How and what to cut plywood without chips

Anyone who is going to create a piece of furniture from a plywood sheet, for example, a stool, a carved box, a wardrobe or a rocking chair, asks what should be taken into account when working to make the product reliable and attractive? Also, many are interested in how to cut plywood (with a jigsaw or a saw).

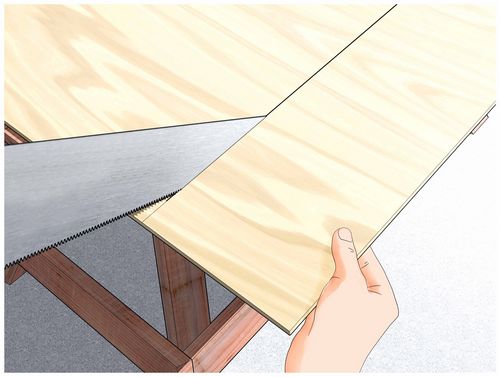

Spraying the sheet material should be done on a solid machine to avoid shaking the treated area

To answer the question, the better to cut plywood and how to do it correctly, you need to get acquainted with all the nuances, subtleties, which should be taken into account in the process in order to achieve a positive result, before work.

Edge processing

In order for the edges to turn out without chips, you need to choose the right tool:

- Needles are used when cutting out complex shapes. Thanks to them, the edges can be made rounded or angular. Set includes triangular, flat and round files.

- For rough products, it is quite possible to do with two files, flat and round.

- When it is necessary to process plywood sheets in front of the rough wall cladding, a flat rasp is used. With the help of it, the master will clean the edge from chips.

- Small parts are sanded with sandpaper.

- Another way to achieve even edges is to glue the “path” of the cut with insulating tape when cutting.

Edge protection against chipping with insulating tape

How to choose a tool for cutting a plywood sheet?

To answer the question of how to cut plywood without chips, you need to find out which tool and in what cases is more appropriate to use.

The choice of the cutting tool depends on the complexity of the drawing, more precisely on the bend radius, which must be cut.

If the bending radius is not more than one centimeter, then a manual jigsaw is used. If the width of the material is about a millimeter, then in this case, you can create many complex shapes.

If the bending radius is more than three centimeters, then an electric jigsaw is used. What file makes plywood dusty? First of all, it should be noted that the radius depends on the width of the material, therefore, the smaller the saw teeth, the more intact the veneer layer will be. For this reason, in order to drink complex figures, they use canvas for metal.

The sketch should be applied to the back of the plywood. This will help prevent chips from rising (if it does rise, then only from the back side).

If you want to spray in a straight line with the mowing line, a circular saw is the most appropriate. With the help of such a tool, you can achieve an even and clean cut.

Sawing tips

How to properly cut plywood to avoid chipping at the edges? To avoid such problems when working, you should take into account some of the nuances:

- How does plywood dust with a jigsaw / saw to simplify the work process? Several clamps will help the beginner master in such a matter. Thanks to them, cutting will be much easier. It is much more convenient to control the material and the tool when the letter is firmly pressed against the table. Due to the reliable fixation of plywood, damage to the table itself can be avoided.

- Drawings of any product can be found on the Internet.

- Drawing from sheet to plywood can be transferred by copying.

- How does plywood dust with a jigsaw to avoid chipping? When working with a hand jigsaw, always make sure that it moves perpendicular to the pile.

The correct position of the jigsaw in relation to the workpiece material

Tips for working with a hand and electric jigsaw:

- When working with an electric jigsaw, observe the angle of the platform. Most often it can be customized.

- In the process of cutting out simple shapes, follow the position of the blade. Spray should come from the front of the shape outline.

- If spraying is done in a straight line with the mowing line, then refer to the pointer (on the platform). If there is no pointer, the contour should be drawn with a pencil.

- To cut a hole of complex shape using an electric jigsaw, you need to make a hole in any part of its contour. The drill diameter must be greater than the blade width.

Piercing the hole for the entrance of the jigsaw file with a special awl

- If you are going to make a hole with a hand jigsaw, then the part should be pierced with an awl. Then you should thread the canvas through it. After the part is fixed again in the frame.

- If an electric jigsaw is used, then the tool is turned in the process of work, and not the plywood letter (if you need to make a turn according to the drawing). When working with a hand jigsaw, turn the plywood.

- If you need to cut out a figure and a plywood sheet with cutouts, then first cut out the cutouts (the letter will be returned much easier than a small detail).

- During the work process, make sure that the material does NOT overheat. When the edge becomes hot, it is necessary to pause the work for a while to allow the saw to cool down. Otherwise, the teeth will lose their sharpening.

- The canvas should be well taut. Otherwise the saw will break.

What material to choose?

Tips for choosing a material:

- To create decorative elements, a plywood sheet with a thickness of about four millimeters is suitable.

- In order to decorate interior items with a carved panel, a plywood sheet with a thickness of eight millimeters or more is suitable.

- A letter six millimeters thick is suitable for making frame interior items. But if they are going to make frameless furniture, then they choose a letter whose thickness is at least fifteen millimeters. It is quite possible to connect pieces of plywood end-to-end, without corners, but in this case it is necessary to make holes in the end part. For additional strength, sealant can be applied to the ends.

- Plywood sheet, the thickness of which exceeds ten centimeters, is mainly used as flooring on a concrete screed. In this case, a layer of waterproofing is placed between the concrete base and the plywood. How to cut 10 mm plywood? An electric jigsaw is the best choice for cutting plywood at this thickness. However, if you need to spray in a straight line with the mowing line, you can also do with a saw.

If we take into account all the subtleties and nuances during work, then the result of all negative moments can be avoided.

Electric milling cutter

It is a hand-held type of power tool used for sawing and drilling wood-based panels. Before starting work in laminated chipboard, using a hand jigsaw, make a small cut, departing from the marking contour by 3-4 mm. The sawing process uses several cutter blades and its bearing device that regulates the cutting depth. It is not so easy to use a cutter, so you need to have some skill with this tool to cut the slab. The movement of the cutter is quite fast and there is a chance of making an uneven spray.

The use of hand tools is advisable in the manufacture of single items from laminated chipboard. For mass production, it is advisable to purchase format-cutting equipment.

Hand saw

This hand tool is used in combination with a metal blade, as it has the smallest teeth. Before work, a sticky paper tape must be glued to the cut site to protect the lamination layer from damage. The hacksaw blade must be held at an angle of 30-35 °, this position reduces the likelihood of chipping on the material. The movement of the hacksaw blade should be smooth, without pressure on the blade.

Cutting rules

Laminated chipboard is made from waste from sawn hardwood and coniferous species, while the plate is lightweight and is used for the manufacture of furniture structures. Most home furniture makers prefer laminated particle board when choosing raw materials for furniture making. This material is very inexpensive, and there is always a wide variety of colors and textures to choose from in outlets. The difficulty in working with chipboard is that it can be very difficult to saw off a part of the letter of the required size due to the fact that the fragile laminated layer creates cracks and chips at the sawing site. Knowing some of the techniques used in work helps to cope with this task.

To cut laminated chipboard, you need to arm yourself with a saw with fine teeth.

For an accurate and high-quality performance of sawing work, you must act in a certain sequence.

- On a sheet of chipboard, you need a cutting line for a tent, where you should glue a paper adhesive strip tightly. The tape will not allow the saw teeth to crush the laminate during the sawing process.

- Using an awl or a knife blade, a groove is made from the recess along the mowing line. Thus, we cut a thin layer of lamination in advance, simplifying our task during sawing. Moving along this groove, the blade of the sawing tool will move along a tangent plane, while cutting deep layers of chipboard material.

- When spraying, it is recommended to hold the saw blade at an acute angle to the working plane of the plate.

- If the sawing work will be carried out using an electric tool, the feed speed of the cutting blade should be minimal so that the saw cannot vibrate and bend.

- After sawing off, the cut of the workpiece must be processed first with a file, and then with sandpaper. The cut must be processed with movements from the center to the edge of the workpiece.

To protect the cut point on the workpiece from further chips or cracks, it is closed by applying melamine adhesive tape, or end edges are fixed, which can have a T-shaped or C-shaped appearance.

Electric jigsaw

In order to make an even cut without damaging the laminated layer, you will need to take a jigsaw file, in which the size of the teeth will be the smallest. It is advisable to use a jigsaw for cutting small-sized sections of plates. Jerks and excessive pressure during work should be avoided. The feed rate of the cutting blade into the tool should be selected as minimum.

Materials and tools

In the conditions of a woodworking enterprise, special equipment is used for sawing a chipboard letter, which is called a format-sawing machine. Some private furniture workshops purchase such a machine, but it is hardly advisable to install it at home due to the high cost. Household power tools will be able to replace such equipment. sawing a chipboard can be done with a circular saw or a hacksaw. The sawing process will take a lot of time and effort, but from an economic point of view, it will be quite justified.

Circular saw

This power tool consists of a small work table and a rotating toothed disc. A circular saw cuts through a chipboard much faster and better than an electric jigsaw. During the sawing process, dust is turned on at low speed. In this case, chips may appear on the opposite side of the saw teeth.

How and what saw the chipboard without chips?

The abbreviation of boards should be understood as a laminated chipboard, which consists of natural wood waste mixed with a polymer adhesive composition, and has a lamination in the form of a monolithic film consisting of several layers of paper impregnated with resin. The lamination process is carried out under industrial conditions under a pressure of 28 MPa and at a high temperature regime, reaching 220 ° C. As a result of such processing, a very durable glossy coating is obtained, which can have different color shades and is highly resistant to mechanical damage and moisture.

How to cut correctly?

Sawing chipboard without chips at home is quite possible with your own hands. It greatly simplifies the task of preliminary creation of a groove with a sharp object in the kerf. Getting to this place, the blade of the cutting tool follows a given trajectory and the dust is much easier. Straight-line cuts on laminated chipboard are much easier to do than cutting a curly letter.

It is extremely difficult to perform curvilinear configurations using household appliances; this can be done only with the use of an electrofrez. This tool performs a high-quality cut and has a lot of additional functions.

To cut a sheet of laminated chipboard using an electromill, you must perform the following steps:

- On the surface of an ordinary chipboard, all the contours of the future workpiece are marked;

- Using an electric jigsaw, the workpiece is cut out, deviating from the intended contour by 1-2 mm;

- The finished sawn template is cleaned with a file or sandpaper;

- A prepared stencil is applied to the letter of the laminated chipboard and fixed with the help of carpentry clamps so that it is in a motionless position;

- Along the contour of the stencil, with an electrofusion cutter equipped with a bearing mechanism, the contours of the workpiece are cut out, cutting off the edge exactly along the intended mowing line;

- After completing the work, the end sides are cleaned and processed with a decorative edge.

The use of an electromill allows you to make a shaped cut of chipboard without chips and cracking.

In four ways of cutting chipboard without chips with a jigsaw, you can find out from below.

Using adhesive tapes

By the same principle, you can protect the back of the cut material. On the mowing line of the cut, tape should be glued to protect against pulling out large fragments. Pasting surfaces is one of the few ways to ensure the cleanliness of a figured cut with a jigsaw. Unfortunately, masking tape is NOT the best for this due to its low strength.

The best quality cut can be obtained by pasting the part with aluminum or fiberglass-reinforced tape-tape. It should be wide enough to cover 15-20 mm on each side of the cut line. The density of the sticker is also important: the tape must be well pressed with a dry rag swab and by any means to exclude the formation of folds.

Tapes with very tenacious glue should be avoided. In the process of tearing, they can carry along with them small fibers and fragments of the laminated surface, dissected by microcracks, which are formed during cutting. Also pay attention to how easy the adhesive is to remove and whether the adhesive adhesion is good enough for rough materials like raw plywood or OSB.

Cutting tools and mechanics of their work

Apart from stationary sawing machines, there are not many alternatives for manual work. From the available tools, you can offer circular and pendulum saws, in the common people referred to as crosscutting and jigsaw. It is also possible to perform a sufficiently high-quality cut using an angle grinder, on which a saw blade for wood with victorious teeth is installed. But this is NOT the most effective and, moreover, not the safest option.

In the process of cutting with any type of power tool, the working bodies move at a very high speed, and after the machining mechanics remains, as it were, behind the scenes. However, understanding it is the key to getting a clean, chip-free edge. The simplest principle is the basis for the work of pendulum dust. The cut is carried out with a direct movement of the saw blade, while the size of the removed fragments completely depends on the size of the tooth and its setting.

Chips appear due to the heterogeneity of the processed material, in particular due to the hard cork of laminated sheet materials or due to the fact that the fibers of solid wood have different densities. Chips can form on different sides of the product, depending on the shape of the tooth, feed force and speed of the tool. When working with a jigsaw, the appearance of chips is due either to the fact that the teeth pull out large fragments from the seamy side, or due to the pushing of the upper layer, in which it is not cut off, but breaks out in large fragments.

The work of the teeth of a circular disc is in many ways similar to a jigsaw, with the only exception that their movement is directed strictly in one direction, and they move at a very high speed. Also a significant factor is the direction (angle) of the applied force: if the jigsaw saw moves strictly perpendicular to the surface, then the circular cuts at an arbitrary angle, depending on both the diameter of the disc and the thickness of the part. This can play into the hands of oblique immersion of the tooth contributes to more accurate cutting of chips, but from the back side, due to the tangential movement of the cutting edges, large fragments can be pulled out. Of course, a circular saw will only be able to perform a straight cut.

Ensuring a perfectly clean cut

For most parts, it is sufficient to reduce the chip size to 0.2-0.5 mm. Such small irregularities of the cut edge are NOT striking, if desired, they can be easily eliminated by removing the chamfer with an emery bar or covered with a wax corrector pencil. It is also possible to grind the end face with emery paper if a sufficient allowance value was given during cutting.

Nevertheless, even at home, it is possible to achieve a cut quality comparable to the result of a cutting machine with two high-speed discs. This is possible only when the tool moves along the guide rail, in extreme cases. along the temporary stop bar.

First, you need to make two cuts about 0.5 mm deep on both sides of the part to indicate the thickness of the cut. Along the edges of the mowing line of the cut, you need to scribble two furrows under a straight ruler. This is done either with a segmented or oblique boot knife (for chipboard and uncoated wood) or with a sharpened drill or victorious cutter (for laminated materials).

The depth of the grooves should be at least half the thickness of the outer layer, inhomogeneous in relation to the main body of material. This method requires high precision matching of furrows and mowing line of the cut, but this is the only way to ensure a perfectly flat cut end, and not requiring additional processing.

Zero-clearance technique

Carpentry craftsmen most often use the principle of finalizing the sole of the cutting tool, which consists in reducing the gap between the working body and the pressure pad. This is almost guaranteed to eliminate the effect of “breaking” the cork in the top layer of the material.

Zero clearance is achieved by attaching the cover plate to the tool base plate. The pad has only one narrow hole (or slot) that fits snugly against the cutting body. Because of this, even with a high feed force, the teeth are guaranteed to cut small chips, and not turn out the chips in the upper layer of the part.

When using pads, it is imperative that they DO NOT scratch or damage the surface of the part. Therefore, most often they are made from a material that is inferior in hardness to the processed one, for example, MDF or drywall. Unfortunately, such an overlay is not enough for a long time, which is why it has to be changed every 4-5 meters of the cut.

durable linings can be made of sheet plastic (PVC, fluoroplastic), fiberglass or metal. In the latter case, the surface of the pad must be carefully polished and soft metals such as aluminum or aluminum should be used to reduce vibration.

How and how to cut plywood and chipboard without chips: straight and curly cut

It is believed that a high-quality cut of wood or sheet materials is NOT possible without a professional tool. Today we will tell you about ways to make a clean, even cut without chips, on our own and NOT using expensive equipment and consumables.

Selection of saw blades and blades

When cutting, cleanliness and processing speed are inversely related. It should be noted that chips on the cut will appear in any case, so the main task is to reduce their size to such a value when they can be easily eliminated by subsequent processing. The size of the chips will be the smaller, the smaller the size of the tooth and the closer to the right angle at which the cutting edge touches the surface of the material. For choosing a circular saw blade, these are two of the most important factors of the three.

The third can be called the setting value. the offset of the adjacent teeth, which is quite simple to determine by attaching a ruler to them. To ensure a clean cut, the wiring should be minimal, but do not forget that in this case, when you try to cut a thick board or a sheet of plywood, the disc may be corny to clamp or the end will burn from strong friction.

Jigsaw blades are more diverse. For a chip-free cut, a series of clean-cut pollen is used, for example, BOSCH has a line of blades called CleanWood. Their main difference is their small size and the absence of a pronounced orientation of the teeth. They are usually in the shape of an isosceles triangle and cut in both directions of travel.

Also saws for a clean cut are distinguished by the almost complete absence of setting and the opposite direction of sharpening the adjacent teeth. In order to ensure the possibility of a figured cut with a small setting, the saws have a very small width, which makes them quite fragile.

For fine cutting of sheet materials, blades designed for working with metal products can also be used. These saws have the smallest tooth size known, so the cut is slow, but with the highest quality. Due to the significant width of the canvases for metal, a final figured cut can be carried out only with a significant bending radius, on average about 60-80 cm.

Also note that the bluntness of the teeth, which is characteristic of low-quality pollen with a “run” of 3-5 meters, also leads to the formation of chips. Therefore, DO NOT skimp when purchasing consumables if the quality of processing is really important to you.

How chipboard gets dusty without chips.

We recently bought a coffee table, the price is inexpensive, but there is a “but”. The height of the table for our interior is too big. It would be nice to reduce the height by 10 centimeters. As they say, we are NOT looking for easy ways, I decided that

I can do it myself.

I remembered that on our site there is a specialist asoleg, who made a computer desk with his own hands, of course, I’m far away from him, but some recommendations can help. I contacted him, explained the problem and he kindly shared his secret. With his permission, I publish his technology for cutting furniture chipboard without chips.

Everything turned out to be corny and simple. Marking the cutting line. Then with a clerical knife, along a ruler, cut through the top layer of chipboard. Just run the knife several times with little effort along the mowing line of the cut. (I recommend practicing on the unnecessary part of the chipboard) If it presses very hard, then the decorative layer will begin to swell and it will not turn out very nice.

Further Departing 1-2 millimeters from the intended mowing line towards the rough part, cut with a jigsaw or a suitable file with teeth directed towards the saw handle. We make a wash on the opposite side of the cut, so that there is no chipping at the end of the cut. And we saw through to the end. Dust should be done carefully, not in a hurry. Then, with a sandpaper of medium grain, fixed on a bar, the butt of the part is cleaned. If necessary, remove the millimeter that we retreated. My cut turned out to be almost perfect, after processing with sandpaper there were no scuffs at all. The photo shows the difference between the left and right side of the cut. Well, and, accordingly, if both parts of the chipboard are needed, we cut it with a knife on both sides of the cut. We measure the thickness of the cut of a jigsaw or saw, add 2 millimeters. It turned out the distance that should be between the slots made with a clerical knife. Cut exactly between THESE lines. Then there will be no seizures on the other side. Naturally, you need to use a sharp tool, I use a tool sharpening machine.

Jigsaw pendulum stroke

The pendulum motion or in another way is called “pumping” is needed to increase the speed of cutting wood, to be able to work with soft materials and to produce complex cuts. The pendulum movement of the jigsaw is carried out according to the swinging principle. It significantly impairs the quality of the cut and, because of this, chips appear on the surface.

We recommend disabling the pendulum stroke to reduce chipping. On the Makita jigsaw, for example, they showed where it turns off. Find out if your jigsaw has this feature and how it is disabled. When the function is turned off, the jigsaw makes standard movements, thereby achieving uniform cutting and improving the quality of the cut.

We cut plywood without chips or burrs

People who are just starting to burn portraits have a question. “How does the plywood get dusty so that there are no chips?” Usually, this difficulty arises when cutting plywood across the grain. Then the top layer of the veneer is chipped off and forms chips and burrs. It’s not pleasant when this is formed when sawing off excess empty fields already at the finished burnt work. Chips can appear for several reasons and most often they cannot be fixed or masked. Below in the article we will consider the reasons for the appearance of such chips and burrs. And also consider what to do so that chips do not appear next time.

Dusty, use a second plywood

Another way to get a very clean cut is to put another letter on the floor of the letter plywood, which you need to saw cut and pull them together using clamps. Top plywood will NOT allow chips to form on the bottom plywood.

The result is a clean and neat cut, no chips on the desired one on the plywood sheet. But the main disadvantage of this method is a large overspending of plywood.

Using masking tape

Before sawing, masking tape can be glued to the plywood for a cleaner cut. It is better to use masking tape rather than regular tape. It leaves no sticky residue on plywood and is easy to remove. Before cutting Make sure the tape is well glued.

This method is not so bad. But personally I don’t like this method.

First, the tape often breaks off during sawing and chips appear in THESE places.

Secondly, if you want to saw off plywood on which a picture made on the Pyroprinter machine has already been burned, there is a risk that small details of the image will remain on the masking tape.

Dusty from the rough side

The fact is that standard saws have teeth to the side of the jigsaw (as opposed to pollen with a reverse tooth). These saws “eat” the tree when moving from the bottom up. When a tooth clings to the top layer of the veneer, it often splits and chips appear. This often leaves the underside with a very good edge. From this, the craftsmen made a simple conclusion that for a clean saw, it is enough to turn the plywood upside down and it is dusty from the “seamy” side. The method gives the best result, so feel free to use.

Pruning with a construction knife

There is also a way to cut the place of the future cut with a construction knife. This way, you trim the top layer of the veneer and it will break at the Undercut, not further. For trimming Use a metal ruler to make a straight line. The kerf is usually 3 mm.

The result is pretty good. I use this method a lot. If, when cutting, I just need to cut off a piece of plywood and discard the second part, then I make only one cut. from the finish side. This option is good to use when cropping a portrait.

Splinterproof liner

This is a special pad for a specific brand of jigsaw. It is simply inserted between the jigsaw legs and is NOT fixed in any way. The liner adjoins the nail file, so it does not allow the pile of the top layer to rise (which is why chips occur), so the dust turns out to be even. At the same time, craftsmen advise using saws from the same manufacturer as the jigsaw. so the quality of the cut will be better with the use of an insert.

The earbuds are sold in sets of 3-5. They are NOT eternal. they have to be changed periodically.

There is an insert, for example, on a Bosch jigsaw, about 400 rubles.

If you have NOT found an insert for your jigsaw or do not want to buy it, then there is a small life hack from the masters. to glue ordinary adhesive tape in the place where you will cut. After that, you need to iron the nails well. Then saw straight over the top of the tape. After that I delete it. The result will be similar to the liner.

You can also make such a sole yourself. Here is an example of how our client made a thin sheet jigsaw pad gesture.

But it is more convenient to make such a platform out of Plexiglas letter. And glue it to the bottom of the jigsaw with double-sided tape.

With a homemade insert, you will also get a clean cut.

The causes of chips

Chipping often occurs because the wrong jigsaw is used for THESE tasks. If you take a saw blade with teeth directed upwards, then such a saw rips off the top layer of the veneer. This is because there is space between the jigsaw foot and the saw. Top veneer fracture occurs exactly in this place.

What to do to get rid of chips:

- Disable the pendulum stroke on the jigsaw

- Use the right quality pollen

- Always cut plywood from the rough side

- By purchasing an anti-splinter liner (or make one yourself)

- Additionally, choose a convenient method from the “clean cut” experience

Let’s consider all the points in more detail in this article.

Jigsaw blades

If you have previously worked with a jigsaw, then you know that if you use the wrong saw, you can ruin the top layer of the material, especially for laminated material. Plywood is a laminated material. it is wood veneer glued together.

In this section, we will look at how saw blades affect the quality of the cut and what they basically are.

Saws come in different sizes and shapes of the teeth, the length of the saw, according to the material for which they are intended, the direction of the tooth, the material from which the saw is made and for what task it was developed. For example, a blade with a large tooth is designed for cutting wood at high cutting speeds for a rough cut. And saws with a shorter tooth will make a smoother cut. Thin (narrow) saws allow for dusting radius and other irregular shapes, while wide ones help keep straight cuts.

The letters “A, B, C, D” mean the size of the teeth, the letter “A” means that the saw is the smallest teeth.

The numbers indicate the length of the saw 1, 2, 3, 7, the length of the blade, the longer the saw, the thicker material it can cut.

For example, Bosch pollen is marked like this:

In addition, the saws also vary in cutting edge geometry.

Personal experience of an engineer in jigsaw saws:

In production, there are tasks both for a smooth saw when working with ready-made portraits, and the need to dissolve a large sheet of plywood when speed is required and quality is not so important. Most saw blades are designed for speed, not cut quality. And even saws with a medium tooth will scuff the surface of the material, i.E. Spoil the top layer of plywood. Not as strong compared to large-toothed saws. Therefore, the engineer adapted himself to use metal saws with a fine tooth up to 1 mm for a smooth cut of plywood. When working with such a file, speed suffers greatly and these saws get very hot. But when you need a responsible work on cutting, the time spent is justified. The engineer uses these saws when he needs to work with an already burnt portrait.

Sawing with a circular saw

To effectively cut a sheet with a circular saw, you should adhere to the following rules:

- Place the plywood sheet on a stable support and make the first notch closer to the middle of the sheet.

- Adjust the cut in depth. To do this, lower the disc and start spraying, while the immersion depth of the disc should be 0.5 cm greater than the thickness of the blade.

- Position yourself to the side of the line of action of the saw to avoid injury due to the high probability of kickback.

- Prepare dust to make the required cut. To do this, attach the saw shoe (part of it in front) to the blade and install the blade on the cutting line, having first bend the cover.

- Make sure there is no interference at the bottom of the sheet.

- Include dust and take your time to plunge its blade into the material. Keep dust firmly in place to prevent kickback. After plunging into the slot of the disc and installing its shoe on the surface of the sheet, return the protective casing back.

- Guide the tool along the mowing line to the end of the blade.

- Turn off the dust and only after its complete stop remove from the slots.

Sawing purposes and suitable tools

Depending on the purpose of sawing, the most efficient way to cut plywood is selected. Among the tools used for work are the following:

- Electric circular saw;

- Hand saw;

- Electric jigsaw.

Consider the features of using various tools for cutting plywood and in which cases it is more expedient to use one or another device.

Features of cutting tools

Each plywood cutting tool has its own characteristics when used. Consider the rules for working with plywood with various cutting tools.

Electric jigsaw

Cutting any plywood is best done with an electric jigsaw. When working with this tool, you should use small saws, cut the blade, press the jigsaw and prevent jerky movements. At the end of the process, the ends of the material are processed using sandpaper.

It is NOT worth purchasing low-quality tools, since after a 5 meter cut, there is a strong bluntness of the cutting edge, which causes chips. The lack of setting and the opposite sharpening of the adjacent teeth and the small width allow for complex curved cuts. But these qualities of saws for fine cutting cause the brittleness of the blades.

Fine cutting of plywood can be carried out with the introduction of blades for working with metal parts. The size of the teeth of such dust is minimal, which greatly slows down the cutting speed, but allows you to achieve the highest quality. Since the width of the pollen for metal is large, it is possible to carry out a figured cut only with a large bend radius (0.6-0.8 m).

Hand sawing

Working with the introduction of a hand saw entails much more labor compared to a circular saw. To properly cut a plywood letter, you need to take into account the following rules:

- Make a vertical notch along the cut line. To do this, you need to place the saw blade and stretch the blade to form a groove.

- Tilt the saw blade towards the formation with the plane of the sheet of an acute angle (from 30 to 40 0) and begin to make smooth movements.

- To keep the cut straight, the forearm and shoulder should be in the same plane. If you deviate from the specified direction, you need to slightly bend the dust in the desired direction and continue working.

- To avoid the formation of a kink, you need to hold the sawn off part of the day with your free hand.

- At the end of the cut, it is required to return the blade to a vertical position and after the work, carry out several movements perpendicular to the plywood sheet.

How to cut plywood

In the production of various finishing works or in the manufacture of furniture, the use of plywood is a common practice. At the same time, home craftsmen face a choice: how to cut plywood and how to achieve a perfect cut without chips. When cutting such material, some difficulties arise: the letter is large in size, and the structure of its base creates difficulties when sawing. Knowing some of the features, you can achieve excellent results when working with an electric jigsaw, hand saw or circular saw. The main condition is to ensure reliable fixation of plywood.

Plywood is a practical and easy-to-handle material

Adhesive tapes

To protect the back side of the plywood, tape is glued along the mowing line of the cut. This method helps to prevent large pieces from breaking off, which is especially effective if the decision is made to use a hand or electric jigsaw. However, any adhesive tape will work for THESE purposes. For example, masking tape in this case will be completely useless due to the small margin of safety.

Before you start sawing, a tape-tape reinforced with fiberglass or aluminum is glued to the surface. The requirements for its width are as follows: on both sides of the mowing line, there should be a margin of 1.5-2.0 cm.It is better to pasting, pressing the tape with a dry cloth, does not allow the formation of wrinkles and gluing.

After the saw blade or electric jigsaw has stopped working, remove the tool after disconnecting it from the mains. Then he will start peeling off the tape. In this case, great care should be taken so that with sudden movements NOT to cause the separation of small fragments of the laminated surface inevitably formed during cutting. Therefore, it is necessary to abandon the use of materials with a strong adhesive base. When choosing such a tape, one should take into account its adhesive ability and ease of cleaning from a rough surface.

Zero clearance

The principle of this technique is to reduce the distance between the blade sole and the pressure pad to the minimum possible. This avoids breaking off the top layer of the plywood. This effect can be achieved by attaching a cover plate to the tool sole. The pad has a slot to retain the possibility of dusting on the intended mowing line. Thanks to this, the teeth are guaranteed to cut small chips and do NOT break the material.

It is important to exclude mechanical damage to the sheet surface overlay. The pad should be changed every 5 meters of cut. The use of pads made of more durable materials (metal, plastic or fiberglass) eliminates the need to frequently change pads, the surface of which must be pre-polished.

Hand saw

When cutting plywood with a hand saw, physical effort is required due to the significant density of the material. This tool is used when it is necessary to cut a sheet of plywood into equal pieces.

A manual jigsaw is considered the best tool and allows you to decide in advance how to cut plywood without chips, saving yourself the need to purchase electrical tools. With its help, you can make a small number of elements of complex shapes. Having certain skills in working with a jigsaw, you can make a neat cut, however, due to high labor costs and low productivity, this method cannot be called optimal.

If you have electrical tools or a simple jigsaw at hand, then you should resort to using a simple hand saw. To cut the letter comfortably and avoid chipping, the tool blade must have a large number of small and well-sharpened teeth. The angle of inclination of the saw to the plywood letter must be sharp. It is recommended to avoid jerking and make steady movements with strong pressure.