how to cut gypsum fiber at home

When decorating, often use gypsum fiber sheet, or GVL. This material was created much later than drywall, so it did not win such wide popularity as GKL. However, thanks to the special composition, these plates have outstanding strength and fire-fighting characteristics with indicators much higher than that of drywall. Therefore, GVL is indispensable for the installation of bulk floors, rough finishing of walls and ceilings, as well as for the construction of all kinds of boxes. The only question that arises when working with this building material is how to cut the GWL from Knauf.

GVL Benefits

To answer our question, we need to figure out what constitutes this material. Gypsum fiber sheets, like gypsum plasterboard, are made from gypsum. But the similarity ends here. The main features of GVL are:

- Reinforcement with dissolved pulp.

- Complete homogeneity of the material.

- Lack of coverage from above.

- Incombustibility.

- High density.

Many manufacturers are engaged in the production of this building material, but the most popular is the GVL manufactured by the Knauf company under the name Superlist. If we continue the comparison of gypsum fiber with drywall of the same company, we see that they ideally complement each other. And the use of these materials during finishing works at the same time will only be beneficial for repair.

Despite the fact that any box can be made from GVL, and the walls will be strong and fireproof, nevertheless, this material cannot be bent like drywall. So, for the installation of complex structures with rounded shapes, it will not work.

But on the floor, in dry screeds with expanded clay (KNAUF-superfloor technology), gypsum-fiber sheets are unparalleled. Their use in the construction of the subfloor will give guaranteed positive results. The floor elements glued from two GVLV sheets with a total thickness of 20 mm have the following useful properties:

- They do not break.

- Do not miss the cold.

- Create a perfectly flat surface.

- Moisture-resistant gypsum boards withstand moisture up to 70%.

Tools necessary for working with GVL

Many who independently prepared for installation and installed drywall, mistakenly believe that they work in the same way with GVL. But here they are waiting for an unpleasant surprise. Gypsum fiber sheets with all their strength properties, when you take them on a break, turn out to be brittle and easily break. By the way, therefore, it is impossible to bend them, like drywall.

Tools for cutting gypsum sheets at home:

- A sharp construction knife with a thickness of 12 mm or more. The blades will often need to be changed, as they quickly become dull.

- A special hacksaw for gypsum plaster, which can be used to cut this material almost without dust.

Some craftsmen argue that it is convenient to cut GVL with a special cutter, which shoemakers use.

- An angle grinder or circular saw is used only in a well-ventilated area and provided that the end justifies the means. This is the fastest way and at the same time very dusty. If you decide to choose this tool, you will have to stock up on respiratory and eye protection.

- An electric jigsaw with a built-in vacuum cleaner is ideal if you install a wood file with a tooth pitch of 4 mm. But there will still be a lot of dust, so work should be done with goggles and a respirator.

Plaster Fiber Cutting Process

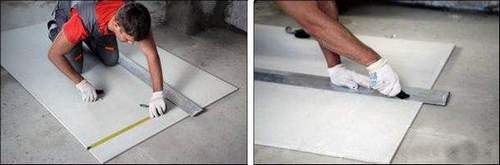

With any method of cutting should be careful and careful when handling gypsum boards. If for work it was decided to use cutters or a special hacksaw, then you need to proceed as follows:

- On the GVL sheet, we make the necessary markup.

- We apply a flat rail to the marking line. You can also use the rule.

- We carry out the knife as many times as necessary so that the depth of cut is at least 2/3 of the sheet thickness.

- We put the rail under the notch line.

- With a sharp upward movement we gently break.

Before cutting, it is better to additionally watch a video on how to properly cut the sheet.

GVL have smooth edge edges and there are usually no problems with joining. But if for a number of reasons there is a need for a slight fit, then a peeling planer is suitable for this purpose.

But the fold is most convenient to do with a boot knife-cutter or a chisel. With a large volume, you can use the router. A 3-4 mm groove cutter will allow you to perform the necessary work in 2-3 passes.

Gvl how to cut. Do it yourself repair in the apartment: photos, videos, instructions

Characteristics, application, installation and decoration of GVL sheets

Gypsum fiber is a relatively new but already very popular material for decorating rooms. It is produced in the form of sheets, the characteristics of which are similar to gypsum boards, but surpass them in many respects. The composition of gypsum fiber sheet (GVL) includes building gypsum reinforced with dissolved pulp, which is "extracted" from ordinary waste paper. Today this material is less known than its older brother. drywall, since it costs slightly more than its counterpart.

Features of GVL sheets

Gypsum fiber has a number of unique characteristics inaccessible to most building and finishing materials:

- Simple installation. Performing repair and finishing works using gypsum fiber eliminates the use of labor-intensive "wet" technologies.

- Structure. Unlike drywall, GVL sheets (boards) have a homogeneous structure with no outer shell. This advantage is due to the increased strength of the gypsum fiber, its ability to withstand ultimate load.

- Environmental Safety. Gypsum fiber is an environmentally friendly product, its level of natural radiation is 3 times lower than that of brick.

- Frost resistance. The material can withstand 15 cycles of freezing and thawing, while drywall after 4 begins to crumble and crack. Thus, GVL sheets can be used in the decoration of unheated rooms (attics, basements, garages).

- Soundproofing. Gypsum fiber perfectly isolates the room from extraneous noise. Its soundproofing characteristics can reach 35 dB.

- Moisture resistance. The use of gypsum boards in rooms with a high level of humidity (bathrooms, kitchens) involves the use of their special type, which has increased moisture resistance. GVLV.

- Resistance to open flame. Due to the absolute incombustibility of the material, the installation of GVL is recommended for rooms with special fire safety requirements.

Plasterboard can be used for wall or floor cladding, the installation of suspended ceilings, interior partitions, the creation of decorative structures and sound-absorbing screens. Gypsum fiber sheets can also serve as fire retardant coatings for rooms with normal humidity conditions.

Along with the use of gypsum boards for walls and ceilings, this material is often used in the installation of dry floor screed. Any topcoat can be laid on top of it. a durable gypsum fiber will provide an absolutely even, reliable surface. It is not necessary to hire professionals to carry out such work; sheets can be stacked independently and very quickly.

GVL installation options

The installation of gypsum boards, although they do not require the use of special skills, must be carried out strictly in stages, it is the observance of a certain procedure that will ensure the necessary operational characteristics of the structure. Surface finishing can only begin after all preparatory work has been completed, including cleaning, leveling, removing defects and priming.

Installation of GVL for walls, floors or ceilings is distinguished by its characteristic features. For example, laying a dry version of the screed will significantly raise the floor level, because of which it will be necessary to file a doorway. If we are going to lay the slabs directly on the wooden floor, we should securely fix its elements and remove all the rotten parts.

The first method of installation work is as follows: you need to lay gypsum fiber sheets on a special glue, using self-tapping screws for GVL as fasteners. We fasten the plates around the perimeter, observing this technology: the thickness of the material is up to 12.5 mm, the length of the self-tapping screws is 40 mm, the pitch is 400 mm. Hats of self-tapping screws must be recessed deep into 1.5–2.5 mm.

The second installation option is the wireframe method. To perform this type of work, only the most common tools and materials are needed:

- plumb line, level, chopping cord;

- drill, angle grinder, screwdriver;

- dowels, self-tapping screws for hot water and metal.

The crate of the structure can be made of wooden beams, but the galvanized metal profile is considered the best material for its manufacture. it is more reliable and durable. The frame must be assembled so that its elements are at a distance of not more than 400 mm from each other.

Carrying out installation work, many novice craftsmen ask the question: what is the best way to cut GVL? There are several options for solving this problem, it all depends on your capabilities and preferences. Some craftsmen recommend cutting a sheet with a knife, others use a circular saw or angle grinder. We believe that the best way out of this situation is to use a jigsaw with a built-in vacuum cleaner. its operation eliminates the formation of a large amount of dust.

It is important to remember. using the first (frameless) method of surface lining, it is necessary to observe a certain width of the gap between the plates (6–8 mm), seal the joints with special gypsum putty and apply special glue for hot-water treatment.

Finish finish

As materials for finishing the coating, you can use any kind of wallpaper, paint or tile. Let’s talk about tiled facing. First, you need to determine a phased workflow, which should consist of processing and marking the surface, preparing the tiles and adhesive composition, the actual laying, as well as the subsequent grouting of the joints.

Tiles for floors and walls have different characteristics and are selected taking into account the individual characteristics of the surface!

- Before laying tiles on GVL, it is required to process the sheets with a special primer and wait for it to dry.

- It is necessary to determine the required number of tiles based on the length and width of the surface being trimmed. Knowing the size of the products, taking into account the width of the seams, you can calculate their total number.

- Now it is necessary to apply the adhesive composition to the surface, distributing it in an even layer with a spatula.

- When laying the tiles on the GVL, it is necessary to press it slightly in order to increase the reliability of fastening. Many experts advise using a rubber mallet for these purposes.

- You should leave the same gaps between the tiles, carefully cleaning them from the adhesive mass. After a day (when facing the walls) or 48 hours (floor), the joints between the tiles must be wiped using special compounds. All this time, the room is required to maintain a minimum level of humidity.

A very important role in measures for facing gypsum-fiber sheet is played by the correct selection of primer and adhesive composition. the quality of tile fastening will depend on them.

The well-known manufacturer of GVL. the company KNAUF. recommends using only high-quality materials for finishing and sequentially perform all stages of the process. German experts advise using a special brand glue for FLIESEN tiles in the work, preparing it in small batches, sufficient to process a surface area of 1 m2.

Video: How to Cut Gvl How to Cut

That’s all, let’s hope that our article will help a beginner craftsman decide on the finish option for his favorite room. If an experienced master respects us with his attention, we will ask him to share his experience and tell how it is better to cut GVL than it can be trimmed, and most importantly. how to avoid mistakes when performing such work.

Home Articles Drywall Gypsum fiber sheet (GVL)

Gypsum fiber sheet (GVL)

Gypsum fiber sheet (GVL) is a fairly hard and durable material that has good fire-fighting qualities. It belongs to the drywall family, but differs from it. Gypsum-fiber sheet (GVL) is made from a mixture of fibers of fluffy pulp waste paper and gypsum, evenly distributed over the entire volume of the sheet, by means of semi-dry pressing.

We use GVL for installation of window slopes when it is necessary to put a tile on a wooden floor or to make a dry coupler. You need to cut the GVL as follows: We apply a rule or any other flat rail to the marking.

Holding the rule firmly, hold the knife 4-6 times. Then, we put the rule under the notch.

and gently break.

Other ways to cut off GVL will be problematic, it is too hard and brittle at the same time.

Sizes of gypsum fiber sheet (GVL) Length: 1500, 2000, 2500, 2700, 3000 meters Width: 500, 1000, 1200 meters Thickness: 10, 12.5, 15, 18, 20 millimeters

Characteristics of gypsum fiber sheet (GVL) Gypsum fiber sheets are ordinary (GVL) and moisture resistant (GVLV). Gypsum fiber sheets are used in residential, civil and industrial buildings with dry and normal temperature and humidity conditions. Moisture-resistant gypsum sheets have a special hydrophobic impregnation and therefore can be used in rooms with high humidity (for example, in bathrooms, bathrooms and kitchens of residential buildings)

How to make a drywall arch and semi-arch

How to sheathe walls and make drywall partitions, calculation, fastening.

All you need to install drywall

How to make a drywall ceiling with your own hands

Niche in the wall

Window slope device

Knauf (KNAUF) Safeboard

How to glue drywall to the wall

BrigadaStroi.ru © 2009-2017. All rights reserved. [email protected]

How to cut GVL: how to cut GVL at home

When decorating, very often use gypsum fiber sheet or GVL. This material was born much later than drywall, as a result of which it did not win such wide popularity as with GCR. However, due to its composition, gypsum-fiber sheets have strength and fire-fighting characteristics much higher than that of drywall. Therefore, GVL is indispensable for the installation of bulk floors, rough finishing of walls and ceilings, as well as for the construction of all kinds of boxes. The only question that arises when working with this building material is how to cut GVL from Knauf.

The advantages of gypsum fiber sheets

To answer this question, you need to understand what constitutes this material. Gypsum fiber sheets. like drywall, they are made from gypsum. But this is where their similarities end. The main features of GVL are:

- Reinforcement with dissolved pulp.

- Absolute uniformity of the material.

- Lack of coverage from above.

- Incombustibility.

- High density.

Many manufacturers are engaged in the production of this building material, but the most popular are sheets made by Knauf. If we continue to compare gypsum sheets with drywall of the same company, we can see that they ideally complement each other. And the use of these materials during finishing works at the same time will only be beneficial for repair.

Despite the fact that any box can be made from GVL, and the walls will be strong and completely fireproof, nevertheless, this material cannot be bent like drywall. So, for the installation of complex structures with rounded shapes, it will not work.

But on the floor, in dry screeds with expanded clay (KNAUF-superfloor technology), gypsum-fiber sheets are unparalleled. Their use in the construction of the subfloor will give guaranteed positive results. The floor elements glued from two GVLV sheets with a total thickness of 20 mm have the following useful properties:

- They do not break.

- Do not miss the cold.

- They have a perfectly flat surface.

- Moisture-resistant GVL withstands humidity up to 70%.

Tools necessary for working with GVL

Many who were engaged in self-preparation for installation and the direct installation of drywall, mistakenly believe that in the same way it is possible to work with GVL. But here they are waiting for an unpleasant surprise. Gypsum fiber sheets with all their strength properties, when you take them on a break, turn out to be very fragile and easily break. By the way, that is why it is impossible to bend them, like drywall.

Tools for cutting gypsum sheets:

- A sharp construction knife with a thickness of at least 12 mm. The blades will often need to be changed, as they quickly become dull.

- A special hacksaw for gypsum plaster, which can be used to cut this material almost without dust.

Some craftsmen argue that cutting GVL is convenient with a special cutter, which shoemakers use.

- An angle grinder or circular saw can only be used in a well-ventilated area and provided that the end justifies the means. This is the fastest way and at the same time very dusty. If you decide to choose this tool, be sure to stock up on respiratory and eye protection.

- An electric jigsaw with a built-in vacuum cleaner is ideal if you install a wood file with a tooth pitch of 4 mm. But there will still be a lot of dust, so you need to work in goggles and a respirator.

The process of cutting gypsum sheets

Whatever you decide to cut GVL, you must always remember about accuracy and caution when working with this building material. If you decided to use cutters or a special hacksaw for work, then you need to proceed as follows:

- The necessary marking is made on the GVL sheet.

- An even rail is applied to the marking line. You can also use the rule.

- We carry out the knife as many times as necessary so that the depth of the cut becomes at least 2/3 of the sheet thickness.

- We put the rail under the notch line.

- A sharp upward movement gently breaks the sheet.

Before cutting, it’s best to watch the video in addition.

Plaster sheets have smooth edge edges and there are usually no problems with joining. But if for a number of reasons there is a need for a slight fit, then a peeling planer is well suited for this purpose.

But the fold is most convenient to do with a boot knife-cutter or a chisel. With a large amount of work, you can use the router. A 3-4 mm groove cutter will allow you to perform the necessary work in 2-3 passes.

If it so happens that you do not have the tools and the necessary skills to perform the above actions and processes, you can always turn to professionals. We will tell you how much it can cost a comprehensive repair or individual work. As well as how long it will take and we will offer the best specialists of your city at the lowest prices!

To calculate the cost of work, fill out the form below. It is fast and free! We will call you and discuss all the details in detail!

Sources: http://ogipse.ru/140-harakteristiki-primenenie-montazh-i-otdelka-listov-gvl/, http://brigadastroi.ru/info/289-Gipsovoloknistyj-list-(GVL).html, http : //mr-build.ru/materiali/chem-rezat-gvl.html

Does Knauf dry floor have flaws, and what are they

The floor with expanded clay backfill was made back in the Soviet Union, so the technology itself is not new, but Knauf improved it. Previously, single-layer sheets of gypsum fiberboard, or plywood, were laid on a leveled expanded clay, in two layers with an offset. This technology is very laborious, as it requires a highly skilled craftsman in every sense. Using the experience of specialists and following their recommendations, Knauf has developed a floor element.

Knauf superlist consists of two moisture resistant gypsum sheets displaced relative to each other. Glued together at the factory, they greatly facilitate the assembly process. Panels have a bottom and top. This was not done by chance, the technological process was worked out to the smallest detail and only during the installation of the coating you understand all the details. When using these panels, labor productivity increases, which helps to reduce the time of installation of the screed. The consumption of glue and self-tapping screws required for bonding plates is markedly reduced. The number of moves is minimized, since the cut-off part of the plate near the wall is used at the beginning of a new row in the opposite direction.

Specifications

The mass of one Knauf superfloor element is approximately 18kg. That allows you to hold it with one hand at the time of installation. The useful area of the element is 0.75 m 2, in combination with convenient dimensions, this allows installation in hard-to-reach places, without losing the speed of installation in open areas. A low coefficient of thermal conductivity from 0.22 to 0.36 W / m will not allow your feet to freeze and will maintain room temperature all the time. Hardness of the front surface, not less than 20 MPa, or more than 200 kilograms per square centimeter.

Dry coupler

Knauf super floor. can be done almost anywhere. When repairing the old floor, sometimes it makes no sense to remove the old base, for example a wooden floor on the logs. And in some cases it must be done, for example, in the old two-story Khrushchev where the floor under the logs can easily fall to the neighbors due to the design features. If the boards still walk, then it is better to rebuild it, or remove it completely. Some slight movement of the boards is still allowed.

1. Floor slab.

2. Logs carrying boards.

4. Polyethylene film

6. Knauf super floor. Glued and fastened with self-tapping screws (GVL Self-tapping screw 3.9×19)

7. Foamy expansion tape

The floor slab (1) is the main bearing plane on which subsequent floor layers are applied. As a rule, the next layer is a floor screed (consists of elements 4 to 7), or the floor on the logs (3 and 2, respectively). A screed is needed to level the floor, since floor slabs are usually installed far from ideal, in addition, an increase in floor thickness leads to a decrease in heat transfer and an increase in sound insulation.

The superfloor made as shown in the figure above allows to minimize heat transfer due to the air cushion. The thermal conductivity of air is 0.025 W / m, an order of magnitude lower than the thermal conductivity of wood. An interesting fact about the soundproofness of Knauf superfloor. A dry screed laid on top of old creaky wooden floors almost completely absorbs the sound of floor creaking, while neighbors can clearly hear the groans of wood. Of course, the squeaks will fade over time, since expanded clay will take the desired shape, but it is better to do everything right from the beginning.

Expanded clay for super flooring should be poured only on a moisture-proof surface. As a rule, it is enough to cover the floor with monolithic polyethylene film, or glued with adhesive tape. This will prevent condensation from forming inside the floor and will always keep it dry. The Knauf superfloor itself is already laid on the aligned expanded clay, and it should rest on a soft foamy substrate (7), which will allow the floor to expand and calmly respond to the movement of the walls. In other words, play the role of a thermal seam.

Knauf super floor. House and Cottage

The so-called KNAUF superfields deserved high authority by right. Many owners want to see such an option for flooring in the apartment.

To name the reasons for the popularity of this design is quite easy. KNAUF superfloors are much easier to install than concrete structures. over, they are characterized by increased thermal insulation, environmental friendliness and excellent reliability. In the process of filling them does not appear too much dirt.

In fact, many flooring options have roughly the same characteristics. But all the same, KNAUF is such a method of arranging the surface under the feet, which can be classified as innovative. On the super floor, it’s easy to put almost any finish. Knauf superfloors themselves are stacked on various types of substrates, including wood. This significantly expands the possibilities of superfloors.

KNAUF superfloors are understood to mean products for the manufacture of which gypsum-fiber sheets of a moisture-resistant type are used. Using these materials, it turns out to assemble the floor screed on its own, resulting in a prefabricated base. This method itself is considered extremely "clean", since it involves the use of expanded clay granules in the form of a heater. In turn, they allow you to increase the thermal insulation of the entire structure.

Due to the fact that expanded clay has a small fraction, it is possible to obtain not only an increase in the thermal insulation capabilities of the surface, but also to make it as even as possible. KNAUF elements are superimposed over the formed layer, for the fastening of which self-tapping screws and glue are used.

To carry out the planned work, you do not need complex tools or expensive materials. In addition to the Knauf superfloor and expanded clay elements, it is necessary to stock up with a damping tape, a plastic film for waterproofing, PVA glue and self-tapping screws on gypsum-fiber sheets. Of the tools you will need a screwdriver, electric jigsaw, level, tape measure and pencil. When all this is on hand, you can begin the main work.

Do-it-yourself installation of the Knauf super floor

The installation procedure for the screed using KNAUF elements will be divided into several stages. The most important of them should be highlighted below.

1. The working base is covered with a film

It will turn out to achieve high-quality vapor barrier if you use the simplest film, but necessarily more than 50 microns thick. When laying the material, in any case, overlap of the individual sheets of 15 cm and a minimum of 20 cm run into the wall. After spreading the film, an edge damper tape is installed. Its height should be equal to the thickness of the future expanded clay layer.

2. Installation of beacons in the room

According to the instructions, KNAUF superfloors can be equipped without the use of beacons. But inexperienced workers are not so easy to do. Therefore, it is better to place the lighthouses after all, using an inverted profile for this. Expanded clay is placed between the edges of the profile. Since KNAUF elements will almost not come into contact with metal profiles, the thermal insulation of the floor will be high.

3. Filling the floor with expanded clay and leveling

Immediately fill up the entire area of the working surface is optional. To begin with, you can fill in expanded clay only in a small area, and then in this place put the KNAUF superfloor. Then you can comfortably move around the room.

4. Stacking Knauf Superfloor

The most important requirement that must be observed during the installation of KNAUF sheets is not to move the product so that it slides on the floor. And due to the fact that the weight of each element is about 17 kg, it is best to work together. Those elements that are placed near the walls should be removed folds.

5. Fastening sheets with screws and glue

It is necessary to impose KNAUF sheets on the floor so that a dressing is formed, as when working with a brick. Self-tapping screws are attached in those places where the field is formed due to the displacement of the gypsum-fiber sheets. Fasteners should be placed in increments of 10-15 cm. The seams are additionally glued with PVA. At least that’s what the material manufacturer advises.

Features of Knauf Super Technology

When using the KNAUF superfloor, you can notice many advantages. Prefabricated floor screed is light in weight, quick to implement, not requiring the use of mortars. The design allows to make the floor insulation higher, which is also a serious advantage.

But do not think that the arrangement of the Knauf superfloor absolutely does not require any skills. Still, such work is associated with some subtleties, without which it will not be possible to achieve high-quality installation of the screed. Therefore, the owner must prepare well before starting the procedure.