Ways to reduce dust emissions

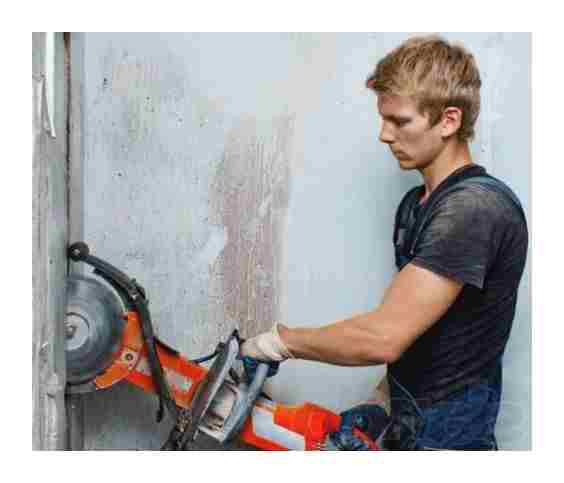

For many craftsmen, dust becomes a significant obstacle when cutting concrete structures. It not only makes breathing difficult, but also significantly reduces visibility, which can affect the accuracy of the work performed.

Very often, craftsmen attach a vacuum cleaner to an angle grinder. During operation of the coal grinder, the switched on vacuum cleaner collects dust, preventing it from scattering in different directions.

There is another way that can reduce dust emissions. It’s called wet cutting. The bottom line is that water is supplied to the disc, which wets the concrete and prevents dust from forming. When using water, use special wet diamond blades.

We cut concrete ourselves

Professional teams that provide services for cutting reinforced concrete products in their arsenal have equipment that allows them to perform all work quickly and with a minimum amount of dust. You will have to call specialists when you need to cope with a large amount of work. Otherwise, you can try cutting the hole yourself.

For this you will need:

- 4 or 5 inch angle grinder (disc diameter 100 mm or 125 mm);

- diamond blade of appropriate size, it can be regular segmented or TURBO.

When choosing diamond blades, you should pay attention not only to the price, it is lower for conventional cutting elements. But also on productivity, this indicator is much higher for turbocharged blades for diamond cutting.

How to cut concrete with an angle grinder

Increasing door and window openings can be a hassle. For many homeowners, carrying out these works becomes a difficult task.

Find out here how to quickly and without unnecessary dust cut the required hole in concrete.

Observance of safety when working with an angle grinder

Cutting holes in reinforced concrete is invariably accompanied by a lot of dust and high noise levels.

Therefore, it is necessary to use personal protective equipment:

- a mask that will protect your eyes from dust and debris;

- respirator. Provides free breathing in a dust cloud;

- special anti-noise headphones. They are able to protect against strong industrial noise, but make it possible to hear the interlocutor’s speech and other quiet sounds;

- protective overalls and gloves. Their use will help protect the skin from injury by large concrete particles.

Compliance with the necessary safety measures will allow work to be carried out even with a large amount of dust.

In the video, we watch how to cut an angle grinder and a concrete perforator:

Like all other tools, the angle grinder is divided into classes, into professional and household tools, as well as by their design features.

This is perhaps the most widely used tool besides the drill. Many people work with an angle grinder, but not everyone is wondering about the correctness of the manipulations performed, from the point of view of personal safety and quality of work. In this article, we want to devote you to the basic subtleties of working with this tool and consider in detail the following questions:

Let’s go in order.

HOW TO CORRECTLY CUT AN Angle Grinder?

Before you get started, you need to prepare your angle grinder. We mean the choice of rig (disc). The following points should be considered here:

- Disc diameter. Remember, the smaller the diameter of the disc, the more revolutions (higher rotational speed) it can withstand, and vice versa.

- The choice of disc depends, first of all, on the material with which you plan to work and the design features of your instrument.

- Pay close attention to the legend and markings on the disc. Having carefully studied them, you will understand whether the selected equipment is suitable for the proposed work.

Also, always follow safety precautions and wear special equipment such as gloves, goggles, long sleeved robes and closed shoes.

First of all, clear the workplace of unnecessary items. Securely fix the workpiece to be processed, having previously marked it on it, if necessary. Getting Started.

Always hold the tool firmly and confidently with both hands. Take a steady body position. You need to stand so that sparks, during work, do not fly onto clothes, and even more so in the face.

Always remember about such a thing as kickback. This is the most dangerous thing that can happen when working with a grinder. It can happen if the disc is strongly jammed in the workpiece. In such a situation, the angle grinder will be thrown back sharply. Monitor the process to avoid this.

Also remember that the power cord of the angle grinder must be isolated from sparks during operation. If you need to move the instrument to a different work surface, be sure to turn it off first, then unplug the power cord. The same should be done in the event of a power outage. As soon as the power goes out, turn off the instrument and then unplug it from the mains. If this is not done, then when power is restored, the angle grinder will start to work in a chaotic mode again and can cause irreparable harm to your health, others or damage objects around.

The most frequently asked question that arises among novice craftsmen is the following: How to cut an angle grinder correctly: for yourself or away from yourself? Many do not betray this special significance, but in vain.

Manufacturers of angle grinders advise their consumers the following: The tool should be used in such a way that the stroke (direction) of the cut coincides with the direction of rotation of the disc.

Experienced craftsmen have a clear answer to this question: You need to make a cut from yourself. This is for your safety. In case the angle grinder is pulled out of your hands, the tool will be thrown in the opposite direction from you. If you cut towards yourself, when the above situation occurs, the tool will fly to your feet. We will not describe the consequences. You can imagine them yourself.

If you are cutting parts or workpieces that have thick metal, cut them in an extremely straight line.

When working on a part such as a corner or when cutting a profile or profile tube, which are usually quite long, cut the overhanging edge. Otherwise, if you make a cut in the place between the supports, an outcome such as a jamming of the disc due to the deflection of the workpiece is possible.

If you are cutting a corrugated sheet (sheet metal sheeting), metal siding (metal siding) or metal tiles, take care of the presence of special anti-corrosion substances that need to be lubricated in order to avoid sudden corrosion.

In case you are cutting paving slabs or paving stones, get a special diamond cut disc.

Reinforced concrete, concrete and other similar materials must be processed with special discs for stone.

If you need to cut a gas or oxygen cylinder, be very careful as it may explode due to the remaining trace of gas or condensation. It is better not to carry out such work at home.

If you need to cut glass or, for example, a mirror. the most trivial ceramic disc will suit you.

When working with material such as wave slate, do not apply extra effort to avoid chipping and unevenness.

Handling rubber with an angle grinder is possible, but unnecessary. If you understand what we mean.

Grooves, springs, rebar or channel can also be cut with an angle grinder.

How I Make Straight Accurate Cuts With The Angle Grinder

Need to cut drywall or polycarbonate? Do this very carefully to avoid chipping and breaking the material. You will need neatness if you need to cut glass mosaics. For example, if you are cutting off excess parts from a pasted arch, cover the cut and the part to be cut off with masking tape or construction tape. This minimizes the possibility of cracks and prevents debris from scattering on the floor after cutting.

HOW TO CUT TILES WITHOUT CHIPS Angle Grinder?

As we said above, the range of applications for the angle grinder is incredibly wide. She also acts as an excellent helper when cutting material such as tiles or tiles. But, a logical question arises regarding the equipment: How is it better to work on tiles? To carry out this type of work, you need to get a grinding diamond wheel and a tile holder. It is hardly possible to work without dust with this material, so take care of a protective mask in advance.

Let’s take a closer look at the process itself and methods of cutting tiles or tiles without chips.

- The easiest way is to cut straight. Fix the tile well so that its edge remains suspended along the mowing line of the cut and get to work.

- The next method to be noted is cutting at a 45 angle. This method is more complicated than the first one. First, we cut the ceramic tile with a straight cut. Then, when cutting the disc, the angle grinder is guided at an angle and remove the unnecessary part. Next, we grind the cut with sandpaper.

HOW TO CORRECTLY CUT ANGLE GRINDER METAL?

- Fragments of the disc, in the event of a break;

- Powerful stream of sparks and small abrasive particles;

- In some cases, the inability to hold the instrument in the hands.

How to Cut Concrete with a Angle Grinder

Now, a few tips for working with metal.

If you have no experience in this type of work, then, for a start, it is worth practicing on unnecessary details. If in the process of work, you decide to change the cutting plane when the disc is inside the workpiece, this will immediately lead to its breakage.

To increase the life of discs, especially expensive ones, they need to be cooled. This is done with water. It is necessary to water the cutting area. It is advisable that you work with a partner who will carry out all these additional manipulations.

Also, breaks of 5-7 minutes every 20-30 minutes of work will help to increase the service life of the equipment, and the tool itself. This rule is especially important when working with household angle grinders. This way you will protect your instrument from overheating.

You should also remember that you should not put pressure on the angle grinder during operation, otherwise it may fail due to overheating, or the disc will jam. If you feel that performance is too slow, try changing the drive.

CAN the angle grinder CUT WOOD?

Many seasoned craftsmen claim that cutting wood with an angle grinder is to be. Our opinion: indeed, it is possible to cut wood with an angle grinder, but it is extremely unsafe, inconvenient, slow and of poor quality. And that’s why.

Firstly, during operation, the disc of an angle grinder gets very hot and becomes incredibly fragile. The slightest misalignment can result in a ruptured disc. You can find out about the consequences of this situation from the pictures on the Internet.

Secondly, when working with a disc equipped with victorious solders, these solders can easily end up under the skin. And this is a direct way to the hospital, because you cannot remove them on your own, plus everything is fraught with infection.

Thirdly, when using a disc on wood, the teeth can grab more wood than you expect, and this, in turn, will lead to that. that the angle grinder will simply rip out of your hands. It is very dangerous!

We hope we have explained in an accessible way why you cannot use an angle grinder when working on wood and you will not even try.

But, as practice shows, many craftsmen at home resort to using an angle grinder in the process of processing materials such as chipboard, chipboard, laminate, OSB board or plywood. This should be cut as carefully as possible and in compliance with all safety measures. Otherwise, you can not only spoil the material, but also be injured.

HOW TO EXACTLY CUT AN Angle Grinder?

In order not to spoil the workpiece and make a high-quality smooth cut of the angle grinder, you will need to perform a number of preparatory measures, which we will discuss in this part of the article.

- Markup. All ingenious is simple. first we mark, then we cut. Take pipe cutting as an example. First, use a chalk or marker to apply the size, then use paper or duct tape. The main thing is that the edge is even. We take the selected auxiliary material and carefully wrap it around the pipe. Its border will be a clear and accurate marking of the cut. When performing work, it is important to remember that under no circumstances should you change the position of the tool stroke. Otherwise, the disc may jam or break. Also, do not put additional pressure on the tool, as this will immediately be reflected in the curvature of the cut and spoil your workpiece.

- It is very important to choose the right thickness of the circle. There is a simple axiom at work: the thicker the material you are working with, the thicker the disc should be. When choosing tooling, consult with an expert in the field and pay attention to the marking of the grinding wheel applied to his shirt.

HOW TO SAFELY CUT AN Angle Grinder?

The work of an angle grinder is a matter that requires constant attention and control, because the consequences of accidents are irreversible. Therefore, before starting work, take care of the following:

- Take care of the protection of all parts of the body: face, hands, eyes.

- Clean the work area from excess, especially the place where the sparks fly out, remove all combustible materials away.

- The workpiece to be machined must always be securely clamped.

- Be sure to install the protective cover.

- Hold the tool firmly while working.

- At the end of the work, wait until the rotation of the disc has stopped completely, place the angle grinder with the disc upwards so as not to damage it, unplug the tool from the mains and make sure that there is no smoke or signs of fire.

WHAT CANNOT BE CUT with an angle grinder? BASIC ERRORS

The list below shows the materials you can work with your angle grinder. It is forbidden to work with materials that are not on the list.

- The angle grinder is perfect for cutting materials such as cast iron, metal, steel, copper, aluminum, iron, titanium. You can cut stainless steel or galvanized.

- With the appropriate attachments, you can also work with plastics, ceramics, glass, plexiglass and porcelain.

- Stone, granite, marble, asphalt, concrete or walls made of it, brick, porcelain stoneware can also be processed by an angle grinder.

an angle grinder is useful if you need to cut water pipes or old heating.

One of the main factors that guarantee the quality of work is the right tooling. If you have any questions or want to purchase discs, please contact our managers at the specified phone numbers. They will recommend suitable discs and advise you on all questions of interest.

How to cut metal angle grinder correctly. Practical tips and tricks

If long pipes are resting on supports, the overhanging edge must be cut. If you cut them in the middle, then due to its own weight, the metal will bend and clamp the disc.

If you do not have the skills to handle an angle grinder, then before starting work, you should learn how to cut on unnecessary parts.

The cut-off wheel only accepts radial forces. Attempting to change the cutting plane while the blade is inside a metal piece will break it.

The disc heel (the near-bottom part of the circle) cuts metal more efficiently.

In order for the angle grinder and discs to serve for a long time, you need to take a break for 20-30 minutes every 5-7 minutes of work. This rule is especially important for low-power angle grinders who are afraid of overheating.

To increase the service life of the discs, especially expensive ones, and to cool the metal, the place of the cut must be watered. It is advisable to carry out the work together.

Aluminum is a very tough metal. When cutting a part of a large thickness, kerosene must be dripped into the seam, observing fire safety rules.

For molding, cutting of sheet metal, curly carving, you should use worn-out discs. “stubs”, so do not throw them away immediately.

Correctly cut the corner not in one go, but separately both shelves.

If long enough pipes, corners, fittings lie on the supports, cut the overhanging edge correctly. If you cut between the supports, the part will bend due to its own weight and jam the disc.

Thick parts are cut only in a straight line. If you need to cut a curly part, straight-line cuts are made first, then the remaining unnecessary parts are removed.

Do not put pressure on the angle grinder. This will cause the blade to jam or break and overheat the angle grinder. If the cutting process is slow, the blade should be replaced.

The resulting cut should not be processed with the side of the disc. For this, a different type of disc is used.

Melted particles of metal and abrasive, falling on plastic products, glass and car headlights, get stuck in them, and then it is almost impossible to remove them. Therefore, before starting work, they need to be removed or protected.

How to choose the right angle grinder

the angle grinder should fit comfortably in your hand.

The correct choice and quality of the angle grinder itself determines the quality of work and the safety of the worker.

When choosing a machine, you should be guided by its main parameters: power and diameter of the cutting abrasive wheel. Its weight is also of no small importance, since it is often necessary to work “by weight”, and dimensions so that you can perform work in inconvenient and hard-to-reach places.

Most buyers at the sight of a powerful angle grinder are somewhat intimidated by the fact that it is more difficult to cope with it than with a low-power one. This is a misconception. Low-power angle grinders are more likely to jam discs, i.e. they are physically unable to “pull out” the disk under heavy loads. The situation of how the disk and the machine itself will behave after reducing the load is unpredictable. The angle grinder will most likely tear out of your hands. The consequence of this will be a break in the disc, damage to the machine and injury to the cutter. Therefore, it is better for novice craftsmen to purchase an angle grinder for a 125 mm disc with a power of 800-1000 W and a spindle speed of 10,000 rpm. This power is enough to cut iron.

For cutting metal, there are machines for a 115 mm disc powered by batteries, but, as practice shows, with their high cost in solving household problems, they do not justify themselves.

The handles of the angle grinder must be rubber or made of a material that will damp vibrations from the machine.

But none of the technical characteristics reflects the convenience and safety in work. The angle grinder should lie comfortably and securely in your hand so that when working with metal you focus on it, and not on how to hold the tool in your hands. It is desirable that the grips are rubber or vibration-damping material with indentations for the fingers.

Low-power angle grinders usually do not have an additional handle.

If any inconvenience was found during the selection, you should look for an angle grinder of a different model.

Basic rules for safe work when cutting metal angle grinder

The layout of the most dangerous sectors during the operation of the angle grinder, taking into account the rebound and destruction of the disc.

The most necessary condition for cutting is strict adherence to the rules of safe work.

Angle grinder manufacturers are constantly trying to minimize the risk of injury and injury by inventing and improving various protection systems. But no one cares about the worker like himself.

The main dangers that arise when cutting metal are the flight of fragments of a broken disc, the flow of sparks and the smallest abrasive particles, the inability to hold the tool in your hands.

If the disc breaks or gets jammed, the angle grinder can be pulled out of your hands at the most inopportune moment and with great force, therefore, before starting work, you should consider the direction of its possible movement.

Safety rules cannot be neglected even when performing small work.

Before starting work, you should:

- Protect face, eyes, hands, and if possible all parts of the body.

- Remove all combustible materials and objects that are in the direction of the emission of sparks.

- Clamp the workpiece to be machined in a vice, if possible. Do not hold the workpiece with your free hand or press with your feet.

- If you install a new disc, you need to “spin” its angle grinder at maximum speed, placing it further: the disc may be defective and fly to pieces.

- Install, adjust and secure the protective cover.

It is best to protect your face with a special face shield when working with an angle grinder.

During work, you should:

- When replacing discs during rest, disconnect the angle grinder from the mains.

- Use goggles or face shield to protect eyes and face. professionals use both for extended work.

- Hold the angle grinder firmly during all work.

- To replace a disk, you need to wait until it completely stops.

- Wear protective gloves. It is undesirable to use cotton gloves, they do not provide sufficient protection, they can ignite, and the threads wrap around the spindle of an angle grinder or disc.

- During work, you need to position yourself so that the face, and, if possible, all parts of the body are not in the plane of rotation of the disk.

At the end of the work, you should:

- wait until the disc rotation has stopped completely and only then put the tool on the floor with the disc facing up so as not to damage it;

- disconnect the angle grinder from the network;

- make sure there is no smoke or other signs of fire.

A typical mistake that is made when cutting metal: if the diameter of the new circle is larger than the size of the protective cover, it is removed. The casing is a protection in case the disc breaks and shatters during the metal cutting process.

Instead of a disc, many people put cutters, saws or other materials at hand. Doing this is strictly prohibited.

How to choose the right discs

There are symbols on the circle that will help you choose the right circle.

When choosing discs, you need to know what they will be used for, pay attention to their diameter and thickness. These are the main parameters of the disks.

The smallest diameter is 125 mm, and the maximum, of the generally available ones, is 250 millimeters. In professional angle grinders, discs can be larger in diameter.

The thickness of the cut part and the maximum depth of cut depend on the diameter of the disc.

If you plan to cut only metal, you need to purchase a cutting disc. It has the smallest thickness from 1 to 1.2 mm, for industrial angle grinders. up to 2.5 mm. This will ease the physical exertion of the angle grinder and the worker. The cut is neat.

If you plan a curly thread on thin metal, then it is done with a disc of the smallest diameter or an old, almost worn out disc.

Many people think that a diamond blade should be used to cut metal. This is a completely wrong opinion. The diamond disc will simply get bogged down in the metal and will be unsuitable for further work.

Experts say that the angle grinder does not have any particular difficulties when cutting metal, even for beginners.

How to cut metal with an angle grinder

There is an opinion that the very concept of “angle grinder” has come into our use because for the first time this tool was brought from an angle grinder. This is partly true. But they developed and began to produce it in Germany. He first came to us from an angle grinder, where he began to be produced in the seventies. Angle Grinder. Correct Tool Name.

When working with an angle grinder, it is imperative to observe safety precautions, namely: wear glasses, gloves, a helmet and a protective apron.

It is impossible to imagine the work of builders, repairmen, mechanics, locksmiths today without an angle grinder. With its help, you can cut a variety of materials, including metal: fittings, bar, water pipes, corner, profile.

The resulting sections can be grinded, polished, sharpened. A large selection of interchangeable attachments makes this tool irreplaceable and versatile.

At the same time, it is the most traumatic tool.

To cut metal, an angle grinder will need:

- mask;

- glasses;

- disks;

- Angle Grinder;

- metal.

Is it possible to use an angle grinder for cutting metal tiles and corrugated board?

At a time when they just started using metal tiles and corrugated board, the instructions said that using an angle grinder for cutting these roofing materials is strictly prohibited. This is explained by the fact that on both sides they are protected with zinc and polymer coatings and painted.

The abrasive disc heats and melts the material. The slices are ragged. Flying sparks also break the paint. All this causes corrosion of the material and a reduction in service life.

Recently, however, builders have begun to use an angle grinder for this work. This greatly facilitates the work, it can be carried out directly on the roof. After cutting, the edges must be treated with anti-corrosion agents, primed and painted.

Correctly cutting metal with an angle grinder is easy. Everything can be learned. The main thing is to follow the safety rules and follow the recommendations.

How to grind an angle grinder different materials

Even if you purchase and install the necessary accessories on your angle grinder, it still means nothing. Processing different materials requires certain knowledge. Without this, it will be difficult to achieve the desired quality.

How to make a sander from an angle grinder?

Such a question can be confusing, because an angle grinder is an angle grinder. But it is very versatile and must be prepared for each operation. To prepare the angle grinder for grinding, you need to purchase a support wheel, which is installed directly on the machine shaft.

To process wood, you need to glue an emery cloth on this circle. The number of sandpaper is selected for the immediate moment of work. On sale you can find both a grinding wheel of the required diameter, and emery wheels of the appropriate size. Velcro emery discs are also available, which are very easy and quick to change on the tool.

In order to convert our angle grinder to concrete grinder, it would be a good decision to purchase a special dust cover. It is good because it has a branch pipe for connecting a vacuum cleaner. The well-known casings are produced by Hilti. On the cover of this company there is a sliding sector that opens part of the wheel for grinding in the corners.

Grinding a metal angle grinder is usually done with standard metal grinding wheels. They have different diameters, different thicknesses and different grains of the grinding surface. But, if you are going to sand an obscenely rusted surface, then first you need to brush it over the metal. Such brushes of the required diameters are also on sale.

We work on concrete

If it was not possible to purchase a branded protective dust cover with a nozzle for a vacuum cleaner, then you can do it yourself. To do this, we take a used bucket from under putty or glue with a diameter slightly larger than the circle of an angle grinder. Cut off the bottom part at a height slightly larger than the assembled grinding part.

We cut a hole in the bottom for installation on the gearbox and a hole for a plastic plumbing corner bend. Now we connect the hose of the vacuum cleaner to the nozzle and work calmly.

The grinding wheel must be dimensioned for stone processing. It is preferable to grind concrete and concrete surfaces with the entire surface of the wheel. This will save machining time, and level the surface plane well.

When sanding a concrete floor, it is necessary to constantly monitor the plane with a construction ruler, because, due to the different density of concrete, indentations can be made. For the processing of butt joints between concrete fillings, it will be sufficient to achieve one level combination.

Sand concrete floors and surfaces well with a Matrix diamond cup. If the angle grinder is 150 mm, then the cup is 125 mm.

How to grind an angle grinder

Do not forget that sanding is always associated with a lot of dust. When preparing for sanding, do not forget about yourself! A face shield and respirator are the best helpers for sanding. You can also find such an option where the mask is combined with a good respirator.

The respirator filter will clog very quickly, so you need to prepare several pieces at once for quick replacement. Only after thorough preparatory work can you start grinding.

Grinding wood

Wood is a unique material. It can be sanded by hand quite well, but with an angle grinder you can achieve very good results. Some snobs argue that you can’t grind an angle grinder at all, but this is from ignorance and inability.

The main secret is that the grinder is used at minimum speed. If the angle grinder has a speed switch, then there will be no problem. At high speeds, the sandpaper will clog very quickly and very tightly with wood. In this mode, it will not be enough for five minutes of work. Optimum speed no more than 6000 rpm.

Another secret is not to sand with the entire area of the wheel. If you sand the entire surface, then circular marks will remain on the wood. So that no traces of sandpaper remain at all or they would be minimal, it is necessary to grind only with the upper sector of the circle. The movement of the machine should be along the grain of the wood.

With this method, you can get excellent results when sanding the lining. The board becomes smooth and does not retain tool marks. You don’t just need to get carried away and change the emery pads on the circle in time.

The frame is polished in a similar way. Here, it is desirable that the support plate is thin at the edge. With such a plate, it will be easier to sand narrow places where the logs meet. Otherwise, this work will have to be finished with a chisel.

Grinding metal surfaces

Metal is ground according to different requirements. Most often, the metal is ground for painting or for further polishing. The main tool is recognized as a support cup with replaceable emery pads. The selection of sandpaper depends on the degree of processing and on the state of the metal.

When sanding, you only need to work with part of the disc. There should be no untreated areas on the surface.

It is desirable to prime the treated surfaces of ordinary steel with a primer. Moisture in the air can coat metal very quickly and cause rust.

Concrete cutting angle grinder. the choice of tool and features of working with it

Today it is difficult to imagine performing the work of locksmiths or builders, repairmen and other similar professions without an angle grinder. It is actively used when cutting, trimming and grinding various materials.

With an increase in the number of attachments, its functions become more diverse. The article invites you to get acquainted with how the concrete angle grinder is cut and its features.

Types of tools for cutting concrete

For cutting concrete, diamond wheels are used, their main dimensions:

- Outside diameter of discs, in the range of 100. 600 mm;

- Thickness, in the range of 0.4. 3.5 mm;

- The bore diameter is more than 15 mm, the optimal diameter is 22.23 mm.

Diamond wheels also differ in other indicators.

These include:

- The quality of the diamonds on the disc;

- The material of the discs themselves;

- Soldering method;

- The form;

- Appointment.

The last two characteristics are the main ones when classifying a tool.

The table shows diamond discs of different configurations of working edges:

According to the spraying technology, circles are distinguished:

- Brazed with silver solder, they are used only for wet processing of concrete surfaces;

- Laser welded. These are the strongest and most durable blades that can withstand dry cutting. Such a diamond disc for concrete for an angle grinder is most often used for cutting reinforced concrete;

- Coated with special compounds, which are then exposed to high temperatures. These are universal discs with average characteristics.

The circles also differ in the degree of concentration of the spraying, which in high-quality tools reaches more than 30%, and the abrasive grit is distributed over the entire volume of the teeth and grooves. With this design, the service life of the wheel is significantly increased; when it is grinded, new layers are opened for cutting the material.

Tip: When choosing a circle for cutting concrete, you should consider all of the above tool characteristics.

Determination of the type of concrete

Before you start cutting an angle concrete grinder, you need to determine its type. The choice of the type of diamond disc depends on this.

- With a cutting depth of about 100 mm and deeper, a metal grill or reinforcement cage can be located. There are special disks for these purposes;

- Consideration should be given to the change in material structure over time. Fresh concrete is more abrasive, while old concrete is more hard. Because of this, the diamond wheels for fresh and old materials must be different;

- There are different concrete reinforcement schemes;

- If possible, it is worth studying in more detail the structure of the material, this will allow you to purchase the most suitable circle for cutting. Materials such as basalt or quartz will quickly dull the edges of the tool. In this case, the diamond segments are selected bound by a soft material, while new diamonds will begin to “open up” faster;

- The cutting speed is influenced by the size of the filler. the larger it is, the slower the work.

Equipment selection

Correctly selected equipment is the key to high-quality and long-term operation of the tool. When purchasing it, you need to pay attention to such basic parameters as: power and diameter of the cutting wheel.

Tip: Often buyers are afraid to purchase high power models. But this is absolutely wrong! It should be borne in mind that a machine with low power may jam discs. the device does not have enough strength to pull it out.

For beginners, you should purchase a tool with the following characteristics:

- Power in the range of 900. 1000 W;

- Spindle revolutions, approximately 10,000 rpm;

- Disc for concrete on an angle grinder with a diameter of 125 mm.

Equipment with such technical characteristics may well cut iron. If, according to the technical characteristics, the selected model is suitable, but it is inconvenient to use it during work, you should give preference to another option.

Features of working with an angle grinder

The concrete angle grinder is an essential tool, but it can also cause injury. This requires following the operating rules when working with the equipment.

These include:

- Work should be carried out only in a sober state and in good health;

- Before starting work, it is recommended to prepare the following devices and protective equipment:

- A face mask or goggles to prevent sparks from entering the face, especially eyes;

- Vacuum cleaner or respirator;

- Gloves, preferably thick or genuine leather mittens;

- Protective clothing that covers all parts of the body;

- Nozzles that are allowed to use the instructions for the equipment;

- Headphones.

- A cover that fits between the instrument and the person.

All of these items will keep the worker safe when cutting concrete.

Cutting concrete along the mowing line

Once the concrete angle grinder has been prepared, work can begin.

- The line of the cut is outlined. At the same time, it is advisable to fix wood bars along the mowing line, which will allow the cut line to be made more even;

- The angle grinder turns on and a cut is made approximately 5 to 10 mm deep;

- Bars are removed;

- The cut is made to the required depth. If the incision is made dry, the procedure should be interrupted periodically to allow the instrument to cool.

The video shows how the concrete is cut correctly with all the details. The process is best done with tool cooling.

- A conventional spray bottle sprays water directly onto the furrow to reduce dust;

- Water is sprayed directly onto the disc, in the absence of a power source nearby. This will reduce the heating of the diamond discs and extend their service life;

- If it is not possible to spray liquid onto the disc, air cooling can be performed. Periodically, the circle should be removed from the cut and given the opportunity to work in air.

If you have any questions about cutting concrete, if you want to know how concrete is polished, an angle grinder and other details on using similar equipment, introduce the video in this article.

Features of cutting angle grinder

After choosing the equipment and the circle for it, before cutting the concrete with the angle grinder, you need to get acquainted with the recommendations for the work:

- The tool must be held with both hands. In this case, if a kickback occurs, it can be held, which will minimize the displacement of the mowing line of the cut;

- Work should be carried out only on a flat surface so that the person’s balance is maintained;

- Place the power cord on the opposite side of the disc to prevent accidental damage. A cut cord may cause a shockwave from the unit and a short circuit in the power supply;

- The tool must be firmly held in your hands until it comes to a complete stop;

- When changing the place of cutting, the angle grinder must be turned off so as not to accidentally touch the surrounding objects;

- In the event of a power outage, be sure to disconnect the equipment from the network. This will prevent it from turning on when power is supplied without operator control.

Tip: During operation, the discs become very hot, therefore, after turning off the angle grinder, it should not be touched until it has completely cooled down.

Is it possible to grind concrete with an angle grinder

Sand the surface before laying the floor covering. As a result, the almost perfect smoothness of the floor is not the only plus of such processing: the latter also protects from excessive dust formation, strengthens the floors.

The good news is that a conventional angle grinder can also be adapted for this purpose. It is convenient to clean corners, hard-to-reach areas with it.

Training

To be satisfied with the result, you must first check everything. It is necessary to inspect the surface for cracks, reinforcement sticking out of it or reinforced mesh. If there is something like this, it must be removed before sanding.

Cracks after shrinkage, various joints must also be pre-sealed. And only when the patched areas of the surface are dry, you can start working.

The floor is composed of gravel, crushed stone and other particles designed to increase its strength. However, they can rip out the disc if their bond in the solution is not strong enough. Therefore, if the floor is freshly poured, it is necessary to wait up to 14 days for the screed to dry.

Note: Drilling and similar work is done prior to grinding. Otherwise, we can assume that it was done in vain.

Grinding concrete angle grinder: how to do it, attachments. 4 explanatory sections

The angle grinder is compatible with many materials. What about concrete? Will she work with him? The guide will tell you about the nuances of such processing.

Grinding process

After the preparation is over, you can start the main work. In itself, this is not difficult: you need to arrange the circle so that it evenly touches the surface. At the same time, you do not need to apply strong pressure on the tool.

Interesting: WEV 10-125 cannot be switched on accidentally due to a special protective function. This ensures the safety of use.

However, there are some subtleties in how to grind concrete with an angle grinder with your own hands:

- First, the surface is covered with a compound that eliminates pores in it: the floor becomes more moisture resistant and stronger.

- For the most even, brilliant effect, diamond discs with a high. from 400. density index are needed.

- To make the garbage easier to collect, the casing will not interfere: with it, the concrete dust will not fly in all directions. There are options that allow you to connect an angle grinder to a vacuum cleaner.

Recommendation: it would be good to choose a tool with dust protection, like the MB 2400PA. Models like these last longer.

Concrete Angle Grinder Attachment

For the processing to be successful, you need to choose the right abrasive disc.

Important! In order not to spoil the device, there should be no pits and bumps on the floor more than five millimeters. So before the angle grinder, it would be wise to do the initial grinding with a tool that is more suitable for this.

What attachment for a grinder is needed:

- Material. The most convenient option is a cup-shaped disc. It should contain particles of solid rocks that grind concrete. In this case, it will be easier to do the job. Using a circle of sedimentary gravel is also possible, but it will be more difficult and not as effective. If there is impregnation on the floor, it is better to choose an accessory with marble, granite particles.

- The form. To eliminate the first. the coarsest. layer, a “double segment” is used. To clean up large pieces, choose a “square”. This prevents damage to the floor and the nozzle itself. For delicate. fine. sanding, the “boomerang” is the best option. If the task is to make the coating glossy at the final stage, then the trapezoidal Frankfurt. an emery base will become an indispensable assistant.

- For any grinding method, individual accessories with different abrasive sizes should be selected. Approximate values are presented in the table.

Recommendation: For safety, it is better to use a device with a rubberized grip, such as the TE-AG 18/115 Li Kit, as this prevents slipping.

How to Sand Concrete Floor Angle Grinder

There are two ways:

- Wet. suitable for mosaic type surfaces or marble chips. In this case, you will need abrasives, which make it possible to achieve a polishing effect.

- Dry. ideal for concrete, but takes longer. Despite the fact that a lot of dust rises, this does not interfere as much as particles of wet concrete: visibility during processing is much better, so the master can notice and eliminate all errors in time.

Tip: in order not to suffer with extension cords, you can purchase a cordless angle grinder, like the powerful 51G203, which is not afraid of overloads.

Safety when working with an angle grinder

In order not to damage the instrument and not harm yourself, the following rules must be observed:

- Make sure the angle grinder is fully functional before starting.

- There must be enough light in the work area.

- The user should wear tight clothing. Sleeves should not interfere with working with the device, and the clothes themselves should not be in contact with the floor.

- Care should be taken to protect the respiratory tract, eyes and hands with gloves, a pair of goggles and a respirator.

- You need to give the device a rest at least once every 15 minutes so that it does not overheat.

As you can see, the angle grinder is very useful for concrete. You just need to choose a suitable grinding wheel for it and act carefully.