is easy to damage the riser connecting several apartments at once. And this is a real disaster, the consequence of which will be the need to replace the common riser and, of course, the boundless indignation of the neighbors.

The cast.iron pipe should be dismantled carefully, adhering to such a priority:

- Turning off the supply of water supply to the apartment.

- Disconnecting with the help of a divorce key of the hose supplying water to the flush tank from the toilet.

- Dismantling the toilet (it is necessary to unscrew the bolts attaching it to the floor).

- The release of the bathroom of the bathroom from extraneous things and equipment that may interfere with the replacement of the pipeline (bidet, sink, washing machine, etc. P.).

- Dismantling the old sewage system. Due to the fact that cast iron is characterized by high fragility, the pipes that are at some distance from the riser can easily be broken with a hammer.

- Removal of pipes brought directly to the old riser.

- Installation of cuff on the bell of the tee. Previously, you need to carefully clean the bell from old lubricants, which prevent the high.quality installation of a new sewer system.

Using a cutter

Before you start using the device for metal, the device must be prepared.

Firstly, we look at whether gas hoses are connected correctly (the oxygen supply hose is connected to the fitting with the right thread, and the hose for supplying combustible gas to the fitting with the left thread).

Secondly, we pull up all the connections and check how sealed they are to avoid the leakage of the mixture during the work of the work.

It is advisable to lubricate the rubber saline seals of the valves with a special lubricant or glycerol. Only after that you can set fire to the cutter and start cutting the metal.

The sequence is extremely simple:

How to cut 3inch cast iron pipe easy.

- First, we open a valve with oxygen, then a valve with a gas;

- We set fire to the combustible mixture out of the release device;

- adjust the stream of flame to the required size and intensity using valves;

- We heat the metal until the heating site becomes straw;

- Open the valve with cutting oxygen and perform the cutting of the material;

- Having completed cutting, we first overlap the gas valve, then oxygen;

- If the tip is very heated, it can be lowered into cold water.

When working, you should be extremely careful and prevent errors.

If you carry out cutting with your own hands, be sure to put on special gloves and a protective mask.

At the same time, the clothes are proper from natural materials, it is advisable not to wear synthetics and flammable materials when working with fire.

Shoes should be comfortable so that it can be easily and quickly move in when an unforeseen situation occurs.

Metal should only be cut on a specially prepared low.fat surface.

If oxygen comes into contact even with a small amount of oil, then the percentage of explosion is extremely high.

Therefore, in no case can you touch the cylinder with oil hands! Smoking during operation in the room is also strictly prohibited!

You should not panic if you have flown or broke through a hose that supplies gas (since the gas is under pressure, this sometimes happens).

Those who are faced with this for the first time, in most cases are scared of a loud sound that occurs at this moment.

In this case, the propane should first be blocked as quickly as possible, and then oxygen.

After use, the gas cutter should be stored in a specially designated place that eliminates the ingress of oil and fat.

The gearboxes are stored separately, and the cutter and welding burner can be placed together.

Detailed instructions for drilling cast iron

The tools and materials necessary for work:

Before drill the hole in the cast iron, you need to clearly define the goals and objectives, t.to. you need to see exactly the final result. During drilling holes in the bath, errors are made without preliminary experience. The three most common are sliding holes, enamel chips and even drill breaks.

Before you start doing anything, you need to make sure that you really have cast iron in front of you. The easiest way is to try to raise the product. If it does not rise due to a huge mass, then there was no error. Otherwise it is ordinary steel.

The most important aspect that cannot be forgotten throughout the work is the lack of haste. Even if it is very necessary and squeeze the deadlines, the cast iron should be drilled with cruising speed, t.to. The material is not only very hard, but also very fragile, which is why you can inadvertently say goodbye to a cast-iron product.

Now you can start preparatory work. At the very beginning of the preparation, it is necessary to install all the necessary marks on the surface with the help of a black or red thick marker. Small points are placed so that during work, not by chance, do not take the drill from the selected positions.

The drill should be made of carbide steel, and its sharpening should be impeccable. The drill should be on a metal with an angle of 116-118 degrees, so as not to scratch the surface, namely. If this moment is not taken into account, then with a very high probability the enamel will not cut off a cautious circle, but will split, letting out cracks around him.

If there is a desire to be safe, then you can use a wooden bar. A hole is made in it, 2 mm exceeding the used drill, so that there are no difficulties in the process of professional activity. This block should be 2-2.5 cm in thickness, so that the drill does not walk even if the hand flutters. The bar will be applied to the surface during operation so that the point marked in advance is visible in the center. It will need to be pressed with 1 hand, while the other is organized the entire workflow.

Often, beginners forget or purposefully ignore the cooling of the drill, which is why the workflow is much slower, and the drill itself wears out faster. In order to avoid this, you need to use a kerosene solution. Its consumption is small enough to evaluate the drill more expensive.

There is another way not to harm enamel and at the same time do everything extremely high quality. use a corner grinder. Instead of the usual cutting disk, you need to string with a grinding, which a patch of enamel is safely cleaned, and only then the actions described above are carried out. This approach does not only minimize risks, but also significantly accelerates the process. Usually grabbed an additional 2 mm to the diameter, t.to. In this case, the result will turn out without a flaw.

The most important primary products of ferrous metallurgy, cast iron are widely used in various areas of world industry. They serve as the starting raw materials for steel production, are used in mechanical engineering. Being known for more than three millennia, this metal today reflects the level of industrial development of its countries producing it.

Throughout history, the production of cast iron has developed and improved. And today, the use of this metal in some types of industry cannot be replaced, so cutting and drilling cast iron is so important. Due to the high carbon m, different methods and a special tool are used for cutting.

As a rule, in domestic conditions, the use of drills with winning nozzles (for example, VK8 can be recommended

). Such a cast iron drill should be used at small speeds, observing the verticality of the effort and performing frequent cooling of the cutting nozzle, preventing it from overheating and blackening.