Grass trimmer disassembly with your own hands

The fact that the electric motor trimmer for grass is out of order is evidenced by:

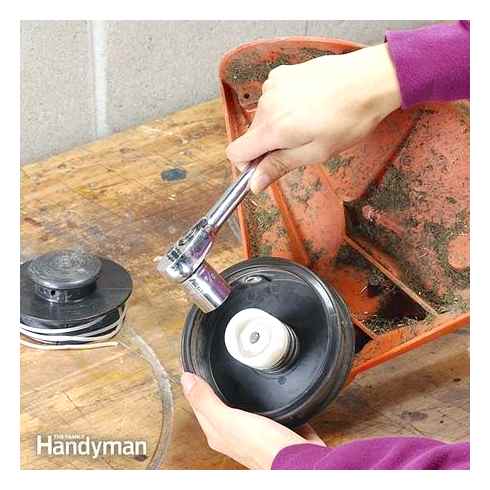

Bolens Trimmer Repair. Removing a Stuck or Seized Bump Feed Knob (Bolens Part # 791-153066B)

What to do with their own hands revive the motor electronic hand-held grass trimmer, its owner must have some knowledge in the field of electrical engineering, to understand the device electric motor and have experience in eliminating defects that arise during the operation of complex household products.

Basically! Diagnostics and elimination of defects begin with visual inspection and cross-checking of power supply cable with a multimeter. If damage is detected, they are disposed of.

Then check that the motor is receiving

Next check whether the 220V voltage is applied to the motor terminals when the push-button is pressed. If there is voltage, it is an indication that the motor itself has failed. In the unlikely case of a faulty trigger, which is best replaced.

Bearings

In most cases, the electric motor loses its function due to faulty bearings. Normally the rotor should rotate freely within the stator. But the lack of lubrication in the bearings, its loss or ingress of dirt inside can be a precondition for the difficult rotation of the rotor. In some situations, it may even seize. In addition, a strong noise when the motor can indicate that the bearings are broken and need to be replaced.

External damages

Before starting repair work, it is advisable to take a close look at the electric motor for any signs of damage. These include:

- presence of dirt and foreign objects inside the motor;

- If the paint on the inside of the motor is darkened, this will show that it has been overheated;

- Chips and cracks on the outer surfaces of the motor;

- Broken components.

Identified flaws on the ability to get rid of. It is then recommended that the collector plates and brushes be wiped down painstakingly with a cloth dampened with alcohol. If the graphite brushes are very worn, they must be replaced with new ones. If there are potholes or burned-out areas on the manifold plates, the latter are machined and polished as follows.

Windings

The magnet wire of the electric motor is made of special strong steel, and its breakage can be caused only by extreme loads. So all the attention in the repair of the electric motor is paid to the integrity of the windings and their insulation, as well as good contact between the mating parts. Inspect the windings for damage in the following way:

- set the switch of the multimeter to the resistance measurement mode (lower limit);

- put the multimeter probes to the graphite brushes or exactly to their contacts.

Basically! The multimeter should show a resistance value less than 100 Ohm.

In this case, when the device indicates an endless resistance, it is recommended, without removing the feeler from the brush contacts, to turn the motor shaft. If with all this multimeter will show resistance in the range from 10 to 40 ohms, then the stator winding is intact, and if less than 5 ohms, then there is an intercircuit closure, which usually occurs when strongly overheating the motor.

Grass trimmer disassembly. Grass trimmer coil repair with your own hands

Grass trimmer ignition coil. faults and repair

Lawn mowers are a popular seasonal tool for removing unwanted vegetation on yard plots. Like any other equipment, these devices periodically break down. Grass trimmer ignition coil repair. one of the popular problems common to gasoline-powered mowers. The ignition system itself is designed similarly on two- and four-stroke ICE, so the elimination of the breakdown is performed almost identically for tools from different manufacturers, whether it is “Lux”, Huter, Husqvarna or other brand. Ways to restore the performance of the ignition coil or replace it with a new one. in the material below.

Magneto. construction and principle scheme of work

The purpose of the ignition coil is to convert rotational energy into a high-voltage discharge and form a spark that ignites the fuel mixture. In internal combustion engines, this part is called a magneto because it generates alternating current from the rotation of a permanent magnetic rotor or armature.

Magneto structurally consists of two windings: high and low voltage. To the latter, a capacitor is connected in parallel with the chopper contacts. Then the leads of the high voltage winding are connected to the spark plug and the housing. They are both wound on a core, between the poles of which there is a rotating magnet magnetized longitudinally.

As a side note! The whole construction looks like a big coil, mounted on a U-shaped core.

Checking the Operation

Before you start diagnosing the magneto, you need to make sure that the problem is actually in this node. To do this, check the entire circuit and make sure there are no other causes of grass trimmer failure.

- First you should carefully inspect the coil for cracks and other external defects on the body. Next, you will need to examine all the elements and assemblies that conduct current, and make sure they are clean.

- The next step is to inspect the high-voltage wires. They must be intact and securely fastened to the contacts, with no traces of rust and with undamaged insulation.

- The next step is to check the spark plug cover. As a result of careless actions, the user often breaks it off the high-voltage wire, and then improvises and creates a homemade mount. It should be understood that any poor connection at this point greatly reduces the power of the arc of the candle.

- Then you need to make sure that the spark plug itself is serviceable. If you fill up the brushcutter with low-quality gasoline, the service life of this part is significantly reduced. In addition, it may be primed or have a lot of soot, preventing the work. Sometimes the spark plug is even stuck and cannot be unscrewed.

- Next, you need to inspect the circuit breaker. On trimmers and chainsaws made in China, it very often breaks down.

How to disassemble the spool with a fishing line from the trimmer for grass

Assembling a fishing tackle, it is periodically necessary to change the line for the trimmer on the reel. This is a fairly straightforward procedure. However, it has a number of nuances. If you do it correctly, it will depend on whether the thread is straight when casting, or if it starts to get tangled. If the fisherman performs the actions incorrectly, the thread can tear. This causes a lot of difficulties. To avoid such troubles, it is necessary to consider in detail how to wind the line for the trimmer on the spool. This technology will be discussed in detail in the article.

The importance of proper winding

In order for fishing to be successful, it is necessary to prepare for it thoroughly. Otherwise a “terrible thing” can “happen”. the weather is fine, the bite is excellent, but the tackle constantly fails and prevents to take advantage of favorable fishing conditions.

To prevent this from happening, it is necessary to set up all fishing equipment in advance. One of the most important stages of preparation for fishing is the correct winding of the line on the bobbin of the fishing reel. Failure to follow the basic rules threatens the angler with tangles and breaks in the line, and fishing instead of pleasure will be an ordeal for the nervous system.

The quality of this work affects the throwing distance. Proper reeling ensures that the bait is thrown at a distance that best matches the specifications of the reel.

In addition, high-quality winding prolongs the life of the line, reducing mechanical friction and reducing the risk of “beards” when casting, because of which it is often necessary to cut the line for the trimmer. Therefore, before starting work, it is necessary to consider a few tips from experienced fishermen on how to wind the line on the bobbin. This is a fairly simple procedure that even a novice can handle.

Winding the line by hand

It is also necessary to consider how to wind the line for the trimmer on the reel manually. If the fisherman has a telescopic spinning line, it should be unwound in working condition. For a rod rod is not necessary, you can work with the lower part of it.

A reel should be secured in a reel holder. There is a hole in the bobbin, on which the line for the trimmer is wound. A pencil, pen, needle, etc. is inserted in the spool. п. If the fisherman has a helper, he will hold the axle, on which the bobbin will unwind. If there is no helper, you can hold the rod yourself between the knees.

Special devices for unwinding line from the bobbin are available. They have the advantage of regulating the line’s winding force and making it even.

Trimmer line is threaded through the rings, from the smallest top piece to the spool. The thread is then secured in the bobbin with the cable guide open. It is then lowered into operating position. You can begin winding line for the trimmer, rotating the spool.

Winding profiles (tapers)

The line is wound differently on the bobbin on different models of spool. The cylindrical and tapered winding methods are used in quality products. A trimmer line laid in profile forms an even trimmer line. With a cylindrical winding, this trimmer line is straight, parallel to the bobbin, with a cone, it is slanted.

Straight taper tapers toward the front of the bobbin, inverse taper expands. Straight taper reduces line friction. The reverse type of laying reduces the likelihood of spontaneous line shedding.

There is a third type of winding. chaotic. Commonly used in cheap Chinese fishing rods. And if such a winding can still be tolerated, using ordinary fishing line for trimmer, then you should refuse to use a cord in such a spool. Poor casts, “beards,” overlaps, and tangles are assured. This leads to failure during fishing, and can spoil the mood of every fisherman.

Determining the amount of winding

In the question of how to wind the line for the trimmer on the spool, for beginners there is a difficulty in determining the amount of winding. It can only be established by experimenting. Experienced fishermen advise to act in reverse order.

If there is a second reel of the same kind, you want to reel it first line for the trimmer, and then tied to it the winding. Remember the basic rule: to wind the line for the trimmer on the spinning reel correctly is possible only if the level of its top layer will not exceed 3 mm from the edge of the bobbin. After that, you should rewind the thread on the main spool, starting from the backing, which, as it should be, will be at the bottom.

If there is no second reel of the same kind, the measurement is made on the main reel, then the line for the trimmer is unwound and rewound on it again, already starting with the winding.

the line for the trimmer is sticking

If the line for the trimmer is sticking together when working, the main reason is the installation of low-quality cord. During operation, the spool gets hot and low-quality strings melt and stick together. The second reason is a collision between the filament and a solid object. In this case, there is a sharp braking, the thread is pulled into the head and gets stuck.

So, replacing the line for the trimmer on the trimmer is not difficult, if you know how to disassemble the spool and perform the winding of the cord. This process is similar for equipment of different brands. A detailed description can be found in the instruction manual of the tool or watch the video.

the line for the trimmer flies out

If a string comes out when mowing, it is another indication that the spring in the bobbin has become loose or has been lost due to careless disassembly of the head. As a result, the cord does not hold and pops out when you rotate it.

What line for the trimmer to choose

Before you stock up on this material for the grass trimmer, you need to decide on the. After all, the usual so-called round line for trimmer is not the only type that exists. How to choose the right one?? You must first define the working conditions.

Choosing by type. The circular trimmer line is the most common. It fits all reels, with a few minor exceptions. This type of material is suitable for mowing fresh, succulent grass. But it might not be able to mow what’s called dead wood anymore. Attempting to mow shrubs with this thread is pointless to mention.

In addition to the conventional type, there are other types that have sharp edges. They are usually “star” or “square. The presence of sharp edges is the main feature and the key difference between these threads.

How to Change the Coil on a Trimmer

The grass trimmer is the most common tool for mowing grass and trimming small shrubs. This device is easy to maintain, thanks to its light weight, even women can handle it. You need the right cutting tool. The last three versions use special cutting heads (discs, knives) or three-dimensional heads with a fishing line inside. Nozzles and fishing line for the trimmer are an expendable tool, but if the knives can be sharpened, the line for the trimmer must be replaced. In this article, we will explain in detail how to properly replace the line for the trimmer.

Types of trimmer heads

Inclined head for grass. is when a spool (bobbin) is inserted with a fishing line (cord) put on it. This design can be installed on both gasoline and electric grass trimmers. The head trimmer is divided into 3 types.

- automatic. The cord is fed after the user has reduced engine speed. Although such bobbins have one disadvantage. A large consumption of threads.

- Semi-automatic. Using this type of head does not require complex manipulation on the part of the user. Their operating principle is designed so that the device operates at full speed. It is enough to slightly push the grass trimmer head into the ground, and thanks to the centrifugal force, the line for the trimmer is removed from the spool, after which it is cut to the required length by the knife, located on the protective cover.

- Manual. To extend the cord, stop the machine, then the trimmer line will be removed by hand.

Based on the above, semi-automatic reels are the best. In addition, there should be single-row and double-row, which are used for mowing tall grass and small with thin stem shrubs.

How to remove and disassemble the coil

Grass trimmer users need to remove and disassemble the spool. Think about how to do this.

A grass trimmer with a mowing head consists of several parts: the cover, springs (not on all models), coils with cord, and covers.

Warning! It must be unplugged.

In trimmers, 2 variants of mower attachment are most often used.

Option

To remove the grass trimmer head, release it. complete disassembly.

- To remove the cover, push down on the latches (catches) located on either side of the cover.

- Once you have removed the cover you will see the coil that you need to remove from the housing. Some reels have a spring under the reel, which you must carefully pull out so you do not lose it in the grass.

- The stud, you will see a Phillips head screwdriver or flat head in the center of the housing. “Star.”.

- You need to unscrew the bolt (counterclockwise).

- Having removed the mount, you can look in different directions to remove it from the gearbox shaft.

Option

In this format, the head twists on the gearbox shaft. Remove it lock the shaft. To do this, three versions, such as the Huter and Champion units, have a hole that can be inserted with either a thin screwdriver or a metal rod.

So, to remove the spool, follow 2 simple steps.

- Insert a screwdriver into the hole and secure the shaft.

- Take hold of the head body and start twisting it clockwise. This is because the thread on the shaft remains.

Scaffolding winding algorithm

Depending on the model used, choose the type, thickness and length of line. The diameter of the cord can be from 1.2 to 4 mm. It knows how to cut.

In extreme cases, use a 2 mm universal scale.

There are 3 ways to know what diameter of wood you can use in a lawn mower.

- Refer to the unit’s manual for information on cord thickness.

- Look at the spool itself. Information about possible line extensions may be marked.

- Insert the line for the trimmer into the socket. If it goes through this, it can be used.

The trimmer line is wound on a spool located in the mowing head. You have to open it first. There are two ways to wind the cord.

First method

To properly determine how many meters of wood to put on the spools, you need to make sure that their diameter does not exceed the diameters of the sides. If you want to insert it into the housing. Once you have decided on the length of the material, you need to load it into the bobbin.

- We need to fold the line for the trimmer in half, it was 10-15 cm longer than the rest.

- Note that the bobbin is divided into 2 parts by the center side, which is where the charging starts. Catch it, use spells, put some effort into it.

- This is very important to determine, the line for the trimmer to the reel. If you want to see what you can find on the reel, you can write with an arrow. There are cases where there is no arrow on the reel. In this situation, you can look at the arrow drawn on the head of the weed whacker and wrap it in the opposite direction.

- We need to behave carefully, with maximum tension.

- Once the cord is finished, the short end of the scaffold must be secured first.

- The other end, the one that is strong in the recess on the opposite side of the coil.

- After fixing the line, cut off its ends, leaving an allowance of about 10 cm.

- Next you must insert the old spool into the mowing head. To do this, install and lift the holes in the outlets, place the stud in the shroud, then apply the necessary force, pull the trimmer line out of the mounting slots and tighten it.

- You can now remove and record it with the snaps.

Second method

Some spools provide a second way of securing the roots: you can charge 2 pieces of string instead of one folded in half. Replace the scaffold using the following algorithm.

- As for when this will be altered, discussed above.

- Bend one end of the cord into a hook.

- Find a pin at the bottom with a hole to secure the wood and insert it into the bent end of the loop.

- On the arrows indicated, you need to wind the cord to the desired level, which is no larger than the diameter of the spool.

- Do the same for the second socket of the spool.

- Caps do not differ in any way from the method described above.

How the line head works on the brushcutter Why you need to know the principle of operation

Depending on the manufacturer, the heads differ structurally not only externally, but also internally. Most reels have a compression spring inside (semi-automatic and automatic). Above is an instruction on how to disassemble the grass trimmer head without a spring, t.е. on the head of the manual type. The principle of dismounting a semi-automatic head with a spring inside is almost identical to the above instruction.

The working principle of a semi-automatic grass trimmer reel is as follows:

- Inside the head is a spool, which is planted on slits that prevent its free movement

- The coil is acted on by a spring that presses it against the slots in the cap structure

- On the lead is wound with a fishing line for the trimmer, the length of which depends on the tool itself. This length is usually between 1 and 4 meters

- If the length of the line needs to be increased, the cylinder is pressed down during work, so that it becomes disengaged from the splines. At the same time the line for the trimmer is reeled off the drum, increasing in length

- After releasing the required amount of line, release the clamp and continue mowing the grass

The advantage of a filament tool is that it does not require sharpening as often as a metal blade. over, if a stone or wood gets in the way, the line for the trimmer simply comes off, without negatively affecting the gearbox and engine of the tool, as it happens in the case of metal cutting discs.

Knowing the construction and device of the types of mowing or trimmer heads, you should proceed to consider the process of filling the fishing line into the grass trimmer spool. After all, this is the point at which most owners of special tools cause difficulties.

Typical malfunctions. causes

Malfunctions that most often occur with the magneto are typical for trimmers of different manufacturers. As a rule, it is a weak spark or its absence, as well as the presence of interruptions in the process.

Method 3

The following steps are necessary for diagnosis:

How To Tips for Easy Restring of Weed Eater with 2 strings

- Open the cap with which the cylinder is closed;

- Remove the high voltage wire cap from the spark plug without unscrewing the part itself to preserve compression;

- put a nail without a cap in the cap tightly, it will imitate the center electrode of the spark plug;

- dielectric material to tie a cap with a nail to the cylinder so that the gap between the candle electrode mimic and the mass ranged from 5.5 to 7 mm (the exact distance for a particular model is recommended to see in the user manual), but at the same time the part is not in contact with the mass;

- With the starter a few times play the engine start, holding the ignition button in the on position;

- If a spark appears, you need to consider what color it is.

A white or bluish powerful spark is normal, while a faint glimmer of orange or yellow hue indicates a broken coil.

Often a cold magneto creates a powerful spark, but when heated due to a defect in the internal nodes does not conduct current. After the coil cools down, the lawnmower starts again and mows the grass with a line or knife until the magneto heats up. This is not normal behavior, so the coil must be changed.

How to Disassemble the Coil grass trimmer Huter. Grass trimmer ignition coil repair with your own hands

Grass trimmer ignition coil. faults and repair

Moths. a popular seasonal tool designed to remove unwanted vegetation on the lawn. Like any other equipment, these devices periodically break down. Grass trimmer ignition coil repair is one of the popular problems common to gasoline-powered mowers. The ignition system itself is designed similarly on two- and four-stroke ICE, so the elimination of the breakdown is performed almost identically for tools from different manufacturers, whether it is “Lux”, Huter, Husqvarna or other brand. Ways to restore the performance of the ignition coil or replace it with a new one. in the material below.

Magneto. design and circuit diagram

The purpose of the ignition coil is to convert the rotational energy into a high-voltage discharge and generate a spark that ignites the fuel mixture. In the internal combustion engine, this part is called a magneto, because in it the alternating current is generated from the rotation of the permanent magnetic rotor or armature.

Magneto structurally consists of two windings: high and low voltage. To the latter a capacitor is connected in parallel with the chopper contacts. Whereas the high voltage winding leads are connected to the spark plug and the housing. They are both wound on a core, with a rotating magnet between the poles, magnetized longitudinally.

As a side note! The whole construction looks like a large coil mounted on a U-shaped core.

Functionality Check

Before you start diagnosing the magnetos, you must be sure that the problem is really with the assembly. To do this, you need to check the entire circuit and make sure that there are no other causes of breakage of the grass trimmer.

- First you should carefully inspect the coil for cracks and other external defects on the body. Next, you need to examine all the elements and assemblies that conduct current, and make sure they are clean.

- The next step is to inspect the high-voltage wires. They must be serviceable and securely attached to the contacts, with no traces of rust and with undamaged insulation.

- The next step is to check the spark plug cap. As a result of careless actions, the user often tears it off the high-voltage wire, and then improvises and creates a makeshift mount. It should be understood that any poor connection at this point greatly reduces the power of the candle’s electric arc.

- Then check that the spark plug itself is serviced. If you refuel your brushcutter with low-quality gasoline, the service life of this part is significantly reduced. It may also be clogged or have a lot of carbon buildup that prevents it from working. Sometimes the plug is even riveted and does not unscrew.

- Next, it is necessary to inspect the circuit breaker. It often breaks down on trimmers and chain saws made in China.

How to Change a Line Spool on a Trimmer

How to tuck the line for trimmer into the grass trimmer reel? Video instruction

Warranty issue factory trimmer for grass trimmer inevitably requires substitution of fishing line.

Having a very rough idea of how to tuck the line into the trimmer reel for grass without helping others, newcomers are reluctant to take on this job. How to remove the head from the How to change the trimmer line in a trimmer. It is therefore necessary to open it first.

But with some ability to master this uncomplicated science is not any difficulty, and presented below a similar annotation will greatly facilitate the process.

Pre-treatment

First, to wind the fishing line requires removing the spool (bobbin, bobbin) from the grass trimmer. certain deeds will depend on the difficulty of configuration and the type of the product itself:

- small electric grass trimmers with the working arrangement of the motor and spool in the bottom, usually have side buttons on both sides of the reel. Pressing them at the same time, the higher part of the spool, together with the internal contents for winding the line, is detached, while the lower part remains on the trimmer. How to wind the fishing line for the trimmer on the grass trimmer spool? With the hand-tooling, the spool is disassembled. How to Change To remove the spool of fishing line, disassemble the head and remove the spool, on the. It is advisable to disassemble the bobbin on a flat, smooth place so that the included spring does not pop out and get lost;

- Electric and gasoline grass trimmers with a curved boom without the possibility of installing a knife, as a rule, have a reel with a special wingnut: in such designs should be one hand to hold the bobbin in a fixed position, and the other counterclockwise rotate the fixing reel on the boom nut, the wingnut. After disconnecting the nut, the entire spool is removed.

- Electric and gasoline grass trimmers with the ability to install a blade on a straight shaft (such as STIHL grass trimmers) have a hole under the reel. To immobilize the rod, a screwdriver or other suitable object is inserted into this hole, and slow rotation achieves a mutual arrangement where the screwdriver enters the hole and the bobbin is fixed. The structure of the grass trimmer reel and its main faults. How to change the blade on a trimmer (in t.ч. video instruction). How to trim a grass trimmer. Replace the blade with the. How to remove the reel from a grass trimmer, disassemble it, change the line for the trimmer and install it back. After that, the spool body is turned clockwise (with the left-hand thread) and removed from the grass trimmer.

For the second and third case, the coils, depending on the design, are disassembled in different ways. Video helps to change the ignition on the trimmer, How to check the ignition coil.

In spools with a drum unscrew the wing nut, in spools with latches press the latch-lock and one part of the spool is released from the other.

If the bobbin halves are connected by thread, it is enough to turn them by hand in opposite directions until they are completely unscrewed.

Changing the line on a brushcutter

How to wind cutting line on the brushcutter reel (grass trimmer) by yourself

Hand-held petrol mower. The video shows in detail how to wind the trimmer line on the grass trimmer or brushcutter spool. Filling the line mowing head trimmer grass itself is simple and does not require any special skills. How to change lines on a spool

In this video I show how easy it is to wind the line for the trimmer on the spool of the manual brushcutter.

Rewinding the line

Slowly completing the disassembly of the bobbin spool without losing any of its parts allows you to get on with the main task of winding the line into the spool. Technological features of the bobbin design and the number of working eyes determine the sequence of operations.

Reel with one working tendril

The simplest variant and uncomplicated sequence of actions:

- Size of the bobbin and length of the original factory bobbin winding determine the recommended length of line for winding. 2 5 m.

- One end of the line is inserted into the fixing technological hole located inside the bobbin.

- line for trimmer is wound on the reel in the opposite direction of the rotation of the bobbin on the trimmer product. as a rule, on the inside of the reel there is an arrow indicating in what direction the winding is conducted.

- A small part of line is left free to be wound outside. it is fixed in a special groove on the inside of the bobbin, designed to hold the bobbin winding while assembling it to the working condition.

- The leftover end of the fishing line is passed through the hole on the outside of the spool.

- The bobbin halves are assembled and put on the trimmer bar.

Reel with two operating tendrils

In this type of spool, you should determine the number of grooves for winding the fishing line lying on the inside of the spool:

A 2-3 m trimmer line is used for both cases. How to remove the spool from a grass trimmer, How to remove the spool and Wind the line for the trimmer on the spool.

In single-cable spools the line for the trimmer is pulled through the through hole, its ends (tendrils) are put together and aligned, and then reeled in the opposite direction to the bobbin rotation direction on the boom. an arrow inside usually indicates the correct reeling direction.

If there are fixing grooves, the ends of the fishing line are threaded into them or held by the fingers of your free hand, threaded into the through hole of the outer half of the bobbin, the bobbin is closed and attached to the rod of the trimmer product.

The difference in the winding of the line in dual reels is that initially a piece of line 2-5 m long is folded in half (to determine the middle fold), and the loop of the fold is inserted into a special groove between the grooves. Both tendrils of the fishing line are wound on their own groove, the fixing of the tendrils and the reel assembly is similar to the above version with one groove.

The first performance of this procedure may seem long and quite time-consuming, but with time and experience, this task will be solved much faster and easier.

Is it possible to make a spool on the grass trimmer with their own hands

There are plenty of trimmer heads for sale (not automatic) that are reasonably priced and of good quality. But sometimes there are situations, for example, in the country, when the trimmer reel is broken, and its repair is impossible, the store is far away, and it is necessary to mow. In this case, you can quickly, literally in a few minutes, make a simple trimmer attachment for fixing the fishing line from ordinary plywood 10-12 mm thick.

- Take a piece of plywood or tex mat and draw a circle around it with a diameter of around 14 cm.

- Cut the disk with a jigsaw or metal saw.

- Drill a hole in the center of the disc to match the diameter of the gearbox shaft. Do not forget to place the washer on the shaft before mounting the blade.

- On the ends of the disc you can screw small brackets or make 1-2 holes on opposite sides. They will serve for threading the fishing line into them.

- To fix the trimmer line, you can screw some screws into the plywood.

Such a homemade mowing head is fixed on the shaft with a nut. It is not possible to screw or unscrew the nut without fixing the shaft. To replace the cord, you just need to loosen the screws, insert a length of line and press it down again.

You can also make the mowing head from a sheet of metal to hold the line on it. How to do this, you can understand from the following video.