The easiest to cut foam: methods of cutting and tips for performing work

In order to cut a certain shape of the insulation, any device for cutting foam can be used:

- knife;

- hacksaw on wood or metal;

- soldering iron;

- corner grinding machine, called the “corner grinder”;

- thin metal wire type of string;

- thermal cutter;

- foam cutting machine;

- Electrician with a heated file.

If a hacksaw is chosen, then its teeth should be as few. All tools that do not heat up to a certain temperature do not guarantee that there will be no foam crushing. Similar tools are used for small volumes of work, but when it is necessary to insulate all the enclosing structures of the house, it is better to use the apparatus for cutting foam, the action of which is based on heating the cutting element.

Types of tools

Studying the question of how to properly cut polystyrene at home, you need to pay attention to the varieties of the tool. They are divided into mechanical and thermal

For independent cutting of an array, with small volumes of work, they prefer the first group of funds.

For home processing of foam, beginners are recommended to choose a mechanical tool. Professional installers and designers prefer heat cutting. In this case, it will be possible to create high accuracy of the edge, create objects of any complexity.

The thermal cutter is quite expensive. Beginning masters who are repairing at home rarely acquire such a technique. But with large volumes of work, it is simply indispensable. Actions using the thermal cutter are carried out quickly and efficiently.

Than and how to cut foam

In order to cut a certain shape of the insulation, any device for cutting foam can be used:

- knife;

- hacksaw on wood or metal;

- soldering iron;

- corner grinding machine, called the “corner grinder”;

- thin metal wire type of string;

- thermal cutter;

- foam cutting machine;

- Electrician with a heated file.

If a hacksaw is chosen, then its teeth should be as few. All tools that do not heat up to a certain temperature do not guarantee that there will be no foam crushing. Similar tools are used for small volumes of work, but when it is necessary to insulate all the enclosing structures of the house, it is better to use the apparatus for cutting foam, the action of which is based on heating the cutting element.

How to cut the polystyrene with a knife so that it does not crumble

When in the process of insulation of walls, overlaps, roofs with your own hands, polymer material slabs are used, thermal cutters are not always justified. Designs, as a rule, have strictly geometric shapes, and it is quite possible to cut the material with a simple knife, the main thing is that the blade is thin, and its length exceeds the thickness of the sheet of insulation. A good tool for such work is a clerical knife if you have to cut a polystyrene foam of small thickness.

For cutting foam with a knife, you need to choose a long blade

The fact is that the blade of such a tool is very thin and when cutting the sheet, a large thickness of a perfectly even cut is unlikely to be achieved, gyrus may form on the cut, which will not allow you to make a tight adjustment of individual parts of the insulation. And this will lead to the formation of cold bridges.

Cut polystyrene on a solid basis so that the sheet does not “play” in the hands. On the surface of the polystyrene slab, marks the desired size are made, after which they lay a stiff ruler or rail, and make a cut with a sharp knife. If the length of the knife blade is not enough, you can make cuts from two opposite sides of the sheet, the main thing is not to go astray. Then, according to the section, the sheet is simply broken. With proper dexterity, the work will take place quickly, without unnecessary noise and electricity costs. Garbage, of course, will be, but not as much as from a hacksaw. The main thing is that the tool is very sharp and the desired length.

Before cutting off the material, the tool must be heated, and also periodically undermine the blade.

Foam is cut by a clerical knife and thermal. comparing the cut line

How to cut polystyrene without the use of thermal devices

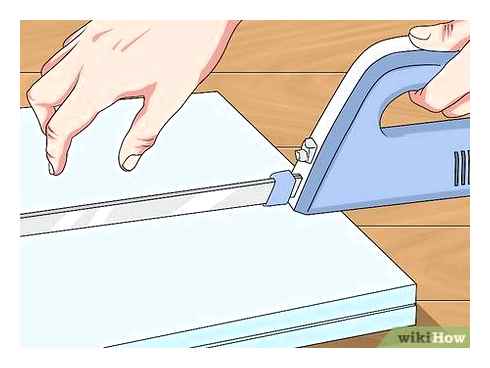

The principle of cutting foam sheets with a hacksaw, independently, will be a canvas for metal or wood, no different from cutting with a knife, the main thing is that the teeth are small and the canvas of sufficient length.

In this case, the cut will be more even and a lot of small garbage is not formed. The movement of the saw must be done smoothly, without jerks. But even with this method of cutting there will be many crumbs of polystyrene foam.

This Chemical Cuts Like a Knife

You can cut foam sheets using an electric jigsaw or angular grinding machine (corner grinder). However, with this method, a huge amount of garbage is guaranteed.

corner grinder for cutting foam

The high speed of rotation of the disk of the corner grinder and fairly large teeth will provoke a strong destruction of the structure of the material at the site. When using an electrician, it is also impossible to get a perfectly flat surface on the cut, due to the vibration of a file, which also leads to the formation of small polymer garbage.

6 Genius Cooler Hacks

The crumbs of foam are least formed when it cuts out if a homemade device for cutting foam is used. The simplest type of such a device is a regular thin wire (string), to the ends of which the handles are attached, for more convenience. The diameter of the wire must be selected the smallest, not more than 0.5 mm. One person cannot cope here, you will need an assistant. The wire is installed according to the intended mark on the foam and make uniform movements on both sides. As a result of friction of the metal wire on polystyrene foam, its heating occurs and the material begins to melt at the site of the cut.

Stange cutting with string is the most effective method in terms of the formation of the minimum amount of garbage, but the time spent on such work is much larger than when cutting other tools.

Which material to choose for cutting

Before starting to work with the material, we need to find out which foam happens, which look is best used for cutting at home.

Polystyrene is unreasonable

This is the most common and familiar to everyone foam, which is familiar to us from packaging from technology. The material is a lot of small white balls that are tightly fastened to each other, but can disconnect from mechanical exposure. It is he who is very widespread and is most often used in the manufacture of products at home.

Polystyrene pressed

This is a similar type of polystyrene, which is simply additionally pressed. Because of this, it has a much denser structure, it is more difficult to crush it, but such material is much more expensive than its not pressed analogue. Due to the high price, polystyrene pressed polystyrene foam has not been widely used, but for some products it can definitely be used, since its structure is quite smooth.

Polystyrene pressed foam

Polyvinyl chloride foam

The rarest and unused type of this material, which has one interesting property. the ability to independently fade during the fire. He does not distinguish hazardous substances, but if it still lights up, then the smoke from it is very dangerous and can threaten health.

How to cut polystyrene without special equipment

The first common question is what to do if you need to cut off the foam, but building a special cutter is too difficult, expensive and useless. There is a way out, even a few.

Methods of cutting foam

Wood hacksaw

Large teeth of the hacksaw allow you to cling to the granules of the foam and quite effectively cut it. To implement this method, you do not need to modify anything yourself, just buy or take a ready.made hacksaw on wood. Similarly, cutting can be carried out using a jigsaw, in this case it will be important to choose the right file for it.

I drank wood

But this method did not get much distribution, since when using it the foam will be crumbled in any case, and it will not be possible to achieve a perfectly even cut. Also, with sloppy use of the tool, the stove can crack and all the work will go down the drain. Therefore, almost always the following methods are used to cut such capricious material.

Cutting with nichrome wire

To use this tool, you will need to additionally assemble the device. It will include not only a nichrome thread, but also a transformer for 12 or 24 volts. It is also necessary to take a piece of a small pipe and table in advance. The string stretch will be organized due to the spring. Nichrome is a material that is part of any hair dryer. The device must function in such a way that the thread is heated and can melt the foam. Thanks to this, it is possible to get various complex forms from the material.

In order for the device to function on the table, a wooden block is fixed. Previously, it is necessary to make a hole in it and install a segment of the pipe. Further, it will need to fix the nichrome wire using the spring. It will heat up only after connecting to the transformer. A piece of foam should be brought to it and give the necessary size.

Cutting an electric corner grinder

Foam is a serial material that can be cut by any sharp object.

Some people use a corner grinder for this purpose. In this case, the choice should be stopped on the thinnest disk.

This version of cutting is simple and comfortable. However, a lot of noise will be created in the process, and after its end it will appear a large amount of garbage.

Foam cutting machine

Polistyle foam is a good insulation, excellent raw materials for various decorative elements, which can be made on your own. For decorative cutting of foam you will need a specialized machine. There are many options for such equipment, it all depends on the proposed design of the product.

Material cutting can be carried out using a tungsten thread. It should be noted that this thread is hot, but its temperature can be configured. You can cut such a thread in addition to foam and other materials. This is especially true in the manufacture of different components intended for stucco.

The necessary stencil is applied to the polystyrene foam plate, and using a tungsten thread, an object is created. This procedure is not difficult, it does not take much time.

Also, for equipment, you can use a building blade, cutter. The device of machines may differ, but the principle of operation remains unchanged. the use of a tungsten thread, which is connected to the mains. Using such a device, you can independently make decorative elements from foam of any configuration.

To perform cutting, it is recommended to purchase the following tool:

If you properly assemble the cutting machine, then there will be no difficulties in the process. The main thing is to use a quality tool, show maximum effort and attentiveness. And to perform such works to experienced craftsmen will not be needed to contact.

Step.by.step instructions for the manufacture of a cutter

First you need to decide on the tools and materials that we need to create a cutter. The list of mandatory materials includes:

- Liszt Burner slab or other dense base, approximately 600 by 400 millimeters. The size can be changed, it will depend on the size of the sheets with which you are going to work.

- Flat wooden rail, about a meter long.

- Material for legs: 4 traffic jams from plastic bottles, a piece of rail or other material.

- Nichrome wire, approximately 0.4 millimeters. You need about half a meter, but it is better to buy with a margin.

- Strack springs. It is for stretching, not compression. Such a spring can be found far from everywhere.

- 10-15 screws.

- Wires, crocodiles for their fastening.

- Computer power supplies and cable for it.

Now let’s move on to the tools that we need for the manufacture and assembly of the structure. These include:

Foam cutting technology

Foam cutting technologies are very different depending on the goals and objectives set for the master. Other products are well carved by an ordinary sharp knife or hacksaw machine, others only with the help of lobby, both manual and mechanical. Often, specialists in cutting letters of foam sheet use the wire heated to high temperature.

A new step in the technology of cutting foam is the use of various machine tools of low and high cost. These machines use completely different methods of cutting. In simpler. the thermal method using a preheated cutting element. In others. cutting a mechanical type using milling plants of various configurations.

complex and expensive types of equipment for foam processing are laser machines that allow you to make products of high geometric requirements from polystyrene raw materials. As a rule, machines for figured and laser cutting are equipped with CNC blocks that allow the operator to form a software algorithm of the machine’s action in a short time, and further equipment work is already happening without human participation.

Each type of equipment for dividing foam into parts is in its price segment, and the higher the quality of the products received and the simpler the process of forming the task, the higher the price of the equipment above.

Why do you need foam figures

Foam products gained their popularity due to their versatility. You can apply polystyrene in almost any field of life, Creative Elements manufactured by Creative are used for the following purposes:

- Decorating the exterior and interior of any building and room. They make: balusters, moldings, columns, cornices, arches, frames for windows, pilasters, and so on. Technical indicators of thermal resistance of foam, its weight, ease of installation left far behind the use of such expensive material as gypsum. Gypsum is destroyed over time and forms cracks, the complexity and timing of manufacture make products from gypsum expensive. Any bends, forms of the possibility of surface decoration of the material will give a unique look inside or outside the room.

- Packaging of goods: furniture, household appliances, fragile products. The small weight of foam allows you to maintain the weight of the goods. This is relevant for overall and heavy goods: sofas, cabinets, armchairs. Foam depreciation allows even heavy goods to maintain the presentation. Foam figures to order are cheap and profitable, which attracts technology manufacturers to use it precisely. Repetition of the shapes and bulges of the plate or refrigerator will allow the most compact packaging, not costly transportation, as well as the perfect appearance in the end.

- Thermal insulation of rooms, pipes. The main competitor of polystyrene in thermal insulation of houses was glass wool. The downside of glass wool is the inability to give it at least some shape and stability. You can cover the house with foam by cutting out beautiful patterns on the facade, plastered and covered with paintwork. The output will turn out several significant advantages: thermal insulation, beautiful facade design and low cost of work. Thermal insulation of pipes allows you to maintain expenses related to heat loss during the operation of pipes.

- Advertising signs, volumetric images and letters. In big cities, it is difficult to attract the attention of customers, customers. Bright volumetric foam signs will be able to help. Creative Elements will be able to give any form to the foam depending on the preferences of the customer. The shape of the cake or pies will attract new customers to the confectionery shop, the voluminous rounded letters of the bookstore names will not leave indifferent ordinary passers.by. In large cities, advertising figure cutting of foam is popular, was no exception.

Choosing glue

For attaching tiles to the ceiling, several varieties of glue are used:

- Universal compositions. Elitans glue is suitable for working with wood, gypsum, concrete. It is convenient in that it forms an elastic seam, however, the composition dries for a long time. common glue “titanium”, it has a viscous consistency, quickly settles. It is similar in composition “Master”, but the pungent smell and a longer drying time are the main disadvantages. The advantage over Titan is an affordable price. “Moment”. expensive, but quality glue. It grows up quickly, but the consumption is greater than that of analogues. The packaging is made in the form of a syringe, so a gun needs it. Universal adhesive compositions also include Dragon, Power, Anserglob.

- Liquid Nails. This type of glue is often used by professionals. Liquid nails are thick, so in uneven areas they are placed in a thick layer. For tiles, choose white glue, without solvents, especially when working with thin material. It is also used to design seams. The most famous brands “Moment of Installation” and “Tytan”. For application you will need a construction syringe.

- Polyvinyl acetate glue. PVA and Bustylate practically do not give an unpleasant odor, but grab longer, and the consumption can be quite large, since glue is applied to the tile itself and on the ceiling.

- The finish acrylic putty. This is a non.standard, but efficient use of a product that has the right viscosity. When gluing for putty, the seams are white, and the gaps are not formed. The surface can be painted. For work you need a spatula.

Using a hand file

Cut the foam plate of a larger thickness exceeding 50 mm, with a knife it will be very difficult and ineffective. If you use an electric jigsaw, there will be a lot of garbage, and the fishing line for the trimmer of the section will not work out. Therefore, the best option for cutting polystyrene foams up to 10 cm thick at home with a handwriter.

To perform work, it is recommended to purchase a wood wood file, which will cut the material with a thickness of 50-100 mm.

How to cut polystyrene so that it does not crumble

Foam or polystyrene foam refers to universal material, which is used for insulation and sound insulation in building structures. The basis of its structure is formed by foamed plastic. This explains why the foam during cutting is often crumbled.

When processing the material, it is necessary to decide what needs to be cut, so that the fishing line for the trimmer of the cut is flat and the crumbs are as little as possible.

Types of tools

Mechanical cutting. The most common improvised means include a knife, a jigsaw, a saw and a corner grinder.

The main attention when choosing a knife is paid to its blade. If it is acute, then the cutting process proceeds faster, and less waste is formed

The knife before the sharp must first be heated.

The disadvantage of the method is that the use of a knife is possible with a foam thickness of 1–5 cm.

Chancellery knife. The chancellery version of the knife is best used for soft material. This knife has thin and flexible blades, so it is not practiced for processing thick plates.

Electric. Pruning with an electrician is used when cutting foam up to 10 cm to thickness. This method does not require much effort costs.

Manual saw on wood. If the thickness of the foam reaches 40 mm, then it is better to cut it with a hacksaw on wood. The method is quite simple and fast, without the cost of special physical efforts.

A saw that has small teeth is better suited. This tool is used only to get straight sections.

“Corner grinder”. The advantages of the corner grinder are that it, as it were, cuts polystyrene, if you use the thinnest circles.

However, thick material with corner grinders is not recommended to cut. You will not get a qualitative result, but there will be an extremely many garbage.

In addition, this option is not very good because of the screech that occurs when the foam is interacted with the circle of the machine. Plus it is added to it and the noise of the engine engine. Therefore, in the case of cutting a large number of foam plates, you should put on headphones from the very beginning of the work. Add the electricity consumption to this list, which will need to be paid.

Cutter of nichrome wire. The practice of working with polystyrene shows that high.quality sawing is formed when using a tool with a heated wire. The edges are even, smooth, and there are practically no crumbs. The advantages of the method can be added to the high speed of cutting and performance in the volume of similarity with industrial.

The active use of the method prevents the complexity with its acquisition due to the absence in stores. With an acute need for the machine, there is only one way out. make a cutter yourself. This is a separate question that is devoted to many good articles on the Internet containing step.by.step instructions and illustrations.

A simple way to cut

Cutting can be carried out with steel thin wire. It should be fixed on wooden handles. They are placed at different ends of the surface intended for cutting. Cutting resembles the process of sawing firewood. You will need an assistant who will take one of the handles. The string is heated from friction, so the fishing line for the trimmer of the saw is obtained even and smooth.

From the review, we can draw a general conclusion that the process of cutting foam is sufficiently simply and quickly. The processing method is selected depending on the chosen tool, work volumes, form (straightforward, winding or voluminous), in which the result should be obtained.

Foam cutting

So, polystyrene foam, like any other material needs to be processed before use. Initially, it is delivered in ordinary plates with a certain thickness. However, far from always the form of the plates is not always enough to use them wherever necessary.

Часто плиту приходится разрезать на куски, подрезать, подчищать. Иногда появляется необходимость срезать на краю плиты декоративную часть или сделать определенный угол.

There are actually a lot of options. But the question is left alone. How to cut polystyrene? It would seem, why still invent some additional units, buy a special cut for foam if you cut it, you can even break it with your own hands. And this is literally.

Here we must turn to the features of the polystyrene foam itself and. The foam itself consists of small polystyrene balls.

The original raw materials in it are a polymer that is mixed with foam aggregates and air. As a result, it turns out a rather supple and very light design, which is easily cut or breaks with your hands.

Just break the foam. this is not the best solution. Fishing line for a trimmer of fracture will never succeed in your exact. Polistyle foam balls will bend it, making the final structure unsuitable for accurate operation.

However, we still note that it is very easy to break or cut foam. That is, cutting foam at home is quite real. Another question is how to do it for sure and with minimal destruction of the material. Here a cutter for foam or any home.made apparatus will come in handy for you.